-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Resources and Environment

p-ISSN: 2163-2618 e-ISSN: 2163-2634

2012; 2(6): 291-296

doi: 10.5923/j.re.20120206.07

Recycle or Dispose Off? Lifecycle Environmental Sustainability Assessment of Paint Recycling Process

Israel Dunmade

Department of Environmnetal Science, Mount Royal University, Calgary, T3E 6K6, Canada

Correspondence to: Israel Dunmade , Department of Environmnetal Science, Mount Royal University, Calgary, T3E 6K6, Canada.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

People are sometimes confronted with the need to decide whether a product should be recycled or disposed off. The purpose of this project was to assess whether it is more environmentally sustainable to recycle paint than to dispose it off in a landfill or not. Lifecycle assessment method was used to analyze potential environmental costs and benefits associated with paint recycling. Data used for the analyses were collected from a recycled paint manufacturing company, literature, and a database. The lifecycle impact analyses of the paint recycling process were based on monthly production of a recycled latex paint brand. Results of the analyses revealed that the process have a monthly 122760.8kg CO2-eq global warming potential (GWP), 1481.6 max kg O2-eq eutrophication potential (EP), and 106.8kg C2H4-eq photochemical ozone creation potential (POCP). The LCA results showed an environmental benefit of eliminating 31,237.29kg CO2-eq GWP, 0.02kg CFC-11eq Ozone depletion potential (ODP), 5943.58kg C2H4 eq POCP and 197.83 max kg O2 eq EP by recycling latex paint rather than disposing it off in the landfill and producing equal amount of latex paint to replace it . Results also revealed that recycling of paint containers and plastics reduces the GWP by 25.34%, ODP by 29.79%, POCP by 15.39%, and EP by 12.47%. Paint recycling is therefore not only economically wise but it is also ecologically sustainable.

Keywords: Environmental Impacts, Environmental Cost, Environmental Benefit, Latex Paint, Life Cycle Assessment

Cite this paper: Israel Dunmade , "Recycle or Dispose Off? Lifecycle Environmental Sustainability Assessment of Paint Recycling Process", Resources and Environment, Vol. 2 No. 6, 2012, pp. 291-296. doi: 10.5923/j.re.20120206.07.

Article Outline

1. Introduction

- Water dilutable (latex) paints are widely used all over the world as a backdrop to the campaign against solvent emissions. They are used for surface protection, beautification and rejuvenation. Latex paints are applied in residential and commercial indoor environments. They are also used in the painting of car bodies[1].About 30 million litres of paint is sold in Alberta, Canada every year. 5-10% of these paints and over 1 million empty paint containers are disposed off annually in Alberta[2]. Similarly, over 16 million gallons of latex paint (WLP) is also disposed off in USA every year[3]. However, increasing awareness of the potential environmental and health risks posed by residual paints necessitated regulation of waste paint disposal. Some of these paints contain combustible materials, volatile organic compounds, lead, mercury, and other heavy metals[4 -7]. Consequently, municipalities are required to collect residual paints from households for proper waste management. For example, waste paint constitutes around 21.7% of the total hazardous waste (HZW) collected by municipalities in Ontario province every year. Waste latent paint alone constitutes 12% of the total HZW[8]. The good news about these waste paints is that many have potentials for reuse, recycling and recovery[9, 10]. Recyclability of waste paints is an indication that their human and environmental risks could be eliminated or minimized by recycling. The largeness of the amount of latex paint disposed annually indicated its high economic potential[11]. As a result of these potentials, a number of organizations are now involved in latex paint recycling. However, recycling of materials also has socio-economic and environmental implications. This necessitates an assessment of the net benefit (or cost) of recycling resources at the end of their useful lives[12]. This case study involved a number of forward looking individuals that sought and experimented how these old paints could be reprocessed, repackaged and reused for various applications. These individuals have been reprocessing and repackaging old paints for about ten years and they wanted to know the environmental worth of their paint recycling effort. They also want to know whether it is more environmentally sustainable to recycle latex paint than disposing it off in a landfill or not.

2. Methodology

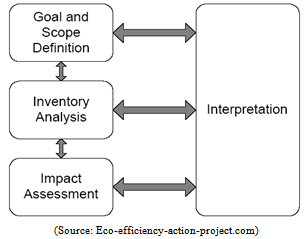

- Lifecycle Analysis (LCA) method was used for this study because it is a comprehensive and proven analytical tool for evaluating potential environmental burdens resulting from resource consumption and emissions by a product or process. It also enables us to assess product/process environmental impacts and to evaluate improvement opportunities that could be implemented to address areas of concerns[13-19]. The method consists of four iterative steps (Figure 1): goal and scope definition, inventory analysis, impact assessment, and interpretation.

| Figure 1. An illustration of LCA process |

2.2. Functional Unit and System Boundaries

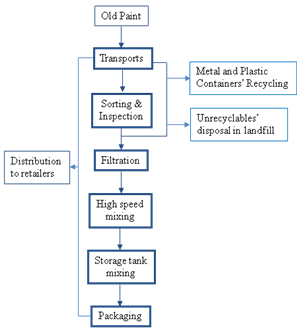

- The functional unit was defined as the mass of a monthly production of 12 colour recycled latex paint in two packages of 4, 10 and 18.9 litres. The company produces 60000 litres of recycled paint every month for sale to the clients. The monthly volume of recycled paint production is approximately 49,800kg by mass.The system boundaries for the analysis are shown in Figure 2. The entire lifecycle was composed of the following stages:- Old paint transfer from municipalities to the company’s recycling facility in Calgary- Sorting and inspection of the paints to oil based paints, reusable latex paint, and unreusable latex paint- Emptying of reusable latex paints into one of the 12 totes based on the paint colour- Compression and transportation of metallic and plastic containers for recycling- High speed mixing of each full tot of latex paint- Filtration of the paints to remove particles and to comply with industry standard- Storage tank mixing of the paints- Packaging of the processed paints into 4, 10 and 18.9 litres containers- Distribution of reprocessed latex paint to retailers- Transportation of oil paints and unreusable latex paint for disposal in landfills

| Figure 2. General flow scheme of paint recycling process |

2.3. Lifecycle Inventory

- Inventory data compilation was implemented by using database included in Simapro 7.2 software. Process specific data used for the analysis was collected from the paint recycling company. The primary data on material and energy use as well as solid waste emissions was collected from the company in 2011. Secondary data was obtained from literature and eco-invent database. Table 1 is a sample of inventory data for the paint recycling process. This conformed to the recommendation in [18].

2.4. Impact Assessment

- Five categories of impact were considered for each dimension of the two impact analyses. The impact categories are global warming potential (GWP), ozone depletion potential (ODP), photochemical ozone creation potential (POCP), acidification potential (AP), and eutrophication potential (EP). All the inventory data that could be found on the available conversion tables and that are greater or equal to 100 mg were mapped into the affected impact categories. 100years time horizon conversion data were used for the characterization of inventory data for global warming and ozone depletion potentials. Conversion factors for average of three European countries were used for the POCP while maximum oxygen conversion data were used for eutrophication potential assessment.

3. Results and Discussion

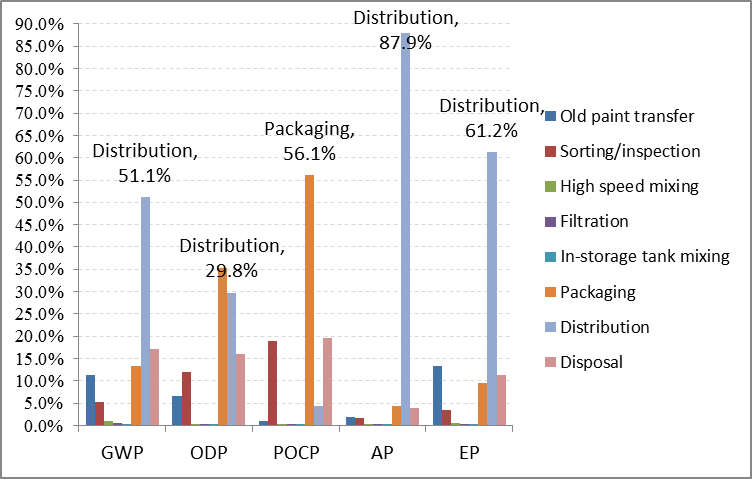

- This study was carried out to determine whether it is more environmentally sustainable to recycle latex paint than disposing it off in a landfill or not. Tables 3 and 4 showed the summary of lifecycle impact analyses of the inventory data collected for this task. Figure 3 showed the percentage contribution of each recycling process stage to individual impact category. Although there were LCA reports on paints, no report was found on LCA of latex paint recycling process that these results can be compared with[20, 21]. In addition, this study was not aim at process comparison. The following interpretation of the study results was based on ISO 14043.

3.1. Interpretation

- The standard (ISO 14043) stipulated a three step process for LCA results interpretation: (i) identification of environmentally significant issues from the inventory data and from the lifecycle impact assessment results, (ii) evaluation of those significant issues, and (iii) drawing conclusion from the evaluated significant issues.

3.1.1. Identification Of Significant Issues

- In determining environmentally significant issues, Carbon dioxide was found to be the most significant substance emitted. From the impact assessment table (table 2), it was discovered that global warming which causes climate change is the most significant environmental issue in the paint recycling process. The method and the data used for this study were evaluated and found to be consistent with the requirements of ISO 14040s.

3.1.2. Evaluation

- Consistency and completeness of the LCA analysis steps taken were evaluated and they were found to be in conformity with the ISO 14043 standard. This was followed by evaluation of the contribution of each process stage to various impact categories. Figure 3 showed percentage contribution of each recycling process stage to various impact categories. One could see from table 3 that distribution stage of the process has an overwhelming influence on the total potential global warming impact of the process. Packaging is another stage of the recycling process that contributes most significantly to ozone depletion potential and photochemical ozone creation (i.e. photochemical smog) potential of the process.

3.1.3. Environmental Savings

- To determine whether it is environmentally better to recycle than to dispose off residual latex paint in the landfill, the difference between total impact of landfilling the residual paint (EIL) and the impact of the latex paint recycling process (EIRP) was calculated. A lower value of EIRP than EIL showed that it is better to recycle than to landfill the paint. This calculation was done for each impact category. The results of the environmental costs and benefits calculation are in Table 3. The negative values indicate environmental benefits.These results showed that recycling latex paint by the process brings significant savings in global warming and photochemical smog impacts. Moreover, the results also showed that recycling latex paint by the process leads to slight increase in eutrophication impact.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||

| Figure 3. Percentage contribution of each process stage to individual environmental impact |

4. Conclusions

- Considering various stages of the process across the four impact categories shown in Table 2, there is no one single process stage that have the most significant impact across the board. Packaging, distribution and disposal process stages are the three stages that require more urgent attention. This conclusion was based on the significance of their impact potentials in most of the impact categories. Recommended improvements for this process are reuse of recycled paint packaging containers, exploration of possible alternative onsite use of old paint fraction that is disposed off in the landfill, and alternative transportation method for the distribution of the recycled paint. Results of this work showed that paint recycling process has appreciable global warming potential which could cause climate change. Furthermore, it showed that paint recycling is not only economically wise but it is also ecologically beneficial. Recycling old paint has lower ecological footprint than sending old paint to the landfill for disposal and producing the same amount of virgin paint in replacement.

References

| [1] | Online available:http://infohouse.p2ric.org/ref/29/28307.pdf. |

| [2] | Online available:http://www.albertarecycling.ca/BasicContent.aspx?id=732. |

| [3] | Online available:http://digitalcommons.library.unlv.edu/cgi/viewcontent.cgi? article=2232&context=thesesdissertations. |

| [4] | M. Agocs, R. Etzel, G. Parrish, D. Paschal, P. Campagna, D. Cohen, E. Kilbourne, and J. Hesse, "Mercury Exposure from Interior Latex Paint", Massachusetts Medical Society, The New England Journal of Medicine, vol. 323, pp. 1096-1101, 1990. |

| [5] | R. Reiss, B. Ryan, P. Koutrakis and S. Tibbetts., "Ozone Reactive Chemistry on Interior Latex Paint", ACS Publications, Environmental Science & Technology, vol. 29, no. 8, pp. 1906–1912, 1995. |

| [6] | L. Sparks, Z. Guo, J. Chang, and B. Tichenor, "Volatile Organic Compound Emissions from Latex Paint – Part 1. Chamber Experiments and Source Model Development", Wiley-Blackwell Publications, Indoor Air (International journal of Indoor Environment and Health), vol. 9, no. 1, pp. 10-17, 1999. |

| [7] | L. Sparks, Z. Guo, J. Chang, and B. Tichenor, "Volatile Organic Compound Emissions from Latex Paint – Part 2. Test House Studies and Indoor Air Quality (IAQ) Modeling", Wiley-Blackwell Publications, Indoor Air (International journal of Indoor Environment and Health), vol. 9, no. 1, pp. 18-25, 1999. |

| [8] | M. Nehdi and J. Summer, "Recycling waste latex paint in concrete. Elsevier publishers, Cement and Concrete research, vol. 33, no. 6, pp. 857-863, 2003. |

| [9] | Walpole, D., "Recycling paint and solvents and reducing use of 1,1,1-trichloroethane", Waste Management, vol. 13, no.2, pp195-197, 1993 |

| [10] | A Mohammed, M Nehdi, and A Adawi, "Recycling waste latex paint in concrete with added value", ACI Materials Journal, 2008 |

| [11] | M. Musick, "Old Paint learns new tricks", JG Press Inc, BioCycle, Vol. 32, No. 5, pp. 50-51, 2009. |

| [12] | Daniel, S.; Pappis, C. and Voutsinas, T. (2003). Applying life cycle inventory to reverse supply chains: a case study of lead recovery from batteries. Resources, Conservation and Recycling 37 (2003) 251-/281. |

| [13] | Online available:www.athenasmi.org/resources/research-projects. |

| [14] | Online available:http://ec.europa.eu/enterprise/sectors/chemicals/files/sustdev /pvc-final_report_lca_en.pdf. |

| [15] | F. Berkhout and R. Howes, "The adoption of life-cycle approaches by industry: patterns and impacts", Elsevier publisher, Resources, Conservation and Recycling, vol 20, no. 2, pp. 71–94, 1997. |

| [16] | Tom Chilton, Stephen Burnley, and Suresh Nesaratnam, "A life cycle assessment of the closed-loop recycling and thermal recovery of post-consumer PET", Elsevier publisher, Resources, Conservation and Recycling, vol. 54, no. 12, pp. 1241-1249, 2010. |

| [17] | Online available:www.ellipsos.ca/.../Christmas%20Tree%20LCA%20-%20 ellipsos.pdf. |

| [18] | Online available:http://www.eea.europa.eu/publications/GH-07-97-595-EN-C. |

| [19] | Katherine Yuracko, Stanton Hadley, Robert Perlack, Rafael Rivera, and Randall Curlee, "Fernald's dilemma: Recycle the radioactively contaminated scrap metal, or bury it?" Elsevier publishers, Resources, Conservation and Recycling, vol. 19, no. 3, pp. 187-198, 1997. |

| [20] | Online available: http://www.thefuturebuild.com/product-life-cycle-assessment-981475/file-files/DC8_JotunPaints_ProductCarbonFootprint_FINAL_for%20Masdar.pdf |

| [21] | Online available:http://www.sveff.se/Branschinformation/LCA_eng.pdf |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-Text HTML

Full-Text HTML