-

Paper Information

- Next Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Marine Science

p-ISSN: 2163-2421 e-ISSN: 2163-243X

2012; 2(6): 110-119

doi: 10.5923/j.ms.20120206.01

Applications of Textiles in Marine Products

Mrinal Singha 1, Kunal Singha 2

1Department of Pharmaceutical Chemistry, CU Shah College of Pharmacy & Research, Gujarat, India.

2Department of Textile Engineering, Panipat Institute of Engineering & Technology, Harayana, India

Correspondence to: Kunal Singha , Department of Textile Engineering, Panipat Institute of Engineering & Technology, Harayana, India.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

This paper reviews some valuable information about the Marine Textile in terms of Raw Materials, Construction, Products, Quality Standards, Standard Evaluation method, Manufacturing process, Manufactures, Market information and the Engineering principle of developing the products used for marine applications made of textile substrates and fibers.

Keywords: Marine Textile, Construction, Products, Engineering Principles, Marine Applications

Cite this paper: Mrinal Singha , Kunal Singha , "Applications of Textiles in Marine Products", Marine Science, Vol. 2 No. 6, 2012, pp. 110-119. doi: 10.5923/j.ms.20120206.01.

Article Outline

1. Introductions

- As in other areas of application, fibres are used in functional applications and more overtly in decorative applications in marine industry. Again safety, like flame retardancy is crucial and weight savings are also important requirements, especially in racing craft. As in other forms of transport, comfort, design and appearance are important in providing passengers with a relaxing atmosphere. To fulfill such multiple properties in a single sheet composites are formed. So composites occupy the maximum marine market. Developing new outstanding features in composites is a challenging task.

2. Materials

- Materials form an integral part of the way composite structures perform. Because the builder is creating a structural material from diverse constituent compounds, material science concepts are essential to the understanding of how structural composites behave. There are three broad groups of composite materials[1,2];• Reinforcements materials• Resins materials and• Core Materials

2.1. Reinforcement Materials: Fiberglass

- Glass fibers account for over 90% of the fibers used in reinforced plastics because they are inexpensive to produce and have relatively good strength to weight characteristics. Additionally, glass fibers exhibit good chemical resistance and processability. The excellent tensile strength of glass fibers, however, may deteriorate when loads are applied for long periods of time[3,5]. Continuous glass fibers are formed by extruding molten glass to filament diameters between 5-25 micrometers. Individual filaments are coated with a sizing to reduce abrasion and then combined into a strand of either 102 or 204 filaments. The sizing acts as a coupling agent during resin impregnation. E-glass (lime aluminum borosilicate) is the most common reinforcement used in marine laminates because of its good strength properties and resistance to water degradation. S-glass (silicon dioxide, aluminum and magnesium oxides) exhibits about one third better tensile strength, and in general, demonstrates better fatigue resistance. The cost for this variety of glass fiber (data on raw E-glass and S-glass fibers) is about three to four times that of E-glass as shown in the table 1.

2.3. Spectra

- Allied Corporation developed a high strength/modulus extended chain polyethylene fiber called Spectra® that was introduced in 1985. Room temperature specific mechanical properties of Spectra®®are slightly better than Kevlar although performance at elevated temperatures falls off. Chemical and wear resistance data is superior to the aramids. Data for both Kevlar® and Spectra® fibers is also contained in Table 1.

2.4. Polyester and Nylon

- Polyester and nylon thermoplastic fibers have recently been introduced to the marine industry as primary reinforcements and in a hybrid arrangement with fiberglass. Allied Corporation has developed a fiber called COMPET®, which is the product of applying a finish to PET fibers that enhances matrix adhesion properties[7,8].

2.5. Treveria

- Hoechst-Celanese manufactures a product called Treveria®, which is a heat treated polyester fiber fabric designed as a “bulking” material and as a gel coat barrier to reduce “print-through.” Although polyester fibers have fairly high strengths, their stiffness is considerably below that of glass[10]. Other attractive features include low density, reasonable cost, good impact and fatigue resistance, and potential for vibration damping and blister resistance.

2.6. Carbon Fibers

- The terms “carbon” and “graphite” fibers are typically used interchangeably, although graphite technically refers to fibers that are greater than 99% carbon composition versus 93 to 95% for PAN-base fibers. All continuous carbon fibers produced to date are made from organic precursors[11,13], which in addition to PAN (polyacrylonitrile), include rayon and pitches, with the latter two generally used for low modulus fibers. Carbon fibers offer the highest strength and stiffness of all commonly used reinforcement fibers. The fibers are not subject to stress rupture or stress corrosion, as with glass and aramids. High temperature performance is particularly outstanding. The major drawback to the PAN-base fibers is their relative cost, which is a function of high precursor costs and an energy intensive manufacturing process.

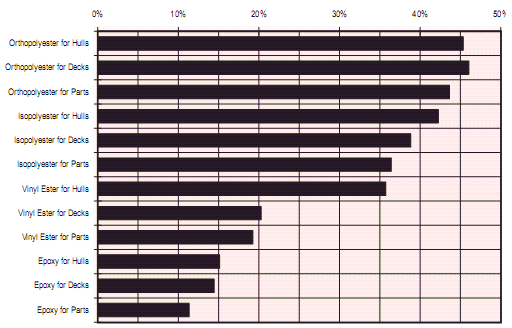

| Figure 1. Marine Industry Resin System Use[15] |

3. Polyester Resins

- Polyester resins are the simplest, most economical resin systems that are easiest to use and show good chemical resistance. Almost one half million tons of this material is used annually in the United States. Unsaturated polyesters consist of unsaturated material, such as maleic anhydride or fumaric acid that is dissolved in a reactive monomer, such as styrene. Polyester resins have long been considered the least toxic thermoset to personnel, although recent scrutiny of styrene emissions in the workplace has led to the development of alternate. Most polyesters are air inhibited and will not cure when exposed to air. Typically, paraffin is added to the resin formulation, which has the effect of sealing the surface during the cure process. However, the wax film on the surface presents a problem for secondary bonding or finishing and must be physically removed[12]. Non-air inhibited resins do not present this problem and are therefore, more widely accepted in the marine industry.The two basic polyester resins used in the marine industry are orthophthalic and isophthalic. The ortho resins were the original group of polyesters developed and are still in widespread use. They have somewhat limited thermal stability, chemical resistance, and processability characteristics. The iso resins generally have better mechanical properties and show better chemical resistance [15,16]. Their increased resistance to water permeation has prompted many builders to use this resin as a gel coat or barrier coat in marine laminates.

3.1. Vinyl Ester Resins

- Vinyl ester resins are unsaturated resins prepared by the reaction of a monofunctional unsaturated acid, such as methacrylic or acrylic, with a bisphenol diepoxide. The resulting polymer is mixed with an unsaturated monomer, such as styrene. The handling and performance characteristics of vinyl esters are similar to polyesters. Some advantages of the vinyl esters, which may justify their higher cost, include superior corrosion resistance, hydrolytic stability, and excellent physical properties, such as impact and fatigue resistance. It has been shown that a 20 to 60 mil layer with a vinyl ester resin matrix[17,18] can provide an excellent permeation barrier to resist blistering in marine laminates.

3.2. Epoxy Resins

- Epoxy resins are a broad family of materials that contain a reactive functional group in their molecular structure. Epoxy resins show the best performance characteristics of all the resins used in the marine industry. Aerospace applications use epoxy almost exclusively, except when high temperature performance is critical[19]. The high cost of epoxies and handling difficulties have limited their use for large marine structures.

3.3. Thermoplastics Resins

- Thermoplastics have one- or two-dimensional molecular structures, as opposed to three-dimensional structures for thermosets. The thermoplastics generally come in the form of molding compounds that soften at high temperatures[20]. Polyethylene, polystyrene, polypropylene, polyamides and nylon are examples of thermoplastics. Their use in the marine industry has generally been limited to small boats and recreational items. Reinforced thermoplastic materials have recently been investigated for the large scale production of structural components. Some attractive features include no exotherm upon cure, which has plagued filament winding of extremely thick sections with thermosets, and enhanced damage tolerance. The processability and strengths compatible with reinforcement material are key areas currently under development has been shown in the figure 1 as a comparative chart[15].

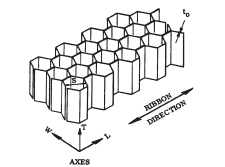

4. Core Materials: Balsa

- End grain balsa's closed-cell structure consists of elongated, prismatic cells with a length (grain direction) that is approximately sixteen times the diameter (Figure 2). In densities between 6 and 16 pounds ft3 (0.1 and 0.25 gms/cm3), the material exhibits excellent stiffness and bond strength. Stiffness and strength characteristics are much like aerospace honeycomb cores Although the static strength of balsa panels will generally be higher than the PVC foams, impact energy absorption is lower[18,21]. Local impact resistance is very good because stress is efficiently transmitted between sandwich skins. End-grain balsa is available in sheet form for flat panel construction or in a scrim-backed block arrangement that conforms to complex curves.

| Figure 2. Balsa Cell Geometry[18] |

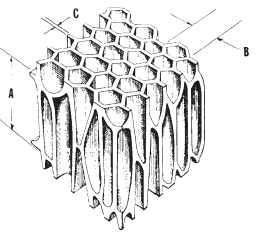

| Figure 3. Hexagonal Honeycomb geometry [18] |

4.1. Thermoset Foams

- Foamed plastics such as cellular cellulose acetate (CCA), polystyrene, and polyurethane are very light (about 2 lbs/ft) and resist water, fungi and decay. These materials have very low mechanical properties and polystyrene will be attacked by polyester resin. These foams will not conform to complex curves and their uses are generally limited to buoyancy rather than structural applications. Polyurethane is often foamed in-place when used as a buoyancy material[23].

4.2. Cross Linked PVC Foams

- Polyvinyl foam cores are manufactured by combining a polyvinyl copolymer with stabilizers, plasticizers, cross-linking compounds and blowing agents. The mixture is heated under pressure to initiate the cross-linking reaction and initiate the cross-linking reaction and then submerged in hot water tanks to expand to the desired density. Cell diameters range from .0100 to .100 inches (as compared to .0013 inches for balsa)[16, 22]. The resulting material is thermoplastic, enabling the material to conform to compound curves of a hull. PVC foams have almost exclusively replaced urethane foams as a structural core material, except in configurations where the foam is “blown” in place. A number of manufacturers market cross-linked PVC products to the marine industry in sheet form with densities ranging from 2 to 12 pounds per ft3.As with the balsa products, solid sheets or scrim backed block construction configurations are available.

4.3. Linear PVC Foam

- Airex® and Core-Cell® are examples of linear PVC foam core produced for the marine industry. Unique mechanical properties are a result of a non-connected molecular structure, which allows significant displacements before failure. In comparison to the cross linked (non-linear) PVCs, static properties will be less favorable and impact will be better. For Airex® individual cell diameters range from .020 to .080 inches.[17]

4.4. Honeycomb

- Various types of manufactured honeycomb cores are used extensively in the aerospace industry. Constituent materials include aluminum, phenolic resin impregnated fiberglass, polypropylene and aramid fiber phenolic treated paper. Densities range from 1 to 6 lbs/ft3and cell sizes vary (figure 3)[18]. Physical properties vary in a near linear fashion with density. Although the fabrication of extremely lightweight panels is possible with honeycomb cores, applications in a marine environment are limited due to the difficulty of bonding to complex face geometries and the potential for significant water absorption. The Navy has had some corrosion problems when an aluminum honeycomb core was used for ASROC housings.

4.5. PMI Foam

- Rohm Tech, Inc. markets a polymrthacrylimide (PMI) foam for composite construction called Rohacell®. The material requires minimum laminating pressures to develop good peel strength. The most attractive feature of this material is its ability to withstand curing temperatures in excess of 350℉, which makes it attractive for use with prepreg reinforcements[23].

4.6. FRP Planking

- Seemann Fiberglass, Inc. developed a product called C-Flex® in 1973 to help amateurs build a cost effective one-off hull. The planking consists of rigid fiberglass rods held together with unsaturated strands of continuous fiberglass rovings and a light fiberglass cloth. The self-supporting material will conform to compound curves. Typical application involves a set of male frames as a form[24, 25]. The planking has more rigidity than PVC foam sheets, which eliminates the need for extensive longitudinal stringers on the male mold. Ainch variety of C-Flex® weighs aboutpound dry and costs about $2.00 per square foot.

5. Core Fabrics

- Various natural and synthetic materials are used to manufacture products to build up laminate thickness economically. One such product that is popular in the marine industry is Firet Coremat, spun-bound polyester produced by Lantor[27].

5.1. Plywood

- Plywood should also be mentioned as a structural core material, although fiberglass is generally viewed as merely sheathing when used in conjunction with plywood. Exceptions to this characterization include local reinforcements in way of hardware installations where plywood replaces a lighter density core to improve compression properties of the laminate. Plywood is also sometimes used as a form for longitudinals, especially in way of engine mounts and the concern over the continued propensity for wood to absorb moisture in a maritime environment, which can cause swelling and subsequent delamination, has precipitated a decline in the use of wood in conjunction with FRP. Better process control in the manufacture of newer marine grade plywood should diminish this problem. The uneven surface of plywood can make it a poor bonding surface. Also, the low strength and low strain characteristics of plywood can lead to premature failures when used as a core with thin skins[17,18,19].

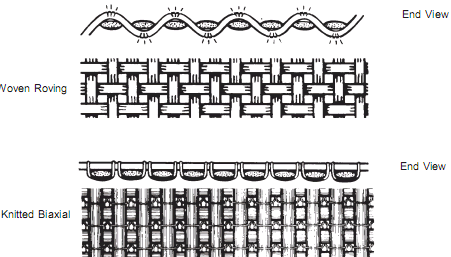

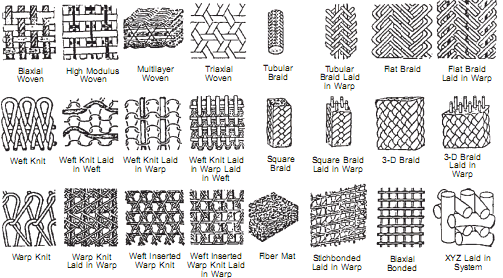

6. Reinforcement Fabric Construction

- Reinforcement materials are combined with resin systems in a variety of forms to create structural laminates. The percent of manufacturers using various reinforcement styles is represented in Figure 4. Table 2 provides definitions for the various forms of reinforcement materials[15, 26]. Some of the lower strength non-continuous configurations are limited to fiberglass due to processing and economic considerations.

|

| Figure 4. Different forms of reinforcement[15] |

| Figure 5. Commercially available weave patterns[15] |

| Figure 6. Different forms of reinforcements[15] |

6.1. Woven Reinforcement Structure

- Woven composite reinforcements generally fall into the category of cloth or woven roving. The cloths are lighter in weight, typically from 6 to 10 ounces per square yard and require about 40 to 50 plies to achieve a one inch thickness. Their use in marine construction is limited to small parts and repairs[28]. Particular weave patterns include plain weave, which is the most highly interlaced; basket weave, which has warp and fill yarns that are paired up; and satin weaves, which exhibit a minimum of interlacing. The satin weaves are produced in standard four-, five- or eight-harness configurations, which exhibit a corresponding increase in resistance to shear distortion (easily draped) and figure 5 shows some commercially available weave patterns[15].Woven roving reinforcements consist of flattened bundles of continuous strands in a plain weave pattern with slightly more material in the warp direction. This is the most common type of reinforcement used for large marine structures because it is available in fairly heavy weights (24 ounces per square yard is the most common), which enables a rapid build up of thickness. Also, directional strength characteristics are possible with a material that is still fairly drapable. Impact resistance is enhanced because the fibers are continuously woven.

6.2. Knitted Reinforcement Structure

- Knitted reinforcement fabrics were first introduced by Knytex® in 1975 to provide greater strength and stiffness per unit thickness as compared to woven rovings. A knitted reinforcement is constructed using a combination of unidirectional reinforcements that are stitched together with a nonstructural synthetic such as polyester. A layer of mat may also be incorporated into the construction. The process provides the advantage of having the reinforcing fiber lying flat versus the crimped orientation of woven roving fiber. Additionally, reinforcements can be oriented along any combination of axes. Superior glass to resin ratios is also achieved, which makes overall laminate costs competitive with traditional materials and the figure 6 shows a comparison of woven roving and knitted construction.

6.3. Omnidirectional Reinforcement Structure

- Omnidirectional reinforcements can be applied during hand lay-up as prefabricated mat or via the spray-up process as chopped strand mat. Chopped strand mat consists of randomly oriented glass fiber strands that are held together with a soluble resinous binder. Continuous strand mat is similar to chopped strand mat, except that the fiber is continuous and laid down in a swirl pattern. Both hand lay-up and spray-up methods produce plies with equal properties along the x and y axes and good interlaminar shear strength[11,29]. This is a very economical way to build up thickness, especially with complex molds. Mechanical properties are less than other reinforcements.

6.4. Unidirectional Reinforcement Structure

- Pure unidirectional construction implies no structural reinforcement in the fill direction. Ultra high strength/modulus material, such as carbon fiber, is sometimes used in this form due to its high cost and specificity of application. Material widths are generally limited due to the difficulty of handling and wet-out. Anchor Reinforcements has recently introduced a line of unidirectionals that are held together with a thermoplastic web binder that is compatible with thermoset resin systems. The company claims that the material is easier to handle and cut than traditional pure unidirectional material. Typical applications for unidirectionals include stem and centerline stiffening as well as the tops of stiffeners. Entire hulls are fabricated from unidirectional reinforcements when an ultra high performance laminate is desired[15].

7. Marine Applications and Quality Standards

- As in other areas of transportation, fibres are used in functional applications and more overtly in decorative applications. Again safety, like flame retardancy, is crucial and weight savings are also important requirements, especially in racing craft. Many safety requirements for furnishings and standards are set by the International Maritime Organisation such as the IMO Resolution A471 (XII) for fire resistance[24]. As in other forms of transport, comfort, design and appearance are important in providing passengers with a relaxing atmosphere.

7.1. Furnishing Fabrics

- Cruise ships can be regarded as ‘floating hotels’[25] and, therefore, textile properties requirements must be of ‘contract standard’[26]. Flame retardancy standards need to be high because of escape restrictions at sea and also because narrow corridors and low ceilings in many vessels make panic more likely in the event of a fire[27]. Fires in hotels and cruise ships are frequently caused by carelessness on the part of smokers. Furnishing fabrics must have durable high standards of flame retardancy and more use is therefore being made of inherently FR textiles. Standards required include DIN 4102 class B and BS476 paragraph 6[28].Carpets are especially important on passenger vessels because of their noise and vibration absorbing properties. They are more pleasant to walk upon than a hard surface and help to reduce physical stress and to provide a calmer and quieter atmosphere. Dyes used must be fast to light, rubbing and salt water. Durability is important because some areas of vessels are in use 24 hours a day and cleaning is done to rigorous schedules. Some ferries in Scandinavia have a million passengers a year; the heavy duty carpet is expected to last over 7 years[28]. Flame retardancy is important and wool carpets are generally Zirpro (IWS) treated. Durable antistatic properties are also generally required, imparted sometimes by the use of conductive fibres which are more durable than chemical finishes.

7.2. Sails

- Natural fibres in sails were first replaced by nylon and polyester, which are lighter, more rot resistant, have lower water absorption and, in the case of polyester, higher sunlight resistance. Sail development has progressed to some lighter laminated types where film is bonded to the fabric. Thus the fabric does not form the surface of the sail, only the reinforcing structure. For racing yachts, where weight is crucial, aramids which provide high strength with light weight, began to be used for the reinforcing structure. However, aramids degrade in sunlight, so that the ultra high modulus polyethylene yarns Spectra (Allied Signal) and Dyneema (DSM) and carbon fibres are now used. The new polyethylene yarn has also found application in heavy duty ropes[29]. The first sails were made from panels of hides or woven natural fibre fabric sewn together.When synthetic fabrics appeared they were used because of their advantages of greater strength and resistance to micro-organisms and mildew, minimal water absorption and less distortion[30].

7.3. Inflatable Crafts

- Inflatable craft have many advantages over rigid boats and have become widely used since around 1960.They are used as life boats and rescue craft, as freight carrying vessels and as pleasure craft, as well as having several military applications. When they are not being used or when they need to be transported to a different site, they can be deflated, folded and packed into a relatively small space. They are made from individual buoyancy tubes or several different compartments, so that, even if a particular section is damaged, the whole craft will still float and be capable of supporting weight. There are national standards and minimum performance specifications for the coated fabric and the craft itself. These standards do not actually specify which materials should be used.A number of different coatings are used, polychloroprene, Hypalon polyurethane and PVC. Nylon fabric about 145g/m2, woven from typically 470dtexin the lighter craft; heavier yarns, typically 940d/tex, are used for larger boats; and even heavier yarns of 1880dtex woven in a 2 ¥ 2 twill may be used in even larger boats. Good tear strength is important to prevent propagation of any damage. Polyester’s higher yarn modulus gives it some advantages over nylon, but generally there are more disadvantages. It is usually more difficult to bond rubber coatings to polyester, and polyester can be degraded by certain compounding ingredients.In addition,polyester is heavier than nylon. If cost allows, aramid fibres may be used, thus saving a significant amount of weight. An aramid fabric weighing 85g/m2 can be used in place of a nylon fabric weighing 170g/m2. Carbon dioxide is used to inflate life rafts, which are designed to be self inflating. Inflated pressure is about 15kPa. Baffles are used to disperse the gas as it emerges from the cylinder, but the chilling effect could embrittle the fabric coating if it is not formulated well out of a material with a low glass transition temperature such as natural rubber. One problem with the making up of inflatable craft is production of durable, air tight seams. This is a time consuming process, but it can be made simpler if a thermoplastic material, such as polyurethane or PVC, is used. PVC, however, has its limitations, but is used in more economical craft[30-32].

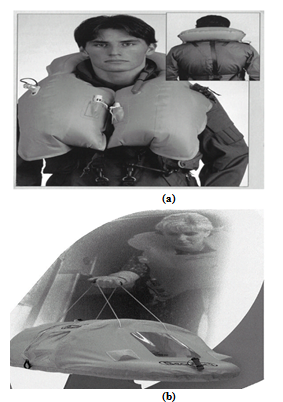

7.4. Marine Safety Apparatus

- Coated woven nylon is used for life rafts, buoyancy tubes, canopies and life jackets, and personal flotation devices (PFD) as shown by the figure 7. Polymer coatings include butyl rubber, natural rubber, polyurethane and polychloroprene, and total weights of the coated fabric are between 230g/m and 690g/m2 Products from coated and laminated fabrics. Quality tests include hydrostatic head to ensure waterproofness (carried out after ageing and after flexing), coating adhesion, breaking load and tearing strength. Life jackets are generally woven nylon coated with butyl or polychloroprene rubber to give total coated fabric weights of between 230 and 290g/m2. Tests for these items include assessment after immersion in water for 24 hours.

| Figure 7. (a). MK.30T Series Lightweight Lifepreserver by Beaufort Air-Sea Equipment Ltd is produced from high performance FR fabrics (b) Baby’s Floating Survival Cot MK4 by Beafort Air-Sea Equipment Ltd will accommodate babies of ages up to 18 months and provides a high level of protection against exposure and drowning. It features a separately inflated floor for thermal insulation and buoyancy, is produced from high visibility and FR materials and the structure has self righting properties[33] |

7.5. Oil Booms

- These articles are designed to contain accidental oil spillages in rivers and estuaries. They are usually produced from woven nylon base fabric of about 175g/m2 coated with Hypalon, polychoroprene, PVC or PVC/nitrile rubber blends. The booms do not normally have to withstand severe conditions and are inflated to a fairly low pressure, but they do have to be oil resistant. A two-compartment structure is generally used so that the boom is still serviceable if one compartment is damaged[33].

7.7. Hovercrafts Skirts

- Hovercrafts were invented in Britain in the mid-1950s and, from the mid 1960s until quite recently,October 2000, they provided a cross-channel ferry service, crossing in 25 minutes in good weather. However, their use is likely to continue in other parts of the world, and they are built to withstand Arctic conditions of - 60°C. The Life Boat Service in the UK are reported to be buying a fleet of about 12, because hovercraft can be deployed on terrain such as marshes where boats cannot go.The skirt material is a nylon fabric coated with a polychloroprene/ natural rubber blend or natural rubber/polybutadiene and compounded for oil resistance. PVC blended with nitrile rubber was evaluated but was not as satisfactory. The nylon cords, e.g. 940dtex/2 and 940dtex/3/3, from which the fabrics are woven are highly twisted to impart fatigue resistance in order to withstand the rapid and continual flexing in use.Fibre to rubber adhesion must be of the highest standard, and a suitable RFL priming coat must be compounded. Nylon is the best overall fibre for this application. Polyester yarns are less affected by water, but in actual use coated polyester fabrics did not last as long as nylon materials[30]. This is believed to be due to a poorer polyester/rubber bond compared with nylon/rubber. Cotton and rayon absorb too much water and are not generally strong enough for this application. Aramids, which are stronger than both nylon and polyester, have been tested, but they broke down quite rapidly because of low fatigue resistance. Leisure sailing in the UK dates from the late 1700s in Devon, but during the last half of the twentieth century became the sport of larger numbers of people and, with increasing disposable incomes, it is set to grow even further. Sails required for competitive racing are different from simple cruise sailing, and sail making is a highly skilled occupation.The sail has to be tailored to the vessel and to the purpose required; sail design is a crucial factor for optimum performance and efficiency.The main requirements for sail cloth are: light weight, dimensional stability (low creep and minimum distortion), puncture resistance, high tear strength, high seam strength, low porosity to wind (i.e. good cover), low water absorbency, good resistance to microbes and UV degradation and smoothness; all these factors contribute to a long service life. Sails which absorb water add weight to the upper parts of the vessel reducing efficiency, while a sail with a rough surface will cause frictional drag. Bias stretch is a limiting factor in sail cloths, and this can be reduce by calendering and by impregnating or coating with a resin. It was usual to ‘break-in’ new sails made from cotton and other natural fibres, i.e. to allow them slowly to stretch before actual use. This is less important for sails made from synthetic fibres and even less important for laminated sail as will be seen below. Sails should be easy to handle and easily stowed away. As with protective clothing, the seam is a point of weakness, and under high stress the sewing holes can become larger and thus influence sail porosity. Under prolonged high stress, fabrics can distort causing the sail to lose its shape. Polyester is better than nylon in this respect, but nylon is better than polyester for spinnaker sails which require a certain amount of stretch and elasticity to allow them to take their shape. Some manufacturers have developed techniques to glue rather than sew seams; they claim that these seams reduce seam distortion allowing sails to maintain their shape longer and that in addition, there are no stitching holes. Some modern racing sails are produced from polyester film laminated to rip-stop woven polyester or nylon fabric. Laminated sails generally have excellent shape holding properties with very little distortion or stretch, because the polyester film has a high modulus of elasticity in all directions. The film, being only thousandths of an inch (100 micrometers) thick, is significantly lighter in weight than a fabric and offers advantages in weight saving. The sail laminate must be bonded with an adhesive which can withstand sea water and UV degradation. Sail laminates can comprise two layers of film laminated to each side of the rip-stop fabric or the other way round, i.e. two layers of rip-stop fabric laminated to each side of a layer of film. More recent laminates are believed to consist of a single layer of film and fabric laminated together. Random-laid nonwoven fabrics have been used; Kevlar and even carbon fibres are also sometimes used for high strength with low weight – but at high cost. Kevlar, however, has poor UV stability, losing strength perhaps twice as fast as polyester. However, in racing, when performance at low weight is all important, the Kevlar, having up to nine times the modulus in grams per denier than high tenacity polyester, is the preferred material. Kevlar can actually lose up to 50% of its strength, but still be stronger than polyester. Total weights of laminates vary from 5 to 6oz (170g/m2 Products from coated and laminated fabrics[23, 25-27]. Ultra modern racing sails comprise film laminated to threads of yarn laid on the bias of the sail to produce an article of high dimensional stability and very light weight. Spectra, the ultra high tenacity polyethylene yarn from Allied Signal (now Huneywell), is even stronger than Kevlar and is used in some sails. It is also lighter in weight than Kevlar with a density of approximately 0.9g/cm3.An even more recent fibre called Vectran has been introduced by Celanese in the USA. This liquid crystal fibre has excellent UV resistance, a modulus similar to Kevlar 29, and virtually zero creep, enabling it to retain its shape and laminate well to films and fabrics. Spectra, Vectran and carbon fibre all have good UV degradation resistance compared with nylons, polyesters and aramids[38]. Laminated sails do not last as long as fabric sails, but they are invaluable when speed and performance are the critical factors. When sails are cleaned, any detergent or cleaning agent must be rinsed away because they may affect laminated bond strength or contribute to UV degradation of the materials. Hot melt adhesive films are generally used, and these factors must be taken into consideration when the adhesive is selected. Development work continues to improve lightness, dimensional stability and overall durability of sails.

8. Manufacturer of Marine Products

- There are around 46 companies in U.S which are manufacturing and supplying marine textile products. Brief information of some of these companies is given as below;

8.1. Tri Vantage - Cleveland, OH

- Company Profile: Distributor of a wide range of marine equipment & supplies including awnings for boats, ships as well as safety vests, lifeboat covers, fabric, hardware such as hooks, fasteners & finishing supplies & trimmings such as fittings, boat tops, covers, tarps, duck sails, seat cushions and interior[13].

8.2. Mauritzon, Inc. - Chicago, IL

- Company Profile: Distributor of marine fabrics, marine fabrics are made from vinyl coated polyester, 100 percent solution dyed acrylic fiber, woven acrylic, PVC featuring water resistance & fire retardance, marine fabrics are available in various colors & sizes[14].

8.3. Bondcote Corp. - Dublin, VA

- Company Profile: An ISO 9001 certified manufacturer of coated & laminated fabrics and mesh for the marine, recreation, military & transportation markets. They also offers MAR1NEONE for the travel, mooring & winter cover markets[10].

8.4. Phifer Inc. - Tuscaloosa, AL

- Company Profile: ISO 9001:2000 certified custom manufacturer of industrial woven fabrics used in signage, healthcare, medical & marine applications. Types include slingable fabrics, cushion fabrics, recyclable fabrics, sustainable fabrics, interior sun control fabrics & exterior sun control fabrics (Brand Names: Phifer)[15].

8.5. Levitt Industrial Textile Co. - Hicksville, NY

- Company Profile: Distributor of display loop fabrics including automotive, industrial & marine display loop fabrics. Display loop fabrics are available in widths of 60 in. & constructed of nylon fabric, soft polyester foam core & nylon tricot backing laminated together. Display loop fabrics are available in some brand names in the market like VELCRO, VELCOIN, VELTEX, Ultramate, ONE-WRAP, VELSTRAP, TEXACRO etc[17, 19].

9. Conclusions

- The broadest uses of a textile composite material involves filamentary reinforcements supported in a matrix that starts as a liquid and ends up a solid via a chemical reaction. The reinforcement is designed to resist the primary loads that act on the laminate and the resin serves to transmit loads between the plies, primarily via shear. In compression loading scenarios, the resin can serve to “stabilize” the fibers for in-plane loads and transmit loads via direct compression for out-of-plane loads. Mechanical properties for dry reinforcements and resin systems differ greatly. Critical to laminate performance is the bond between fibers and resin, as this is the primary shear stress transfer mechanism. Mechanical and chemical bonds transmit these loads. Resin formulation, reinforcement sizing, processing techniques and laminate void content influence the strength of this bond. Thus in that current context the textile fibers can be used as a potential options for the reinforcements in the marine applications in the near future.

References

| [1] | Composite Tandem Wing Boosts Hydroplane Stability, Advanced Composites, Advanstar Communications, Sep/Oct 1992, pp. 15-16. |

| [2] | Market Development, CI on Composites, SPI Composites Institute, New York, NY, Aug/Sep 1994, pp. 10-11. |

| [3] | Guide for Building and Classing Offshore Racing Yachts, American Bureau of Shipping, 1986, Paramus, New Jersey. |

| [4] | Engineers' Guide to Composite Materials, Metals Park, OH; American Society for Metals, 1987 ed II. |

| [5] | Evans, J. Harvey, Ship Structural Design Concepts, Cambridge, MD; Cornell Maritime Press, 1975. |

| [6] | Noonan, Edward F., Ship Vibration Guide, Washington, DC; Ship Structure Committee, 1989. 3-5 Schlick, O., “Further Investigations of Vibration of Steamers,” R.I.N.A., 1894. |

| [7] | Guide for Building and Classing High-Speed and Displacement Motor Yachts ,bythe American Bureau of Shipping, Paramus, NJ, 1990 |

| [8] | NAVSEA High Performance MarineCraft Design Manual Hull Structures, NAVSEACOMBATSYSENGSTA Report 60-204, July 1988. Distribution limited. |

| [9] | DnV Rules for Classification of High Speed Light Craft, Det Norske Veritas, Hovik, Norway, 1985. |

| [10] | Schwartz, Mel M., Composite Materials Handbook, McGraw Hill, New York, 1984. |

| [11] | “Composite Hull Increases Submarine's Range of Action.” Composites, Vol. 14, No. 3 (July 1983) p. 314, in Engineered Materials Handhook , Vol. 1, Composites, ASM International, 1987. |

| [12] | Engineers' Guide to Composite Materials , Metals Park, OH; American Society for Metals, 1987 ed I. |

| [13] | Smith, C.S., Design of Marine Structures in Composite Materials, Elsevier Science Publishers LTD, 1990. |

| [14] | Feichtinger, K.A.“Methods of Evaluation and Performance of Structural Core Materials Used in Sandwich Construction,” Proc. of the 42nd Annual Conference SPI Reinforced Plastics/Composites Institute. 2-6 Feb., 1987. |

| [15] | Johannsen, Thomas J., One-Off Airex Fiberglass Sandwich Construction , Buffalo, NY: Chemacryl, Inc., 1973. |

| [16] | Hexcel, “HRH-78 Nomex® Commercial Grade Honeycomb Data Sheet 4400.” Dublin, CA., 1989. |

| [17] | Timoshenko, S., Strength of Materials, Part I, Elementary Theory and Problems , Robert E. Krieger Publishing, Huntington, NY 1976. |

| [18] | ASTM E 1317-90, Standard Test Method for Flammability of Marine Surface Finishes, May 1990, ASTM, 100 Barr Harbor Dr., W. Conshohocken, PA 19428-2959. |

| [19] | “How to Build a Mold,” Marine Resin News . Reichhold Chemicals, Inc. Research Triangle Park, NC, 1990. |

| [20] | Marine Composites; second edition;Erik Green Associates; 1999; pp 279-288. |

| [21] | International Maritime Organisation, ‘Fire Test Procedures’, 2nd edition IMO 844E, London 1993. |

| [22] | U. Girrbach (Hoechst),‘Decorating ship interiors with flame retardant fabrics’, Textile Month, 1995;April 25. |

| [23] | Mo’shea, ‘Interior Furnishings’, Textile Prog., 1981 11(1) 1–68. |

| [24] | J. Troitzsch,‘International Plastics Flammability Handbook, 2nd edition, Hanser Publications, NewYork, 1990, 322–323. |

| [25] | P. Lewis, ‘Polyester “safety fibres” for a fast-growing market’, Textile Month, 1997 April 39–40. |

| [26] | G. belgrano and Co’connell, ‘Carbon sails to the front’, Tech. Textiles Int., 1992 May 28–31. |

| [27] | Gardiner ER, ‘Marine applications’, in Textile Reinforcement of Elastomers (Editors Wake WC and Wootton DB), Applied Science Publishers, London 1982, 197–223. |

| [28] | Thomas EJ, ‘Coated material for specialised end uses’, Progress in Textiles Coating and Laminating, BTTG Conference, Chester 2-3 July 1990, BTTG, Manchester. |

| [29] | Sowden E (Avon), ‘Fabric design factors in the production of inflatable craft’, JCF, Vol 13 April 1984, 250–57. |

| [30] | Howard-Williams J, Sails, Sixth Edition, Adlard Coles, London 1988, 39–69. |

| [31] | Anon, ‘Weaving into the wind’, World Sports Activewear, Dec 1995/Jan 1996, 16–19. |

| [32] | Anon, ‘Carbon sails to the front’, TTi, May 1992, 28–31. |

| [33] | Modeling of Marine Rope Fatigue Behavior; J.F. Mandell ; Textile Research Journal; 1987; 57; 318 |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-Text HTML

Full-Text HTML