-

Paper Information

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Resources and Environment

p-ISSN: 2163-2618 e-ISSN: 2163-2634

2013; 3(2): 20-23

doi:10.5923/j.re.20130302.02

Study of Technical and Economical Viability of Combined Solar-Fuel Energy Plant

Fuad Mammadov

Azerbaijan State Oil Academy, D. Aliyeva 227, Baku, Azerbaijan, AZ1010

Correspondence to: Fuad Mammadov, Azerbaijan State Oil Academy, D. Aliyeva 227, Baku, Azerbaijan, AZ1010.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

The ways of high-grade solar energy application in cleaning process of oily waste in oil-fields are being studied. The scope of the theme is economized of non renewable energy and environmental safety. The technological process studied was accepted from technical and economical aspects. Taking into consideration ecological and economical efficiency of solar energy application and utilization of today’s standard plants methodical approach was described. Expediency of renewable energy sources usage in this process was determined.

Keywords: Solar Energy, Oily Waste, Cleaning Process

Cite this paper: Fuad Mammadov, Study of Technical and Economical Viability of Combined Solar-Fuel Energy Plant, Resources and Environment, Vol. 3 No. 2, 2013, pp. 20-23. doi: 10.5923/j.re.20130302.02.

Article Outline

1. Introduction

- At present both in different fields of industry and in life Azerbaijan Republic faces lack of energy which has got renewable sources and especially solar energy potential. Generally we have definite perspectives in solar thermal utilization in oil industry. First of all this is explained by geographical location, scientific-technical potential, investment opportunities of our country. Development of solar energy application both economically and ecologically is efficient[1]. That’s why the ways and the opportunities of solar energy application in the daily life and the industry are being determined. Opportunities of solar energy application should be increased firstly in the industry fields in where a great deal of oil and gas are used. One of the fields is the oil and gas extracting enterprises. In this field in the process of oil treatment a great deal of natural gas is used to get heat energy. As a fuel instead of gas solar thermal application has great advantage both from economical and ecological facets. That is why solar thermal application in oily waste treatment process is an actual problem. The results obtained from researches at the experimental parabolic through solar power engineering plant are proof for the above mentioned[2,3].

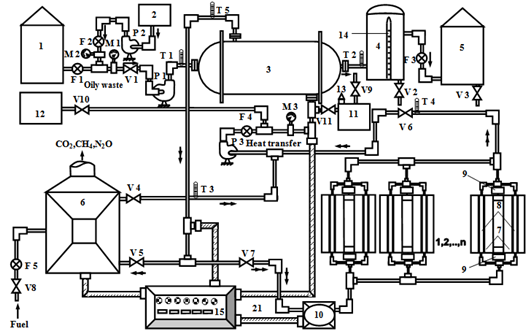

2. Development and Analyses of Combined Solar-fuel Energy Plant

- By developing solar plants with parabolic-trough concentrators we may concern to the economical efficiency of heating energy obtaining:v High intensity of average solar radiation for a year in the (700-900W/m2, 250-270 days/year);v Today’s lack of energy;v Increasing of natural energy resources, oil and oil productions’ selling cost in home and world markets fast;v Intensive increasing of the demands to the energy in the world;v Demands to the energy in the development of the economical situation of our country and socio-economic state of the population;v Too great enterprises prefer the independent energy sources;v Gravity of the measurements of ecological safety to prevent environment from being polluted;Taking into all of them technological scheme of combined solar-fuel power plant has been developed for oily waste treatment in oil fields.To supply plant’s continuous work along a year, especially at nights and in cloudy weather technological scheme of combined solar-fuel energy plant have been developed.Working principle of the combined solar-fuel power plant is as a traditional like in the oil fields but it consists of additional concentrators’ system and other interior pieces. Heat transfer enters the solar reactor (8) when solar flux is more than 400 W/m2 and circulates in the general system. In this case valves (V4, V5) of the entrance and the exit of the furnace (6) are closed and valves (V6, V7) of the entrance, the exit of the collector (7) are open. Heat transfer is heated to 85-90°C by solar thermal. Heat transfer goes out from solar reactor and enters the heat exchanger via the pump (P3). Giving its heat to the oily waste here heat transfer becomes cool and comes into the system again and circulates. The oil which comes from the untreated oily waste tank enters the heat exchanger via the pump (P1). Demulsifier is added to the unheated oily waste by the pump (P2) from the demulsifier tank (2). Heat exchanging process happens between heat transfer and oily waste in the heat exchanger, oily waste is heated to the required temperature and then the oil leaves the heat exchanger and begins to move to the sedimentation tank. Here the heated oil have been kept for some time, during this time the separated water is taken out from the sedimentation tank via the valve (V2) due to the level meter's showing (14), and the treated oil is pumped to the commercial oil tank.As above mentioned for plant’s continuous work valves (V4-V5) of the furnace are opened and valves (V6-V7) of the collector are closed and the process goes on the above mentioned cycle. Operating panel and instrumentation (15) are controlling measurement and conservation of stable temperature of the collector, oil, and heat transfer (water) which circulate in the furnace along the system.If combined solar-fuel energy plant is applied in the process, then permanent oily waste treatment process along 24 hours might have been supplied[4,5].

| Figure 1. Technological scheme of combined solar-fuel energy plant |

P3) 17. Flowmeter (F1

P3) 17. Flowmeter (F1 F5) 18. Thermometer (Т1

F5) 18. Thermometer (Т1 Т5) 19. Manometer (М1

Т5) 19. Manometer (М1 М3) 20. Valve (V1

М3) 20. Valve (V1 V11) 21. Monitor cable

V11) 21. Monitor cable | Figure 2. General view of the parabolic trough solar energy plant |

|

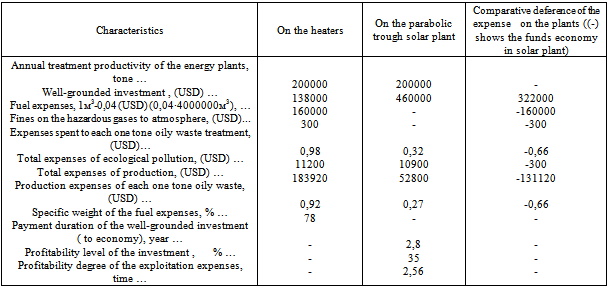

3. Economical Calculation

- By the purpose of oily waste treatment extracted in OGPD in the oil field, the methods of economical efficient estimation of investment projects applied in international practice for economical efficiency determination of the building and application of solar plants can be utilized. While estimating economical efficiency expenses being done to building and exploitation of the plant considered in the project and benefit or financial results are estimated and compared taking into consideration the time. Thus expenses being spent for the project realization and financial benefits being expected to get are estimated at the same time. While estimating the capital efficiency in advance depending on the time discount coefficient is used[6]. Having determined discount coefficient index bank per cent norms the benefit of the capital put by investor and so on can be important. Discount coefficient (Dc) is calculated according to the following formula:

| (1) |

| (2) |

| (3) |

| (4) |

| (5) |

4. Conclusions

- Methodology proposed can be used to realize investment projects in oil industry and especially in OGPD.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML