Baha T. Chiad1, Mohanad M. Azzawi2, Dunia K. Mahdi2

1Department of Physics, College of Science, Baghdad University, Baghdad, Iraq

2Lasers and Optoelectronic Center, Ministry of Science and Technology, Baghdad, Iraq

Correspondence to: Dunia K. Mahdi, Lasers and Optoelectronic Center, Ministry of Science and Technology, Baghdad, Iraq.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

Abstract

In this work new hybrid pumping methods have been developed using cone mirror type cavity. These types could provide pumped light from many directions on the laser active media. Low threshold pumping has been achieved, with low cost.

Keywords:

Solar Laser, Hybrid Pumping, Active Media, Cone-type mirror

Cite this paper: Baha T. Chiad, Mohanad M. Azzawi, Dunia K. Mahdi, Study of New Type Lasers Cavity for Solar Pumped Laser System, International Journal of Optics and Applications, Vol. 3 No. 1, 2013, pp. 1-7. doi: 10.5923/j.optics.20130301.01.

1. Introduction

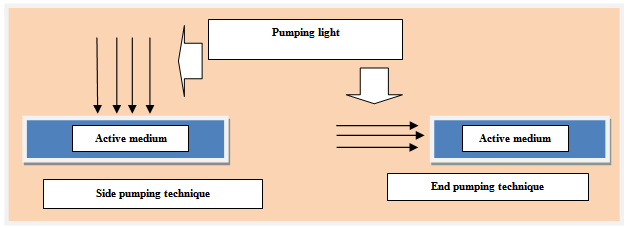

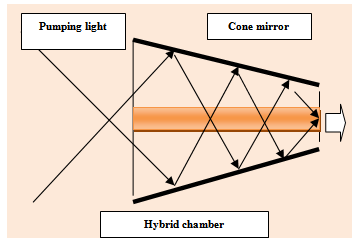

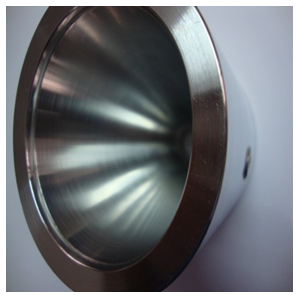

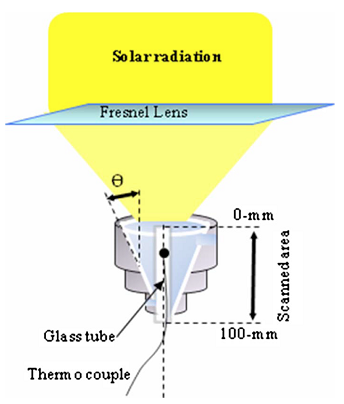

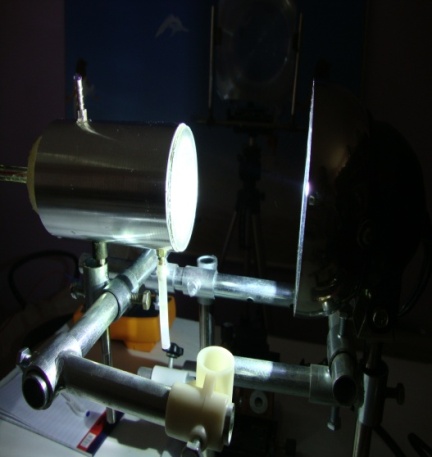

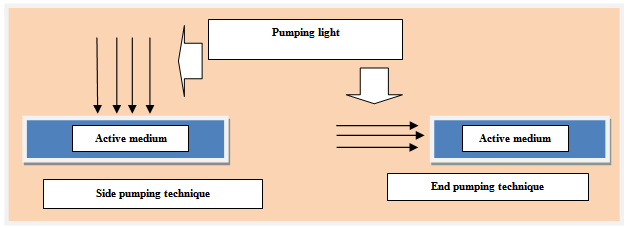

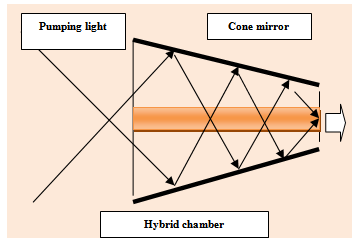

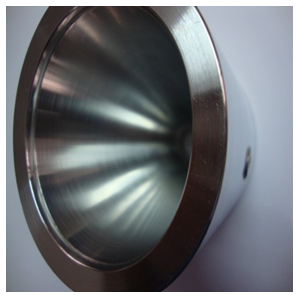

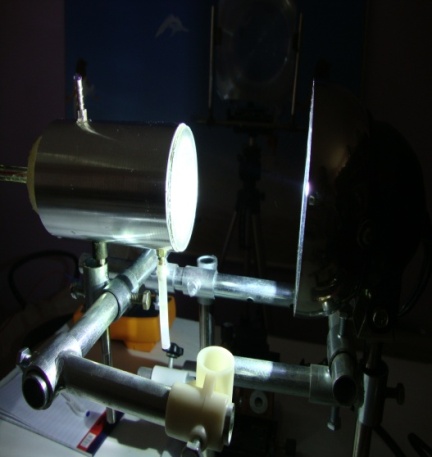

The idea of directly converting broadband solar radiation into a coherent and narrowband laser radiation is almost as old as the laser itself , solar laser's disease since 1966 and development continues to this day[1,2,3,4,5,6]. Solar laser is one of the novel branches in recent technology. This branch has been developed form the combination of two sciences, Solar energy and laser physics. The efficiency in the transfer of radiation from the source to the laser element determines, to a large extent, the overall efficiency of the laser system. The optical design, besides providing good coupling between the source and the absorbing active material, is also responsible for the pump power distribution in the laser element which influences the uniformity, divergence, and optical distortions of the output beam.In the development of solid-state lasers, many different optical designs have been employed to transfer the radiation from a light source to the active material. Depending on the shape of the active material and the type of pump source used, one can broadly divide pumping geometries into systems in which the active material is side-pumped, end-pumped, face-pumped, or edge-pumped[7,8,9,10,11,12].There are two major techniques for solar pumping solid state lasers: side pumping and end pumping are illustrated in figure (1); in the side pump technique only a small area of media is pumped. This small area could not absorb sufficient radiation to reach threshold of lasing process. In the end pump technique the main disadvantage is that the pumped light can be injected only from one direction.There is another technique which recently employed in pumping solar laser systems called hybrid pumping technique[13,14, , and 15]. New hybrid pumping methods using mirror type cavities which could provide pumping light from many directions along the laser media.Chamber could provide a high optical transformation of solar radiation through the laser media. In order to design more effective pumping chamber, it is necessary to find the power distribution of concentrated solar radiation at the focus of fresnel lens.Although the Fresnel lens is able to focus solar power into a focal point, a second concentrator is necessary to increase pumping power for laser media. We developed a pumping cavity that has a cone-type mirror inside it made of aluminum. We designed a new pumping cavity to further concentrate the focused solar power by the Fresnel lens. A photograph and the schematic diagram of the cavity are shown in figures (2) and (3), respectively. | Figure 1. pumping configurations |

| Figure 2. cross section of hybrid chamber |

| Figure 3. photograph of hybrid chamber |

2. Experimental Measurement of the Power Distribution

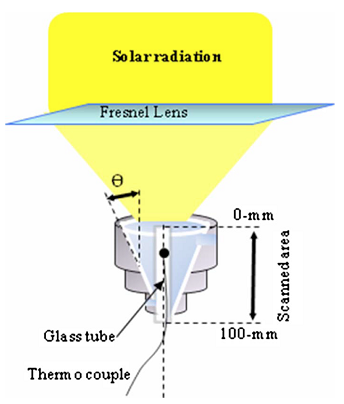

The performance of the pumping chamber could be evaluated by pumping power distribution along the axis of laser rod, which was measured by the method described below. Figures (4 and 5) show the experimental setup for the measurements. During measurements, laser rod was replaced by a fused silica glass tube. The power distribution in the fused silica glass tube was measured by scanning a thermocouple device inside the tube sunlight or sunlight simulator (xenon lamp), which could provide the similar spectrum as that of the sun. A series of experiments have been utilized to test all these parameters . These experiments will be very important in designing of a cavity for direct solar pumping. | Figure 4. Experimental setup of scanning power distribution on the laser rod axis by scanning thermocouple(4 ) |

| Figure 5. Experimental on natural sunlight |

3. Results and Discussion

3.1. Test of the End -Pump Distribution

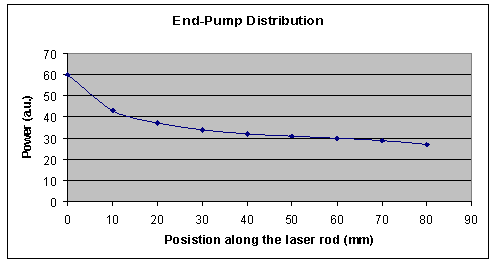

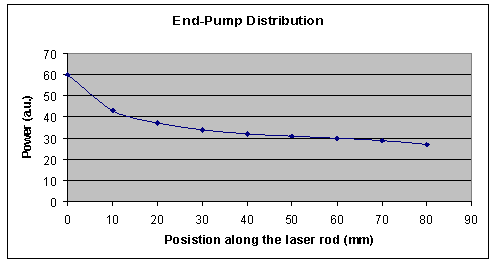

The system set-up of the power distribution along the laser rod is illustrated in figure (4), from which the relationship of the measured power versus position along laser rod is plotted in figure (6).The high peak power value at the front of the rod (zero position) corresponds to the light directly focused from the Fresnel lens or sun-light simulation (xenon lamp).The power decreases with position along laser rod length. This undesired power drop does not serve the pumping .Thus, it is concluded that active medium rod with end pump technique is not practical, but rather this technique is preferable with small-size crystals.

3.2. Side- pump Distribution

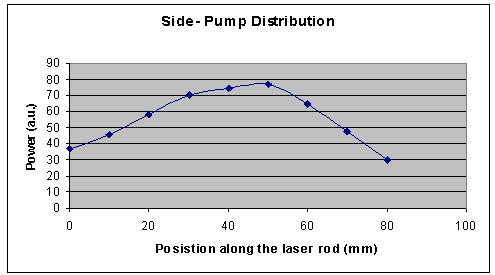

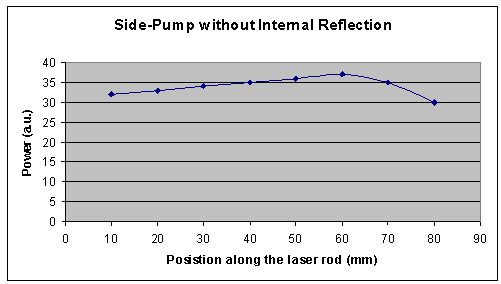

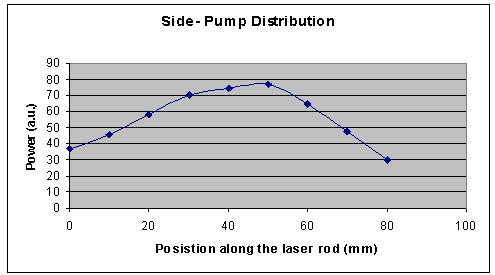

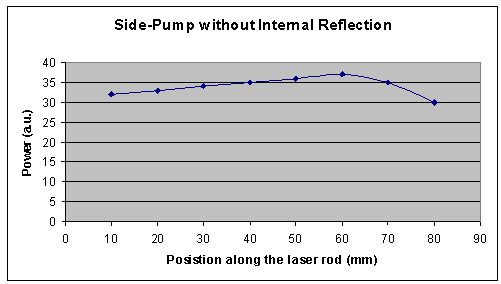

There are "two techniques" for side pumping:a- Indirect pumpingFrom the practical procedures in the previous steps of the experimental set-up illustrated in Figure (7), a relationship of power versus position along laser rod is drawn in Figure (8). The Power increases with the length along the laser rod reaching a maximum peak and then decreases. This peak is due to power refocused by the internal surface of the chamber. b- Direct pumping When the reflection from chamber inner surface are prevented and light is directly pumped to the center of laser rod, the power distribution relationship along the laser rod is plotted in figure ( 9).It was verified that direct pumping technique is so important due to power distribution more homogeneity.

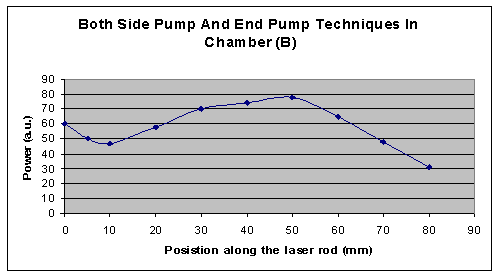

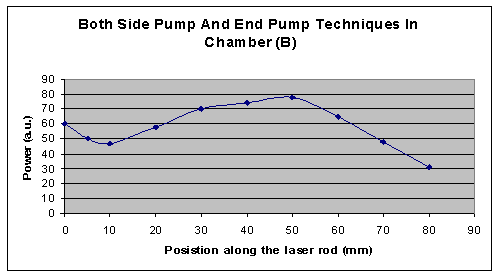

3.3. End Pump and Side Pump Distribution

When the tests were completed, we deduced the importance of both the end and side pump in providing high radiation transfer efficiency from the source to the laser rod. On this basis, a hybrid pump chamber has been tested and the experimental setup of sensor- scanned power distribution along the laser rod is illustrated in figure 4. Hybrid chamber (B) has an aperture diameter of 50mm and a length of 80mm. Figure(9) shows the power distribution along the laser rod.  | Figure 6. The relationship of the measured power versus position along laser rod in end pump case |

| Figure 7. Experimental arrangement of side pump |

| Figure 8. The relationship of the measured power versus position along laser rod in side pump case |

The distribution curve possesses two peaks at the input and at around 50-80 mm from the input aperture. The first peak corresponds to the light directly focused from the Fresnel lens while the second peak is due to power re-focusing by the chamber internal surface.

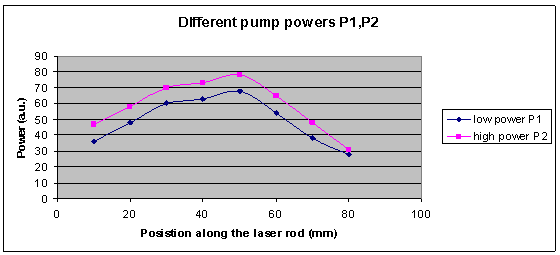

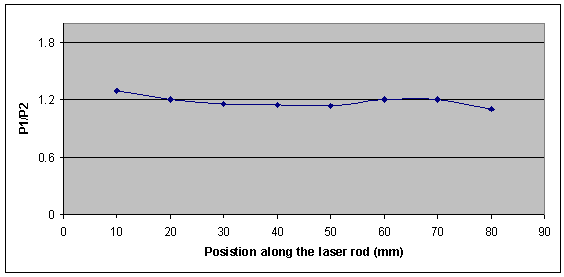

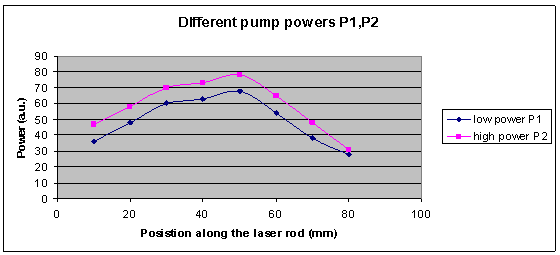

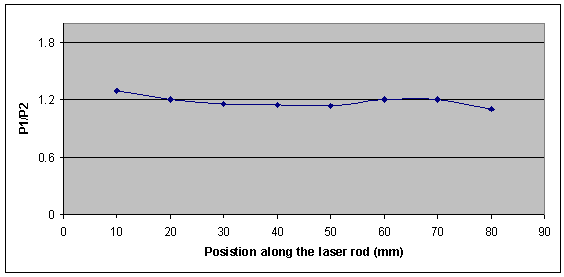

3.4. The Distribution of Hybrid Chamber in Different Powers

In this test, chamber (B) was used with two different pumping powers.P1 the low power and P2 the high power .The end-pump technique is excluded in this test and power distribution is represented in figure(9). From the above tests, the following conditions can be deduced:1- The profile of power distribution should be the same for different input power to the chamber, since the solar irradiation is variable during real solar lasing experiments.2- The local power at each point on the rod axis should depend on the input power on the entrance window of cavity, and the relationship between local power and input power should be the same for all points, in other words there should be a linear relationship between normalized local power and the input power at all points along the rod axis as shown in Figure (12). | Figure 9. The relationship of the measured power versus position along laser rod in side pump without internal reflection case |

| Figure 10. Both side pump and end pump techniques in chamber (B) |

| Figure 11. Different pump powers p1,p2 |

| Figure 12. Relationship between normalized local power and the input power at all points along the rod axis |

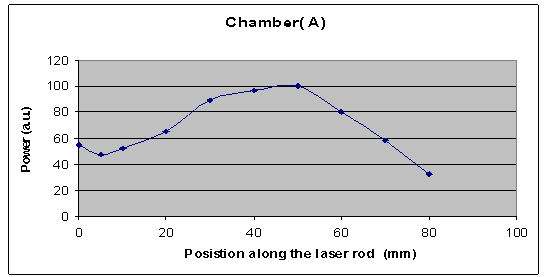

3.5. Dependence of Distribution on Hybrid Chamber Aperture

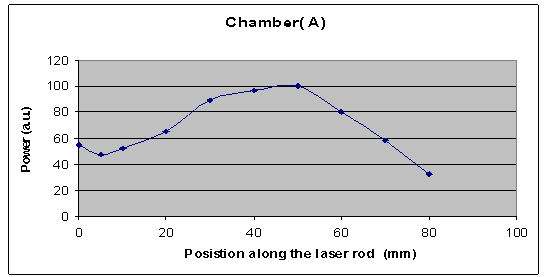

Using the same experimental set-up of figure 7, the power distribution is scanned along the laser rod axis using chamber (A) with both aperture diameter and length of 80mm. The result is plotted in figure (13). | Figure 13. Both side pump and end pump techniques in chamber (A) |

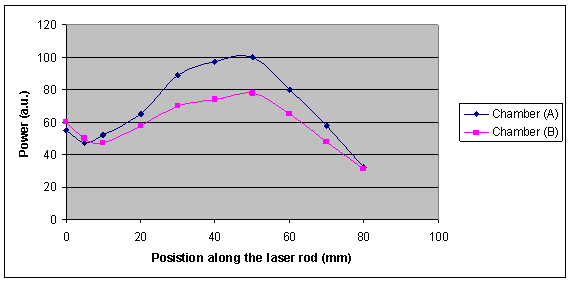

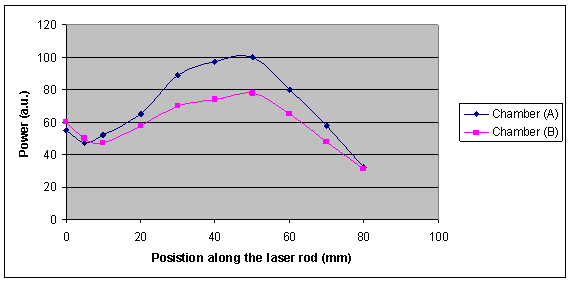

When the results of chamber A&B are compared, , some kind of similarity is obtained as illustrated in figure (14). | Figure 14. A comparison relationship of the measured power versus position along Laser rod using chambers (A&B) of different aperture diameters |

| Figure 15. A comparison relationship of the measured power versus position along laser rod using chambers( B&C) of different inner mirror lengths |

Both distributions have two peaks at the input and at around 20-70 mm from the input aperture. Furthermore, the peak width obtained with chamber (A) is wider than that of chamber (B). The energy distribution in the pumping chamber can be altered with the angle of inner wall mirror. Chamber (A) has superior performance in terms of total power, peak power as well as the width of the peak.

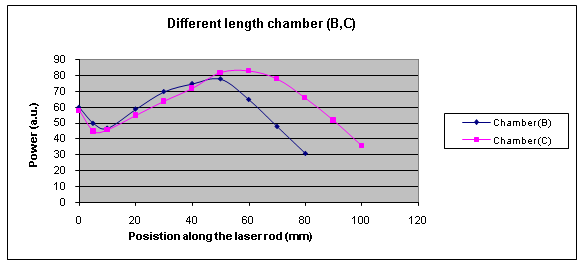

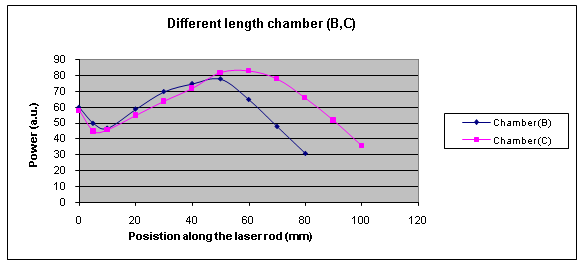

3.6. Effect of Hybrid Chamber Length

The performance of cavities B&C is compared by changing the angle and length of the inner mirror. These cavities have the same input window diameter of 50mm and the length of the cone-type mirror (L) is varied as 80mm and 100mm for cavities (B) and(C) respectively. Figure (15) shows the performance of the two cavities B&C.The position of the peak power is determined by length of a taper mirror. In addition, a longer taper wall has smaller angle, and the number of reflections for a small-angle mirror is larger than that for large-angle mirror. Therefore, a longer taper cavity should have better ability for confinement of light. Since it is important to confine light inside the cavity and get high power density. In summary, a chamber with large enough input aperture and small conical angle has good performance in lasing experiments. It is expected that chamber (D50, 20°), which has large enough input aperture, and at the same time a small enough conical angle, could generate the highest value of laser power in real experiment.

4. Conclusions

Although the Fresnel lens is able to focus solar power into a focal point, a second concentrator is necessary to increase pumping power for laser media We developed a pumping cavity that has a cone-type mirror inside it . We designed a new pumping cavity to further concentrate the focused solar power by the new Fresnel lens. The pumping method included a hybrid configuration that uses both advantages of end-pumping and side-pumping at the same time. The mirror-type inner wall of pumping chamber increases the number of passes through laser media, thus absorption rate along the rod increased. Consequently, the specially designed hybrid chamber shows an excellent. focusing property of focused sunlight to the laser media and low threshold pumping has been achieved with low cost. The performance of the pumping chamber was examined in terms of the power distribution on the laser rod axis by scanning the thermocouple.

References

| [1] | C. G. Young, Appl. Opt. 5,6, 993 ,1966. |

| [2] | C.B. Roxlo and Eli Yablonovitch: Optics Letters. 8,5,271,1983. |

| [3] | In Heon Hwang and Ja h .Lee :IEEE Journal of Quantum Electronics.27,9,2129,1991. |

| [4] | Haruo Arashi, Dave Cooke and Hitoshi Naito: Japanese. Journal of Applied Physics.34, 9A,4795, 1995. |

| [5] | A.A.Seregin and E.A. Seregin : Laser Physics.15,3,401,2005. |

| [6] | M. Endo: Optics Express.15,9,5482,2007. Publishing by OSA. |

| [7] | W. Koechner, Solid-State Laser Engineering _Springer, New York, 1985. |

| [8] | H. Arashi ,Y. Oka , N.Sasahara ,A. Kaimai and M.Ishigame: Japanese. Journal of Applied Physics.23, 8, 1051, 1984. |

| [9] | M. Weksler and J. Shwartz : IEEE Journal of Quantum Electronics.24,6,1222,1988. |

| [10] | M A Mosalam Shaltout ,M Medhat and Y A Hadi: Proc. Indian Acad. Sci.110,3 ,335,1998. |

| [11] | S.Bakhramov,Sh. Payziyev, and A. Kasimov: Journal of Renewable and Sustainable Energy.1,063103,1,2009. |

| [12] | Dawei Liang, Rui Pereira :Optics and Laser Technology. 41, 6,687, 2009. |

| [13] | T. Ohkubo, T. Yabe, K.Yoshida, S.Uchida, T. Funatsu, B. Bagheri, et al: Optics Letters.34, 2 ,175, 2009. |

| [14] | T.Yabe, B.Bagheri, T.Ohkubo, S. Uchida, K. Yoshida, T.Funatsu, et al: Journal of Applied Physics 104, 083104- 1 ,2008. |

| [15] | T.Yabe, T. Ohkubo, S.Uchida, K. Yoshida, B.Bagheri, T.Funatsu, A.Mabuti, et al Journal of Physics: Conference series 112,042072,1, 2008. Publishing by IOP. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML