-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Plant Research

p-ISSN: 2163-2596 e-ISSN: 2163-260X

2022; 12(1): 1-7

doi:10.5923/j.plant.20221201.01

Received: May 18, 2022; Accepted: Jun. 24, 2022; Published: Aug. 6, 2022

Effect of Crosslinking of Taro Starch

Galicia Domínguez Raquel Susana1, Galicia Domínguez José Alfredo2, Ortiz González Sandra2, Aguirre Espíndola Gabriel Gerardo2, Aldeco Pérez Mariana2

1UTTCAM, Av. Technological University 1 Barrio La Villita, Tecamachalco, Puebla

2Faculty of Veterinary Medicine and Zootechnics, Meritorious Autonomous University of Puebla, 7.5 Carretera Cañada Morelos – El Salado Tecamachalco, Pue, México

Correspondence to: Galicia Domínguez Raquel Susana, UTTCAM, Av. Technological University 1 Barrio La Villita, Tecamachalco, Puebla.

| Email: |  |

Copyright © 2022 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Background and objective: Starch is the main reserve polysaccharide for most vegetables, and the main source of calories for humanity since it is very abundant in nature. The present study aimed to evaluate, obtain and characterize the native and modified taro starch and suggest possible applications in the food industry in the region. Materials and methods: The triphosphate (STPP) was used with a starch sample, adding hydrochloric acid, distilled water, on the other hand, in a second sample trimetaphostafo (STMP) was used, adding distilled water and hydrochloric acid, they were placed in the reactor at 65 degrees centigrade for 3 hours with pH of 11. Subsequently the pH is lowered to 6.5. Washing with distilled water 7 times while stirring in a centrifuge, the distilled water is decanted and the residue is transferred to a Petri dish, putting it in a drying oven overnight. Afterwards, the sample is ground, sifted, and stored in a three-layer bag, labeling it for later analysis. Results: Crosslinked starch 50:50 and 90:1 is obtained, with the qualities of granules with a humidity of 7%, with protein of 4.7%. Conclusion: The product obtained has the ability to retain more moisture, reflected in the degree of gelatinization, with this some food processes benefit, allowing the resulting product to have greater stability.

Keywords: Effect of crosslinking, Taro Starch, Colocasia esculenta Schottt, Stability, Moisture

Cite this paper: Galicia Domínguez Raquel Susana, Galicia Domínguez José Alfredo, Ortiz González Sandra, Aguirre Espíndola Gabriel Gerardo, Aldeco Pérez Mariana, Effect of Crosslinking of Taro Starch, International Journal of Plant Research, Vol. 12 No. 1, 2022, pp. 1-7. doi: 10.5923/j.plant.20221201.01.

Article Outline

1. Introduction

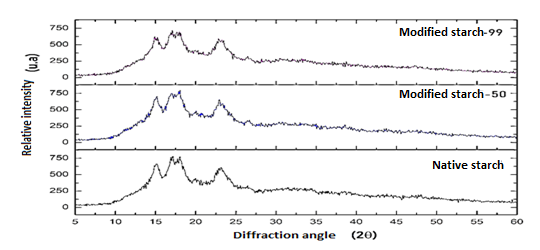

- Starch, used as an additive or as a main component, is of the utmost importance in the food industry, because it functions as an adhesive, film former, thickener, binder, preservative, among others. [1]; Furthermore, according to Torres et al. [2] provides between 70 and 80% of the calories consumed by humans, making it the most important carbohydrate [3]. However, the sale price of conventional sources of starch is high and their availability is often at risk, which means that the search for unconventional sources has intensified. [4], to satisfy the industrial demand, try to solve the problems in the production and the search for starches with better properties and characteristics and low costs [5].The tubers meet these requirements and among them is Malanga (Colocasia esculenta L. Schott), because it is an alternative crop with great potential and can replace those that are marketed today. [6]; however, it must be very clear that starches have many limitations for their industrial use, for this reason their modification is necessary in order to improve the functional properties and extend the range of application, they can also obtain functional properties that are not present in native, therefore they are products with higher added value [7]. In recent years, not only physical, enzymatic and chemical modifications have been carried out, but genetic modification of the plant's DNA has also been carried out, and not only the treatment of the granules. Considering the above data, the objective of this project is to study the functional properties of Malanga starch to obtain a variety with better characteristics for industrial use, which can be resistant to mechanical processes and stable in gelatinization.First, it should be mentioned that starch is the main reserve polysaccharide of most vegetables and the main source of calories for humans. It is composed of amylose and amylopectin and depending on the proportions of these two components, it will be the functionality or the properties that the starch will possess. During the development of the investigation it was observed that the content of amylopectin (730.7 g/kg) of Malanga starch was higher than that of amylose (269.2 g/kg). Likewise, the value is similar to that of potato starch (741 g/kg) and higher than that of corn starch (707 g/kg) [8].Some molecules are solubilized, particularly amylose, which diffuses into the water and, if heating continues, breaks down and partial solubilization is observed. [9]. With this modification, crosslinks are created in the starch granules, improving resistance to mechanical processes and acid environments. The viscosity profile of starch becomes much more stable as the gel structure is strengthened, they are also known as cross-linked starches. During some events within the processes, the molecular order is lost, and therefore the birefringence, the granules lose their crystallinity, absorbing a large amount of water, which causes swelling, modifying their size [10].Chemical modification is one of the techniques for the diversification of the use of starches that allow changing their structural characteristics, which consists of the introduction of low levels of substituents in the starch molecule, improving its functional characteristics. Thus, modified starches are used in the food industry as stabilizers, preventing separation in emulsions [11]. In addition to this, acetylation acetylation depends on certain factors, such as: the source of the starch, the concentration of acetic anhydride, reaction time and the Ph. Due to the fact that chemical modifications confer special characteristics to starches, it is possible to modify its gelation, making the bonds of its structures stronger depending on the type of modification or chemical compound used for the modification [12].In starch granules that are not surrounded by any shell, the amylose and amylopectin molecules are arranged radially forming a series of concentric layers, alternately having an amorphous and a crystalline structure in which the chains are associated in helical morphology and in an orderly manner [13]. The functional properties of starch vary according to the function, quantity and constitution of the amylopectin and amylose molecules, the structure of the grain, as well as each of the minor constituents. Native starch granules vary greatly in shape and size (from 0.1 to 200 µm). In crosslinking, the temperature must be controlled, since at high temperatures the starch granules begin to swell forming gels, that is, the hydroxyl groups become available for the anhydroglucose groups. Cross-linked starches, due to their modification, change their stability at controlled temperatures, which are analyzed with different chemical, physical, biological or enzymatic techniques, reducing the crystallization of starch, amylose and amylopectin, increasing the hydrophobic capacity of starch as well as the thermal capacity.In the analysis of Malanga starch, type A crystals were found that produce compact helices with a low proportion of water. The crystalline structure of the sample was analyzed with an X-ray diffractometer, identifying the characteristic peaks in 2θ for the amorphous and crystal clear. The samples were analyzed in 2θ from 5 to 60° with a current of 30 mA and a voltage of 40 kV.With the results obtained during the crosslinking, it was shown that there were important changes in size, and its gelation properties were greater, this benefits the formation of thickeners, emulsifiers and stabilizers during some industrial processes, giving improvements in many products due to changes in temperature giving a better appearance to the products.

2. Material and Methods

- Study area: The research was carried out from January 28th to May 28th, 2020 in the UNIDA food engineering laboratory, Technologic Institute of Veracruz, which is a is a higher education institution focused on the training of trained personnel in scientific and technological areas and on conducting research in them, to promote the economic and social development of México. Av. Miguel Ángel de Quevedo 2779, Col. Formando Hogar, 91897 Veracruz, Veracruz, México.MaterialsIn this work, native taro starch, sodium trimetaphosphate (STMP), sodium tripolyphosphate (STPP), sodium hydroxide (SH) and sodium sulfate (SS) from the Sigma-Aldrich brand were used, which were provided by the food engineering laboratory of UNIDA.CrosslinkingThe cross-linked starch was prepared using the method of Seib and Woo. In a 50% starch solution, the crosslinking agents, sodium trimetaphosphate (STMP) and sodium tripolyphosphate (STPP) were added with a ratio of 50:50 and 99:1 of STMP: STPP, respectively. The amount of crosslinking agents added was 6%, 5% sodium sulfate (SS) was also added with respect to the amount of starch. The pH of this mixture was adjusted to 11 by adding 0.1 M sodium hydroxide (SH). This suspension was constantly stirred and heated at a temperature of 45°C for 3 h. The suspension was then neutralized to pH 6.5 by adding 1M HCl. The starch was obtained by centrifugation in a Veronesi centrifuge (Mod. SAT 130) and washed with water (7 washes). The suspension was dried in an oven (Imperial V, USA) at 40°C) overnight, to obtain the modified starch.

|

3. Results

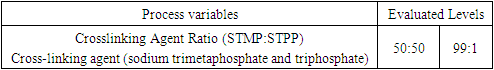

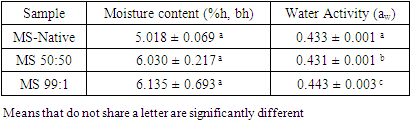

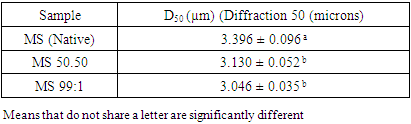

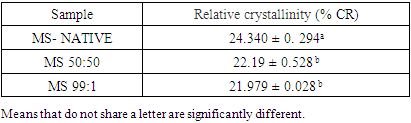

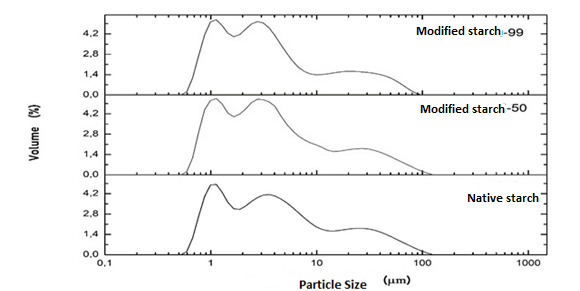

- Moisture content and water activityThe X-ray diffraction pattern is used to differentiate between cereal and tuber starches, as well as to detect changes in the crystallinity of amylopectin caused by physical, chemical and enzymatic treatments of the starch granules. Once identified, the respective experimental table is generated in which three modification situations are contemplated for this molecule, that is, working with native starch (unmodified), with modified starch in a 50:50 (MS50) and with modified starch at 99:1 (MS99), The results show that the size of the Malanga starch granules were different (p<0.05) with average diameter values of 3.396 ± 0.0184, 3.136 ± 0.0056 and 3.046 ± respectively.These values are within the range of those reported by Aboubakar, Njintang, Scher and Mbofung, who observed sizes between 1-5 μm, for six varieties of Malanga starch studied; the results suggest that the size of the granule reflects the different origins of the starches.The results on the moisture content (% H, bh) and water activity (aw) of the native and cross-linked starch are shown in Tabla 2. According to ANOVA (Analysis of variance), crosslinking did not present a significant effect (p <0.05) on moisture content, but it did on water activity. The moisture content reached oscillates around 6%, which is lower than that reported in the literature for taro starch by Palomino et al [15]., (2010) (9.47% - 10.82%), Aboubakar et al. [16] (8.2% - 9.6%), among others. The values obtained in this study are in the generally accepted humidity range for dry products with a desirable shelf life.The aw value depends on the composition, temperature and water content of the product. It affects the quality characteristics, such as: microbiological risk (Critical parameter for shelf life studies in relation to the growth of Listeria monocytogenes).

|

| Figure 1. Granule size distribution of native taro starch and chemically modified starch |

|

|

| Figure 2. X- ray diffraction patterns of cross-linked starches |

4. Discussion

- The result showed that the phosphated starch showed a decrease in moisture content compared to its native counterpart (7.21%) +0.86. en palabras de Torres Becerril, the native malanga starch presented an A type diffraction at 2θ= 15°, 17°, 18°, 23°, a diffraction pattern A type has been reported in starch from Mexican taro (Colocasia esculenta L.) compared to what Agama-Acevedo et al and Janet et al report, emphasizing that the type A diffraction pattern usually occurs in Malanga starches. In addition, these results are consistent with the results found in the studies of acetylated corn and ginger starches reported by Schmidt et al [21]. The crosslinked starch presented typical broad peaks at 2θ= 9° and 20°. This diffraction pattern indicates that with the esterification process, the native crystalline structure of the starch is destroyed and a new structure is formed in the crosslinked starches. According to the results obtained, it was decided to use the treatment of 700 rpm and 50 min, since it allowed obtaining a material with lower crystallinity, greater homogeneity of particle diameter, and a higher percentage of amylose, which will favor the crosslinking reaction. These values are within the range of those reported by Aboubakar, Njintang, Scher and Mbofung, as mentioned by Torres et al, who observed sizes between 1-5 μm, for six varieties; the results suggest that the size of the granule reflects the different origins of the starches. Thus, the reaction conditions used allowed obtaining modified starches with similar viscosity profiles. Therefore, it is important to make a physicochemical characterization of crosslinked starches, applying various analyzes such as differential scanning calorimetry, rhyological tests, chromatography and evaluating the formation of paste through viscosity analysis. On the other hand, Jhoty et al, found that when they crosslinked the starch, it showed a growth in the peak of maximum viscosity, (0.25 and 0.50%), however when crosslinking at higher concentrations of the reactant (0.75 to 1) they observed a drastic drop in the viscosity.Crosslinked starch contains two types of primary (6-OH) and secondary (2-OH) hydroxyls. These hydroxyls are capable of reacting with multifunctional agents resulting in crosslinked starches. Crosslinking is done to limit swelling of the granules under cooking conditions or to prevent starch gelatinization.The limitations for the deeper development of this work was time, which is important to carry out more tests with respect to taro starch, in the same way it is suggested to carry out tests with different concentrations of reagents to set a standard. In addition to this, it is recommended to carry out studies to check the behavior of viscosity, elasticity and their relationship. It would be very interesting to carry out physical, chemical and nutritional studies with starches with different maturation times and check if there are significant differences between the results obtained and the results of this study. In addition to this, it is recommended to carry out studies to check the behavior of viscosity, elasticity and their relationship. It would be very interesting to carry out physical, chemical and nutritional studies with starches with different maturation times and check if there are significant differences between the results obtained and the results of this study.

5. Conclusions

- The characterization tests of the products revealed the changes in the chemical structure, morphology, crystallinity, thermal stability of the starch that resulted from the imposed chemical modification, and which in turn were a function of the level of modification, reaching the recognized capacity. of chemically modified starches to act as a source of resistant starch. The evaluated starches presented physicochemical and functional properties that make them viable for use in various food processes or other industrial applications, their low moisture content suggests the use of other crosslinking techniques in order to evaluate more parameters, concentrations or temperatures to obtain better results, with the aim of allowing the alternative use of Malanga as a source of obtaining sustainable starch in the region.

Significance Statement

- This study is very important because it discovered that it is possible to prove that starch, when modified, increases its water retention, allowing some products that contain starch to be more stable and its modification is not altered when processed. This study allows more research to be done in the field of bio food processes to find other ways of modifying other types of starches and not just the one used in this study. It will also help researchers in the area to carry out more research to strengthen the findings of this work and explore in more detail the benefits that can be obtained from the study of Malanga and starch.Conflicts of interest: The authors declare they have no conflicts of interest with regard to the work presented in this report.

ACKNOWLEDGEMENTS

- Thanks to UNIDA (Food Research and Development Unit) for their support in conducting this study, especially MC. Jazmin Rodríguez and Dr. Guadalupe del Carmen Rodríguez Jiménez director of the Food Engineering Laboratory.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML