| [1] | S.U.S. Choi, “Enhancing thermal conductivity of fluids with nanoparticles”, Proceedings of the 1995 ASME International Mechanical Engineering Congress and Exposition, San Francisco, CA, USA, 1995. |

| [2] | Xiang-Qi Wang; Arun S. Mujumdar “Heat transfer characteristics of nanofluids-areview”,International Journal of Thermal Sciences, 46, 1-19, 2007. |

| [3] | Xiang-Qi Wang; Arun S. Mujumdar “A review on nanofluids - part II:experiments and applications”, Braz. J.Chem. Eng.,25, 631-648, 2008. |

| [4] | H. Masuda, A. Ebata, K. Teramae, N. Hishinuma, “Alteration of thermal conductivity and viscosity of liquid by dispersing ultra-fine particles (Dispersion of G-Al2O3, SiO2 and TiO2 ultra-fine particles)”, Netsu Bussei (Japan) 4, 227–233, 1993. |

| [5] | J.A. Eastman, S.U.S. Choi, S. Li, L.J. Thompson, S. Lee, “Enhanced thermal conductivity through the development of nanofluids”, Fall meeting of the Materials Research Society (MRS), Boston, USA, 1996. |

| [6] | S. Lee, S.U.S.Choi, S. Li, J.A. Eastman, “Measuring thermal conductivity of fluids containing oxide nanoparticles” Journal of Heat Transfer, Transactions ASME 121, 280–289, 1999. |

| [7] | Y.M. Xuan, Q. Li, “Heat transfer enhancement of nanofluids”, International Journal of Heat and Fluid Flow 21, 58–64, 2000. |

| [8] | J.A. Eastman, S.U.S. Choi, S. Li, W.Yu, L.J. Thompson, “Anomalously increased effective thermal conductivities of ethylene glycol-based nanofluids containing copper nanoparticles”, Applied Physics Letters 78, 718–720, 2001. |

| [9] | Keblinski, S.R. Phillpot, S.U.S. Choi, J.A. Eastman, “Mechanisms of heat flow in suspensions of nano-sized particles (nanofluids)”, International Journal of Heat and Mass Transfer 45, 855–863, 2002. |

| [10] | H. Xie, J. Wang, T.G. Xi, Y. Liu, F. Ai, “Thermal conductivity enhancement of suspensions containing nano sized alumina particles”, Journal of Applied Physics 91, 4568–4572, 2002. |

| [11] | H. Xie, J. Wang, T.G. Xi, Y. Liu, F. Ai, “Thermal conductivity enhancement of suspensions containing nano sized alumina particles” Journal of Applied Physics 91, 4568–4572, 2002. |

| [12] | B.X. Wang, L.P. Zhou, X.F. Peng, “A fractal model for predicting the effective thermal conductivity of liquid with suspension of nano particles”, International Journal of Heat and Mass Transfer 46, 2665–2672, 2003. |

| [13] | D.S. Wen, Y.L. Ding, “Effective thermal conductivity of aqueous suspensions of carbon nano tubes (Nanofluids)”, Journal of Thermophysics and Heat Transfer 18 (4), 481–485, 2004. |

| [14] | P. Bhattacharya, S.K. Saha, A. Yadav, R.S. Prasher, “Phelan and Brownian dynamics simulation to determine the effective thermal conductivity of nanofluids”, Journal of Applied Physics 95, 6492–6494 , 2004. |

| [15] | S.P. Jang, S.U.S. Choi, “Role of Brownian motion in the enhanced thermal conductivity of nanofluids”, Applied Physics Letters 84 (21),4316–4318, 2004. |

| [16] | T.K. Hong, H.S. Yang, C.J. Choi, “Study of the enhanced thermal conductivity of Fe nanofluids”, Journal of Applied Physics 97, 06411-1-4, 2005. |

| [17] | D. Wen, Y. Ding, “Formulation of nanofluids for natural convective heat transfer applications”, International Journal of Heat and Fluid Flow 26 (6) (2005a) 855–864. |

| [18] | S.Lee, S.U.S. Choi, “ Application of metallic nanoparticle suspensions in advanced cooling systems”, International Mechanical Engineering Congress and Exhibition, Atlanta, USA, 1996. |

| [19] | B.C. Pak, Y.I. Cho, 1999. Hydrodynamic and heat transfer study of dispersed fluids with submicron metallic oxide particles. Experimental Heat Transfer 11, 151–170. |

| [20] | Y.M. Xuan, Q. Li, 2003. Investigation on convective heat transfer andflow features of nanofluids. ASME Journal of Heat Transfer 125, 151–155. |

| [21] | Y.M. Xuan, Q. Li, 2003. Investigation on convective heat transfer and flow features of nanofluids. ASME Journal of Heat Transfer 125, 151–155. |

| [22] | Putra, W. Roetzel, S.K. Das, “Natural convection of nanofluids”, Heat and Mass Transfer 39, 775–784, 2003. |

| [23] | K. Khanafer, K. Vafai, M. Lightstone, “Buoyancy-driven heat transfer enhancement in a two-dimensional enclosure utilizing nanofluids”, International Journal of Heat and Mass Transfer 46, 3639–3653, 2003. |

| [24] | D.S. Wen, Y.L. Ding, 2004. Experimental investigation into convective heat transfer of nanofluids at entrance area under laminar flow region, International Journal of Heat and Mass Transfer 47 (24), 5181–5188. |

| [25] | Roy, C.T. Nguyen, P.R. Lajoie, “Numerical investigation of laminar flow and heat transfer in a radial flow cooling system with the use of nanofluids”, Superlattices and Microstructures 35, 497–511, 2004. |

| [26] | S.E.B. Maiga, C.T. Nguyen, N. Galanis, G. Roy, “Heat transfer behaviours of nanofluids in a uniformly heated tube”, Super lattices and Microstructures 26 (4), 543–557, 2004. |

| [27] | Y. Yang, Z. Zhang, E. Grulke, W. Anderson, G. Wu, “Heat transfer properties of nano particle-in-fluid dispersions (nanofluids) in laminar flow”, International Journal of Heat Mass transfer 48, P1107–P1116, 2005. |

| [28] | A.G.A. Nanna, T. Fistrovich, K. Malinski and S.U.S. Choi, “Thermal transport phenomena in buoyancy-driven nanofluids”, in Proceedings of 2005 ASME International Mechanical Engineering Congress and RD&D Exposition, 15-17 November 2004, Anaheim, California, USA, (2005). |

| [29] | A.G.A. Nanna and M. Routhu, “Transport phenomena in buoyancy-driven nanofluids– Part II”, in Proceedings of 2005 ASME Summer Heat Transfer Conference, San Francisco, California, USA, 17-22 July 2005. |

| [30] | S.K. Das, N. Putra, W. Roetzel, “Pool boiling characteristics of nano-fluids” International Journal of Heat and Mass Transfer 46, 851–862, 2003a. |

| [31] | S.K. Das, N. Putra, W. Roetzel, “Pool boiling of nano-fluids on horizontal narrow tubes”, International Journal of Multiphase Flow 29, 1237–1247, 2003b. |

| [32] | S.M . You, J.H. Kim, K.H. Kim, “Effect of nanoparticles on critical heat flux of water in pool boiling heat transfer”, Applied Physics Letters 83, 3374–3376, 2003. |

| [33] | C.H. Li, B.X. Wang, X.F. Peng, “Experimental investigations on boiling of nano-particle suspensions”, Boiling Heat Transfer Conference, Jamica, USA, 2003. |

| [34] | S. Witharana, “Boiling of refrigerants on enhanced surfaces and boiling of nanofluids”, Ph.D. Thesis, The Royal Institute of Technology, Stockholm, Sweden, 2003. |

| [35] | P. Vassallo, R. Kumar, S. Damico, “Pool boiling heat transfer experiments in silica-water nano-fluids”, International Journal of Heat and Mass Transfer 47, 407–411, 2004. |

| [36] | J.P. Tu, N. Dinh, T. Theofanous, “An experimental study of nano fluid boiling heat transfer”, In Proceedings of 6th International Symposium on Heat Transfer, China, 2004. |

| [37] | D.S. Wen and Ding Y.L., “Experimental investigation into the pool boiling heat transfer of aqueous based alumina nanofluids”. Journal of Nanoparticle Research,7, 265–274,2005 |

| [38] | M.K Ramis, Jawaz Pasha, Shebeer A Rahim, “Heat Transfer Enhancement Using CuO Nanofluids -The Effect of Sonication Time on the Paradoxical Behaviour”, International Journal of Engineering Science and Technology, Vol. 4 .07 (2012), pp 3514-3520. |

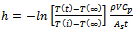

where Lc is the characteristic length and ks is the thermal conductivity of the test piece. It was found that the value of Bi was far below 0.1, which is the required condition to carry out the lumped parameter analysis.

where Lc is the characteristic length and ks is the thermal conductivity of the test piece. It was found that the value of Bi was far below 0.1, which is the required condition to carry out the lumped parameter analysis.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML