-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Plant Research

p-ISSN: 2163-2596 e-ISSN: 2163-260X

2012; 2(1): 35-38

doi:10.5923/j.plant.20120201.05

Effect of Potassium (K) Source on Oil Palm Yield at Okomu Oil Palm Plc, Ovia North East L.G.A. of Edo State

Imogie A. E.1, Oviasogie P. O.2, Ejedegba B. O.2, Udosen C. V.1

1Agronomy Division

2Chemistry Division

Correspondence to: Imogie A. E., Agronomy Division.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

The study investigated effect of K sources on oil palm fresh fruit bunch (ffb) production at Okomu Oil Palm Plc, from 1999 to 2008. Two sources of K were evaluated at four rates. The sources of K evaluated were inorganic fertilizer Murate of Potash (MOP) at 1.0, 1.5, 2.0 and 2.5 kg/palm/year and local rock mineral that is Potassium Rock Mineral (PRM) at 1.67, 2.50, 3.33 and 4.16 kg/palm/year respectively. These were evaluated along the Control that is the zero application. The field layout was Randomized Complete Block Design (RCBD) in four replicates. Data were collected on oil palm fresh fruit bunch (ffb) production components (mean bunch number, mean bunch weight kg / bunch and ffb production ton / ha). Data collected were subjected to analysis of variance (ANOVA) and their means were compared using New Duncan’s Multiple Range Test (DMRT) at 5% level of probability. Applied K source enhanced soil nutrient status thus making the soil nutrient available for optimum oil palm ffb production over the control. The applied K source significantly P ≠ 0.05% affected ffb production. Bunch number, bunch weight and ffb production were significantly higher in palm receiving K fertilizers than the control. As rates of K application increases the ffb production also increases until what seem to be optimum rates of 2.0 K / palm / year was reached beyond which there was no significant increases in ffb production. Generally palms treated with K fertilizers in- respective of source of K fertilizer were highly significant than the control.

Keywords: Potassium Rock Mineral, Fresh Fruit Bunch (FFB), Components, Yield, Production

Cite this paper: Imogie A. E., Oviasogie P. O., Ejedegba B. O., Udosen C. V., Effect of Potassium (K) Source on Oil Palm Yield at Okomu Oil Palm Plc, Ovia North East L.G.A. of Edo State, International Journal of Plant Research, Vol. 2 No. 1, 2012, pp. 35-38. doi: 10.5923/j.plant.20120201.05.

Article Outline

1. Introduction

- Potassium is important in the growth and development of the oil palm and is required in the plant’s general metabolism in the movement of the stomata (water economy), activating cell division (Manciot, et al. 1981). Potassium action is equally manifest in all production factors; that is number of inflorescences and fruit bunch (ffb) production. According to Amalu (1990), insufficient potassium in the soil give rise to poor growth of palms, with thin trunks, sparse canopy, few and smaller fronds and leaflets. Omoti (1989) reported that over 50% of the total potassium in the soil is removed by fruits which are permanently lost to the plantation. This loss of nutrients must be made good by fertilizer application, if good yields are to be obtained and sustained. Improving the fertility of the soil has consistently been pinpointed as one of the most critical factors (among myriad of others) in the bid to promote the sustainability of agriculture in Nigeria. A very crucial aspect of improving and maintaining soil fertility is the application of deficient nutrients of which potassium is one of the most important in oil palm cultivation both in the nursery and in the field (Omoti;1989). Potassium fertilizer is usually apply to oil palm as inorganic fertilizer in form of Murate of Potash (MOP), NPKMg (12-12-17-2) e.t.c., howerever with the soaring cost and scarcity of these fertilizer, the fertilization of oil palm plantation has become very expensive indeed. The oil palm fertilization accounts for 25-30% of the total production costs in mature palm (Omoti, 1989). These have necessitated the need to look inwards for the alternative source of minerals such as potassium rock bearing minerals as fertilizers for oil palm manuring (Mc Chellen and Kamwengery, (1992).Research Scientists and Organization have advocated the direct application of local bearing rocks as fertilizers to recapitalise the soils (Gerner and Baanante, 1995; Isenmila and Omoti; 2003; Kuyvenhoven and Lanser, 1999). The advantages of using potassium rock bearing rocks as fertilizer lies in their relatively cheap, environmentally friendly and readily available over the conventional inorganic fertilizer Murate of Potash. The minerals are found in abundant quantities in (NIFOR, 1998). The cost of acidulation is removed, high in potassium and other plant nutrients such as phosphorus, magnesium. However, their use as fertilizer for oil palm fertilization is still at its lowest web. Thus, there is the need to evaluate the effect of potassium bearing rock minerals as fertilizers on oil palm fresh fruit bunch (ffb) production and this will enable us to developed alternate fertilizer for oil palm fertilization, thus helping farmers to maximize their returns in oil palm investment.

2. Materials and Methods

- The trial was conducted at Okomu Oil Palm Plc., located at Udo Village, in Ovia North East Local Government Area of Edo State. Oil palm plantation established in 1993 with NIFOR EWS Seedlings G99 at Okomu was used for the trial. The trial commenced in 1998 when the palms were about 5 years old. Two sources of potassium (K) fertilizers were evaluated at four levels each along with control. The two sources of K tested and their rates are as follows:-(a) Murate of Potash (MOP) at 1.0, 1.5, 2.0 and 2.5 kg / palm / year.(b) Potassium Rock Minerals (PRM) at 1.67, 2.50, 3.33 and 4.16 kg / palm / year respectively. These were compared with the control. Basal application of 0.5 kg Urea, 0.5 kg SSP and 0.5 kg dolomite (Mg) / palm / year were applied to all treatment palms except the control.The trial consists of 9 treatments and these were laid out on the field as Randomized Complete Block Design (RCBD) replicated four times. Each treatments plot consists of 8 palms and guard row palms separating each plot and block from each other. Two palms row make one block with 4 palms per row in a plot and each separated by guard row palm before the next plot and also palm row separating block. The blocks were parallel to each other. Treatments were applied at a radius of 1m away from the palm base. The fertilizers were evenly spread round the palm base within the ring weeded circle of 2.0 m diameter. The chemical composition of the Potassium Rock Mineral was determined. The K of the potassium rock mineral was extracted in 6N HCL, and there after the nutrients in the extract were determined using various analytical procedures Table 1. Soil samples were collected from two depths 0-15 cm and 15-30 cm before and 24 months after treatments application. The composite soil samples collected were bulked, processed and analysed for soil physical and chemical properties Table 2 using standard soil analytical procedures. Leaf samples were collected 24 months after treatments application. Leaf 17 was sampled, processed and analysed for leaf nutrient composition as affected by applied varied rates of K fertilizers Table 6. Data were collected on fresh fruit bunch (ffb) production components on forthrightly bases. The data collected were analysis statistically using analysis of variance (ANOVA). When F was found to be significant, their means were separated using New Duncan’s Multiple Range Test (DMRT) at 5% level of probability.

3. Results and Discussion

- The chemical composition of Potassium Rock mineral (PRM) evaluated along with imported Murate of Potash is presented in Table 1. The composition of the fertilizer nutrients in analysed PRM indicates that potassium rock mineral is an excellent source of K. It is high in K2O (36.02 %), P2O5 (11.84 %) and Mg (3.65 %) content but low in Ca (16.25 %) which makes it an excellent fertilizer material for the fertilization of palms. The soil physical and chemical properties of the experimental sites before treatments application is presented in Table 2. The results of the physical and chemical analyses of the soils show that the coarse fractions (sand and silt) dominate the soil texture. The soil mean pH values of 5.69 indicates moderately acidic soils. The organic carbon, total available N and exchangeable cations were relatively very low. The organic carbon values (0.12g kg-1) were below the critical value of 10g kg-1 considered to be optimum for optimum crop production. Application of K sources slightly increased soil pH, available P2O5 and exchangeable calcium 24 months after treatments application Table 2. Isemila and Omoti, (2003), reported that rock minerals build up soil nutrient gradually and among such nutrients is soil available P. This may be attributed to their slow nutrient released in the soil.

| |||||||||||||||||||||||||||||||||||

4. Effect of Applied Varied Rates of K Fertilizers on FFB Production

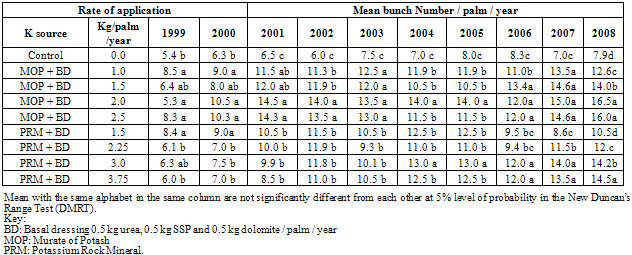

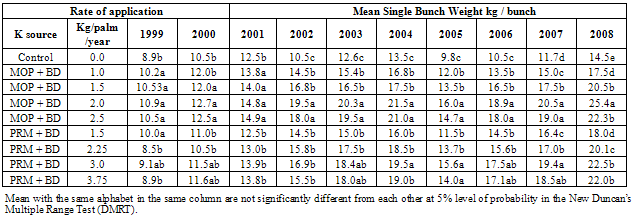

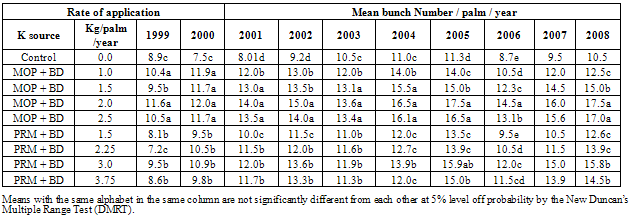

- The oil palm mean bunch number production as affected by applied varied rates of K is presented in Table 3. Statistical analysis shows that treatments had significant (p 0.05) effect on mean bunch number / palm. Highest mean bunch number (16.0) was obtained when K was applied at 2.0 kg / palm / year. Table 4 show mean single bunch weight (kg / bunch) as affected by applied K fertilizers. Mean single bunch weight (kg/bunch) were significantly (p 0.05) affected by applied varied rates of K fertilizers. Mean single bunch weight increases as rates of application increases until what seem to be optimum 2.0kg / palm / year was reached beyond which there was a declined in mean bunch weight.The markedly effect of K on fresh fruit bunch components irrespective of sources over the control show that K is an essential element required by oil palm for optimum yield. Omoti (2003) reported that K and N are the key element required by mature palm for optimum fresh fruit bunch production. Potassium play essential roles in palm flowering (inflorescence production) and fruit formation this may be seen as palm treated with K fertilizers has high bunch number, bunch weigh and ffb production (ton/ha) than the control. The responded of palms to varied rates of K increase as K rate increases until what seem to be optimum rate 2.0kg / MOP / palm / year and 3.33kg PRM / palm / year was reached beyond which there was no significant increases as rates increases.

|

|

|

|

5. Conclusions

- Locally sourced potassium rock mineral compete favourably with mutate of potash as K sources for manuring oil palm. Applied K irrespective of sources performed had significant effects on fresh fruit bunch components. The highest bunch number, bunch weight and ffb (ton/ha) were obtained when K was applied at 2.0kg MOP/palm/year and 3.0kg PRM / palm / year from 2004 to 2008 of the production season. Application of MOP at the rate of 2.0kg/palm/year was highly significant over the potassium rock mineral, however increasing MOP to 2.5kg/palm/year did not produced any appreciable increased, thus 2.0kg/palm/year of MOP seem to be optimum rate of application for MOP and 3.0kg/palm/year for PRM. PRM application for a period of nine years on the soil had positive effect on oil palm fresh fruit bunch production. In conclusion for quick response to alleviate K deficiency MOP should be used, however for long term corrective measures PRM can be used as a substitute.

ACKNOWLEDGMENTS

- The authors are grateful to the Executive Director of Nigerian Institute for Oil palm Research (NIFOR) for the support in kind and cash for the success of this work. Important to thank too is the Management and Staff of Okomu Oil Palm PLC, were the project was executed for their concern to make this work successful.

References

| [1] | Amalu. U. C. (1990): Studies of potassium in soils supporting coconuts in Southern Nigeria: 1. Potssium status and relationships with some soil properties. Nigerians Journal of Palms & Oil Seeds. Vol X and XL. 23 – 39 |

| [2] | Gener, H. and Baanante, C.A. (1995): Economic aspects of phosphate rock application for sustainable agriculture in West Africa. In Gerner, H and Mokwunye, A.U. (Eds), Use of phosphate Rocks for sustainable Agriculture in West Africa, IFDC, Misc. Fert. Studies No. 11, Pp 134 – 141 |

| [3] | Isemila A.E. and Omoti U (2003): Evaluation of locally sourced magnesite as magnesium source for oil palm. Nigerian Journal of Soil Science 14: 1 - 8 |

| [4] | Kuyvenhoven A. and Lanser P. (1999): Economic criteria for public investment in phosphate rock application for soil fertility improvement with emphasis on Sahelian Countries. African Fertilizer Market 12(12): 4 – 12 |

| [5] | Manciot, R; Oliagnier, M. and Ochis, R. (1981): Potassium nutrition and fertilization of coconut around the world. Potash Review Subject 27, 98th Suite No. 12, Pp. 1-2 |

| [6] | Mc-Chellen G.H and Van Kamwengery S.J. (1992): Relationship of mineralogy of sedimentary phosphate rock activity. Proceeding Workshop on Phosphate Source in Acid Soil. Kwala Lumpur, Malaysia, 1990, Pp 1 – 17 |

| [7] | NIFOR (2005): A brief on the Institute and highlights of achievements in research and production. October 2005, Pp 12 – 13 |

| [8] | NIFOR (1998): Annual Reports Pp 61 – 63 |

| [9] | Omoti U. (1989): Fertilizer use economy in the oil palm in Nigeria through nutrition recycling. Proceeding of the International Conference on Palm and Palm Products, NIFOR 21st – 25th November, Pp218 – 231 |

| [10] | Steel R.G.D. and Torrie, J.H. (1984): Principles and procedures of statistics, Mc Graw Hill Book Co, New York, U.S.A. Pp 154 – 200 |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML