Moshe Gophen

Migal-Research institute in the Galilee. POB 831 Kiryat Shmone Israel (11016)

Correspondence to: Moshe Gophen, Migal-Research institute in the Galilee. POB 831 Kiryat Shmone Israel (11016).

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

Abstract

Skin separation and its commercial disadvantage in Date (Phoenix dactylifera) fruits is a world wide concern. Skin separation is mostly known in several varieties as Barhee and Majhul. There is Date varieties which are not producing skin separation and others do so. In order to study skin separation phenomena two date varieties were comparatively studied: Dayri where skin separation do not occur and Barhee which fruits are strongly produce skin separation. The study is focused on the fruits skin mechanical properties and the anatomical trait. It was found that the skin of Barhee fruits is less flexible and more rigid and therefore resisting artificial stretching force and tend to make folders while disconnecting from inner soft tissue whilst Dairy fruits have the opposite properties. One of the reasons for such property is the line order of the epidermis cells in Barhee and circular order in Dairy. More differences in skin properties support the final result of high skin separation in Barhee and zero in Dayri.

Keywords:

Barhee, Dayri, Skin Separation, Mechanical Properties

Cite this paper: Moshe Gophen, Skin Separation in Date Fruits, International Journal of Plant Research, Vol. 4 No. 1, 2014, pp. 11-16. doi: 10.5923/j.plant.20140401.03.

1. Introduction

The cultivation of dates (Phoenix dactylifera) in Israel started during early 1920`s of the previous decade and research started immediately. An essential issue of dates growing research in Israel was from the very beginning, the fruits management which is controlled by market demands. Nevertheless, fruits management was not limited to the last management steps but also to early stages of their development including environmental conditions, irrigation and nutritional regimes[11]. The Phoenix spp. belong to the family Arecaceae of which 210 genera and more than 4000 species are known[12]. The location of cultivated varieties is mostly in desert climate conditions: Arabian-Sahara- Persian-Northern India and also in the USA, Australia and in South-European countries. Several hundreds of Date Palms varieties are known in the world of which only 10 are common in Israel. The fruits of, Barhee, variety are marketed both as ripe and unripe[1, 2] stages. The fruits of one variety, Egyptian origin, Hayani, is marketed as wet and all others as dry or semi-dry forms. The total planted area of Dates in Israel (2012) is 4300 ha of which 70% are Majhul and 7% - Barhee (B. Glazner, personal communication). The annual marketed harvest in 2012 was 35X103 tons of which Majhul - 24.5x103 t and Barhee-3.5x103 t. Israeli export of Dates in 2013 included 10X103 t Majhul and 1.0X103 t Barhee crops (B. Glazner, personal communication). The marketing of Barhee as unripe is due to the high level of sugar content. Nevertheless, if skin separation in Brhee fruits could be reduced, ripe- half-dry fruits market is unlimited. Consequently the elimination of skin separation in both Barhee and Majhul fruits is a significant concern. Skin separation of Majhul fruits[3] is a very hot issue in the economy of this Northern –Africa originated variety. Within the present conditions of date growing economy in Israel the Majhul occupy the major role. However, the commercial value of its market is severely affected by skin separation phenomena. In fact, skin separation of Palm Date fruits is relevant to all cultivated varieties in Israel. However, the level of appearance is different. With the exception of Majhul and Barhee, the commercial value of all other varieties is due to other fruit properties such as taste, sugar content and agro-mechanical properties. In Barhee and Majhul the skin separation of ripe fruits is the only one factor which predominate the commercial value. The Barhee fruits were selected for the present study because of the skin separation extremism on its fruits. The Dayri fruits were choose as comparative type because skin separation on its fruits is extremely low.At the beginning of the investigations of the skin separation case scientists were focused on the issues of fruit anatomy and the potential involvement of enzymes in the process[9, 10, 11]. Moreover, microclimate conditions inside and outside of the fruit bunches as well as irrigation and nutritional regimes were also intensively explored[11]. As a consequence, transpiration and elements intake became a common subjects of investigation. A new direction of research was pointed out by Bernstein et al[7] and Gophen[5]. Their approaches emphasize the importance of the impact of the mechanical properties of the skin predominate its separation phenomena. In this paper experimental study combined with fruit anatomical trait aimed at analyzing the mechanical property of the skin and consequently its separation are presented.

2. Material and Methods

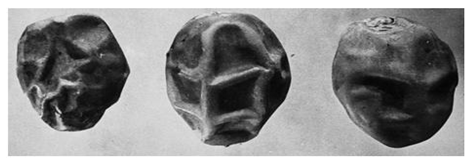

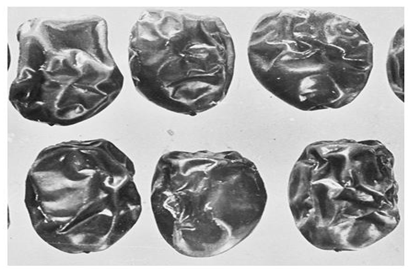

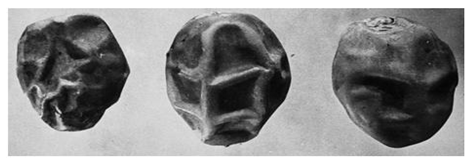

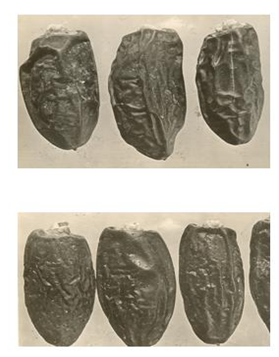

Anatomical PropertiesFor the analysis of the mechanical properties of fruit skins two Date Palms Varieties were comparatively studied: 1) The Barhee of which skin is strongly separated during drying of ripe fruits; 2) The Dayri variety of which skin separation during fruits desiccation is very low. The properties of the ripe fruit skin of Barhee and Dairy were comparatively analyzed and the following three levels of separation were in use (Photo 4): Weak: 0-35% separation; Mid level: 35-75 separation and Extreme: 75-100% separation. For the anatomical observations, fruits at all ages were collected from three year crops and ripe fruits for mechanical and chemical studies were taken from the Date Fruit Packing Institute, in Zemach, Jordan Valley. Unripe fruits for anatomical studies were taken from trees and immediately soaked in FAA fixative (70% Ethanol, Iced Acetic Acid, and 38-40% Formalin: V:V:V= 18:1:1) for 24 hours. Than, to achieve tissue softening they were soaked in gradual increasing mixture of Cedar Oil in 100% Ethanol up to pure Cedar Oil. Than the fruits were placed in pure low melting point Paraffin (46-480) for 2-7 days for blocks preparation for microtome sectioning. Cross sections were dyed by Fast-Green-Safranin. Due to the incomplete impregnation of the Paraffin into the tissues, another technique was carried out, the Methacrylate[4; 8]. Microscopical transaction slides (transmitted light) and epidermis surface (polarized illuminated light) view were carried out. The transaction slides gave an indication of the fruits soft tissues deformation during progressed ripening process followed by skin separation. The epidermis surface view represented stomata density and cells order orientated distribution. Ten un-ripe fruits were taken for each variety and three surface zones were checked where 10 randomly chosen microscopic view fields were counted.Ash and water contentThe ash and water contents in the skin were defined after gentle skinning of stripes from ripe fruits with careful avoidance of soft tissue adhesion on their inner side. Wet and dry weights were measured before and after desiccation of the stripes in 105℃ for 24 hrs. Water content in ripe and unripe fruits of Barhee and Dayri was also measured. Ten groups of 3 fruits each were collected from commercial unripe and ripe stocks in the Zemach Packing Institute. Each fruit was cut into two halves and the pip was removed. The unripe (60 pieces) and ripe (60 pieces) were placed in an oven at 65℃ for 13-15 days until daily weight decline was less than 0.05g per 2 pieces fruit. Initial and final weights were measured.Skin SwellingAir dried skin pieces with known dimensions (3x3mm) were placed in NaOH solution (0.5N) for 24 hrs. Than the squared pieces were placed on slide and their perimeter was measured microscopically by stage micrometer. The additional total perimeter length was calculated. Skin ThicknessSkin stripes were removed from 10 ripe fruits collected from 10 trees of Barhee and Dayri and washed by water, than dried by low speed fan wind blow during two hours. Three skin zones of the fruit surface were sampled: 1) Close to top, proximal; 2) Close to top end, distal; and 3) middle zone. Skin thickness was measured by Micrometer combined with pressure indication. Similar pressures were operated during thickness measurements. Total number of measurements was 600= (10 Barhee+10 Dairy fruits) X 3 stripes per fruit X10 measurements on each stripe. Skin Elasticity (3; 7)Skin stripes of 2mm wide and 3-4 cm long were gently removed from the mid zone of Barhee and Dayri ripe fruits and inner residuals of soft tissues were removed by water flush followed by few minutes low velocity fan wind blow drying. The long axis of the stripes was parallel to that of the fruit. One stripe at a time was placed between two holders of a tension-meter instrument with 1 cm distance between them. The two holders moved apart slowly and the operated force was recorded continuously versus time (scale units) which express elongation rate i.e. elasticity or strain or flexibility. When the stripe was torn the final operated force was documented. The expression of the tension process was recorded as curved line (Fig.2). The more the skin is elastic the horizontal elongation is flatter with longer distance. The more the skin is rigid the vertical slope is steeper and the tearing force is higher. Measurements were done on uncoated and coated (4 substances, (see text) ripe fruits. Full scale of measured pulling apart forces were scaled as 200g, 400g and 1000g according to strain capabilities. Chart speed was 10 Cm/min., and the speed of pulling apart was 0.2 Cm/Min. Fruit Coating and Perforating (Photos 5,6,7,8)In order to reduce or enhance rate of desiccation and consequently level of skin separation two experiments were carried out: A) To slow down the rate of desiccation aimed at reduction of separation level, the fruits were coated by oily substance which also probably enhanced skin elasticity. The coating was achieved by 4 types of oily substances which also produced a commercially attracted shining view of the fruit without changing its taste. Four materials were tested: 1) Emulsion of 23% Polyethilen and liquidized wax (commercial title-Tag); 2) Paraffin Oil (commercial title-Ondia); 3) Acetilated monoglyceride (commercial title-Myvacet); 4)Mixture of 34% Polyvinyle chloride (PVC) and liquidized Nitrite Rubber (commercial title-XA-0.3). B) Skin perforation, achieved by fine needle holes aimed at enhancement of both desiccation and skin separation. The artificial orifices penetrated only the skin thickness at a distance of 3-4 mm between holes all over the fruit surface.

3. Results

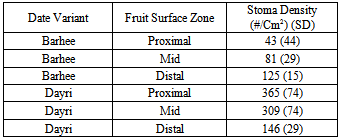

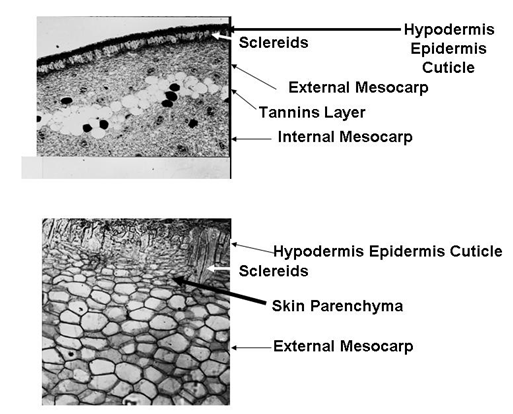

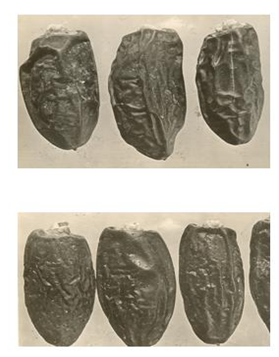

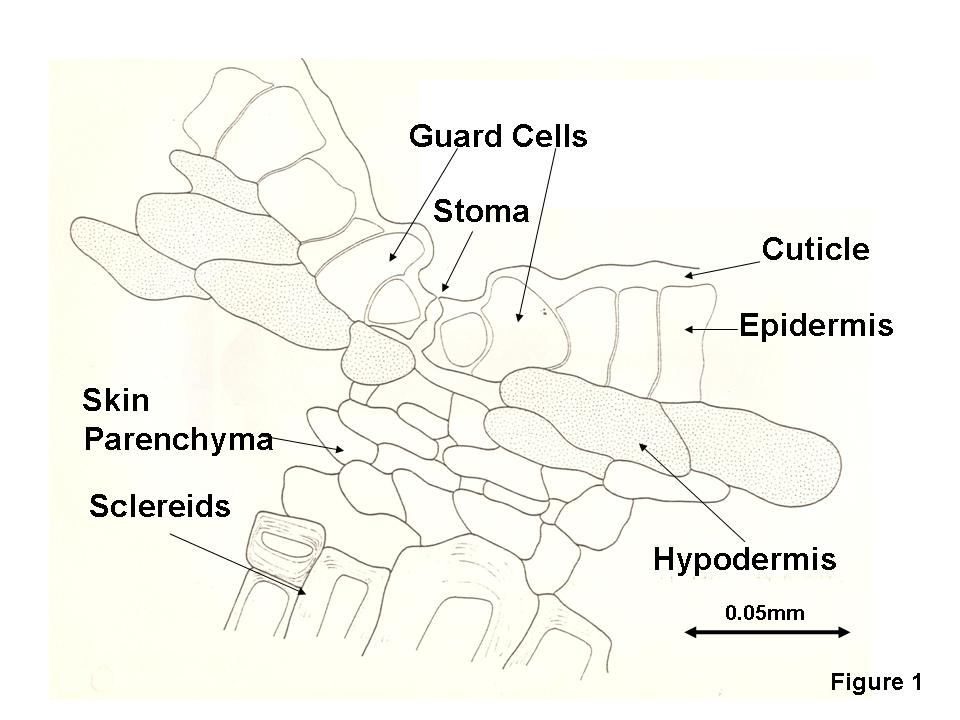

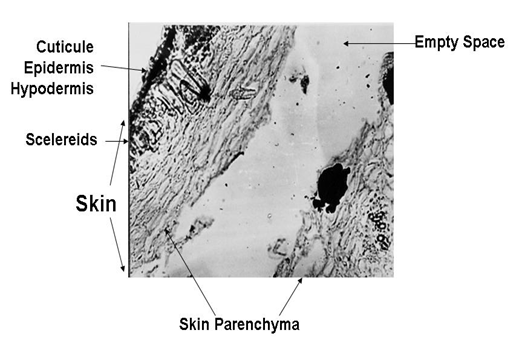

Anatomical Observations (Fig. 1; Photos 1,2)The following cell layers of the un-ripe fruits were indicated (from innermost outward): Endocarp- the inner layer comprised of small and dense cells. This layer is clearly indicated during pre-ripe stages and completely modify by cells disintegration after ripeness producing white membranal wrapping of the seed. Mesocarp- above endocarp, the majority of the fruit soft tissues comprised of big parenchyma cells with minimal inter-cellular spaces with bundles of vasculars longitudinal oriented (proximal - distal axis) are scattered. The Mesocarp is comprised of two layers: External and internal. Between those two layers there is a 3-10 cell thickness layer containing Tannins. The Tannin layer is stretched all over the entire fruit except at the proximal and distal zones. | Figure 1. Schematic draw of cell structure of stoma and tissues in the vicinity of Barhee fruits |

| Photo 1. Microscopical view of un-ripe Barhee fruit: Upper panel X35, Lower Panel X100. The fruit anatomical layers are indicated (see text) |

| Photo 2. Cross section of ripe Dayri fruit. Formed skin is indicated. X100 |

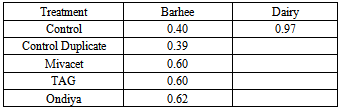

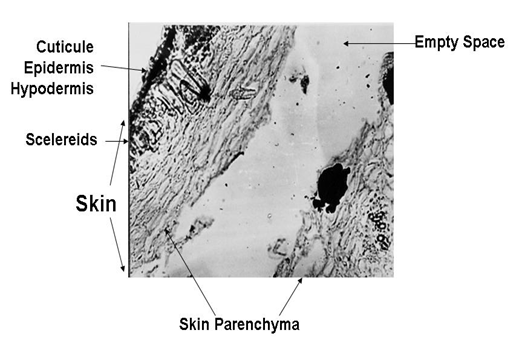

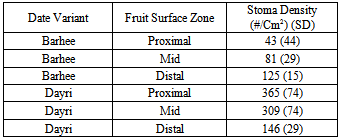

Exocarp- The external zone is comprised of 4 thin layers (from outmost inward): 1) Most External: non-cellular Cuticle; underneath the cuticle there is a uni-cell layer of the Epidermis made of elongated cells; underneath the Epidermis there is a layer of 1-2 elongated cells, the Hypodermis. This layer is missing underneath the stomata where the micro-space of the stomata is bounded by parenchyma cells. Underneath the Hypodermis there is a thin layer of the Prenchyma of the Skin including bundles of vasculars and under this layer there is the layer of Sclereid Cells, also entitled Stone Cells. The sclereid cells are elongated radially oriented (their long axis is parallel to fruit radius). These cells contain large nucleus which almost disappear during ripening process. The Stomata densities and orientation were microscopically observed and counted by illumination of polarized light: 10 view fields were counted in each zone of 10 different fruits. Totally averaged results (SD)`s are given in Table 1:Table 1. Averages and (SD) of Stomata densities (No/Cm2) in unripe fruits of Dayri and Barhee. Three zones were counted: Proximal, Mid and Distal

|

| |

|

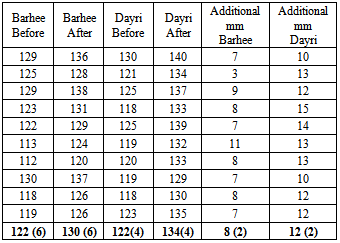

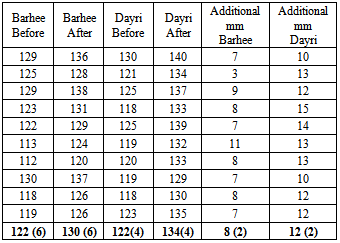

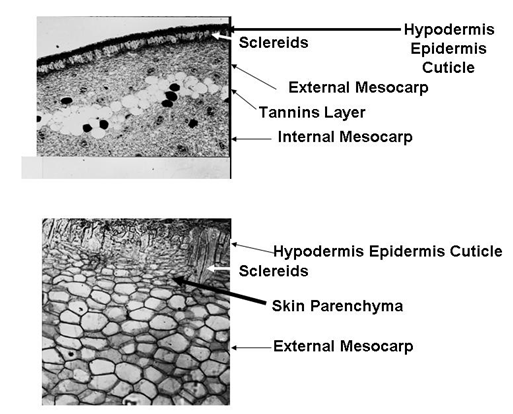

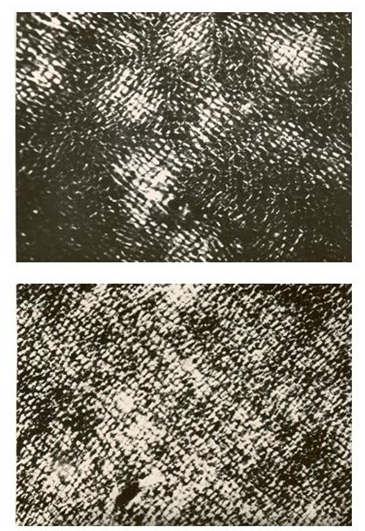

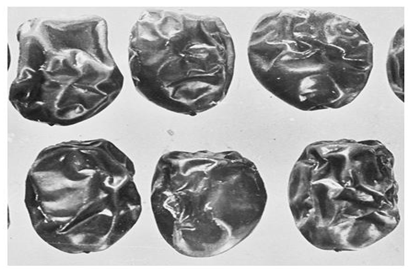

The density of stomata in Dayri fruits is prominently higher th.an in Barhee fruits.The Epidermal cells orientation with stomata in between is significantly different between Barhee and Dayri fruits (Photo 3). The epidermis cells of Barhee are oriented as long parallel rows and those of Dayri form a circular clusters.The impact of NaOH (0.5N) on swelling of skin squares (app. 3X3 mm) removed from ripe fruits of the two varieties is presented in Tab.2.Skin thickness measurements were analyzed by ANOVA (p<0.05) test and the results were as follows: Barhee (131 micron; SD=13) were significantly (p<0.0001) lower than the Dayri values (162 micron; SD=17). The Barhee skin is consequently significantly thinner than that of Dayri.Table 2. Averaged increment of total perimeter length (mm) (SD). Ten pieces of each variety were measured total averages (SD) are given (bottom line)

|

| |

|

| Photo 3. Skin surface view of Dayri (upper) and Barhee (lower) illuminated by polarized light. X100 |

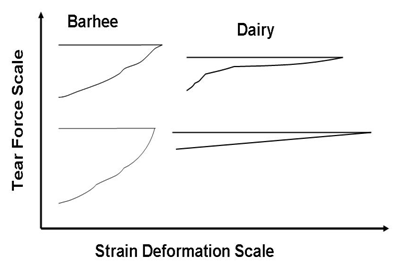

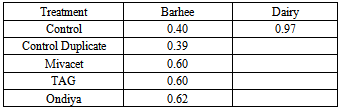

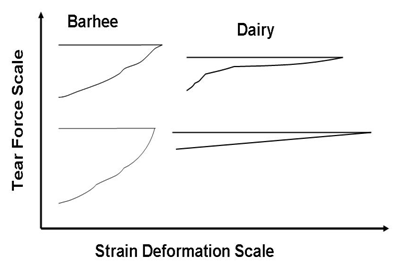

During the ripening process the anatomical structure is modified accompanied by biochemical changes. The cuticle is not modified during ripening except folders production during fruit desiccation. The Epidermis remain more or less the same during ripening. The parenchyma cells of the skin and the external Mesocarp significantly shrink and cell wall become soften and loose their internal (turgor) pressure and their original shape. The skin dissociation occur inside the parenchyma of the external Mesocarp located between the Sclereid (stone cells) and Tannin (Photos 1,2). The skin separation zone is the same in both variety. Consequently, it is suggested that if skin separation apart is anatomically similar between the two varieties the consecutive dissimilarity of skin separation between Barhee and Dayri fruits, is therefore due to the difference between mechanical properties of the skin of the two varieties.Dry Matter, Water and ash contents of skin and fruit. The dry matter content of Barhee skin was 34% and that of Dayri-46%. Ash content in Barhee skin was 5.1% and that of Dayri- 4.0%. The average (SD) % of water content in unripe fruits of Barhee and Dayri were 58.0% (3.4 SD) and 48.4% (7.8 SD) respectively. The averaged % (SD) of water content in ripe Barhee and Dayri fruits were 52.8% (9.2 SD) and 31.1% (2.0 SD) respectively. ANOVA test (p<0.05) was used to test differences in water contents and results indicated the following significant changes: Water content of ripe is significantly (p<0.0001) lower than unripe in Dayri fruits. Water content of ripe fruit of Dayri is significantly (p<0.0001) lower than that of Barhee. Therefore, water loss during desiccation in Barhee fruits is higher than the loss of water in Dayri fruits. Moreover, the higher water content in unripe than ripe Barhee fruits is insignificant (p=0.0731). Conclusively, during fruits desiccation the water loss of Dayri is lower than that of Barhee which is probably an indication to higher shrinkage of soft tissue of Barhee fruits.Coated fruits by 4 substances as well as perforating did not indicate differences between perforated and control fruits. In coated Barhee fruits shrinkage of soft tissues was accompanied by partial attachment of the skin. In perforated Barhee fruit skins was entirely disconnected from soft tissues but completely attached in Dayri. Coating of Barhee fruits by oily substances (4 types) before drying reduced skin separation from high (75%) to low level of (25% )of separation (photo 4). Stripes from coated skin were also tested for the tearing force machine. Tearing forces and coating (Fig.2) | Figure 2. Tear Vs. Strain forces chart of Barhee (left) and Dayri (=Dairy) (right) skin stripes (see text) |

| Photo 4. Barhee ripe fruits after desiccation representing three levels of skin separation: Left- 25-35%; Middle-35-75%; Right->75% |

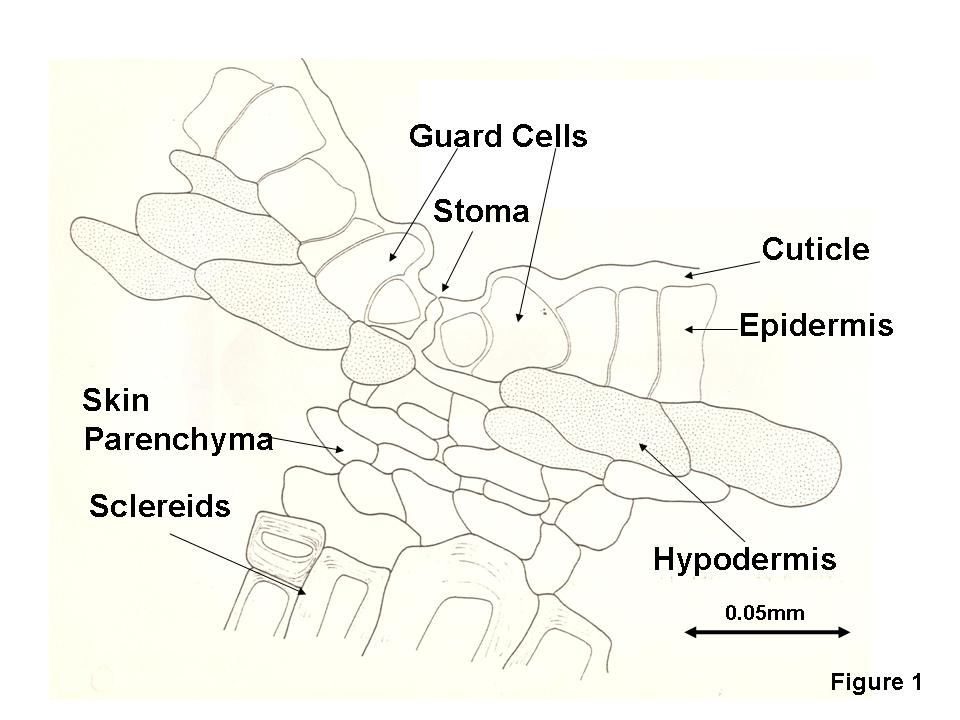

Figure 2 illustrate curves of skin stripes stretching of Barhee and Dairy fruits. The slope of Barhee curve is steeper, the horizontal distance is shorter but that of the vertical is longer in Barhee than that of Dayri chart. Dayri curve is horizontally longer and vertically shorter. The final result is greater factor of elasticity in Dayri skin. The tear force (TF) and the Strain Capabilities (SC) of the two varieties fruit skins stripes were recorded and calculated by Scale Units. The Factor of Elasticity (EF) of the skin was calculated as follows: EF=SC/TF; Where: TF as measured (Y axis); SC=Taken from the scaled chart paper (X axis).Results of EF values are given in Table 3.Table 3. EF values (see text) of skin stripe taken from ripe fruits of Barhee (coated and uncoated) and Dayri fruits (Photos 5,6)

|

| |

|

| Photo 5. Ripe and desiccated Barhee fruits treated by soaking in Myvacet |

| Photo 6. Ripe and desiccated Barhee fruits treated by soaking in XA 0.3 |

The tear forces (TF) of the two varieties were close but the Strain capabilitiy (SC) of Dayri was larger than that of Barhee and therefore the Factor of elasticity (EF) of Dayri is higher. It can be concluded that the higher the EF value is, the lower level of skin separation occur. The factor of Plasticity is the reciprocal of Elasticity value. The factor of Elasticity is lower and that of Plasticity is higher in Barhee than Dayri fruits. Coating fruits by 4 substances reduced level of separation in Barhee dates from 75% to 25%. Perforating ripe fruits of Barhee (Photo 7) enhanced skin separation to a level of complete disconnection between soft tissues and skin layers. In Dayri fruits there was no impact of coating and perforating on fruits. The fruits of Dayri represented zero skin separation in all treatments (Photo 8). | Photo 7. Ripe and desiccated Barhee fruits treated after perforating |

| Photo 8. Ripe and desiccated Dayri fruits treated without perforating (upper) and after perforating (lower) |

4. Discussion

Pioneering studies of skin separation in dates were documented by Nixon[9] and Nixon and Reuther[10]. They attributed the skin separation case to the micro-climate conditions in vicinity to fruit bunches while connecting to the tree. Nixon and Reuther[10] related partial impact of fermentation within the fruit during ripening process to skin separation. Soft tissues shrinkage as a result of water loss is a general process occurring in all date fruits during ripening development. The ability of the skin to follow the soft tissue shrinkage and being attached to it is due to mechanical properties of the external layers (cellular and non-cellular), the skin. The phenomena of "Skin Separation" occur when skin layer is separated from the soft tissues and air is penetrating in between. The critical question is why skin is not continuously attached to the soft tissues during fruit desiccation? The answer has probably two parts: A) The rate of water loss and B) the mechanical properties of the skin. In my study I focused on the second part. It is suggested that slow down of the desiccation process of ripe fruits will reduce level of skin separation, but it will probably deteriorate their taste and cause additional commercial difficulties. The results of coating experiments in Barhee pointed out on the possibility to change mechanical properties of the skin without significant change of the desiccation rate and probably the commercial value of the fruit. Anatomical observations did not confirm difference of tissues modification process during ripening in the two varieties. However skin separation occur in Barhee and not at all in Dayri fruits, therefore the study was focused on comparative investigation of their mechanical properties of the skin. The arrangement of the epidermis cells in Dayri enabling the skin to be folded smoothly in all directions which probably is the reason why it follows being attached to the shrinking soft tissue. Nevertheless epidermis cells in Barhee fruits are oriented in parallel rows resulting in unattached skin bow shape fragments unfolded and separated from the soft tissues. The higher density of stomata in Dayri enable skin folding capability of small fragmental sections attached to the soft tissues. The skin of Dayri fruits is thicker with lower water and higher ash contents which in comparison with Barhee skin, reduce the capability of the skin to be separated as Barhee skin is doing by the formation of unfolded bow shape skin separated from the soft tissues. When Barhee skin is desiccated water loss is higher than in Dayri skin. Barhee skin is thinner and loose more water than that of Dayri and therefore separation is enhanced in Barhee. The higher level of swelling in Dairy skin emphasizing its higher flexibility than that of Barhee skin. Barhee skin is more rigid than that of Dayri. The tear forces measurements indicates that in the case presented here, the difference of skin mechanical properties between two date varieties can clarify skin separation in Barhee fruits. The comparative mechanical properties described here explain why Dayri skin is more elastic and plasticity is lower than that of Barhee. It can be exemplified as a comparison between two elongated pieces of wood: one made of parallel microsieves and another with mixed microsieves orientation. The first can be folded to a bow shape and the latter will be broken by folding: the Dayri is the broken and the Barhee is the folded. Nevertheless slow down of the desiccating process might reduce skin separation level. Nixon[10] stated: Skin separation is completely absent if fruits are not desiccated but drying of date fruits can be made without skin separation. Haas and Bliss[6] related skin separation only to high rate of desiccation, softening of the peripheral fruit region and internal fruit pressure. Shapira et al[11] related skin separation in Majhul to irrigation and elemental uptake regimes. The difference of mechanical properties between Barhee and Dayri fruit skins was the main issue of this study. The results of the research presented here was an attempt to understand why Dayri fruits are not "skin separated" and those of Barhee are almost entirely "skin separated". It is likely that the differences in mechanical properties of the skin between the two varieties justify the skin behavior during desiccation process: separated in Barhee and not separated in Dayri. The research carried out on Majhul fruits[7; 11] were focused on skin behavior in Majhul under periodical fluctuations of external condition and therefore results interpretation are respectively slightly different from the present study. Nevertheless, the management option for fruit quality improvement are similar[7]: To use oily substances impregnation into the skin aimed at elevation of elasticity (E factor), reduction of skin softness and slackness to become stiffer. The skin of "non-separated fruits" as in Dayri is stiffer and more resistant to strain forces (stretching) not like the Barhee soft and pliable separated skin.

5. Conclusions

If we ignore the option of slow desiccation rate as a result of commercial constrains, it can be concluded that in Barhee fruits the skin separation level is mostly affected by the mechanical properties of the skin. The agro-mechanical procedures of irrigation, nutritional regime and fruit management while on tree are of secondary importance in the case presented here. Whilst the mechanical properties of the skin affecting primarily the skin separation trait of Barhee fruits.

References

| [1] | Bernstein, Z. 2004 a, The Date (Palm). Chapter: Skin Separation. Pp 296-300. Laor Publisher, pp. 371-386. (in Hebrew). |

| [2] | Bernstein, Z. 2004 b, The Date (Palm). Chapter: Date Variants in Israel. Laor Publisher, pp. 371-386. (in Hebrew). |

| [3] | Bernstein, Z. and I. Lustig, 2006.Skin separation in Majul dates. The Planters Magazine (Alon Hanotea), 60: pp.18-21. (in Hebrew). |

| [4] | Feder, N. & T.P. O`Brein. 1968. Plant microtechnique: some principles and Methods. American Journal of Botany. V. 55.pp. 123-142. |

| [5] | Gophen, M. 1966. Skin separation in Barhee dates. MSc Final Project. The Department of Botany Hebrew University in Jerusalem. 62 p. (in Hebrew). |

| [6] | Haas a, A.R.C. and Bliss, D.E. 1935. Growth and composition of Deglet Noor,dates in Relation to water injury. Hilg. 9 (6); 295-344. |

| [7] | LUSTIG, I. and BERNSTEIN, Z. 2013. The Correlation between the Mechanical Properties of the Skin of the Date Fruit and "Skin separation" in cv. Medjhool. (Submitted). |

| [8] | Meira, R. N. S. A., & Martins, F. M. 2003. The inclusion of hebalized material using methacrylate for plant anatomy studies. Rev. Arvore Vol. 27 no. 1 Vicosa Jan/Feb. pp. 12-18. |

| [9] | Nixon, R. W. and W. Reuther. 1947. The effe3ct of environmental conditions prior to ripening on maturity and quality of date fruit. Amer. Soc. Sci. Proc. 49: pp 61-81. |

| [10] | Nixon, R. W. 1961. Skin separation in soft dates. Date Growers` Inst.Rpt. 38: pp 10-13. |

| [11] | Shapira, O., I. Shumer, and A. Schwarz 2012. Mineral composition and the rate of water loss: Does it related to skin separation in dates. The Planters Magazine (Alon Hanotea) 1: January 2012.pp.22-32. (in Hebrew). |

| [12] | Stoler, S. 1977. Date Growing in Israel. Hakibutz Hmaeuchad Publisher. (in Hebrew). |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML