-

Paper Information

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Resources and Environment

p-ISSN: 2163-2618 e-ISSN: 2163-2634

2013; 3(5): 129-134

doi:10.5923/j.re.20130305.03

Environmental Profile Assessment of a Plastic Framed Tambourine Musical Instrument – A Lifecycle Approach

Israel Dunmade

Department of Environmental Sciences, Mount Royal University, Calgary, Alberta, Canada T3E 6K6

Correspondence to: Israel Dunmade, Department of Environmental Sciences, Mount Royal University, Calgary, Alberta, Canada T3E 6K6.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

Tambourine is produced and used for gospel music and folk dances all over the world. About 1.2 million of tambourines are purchased annually. Majority have about 2years lifespan before its disposal in the landfill. This short lifecycle presents great potentials for environmental pollution and resource depletion. With the increasing desire for awareness of ecological footprints of our commonly used products, it becomes necessary to evaluate the potential environmental impacts of tambourine. Doing so would enable users to make informed choices and manufacturers to identify hotspots requiring improvements. This research paper is a report resulting from the use of lifecycle assessment (LCA) process for evaluating the environmental profile of a plastic tambourine. The process, according to ISO 14040-44 standards involved goals and scope definition, lifecycle inventory, lifecycle impact analysis, and interpretation. The assessment was implemented with the aid of SimaPro software version 7.3.3. Results of the analyses revealed that climate change and ozone depletion are the significant potential environmental impacts. Each plastic tambourine has 664.065KgCO2-eq in Global Warming Potential and 0.227kgCFC-11-eq as its Ozone Depletion Potential. Further examination also showed that most of the impacts are from tambourine distribution and plastic material use. As there was no report found on LCA of tambourine, this study provides insights on potential environmental impacts of tambourine and where urgent attention is needed.

Keywords: Environmental Profile, Lifecycle Assessment, Musical Instrument, Percussion Instrument, Tambourine

Cite this paper: Israel Dunmade, Environmental Profile Assessment of a Plastic Framed Tambourine Musical Instrument – A Lifecycle Approach, Resources and Environment, Vol. 3 No. 5, 2013, pp. 129-134. doi: 10.5923/j.re.20130305.03.

Article Outline

1. Introduction

- Lifecycle assessment (LCA) has been described as an objective process for evaluating the environmental burdens associated with a product, process, or activity by identifying and quantifying energy and materials used and wastes released to the environment; to assess the impact of those energy and materials used and releases to the environment; and to identify and evaluate opportunities to effect environmental improvements[1-4].Conducting an LCA of Tambourine becomes necessary because over the last two decades, environmental issues have been gaining prominence both in the private and public sectors. The focus is shifting from site specific environmental degradation to include remote impacts of our industrial activities. There are also an increasing number of customers that are interested in the environmental information of our commonly used products. LCA provides comprehensive information on the environmental burdens associated with products and processes. It also enables us to assess impacts of those burdens on humans and various ecosystems. Moreover, there is an increasing use of lifecycle assessment in various sectors of our economy and programs. Examples of such programs include LEED (Leadership in Energy and Environmental Design) certifications for buildings, in the formulation of government procurement policies, and in pollution prevention programs. Similarly, manufacturing companies are adopting lifecycle assessment, design for environment, and environmental management systems to evaluate their products and to reduce their ecological footprints. Consequently, LCA is an appropriate tool for evaluating the environmental profile of Tambourine [5-10].Tambourine is among the few instruments of percussion that have remained unchanged over a long period and one of the oldest instruments used all over the world[11]. According to Browser, “A tambourine is a circular frame with jingles attached to it. Shaking or hitting the tambourine causes the jingles to move, creating the tambourine's sound. A tambourine may look like a simple percussion instrument, but it's used in a number of ways to get a variety of sounds. Tambourines add accents and rhythms to almost any kind of music, including pop, rock, Latin, marching bands and symphonies”[12]. The statistical data on the demand for tambourine is not available but it is estimated to be about 1.2 million units per annum. Majority of the demand is by evangelical Christians in developing countries such as Nigeria and South Africa. Other categories of users are musicians and folk dancers in the Middle East countries. The lifetime use of a typical plastic tambourine is about 3 years. Tambourines that are used by hitting one of its ends against the other hand usually have a shorter utilization lifespan. The reason is because such tambourine’s frame usually fracture or break at some joint between the handle and the adjoining side that hits the other hand. When the failure occurs, the user has no choice but to purchase another one. Investigations revealed that plastic tambourine are not repaired but they are simply tossed into a landfill. With such a short utilization lifespan and looking at the big picture, it becomes necessary to evaluate the environmental implications of the cycle of resource extraction, manufacture, use and landfilling of damaged tambourine. The potential environmental impacts of the plastic tambourine were evaluated by using LCA process as stipulated in ISO 14040 series. The implementation of the LCA process is described in section 2. Results of the analysis are discussed in section 3. The paper was ended with the conclusions drawn from the results of the analysis.

2. Methodology

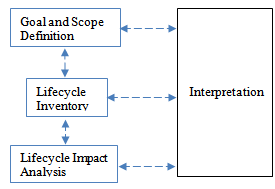

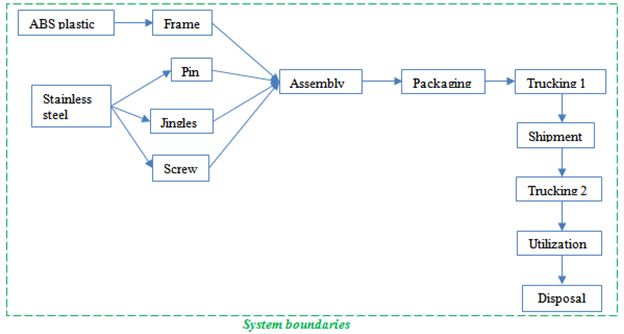

- Fig. 1 is a diagrammatic illustration of the LCA process. The process involves defining the goals and the scope of analysis, preparing a lifecycle inventory of the product data, analyzing the potential lifecycle human and environmental impacts, and interpretation of the results of the analysis [1],[2],[13].

2.1. Goal and Scope Definition

- This is the first stage of the LCA process. Reasons for the study, intended audience and the scope of the study that is necessary for the achievement of the goals are determined at this stage.

| Figure 1. Lifecycle Assessment Process |

2.1.1. Objectives of the Study

- The goal of this LCA was to determine the potential environmental impacts of a plastic tambourine to which LCAs’ of other types and processes of making tambourine can be compared. Understanding the ecological footprints of the tambourine would provide an insight into its inherent sustainability. Information from this LCA would be useful in identifying the hot spots in the manufacturing process. Tambourine manufacturers would find this information useful for further technological advancement of their tambourine. It will also help them in identifying where and how to reduce overall resource use and environmental impact of their tambourine and/or its production process. Moreover, it would help environmental conscious tambourine users (the public) to make informed choices.

2.1.2. Scope Definition

- The scope of this LCA study is cradle to grave. It involved all the processes from extraction of materials to the disposal of the plastic tambourine. The system boundary is illustrated with Fig. 2. The functional unit for the LCA analysis is a 221/2 cm diameter half-moon black plastic “Rocker ™” tambourine that could make varieties of “metallic tingling” sound. The product is 289.4 g by mass.

| Figure 2. System boundaries of tambourine’s lifecycle |

2.1.3. System Boundaries

- Investigations revealed that the model of plastic tambourine is manufactured in Jiangsu, China. It is shipped to a distributor in Toronto from where batches are sent to retail outlets all over Canada. The sample used in this analysis was purchased in Calgary. It was used for about two and half years before it fractured and became unusable. The black plastic tambourine has 32 jingles arranged in two rows of eight gangs. In the laboratory, the whole assembly was weighed, disassembled, and its various component parts were weighed to obtain the mass value. In addition, measurements of the dimensions of the tambourine, the slots, pins, and fasteners were taken. Investigations were carried out on the manufacturing, distribution, use and end-of-life management of the product. Investigations revealed that ABS plastic material was used to manufacture the plastic frame by injection moulding. This is followed by cutting slots for the jingles on the plastic frame. The spacing of two row jingles is about 0.5cm. The number of cuts on each row varies but for this tambourine there were 16 cuts with eight cuts on each row. Stainless steel is the material used for making the jingles for this tambourine. Each jingle which is 3.7cm in diameter has a 6mm diameter hole and was pressed to shape. The jingles are paired for each slot. In addition, two pairs of jingles are loosely pegged in the plastic frame by a 4.5cm long stainless steel pin. Experience shows that these pins thin down and break during use. Pin breakage often serves as the onset of deterioration for tambourines as it results in the loss of jingles. This is then followed by eventual fracture of the plastic frame which marks the end of useful life for tambourines. Broken tambourine are not repaired nor disassembled for reuse. They are generally tossed into a landfill.

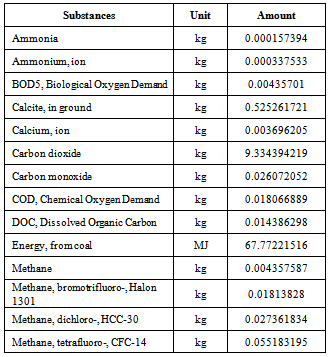

2.2. Lifecycle Inventory

- Lifecycle inventory is the second stage in the LCA process. It involves compilation and quantification of the product data for the third stage of LCA. Data used in this report was collected through measurement, desktop research, and interviews with a retailer. All attempts were made to collect and use the most up-to-date primary data available. However, secondary data from databases such as Ecoinvent databases as well as data from reports were chosen where primary data was not available. The data collected was entered into SimaPro LCA software. Table 1 is an extract of major lifecycle inventory outcome of the data entered in the software.

|

2.2.1. Limitations, Assumptions and Exceptions

- Energy consumption for the product manufacture and packaging used for the transportation were not included in the analysis because the data was not available.

2.2.2. Relating the Data to the System

- The analysis was based on one unit of half-moon shape plastic tambourine of 221/2 cm in diameter and 289.4g by mass. All collated data were processed in relation to the product.

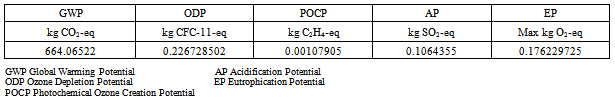

2.3. Lifecycle Impact Assessment

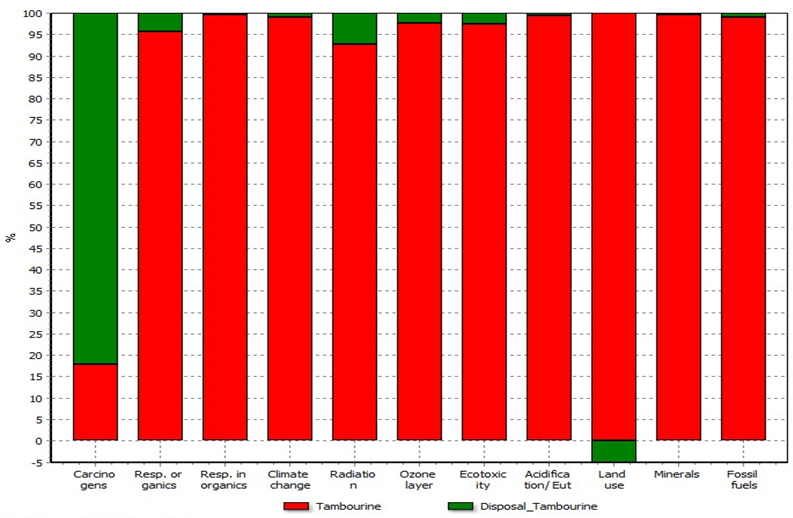

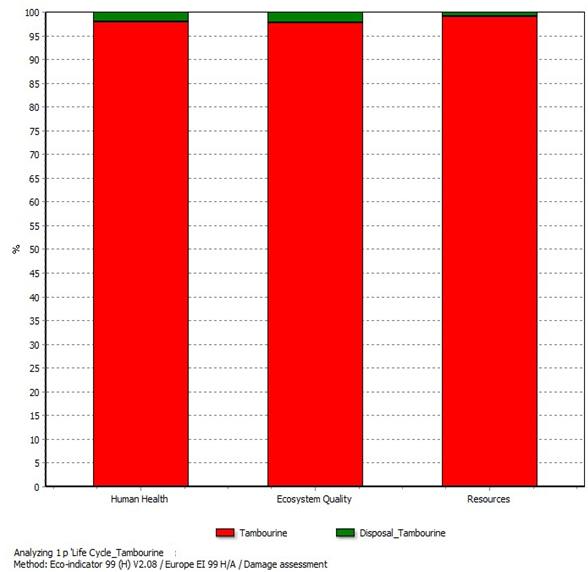

- The lifecycle inventory data was classified into various impact categories such as climate change, ozone depletion, land use, ecotoxicity, acidification, and others. Table 2 and Fig. 3 show the results of characterization of relevant data in each impact category while Fig. 4 shows the potential impacts of tambourine on human health, ecosystems and resources.

|

| Figure 3. Lifecycle Impact Analysis of Tambourine |

| Figure 4. Lifecycle Impact Analysis of Tambourine _ Damage Assessment |

2.4. Interpretation

- This is the last stage of the LCA process. It consists of the identification of significant issues, evaluation of the LCA data and process, and conclusions from the results.

2.4.1. Identification of Significant Environmental Issues

- The purpose of this step was to identify input and output data from the inventory table and impact analysis results that represent the most important results of the study in relation to the goal and scope definition. Two commonly used approaches for this purpose are the contribution analysis and anomaly assessment. In this study, comparative contribution of various substances and impact categories in the results were examined to determine their significance. A look at the lifecycle inventory data revealed that environmental releases of heat and carbon dioxide are the significant environmental issues. The lifecycle inventory also showed that there were significant amounts of rocks and gravel disturbance as well as environmental releases of Styrene and Phenol. Moreover, an examination of the lifecycle impact analysis results revealed that global warming is the greatest potential environmental impact of the plastic tambourine. Other two potential environmental impacts of note are ozone depletion potential and eutrophication potential. A critical look at the various stages of the tambourine lifecycle shows that the most significant impact is from tambourine distribution and the plastic material use.

2.4.2. Evaluation

- The data and processes selection as well as consistency with regard to the methodology of the study was examined at this stage of the LCA process. The aim was to establish confidence in the result of the study, based on the preceding stages of the LCA, especially in relation to the goal and scope of the LCA study. The evaluation revealed that the process used was consistent with the ISO 14040s standards and the results would be reliable.

3. Results and Discussion

- A look at the result of the analysis shown in Table 1 and 2 revealed that the lifecycle energy consumption for each tambourine is 67.8MJ. Currently the main source of the energy is coal. Moreover, carbon dioxide emission is the main environmental burden from the plastic tambourine. In addition, the study revealed that the greatest potential environmental impact of tambourine is the possibility to affect climate change. It can also cause ozone depletion which may lead to skin cancer. Other potential impacts are acid rain that could result in soil degradation and water contamination. It could also cause some damage to the aquatic lives. Consequences of all these impacts would not be limited to negative effects on human health and ecosystem welfare but it would also affect food and other resource availability. Furthermore, resources that would have been used for further improvement of the standard of living of the populace and community infrastructure would have to be diverted to remedy various problems caused by these impact. Thus, social, economic and environmental sustainability would be affected both at the micro- and macro- levels.

4. Conclusions

- This study provided an insight on the potential environmental impacts of Tambourine. It shows that a product though simple in configuration can have debilitating impacts on human health and ecosystem welfare. Results from this study showed that distribution is the lifecycle stage that contributed most significantly to the ecological footprint of the tambourine. The distribution system, which has to do with the transportation of the product to clients, would require re-consideration in order to reduce its potential impacts on the environment. The sourcing of the product nearby, from a Canadian manufacturer, would therefore be necessary for significant reduction in the impacts. Further study would be necessary to compare tambourine made from wooden frame and other materials with the result of this study so that consumers can choose a more environmental friendly tambourine model. Availability or encouragement of a take-back program, disassembly and reuse of tambourine component parts such as the jingles, screws and pins would also reduce its potential environmental impacts. In addition, conducting a lifecycle costing and social lifecycle assessment study on the product would be necessary to provide a balanced view of the economic and socio-cultural aspects of the product.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML