Camila Coimbra1, Marco Antonio Gaya de Figueiredo1, Harrison Lourenço Corrêa2, 3

1Universidade do Estado do Rio de Janeiro – Instituto de Química, Departamento de Operações e Projetos Industriais, Brazil

2Universidade Federal Rural do Rio de Janeiro – Instituto de Tecnologia, Departamento de Engenharia Química, Brazil

3Universidade Federal do Paraná – Setor de Tecnologia, Departamento de Engenharia Mecânica, Brazil

Correspondence to: Marco Antonio Gaya de Figueiredo, Universidade do Estado do Rio de Janeiro – Instituto de Química, Departamento de Operações e Projetos Industriais, Brazil.

| Email: |  |

Copyright © 2017 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Abstract

To develop researches related to demands of an emerging country like Brazil requires application of technology and expressive resources (human and financial). In the oil and gas exploration, where Brazil has large expertise, many innovations begin in a lab environment. Reproduction of industrial processes in bench and pilot scales involving chemical reactions, wastewater treatment, catalysis, organic synthesis etc. is one of the activities realized by the researchers of the segment. To ensure that such activities are carried out with minimal risk to researchers and employees is a challenge for fomenting institutions, including higher education. The aim of this study was to gather information on vulnerability risks in a laboratory certified by Petrobras (located at the Universidade do Estado do Rio de Janeiro), taking it as a starting point for future implementations in Brazilian academic research environments. The methodology for risk identification was based on document Emergency Management Guide for Business and Industry. Its use allowed obtaining an overall vulnerability index (IGV) to reflect the risk of laboratory activities, allied to practices already adopted by Management Systems of the Laboratory of Engineering and Technology of Petroleum and Petrochemical (LETPP).

Keywords:

Laboratory, Oil, Vulnerability index, High Education Institution

Cite this paper: Camila Coimbra, Marco Antonio Gaya de Figueiredo, Harrison Lourenço Corrêa, Identification of Vulnerability in Petrochemical Research Laboratory - A Case Study, Management, Vol. 7 No. 6, 2017, pp. 185-193. doi: 10.5923/j.mm.20170706.01.

1. Introduction

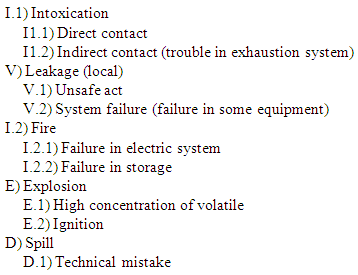

Technical progress is essential for emerging countries, like Brazil. Thus, the universities have great responsibility over economic growth due to their activities related to innovations and development of new technologies, through teaching, research and extension programs. For this, the Higher Education Institutions (HEIs) develop several activities in their labs, including the use of chemicals with potential risks to both human health and to the environment.Regardless of the type of activity performed in a chemical laboratory, there are various risks involved in these working environments where we can include chemical hazards: fumes, dusts, gases, compounds or chemicals in general. Non-ionizing and ionizing radiation, vibration, heat, cold, abnormal pressures are some examples of physical risks. And in some cases, there is the biological hazards such as viruses, bacteria, fungi, parasites, among others. About the risks mentioned the accidents occur mainly in laboratories for the following reasons: lack of organization of the workplace, misuse of equipment or substances; inadequate storage, handling and transportation of chemicals, use of defective glassware; negligence or lack of correct techniques, work performed by a person not qualified in certain techniques, failure to follow safety rules, misuse or nonuse of personal protective equipment (PPE) and collective protection equipment (CPE) appropriate to the risks; lack or inadequate maintenance of the laboratory. The accidents that have these causes are usually involved with poisoning, spills, thermal burns, physical injuries, chemical burns, electric shock, fire, explosion, contamination by chemical and biological agents, and exposure to ionizing and non-ionizing radiation.These risks can be minimized or even eliminated by the use of correct PPE and CPE. In addition, the risks are considerably reduced with adoption of safety training for laboratory technician. So, the Murphy’s Law will have less probability to occur [1]. Information about the proper use of equipment or training in prevention and the principles of fire fighting, abandonment areas, first aid training on the hazards of storing, handling, spillage and disposal of chemicals, training and knowledge of the prior use of the Information Sheet Safety of Chemicals are essentials. The Material Safety Data Sheet (MSDS), for example, is the principle method for communicating hazard information. The chemical information shown in MSDS is transferred throughout the all chain of chemical products [2]. Besides, a chemical lab must follow some waste management requirements. This also warrants the safety [3].Thus, it is important to have a system of quality management, health, safety and environment for the reduction and control of risks in the public sector organizations like universities [4].

1.1. Quality, Occupational Health & Safety and Environmental (QHSET) Policy

QHSE is a real concern faced by enterprises, especially those with high risks of accidents and incidents, usually associated to lack of training and monitoring procedures performed. This concern came with the economic motivation and measures of prevention and control for eliminating and/or reducing the negative impacts on businesses.Over time, it was possible noted that when the production is interrupted due to accidents, large damages are generated for both employees and companies. Thus, the concern for safety, health and environment has become part of the corporate policy. The QHSE policy varies according to the functions performed by each company according to their business profile.An integrated system Quality, Health, Safety and Environment, once employed correctly, ensures the effectiveness of the organization, while reducing the risks associated to the activity and reducing their environmental impacts.

2. Theoretical Reference

Identifying vulnerabilities and consequent proposition of an emergency plan to reduce them are undeniably important to the risks reduction. For this, the understanding and application of concepts related to safety and health at work are essentials.

2.1. Hazard Definition

According to the standards BSI OHSAS 18001 and BS 8800, hazard is any situation or a source with the potential to cause personal injury, health problems, damage to property, the working environment. To have a hazard condition, there may be a combination of these factors.

2.2. Risk Definition

Risk can be defined as the extent of damage or potential damage expressed in terms of statistical probability of occurrence and intensity or magnitude of the previsible effects, or as the relationship between the probability that a menace of adverse event or accident occurs with the degree of vulnerability related to receptor system involved [5]. Even by the standards BSI OHSAS 18001 and BS 8800, the risk is defined as a combination of probability of consequences of a hazardous event occurs.In this study, the concept of risk is aligned to the probability of occur accidents involving chemicals handled by the Laboratory of Engineering and Technology of Petroleum and Petrochemicals (LETPP), located at Universidade do Estado do Rio de Janeiro (UERJ) and its consequences for the worker / collaborator and the environment.

2.3. Vulnerability Definition

Conceptually, the vulnerability is intrinsic to the body or receptor system in interaction with the magnitude of an adverse event or accident, featuring the adverse effects, measured in terms of intensity of the likely damage condition.It may also be understood as the relationship between the magnitude of the menace and, if it goes ahead, the intensity of the consequent damage. The probability of a particular community or geographic area to be affected by a potential menace or risk of disaster or accident shall be established based on technical studies. When we consider the small chemical facilities like laboratories from universities, the vulnerability also exists. This occurs because many labs store quantities of chemical products. These are usually capable of causing fires, explosion and toxic releases [6].

2.4. Management Systems

A management system is conceptualized as a set of personnel, resources and procedures within any level of complexity, whose integrated components interact in an organized manner to accomplish a specific task and achieving (or maintaining) a given result [7].The goals of a management system must allow increasing of services more and more, through continuous improvement in operating results.For these goals be achieved, the adoption of a method of analysis and troubleshooting is required. Usually this method is based on the PDCA cycle (Plan, Do, Check and Act), applied for several management systems. The PDCA is shown in Figure 1.Legend:(P – Plan) – establish goals and processes;(D – Do) – implementing the processes;(C – Check) – monitoring and measuring of processes and products;(A – Act) – acting to improve continuously the performance of the processes. | Figure 1. PDCA cycle [8] |

For this figure, it is clear the importance of this tool in establishing related functions in each section by means of logical blocks of management, aiming the continual improvement.

2.5. FEMA and Management Emergencies in High Institutions of Education in USA

The Federal Emergency Management Agency (FEMA) is a coordinating body for the United States government in preparedness, prevention and mitigation, response and recovery of all territorial disasters, whether natural or technological, including acts of terrorism.FEMA began development of an Integrated Emergency Management [9], with wide approach to various risks, including management, control and warning systems that are common to the entire range of emergencies from small isolated events to emergency level maximum considered for that country: war.The national agency coordinates risk reduction program and crisis management programs. In addition, it extends its doctrine to all segments of professional activities, including universities and research centers through the project called Emergency Manager Training.The Emergency Management Higher Education Project (Emergency Management in Higher Education) was implemented along with a Training Emergency Management. The primary goal of the program is to work with universities, professional in emergency management, and interested organizations to help in the creation of a system of emergency management in a sustainable way (for the sustainability of educational development). This program aims too training for disaster reduction through formal education, experiential learning and practical experience with focus on prevention, preparedness, response and recovery of the entire range of natural and technological hazards that menace communities, states and nation. As any emergency management system, the management related to HEI includes not only the response to emergencies. But other components: planning, mitigation and obtaining grants [10]. The need for safety in academia labs is recognized by most researchers of higher education. But the requirements and techniques for securing chemicals materials are still evolving [11].FEMA has produced a method for developing emergency management actions. It contains four steps, which will be described in the next section.

2.5.1. Four Steps in the Planning Process

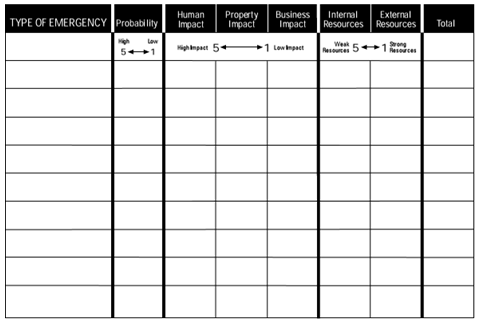

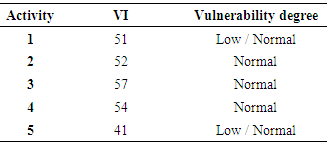

In each of the "steps" used in the preparation of emergency plans process, FEMA defines an action and gives other specific actions. It is recommended that these actions be completely explored and that all the details related to emergencies be included.The Four Steps contains a complete description of these specific actions giving to the manager of the emergency plan the main data to obtain a full view of all the elements to manage. The four steps established by the method are:Step 1: Establish a planning teamStep 2: Analyse capabilities and hazardsStep 3: Develop the planStep 4: Implement the planThe most important "step" and more complex for implementation is Step 2: Analyse capabilities and hazards. Its specific actions require that all the information about the "framework" of standards and laws related to emergencies are collected. It is important that emergencies are analyzed from the perspective of emergency policy. They must be based on mechanisms against risks, accidents and disasters, for the prediction of emergency scenarios.Identification of some elements related to emergency scenarios is very important, because financial and office decisions depend on them.When we consider a HEI whose activities are related to chemistry at level of research or educational, an elaboration of emergency scenarios require methods of risk analysis. It is necessary, for example, to evaluate if in the chemical lab there is obvious security weakness. Indeed, the manager must make a review of the infrastructure of lab. This includes all utilities (gases, compressed air), entrances and exits, water supplies, process control, backup power systems, hazardous material storage tanks, fire alarm and sprinkler systems [6]. The guide FEMA presents a simple method based on a matrix of vulnerability analysis where probabilities of occurrence of emergencies are estimated, as well the potential impacts and an assessment of the available resources, according to Table 1.Table 1. Matrix of vulnerability (FEMA, 2009)

|

| |

|

Based on this matrix is possible to classify the emergencies in order of severity. Actions to be made in the plan:• To list potential emergencies• To estimate probability• To assess the potential human impact, the potential property impact, the potential business impact and the internal and external resources.The guide FEMA adopted the following concepts for the columns of probability: Human Impact; Property Impact; Business Impact; Internal Resources; External Resources. The values are from 1 to 5. Lower values are related to low probability and impact. While high value corresponds to high probability and impact. For the items "resources", high values are related to its high quality.As the scoring criteria, the method considers:a) Probability: The probability of occurs each emergency is evaluated subjectively. This item becomes more important when historical records or series of accidents are analyzed;b) Human impact, property impact, external and internal resources: Here, some items are analyzed: possibility of death or injury, property damage (replacement cost, cost of a temporary replacement), environmental pollution, disruption of academic activities and services (lack of workers, failure to meet schedules, loss of scholarships and covenants, deficits in knowledge production);c) Internal and external resources: For this item, the guide suggests that the team gives a value to its internal and external resources. For better resources, lower score is given for the item. Proper emergency response depends on the quantity and quality of resources.At the end, add up the values of the columns for each emergency. The smaller the score, the lower the vulnerability.

2.6. Normative and Legal Aspects

2.6.1. Certificate of Conformity - ISO

The International Organization for Standardization is an organization that brings together the concepts of standardization of numerous countries. It was created to facilitate the international coordination and unification of technical standards. In Brazil, the organization responsible for the ISO is the Brazilian Association of Technical Standards (ABNT). Currently is also responsible for the standardization of management standards, impacting not only in the manufacturing sector, but also in services, contributing to society as a whole, especially in terms of safety and compliance with legal requirements. ISO 17025 is an international standard that indicates that the testing laboratories and calibration operate in a quality system, are technically competent and generate technically valid results.The standard covers every aspect of laboratory management, from sample preparation to the quality of the analytical testing, recordkeeping and reporting. Includes inspection document control, corrective and preventive action, accommodation and environmental conditions, equipment, measurement uncertainty, evidence of traceability and sampling.

2.6.2. Brazilian Regulatory Standards

Normative NR-5 – this normative creates the Internal Commission for Accident Prevention (CIPA) which aims to prevent accidents and illnesses resulting from work in order to make it compatible permanently working with the preservation of life and health promotion worker.Normative NR-6 (Personal Protective Equipment) - according to NR 6, Personal Protective Equipment (PPE) is every device or product, used for individual use by the employee, for the protection of risks against the safety and health at work. The employer must provide users appropriate PPE in perfect condition and operation; to require their use; and to train workers on the proper use, storage and maintenance; and to replace immediately if damaged or lost.By this normative the employee: must use the proper PPE, using it only for the purpose for which it was intended; must be responsible for its safekeeping and conservation and; must notify the employer of any change that makes it useless.Normative NR-15 (Activities, operations and unhealthy agents) - this document describes the activities, operations and unhealthy agents, including their tolerance limits.Normative NR-16 (Activities or dangerous operations) - according to the regulations approved by the Brazilian Ministry of Labor, activities are dangerous when their nature or working methods involve prolonged contact with flammable or explosive under conditions of high risk. Activities which involve the chemical or autocatalytic degradation; the action of external agents such as heat, humidity, sparks, fire, seismic phenomena, shock and friction.Normative NR-17 (Ergonomy)- this document establishes parameters that allow the adaptation of working conditions to the psychophysiological characteristics of workers in order to provide maximum comfort, safety and efficient performance. Working conditions include aspects related to physical efforts, like transportation and disposal of materials, optimal working positions in office and the own organization of work.Normative NR-25 (Industrial wastes) - In his first item deals with gaseous wastes and their disposal on the environment. The second deals with the liquid and solid wastes (generation, treatment and disposal), in order to avoid risks to health and safety of workers.Normative NR-26 (Signs and safety) - NR 26 aims to standardizing the colors that should be used in the workplace to prevent accidents, identifying safety equipment, delimiting areas, identifying the piping used for transfer of liquid and gas and warning against risks. Colors for safety should be adopted in workplaces in order to indicate and warn about the risks involved. The use of color does not exempt the use of other ways of prevention of accidents.Normative NR-33 (Safety and Health at Work in confined spaces) - this document establishes the minimum requirements for identification of confined spaces and the recognition, evaluation, monitoring and control of risks, in order to permanently ensure the safety and health of workers who interact directly or indirectly in these locals.

3. Justification

Undergraduate and post graduate courses in Chemical Engineering or Chemistry have several activities in labs that increase the risks of accidents related to the academic researches. In the absence of an institutional system able to implement and manage the risks related to the environment in the HEI, this paper aims to address the importance of security in Brazilian HEIs. For this, taking as an example the LETPP, the authors will show the importance to adopt safety, health and environment standards in academic labs.

4. Goals

The aim of this study is to propose a global vulnerability index according to the Regulatory Standards and applicable Environmental Laws. This index can be used as support for the Quality Management System of laboratory in different HEIs that develops knowledge in Chemistry and Chemical Engineering.

4.1. Specific Goals

• Raise the respect and trust of all users of the institute of chemistry for matters of Health, Safety and Environment, seeking continuous improvement.• Analyze the vulnerability of the Chemistry Lab coordinated by researcher Professor Marco Antonio Gaya de Figueiredo.• Use the vulnerability index proposed to quantify the vulnerability of the laboratory analysis.

5. Methodology

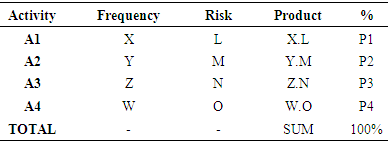

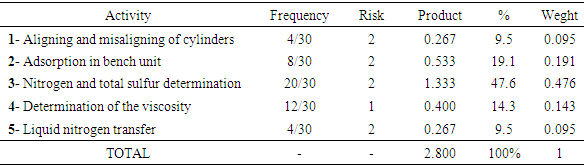

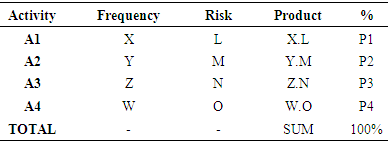

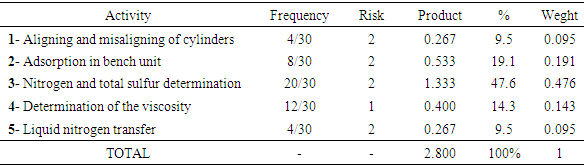

The degree of risk of the activity was evaluated according to appropriate questionnaire. Items related to the frequency of activities and the frequency of maintenance of safety items were included. The "weight" of each activity was defined as follows: the authors multiplied the monthly frequency by the risk of the activity, obtaining a value for each activity. The sum of the values is 100% and the "weight" is a percentual from the total, as shown in Table 2.Table 2. Determination of weighting for each activity

|

| |

|

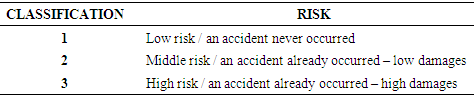

The frequency (how many times the activity is performed per month) and the risk were defined through interviews with laboratory collaborators. The interview, which is attached (Annex 1) was based on the Regulatory Standards NR5, NR6, NR15, NR16, NR17, NR25, NR26 and NR33 established by ABNT and presented in Section 2.5 of this paper.The monthly frequency was obtained using as a basis 30 days/month, 4 weeks/month and 5 days/week (Monday to Friday). Then, an activity that has a weekly routine (once a week) will have a monthly frequency equal to 4/30 and an activity that has a daily routine, have a monthly frequency equal to 20/30 and so on.Risks were rated on a 1-3 scale based on historical records or series of accidents, as shown in Table 3.Table 3. Risks classification

|

| |

|

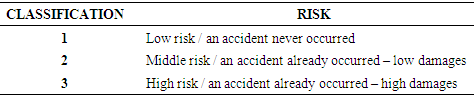

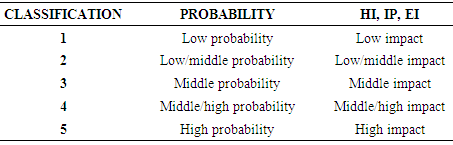

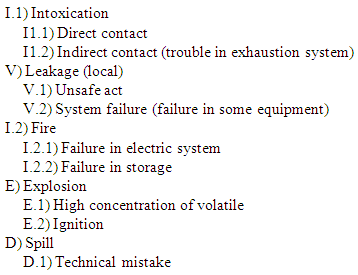

The Individual Vulnerability Index (for each activity) was evaluated according to some potential emergencies: Each emergency was analyzed following these parameters: probability of occurrence, human impact (HI), property impact (PI) and environmental impact (EI). Each parameter, in turn, was rated on a scale from 1 to 5. The interpretation of the values is shown in Table 4.

Each emergency was analyzed following these parameters: probability of occurrence, human impact (HI), property impact (PI) and environmental impact (EI). Each parameter, in turn, was rated on a scale from 1 to 5. The interpretation of the values is shown in Table 4.Table 4. Classification of the parameters for probabilities HI, IP, EI

|

| |

|

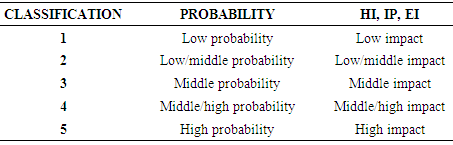

Finally, for each emergency, it is possible to obtain a value related to the sum of each parameter analyzed. The VI is obtained by adding the sums of vulnerability (for each type of emergency), as shown in Table 5.Table 5. Matrix to be used to define the Vulnerability Index

|

| |

|

6. Results and Discussion

6.1. General Analysis for the LETPP Lab

The lab is located in room 403 at Haroldo Lisboa da Cunha Building (Campus Maracanã, Rio de Janeiro). The cylinders of gases are placed out of the building. In present day, LETPP lab is used in graduate and post graduate courses. The lab also does services for private companies to meeting external demands in the area of analysis of chemical processes. The lab develops products and processes in several areas of petroleum and petrochemical industry, having as basis the diesel product. | Figure 2. Partial view of LETPP Lab |

The five main activities conducted in the laboratory are: alignment and misalignment of cylinders of gases (made in house gases), adsorption in bench unit, determination of nitrogen and sulphur total, determination of viscosity and transfer of liquid nitrogen. Each activity has a specific instruction that is stored in folders kept inside the lab.Most activities involve handling flammable liquids like diesel, toluene and acetone.The lab has PPEs and CPEs and its own Risk Map. It is reviewed periodically with the contribution of employees. In contrast, the LETPP lab has no material required to provide first aid, claiming that the University already has an internal health department able to take care of emergencies (DESSAUDE/UERJ). And the levels of exposure to unhealthy substances are not controlled. Waste and reagents are labeled, identified and stored in wall cabinets in cement with exhaustion system. The lab has a deal with a certified company for collect, transportation and disposal of its wastes, following the local environment requirements.LETPP lab has a modern control system for its equipments that indicates if they must be calibrated. The calibrations are recorded in the own system. In the lab there are no escape route signs, since it has only one door, opening from the inside out. Fire extinguishers are in the validity and they are in periodic maintenance.

6.2. Determining the “Weight” of Each Activity in GVI

The results for the "weight" of each activity in the global vulnerability index are shown in Table 6.Table 6. Determination of weighting for each activity

|

| |

|

As described in attachment 1, there were only two accidents in the LETPP laboratory: overheating in freezer, promoting the melting of the diesel drums and its spill, and the leakage in the cylinders. This last one was quickly identified because the lab has a weekly routine of alignment and misalignment of cylinders, which lets you control the weekly consumption. By these reasons, the activities involving operations with cylinders and diesel handling were classified like risk 2.The results for the individual vulnerability index of each activity are shown in Tables 7, 8, 9, 10, 11.

6.3. Individual Vulnerability Index (IVI)

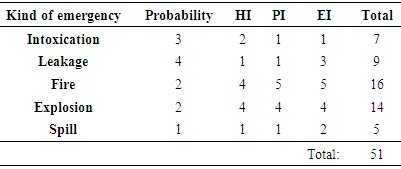

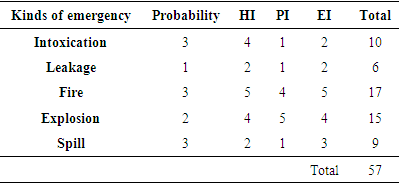

6.3.1. Activity 1 - Openning and Closing of Gas Cylinders

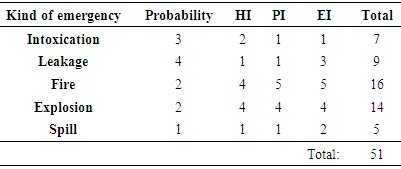

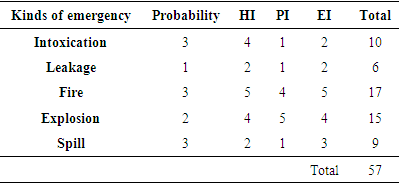

Nitrogen, helium, argon and synthetic air are stored properly in an own building, located outside lab and Chemical Institute. The probability of occurrence of emergencies nominated as "leakage" and "intoxication" are 3 and 4, respectively. Because a leak has occurred, increasing the probability of toxicity. The emergencies nominated as "fire" and "explosion" received value 2. In this case it was considered that the fire will only occur if the electrical system fail or any trouble in storage happens. As the electric system is new and well signed and the storage is realised with safety (following internal rules and protocols) and analyzed weekly, the value 2 was considered a good value to describe them. The value 1 was used to describe the emergency "spill" because the probability of spill to occur in any cylinder is small, since the cylinders are very safe. The value 1 was used to describe the emergency "spill" because the probability of spill to occur in any cylinder is small, since the cylinders are very safe.In relation to human impact (HI), the emergencies nominated "explosion" and "fire" received the value 4 because among the five emergencies analyzed was considered that these would be major sources of human injuries. But as the building of gases not have people every day (only 1 time per week) this has made the human impact did not receive the highest value. The emergence "intoxication" has scored 2 because its occurrence is due to some trouble in exhaustion system or some leakage out of control. The emergencies "spill" and "leakage" received lowest score for human impacts, getting value 1.Among the emergencies analyzed, "fire" was considered an item with the more risk for damage (score 5) to Haroldo Lisboa da Cunha Building, where is the Institute of Chemistry, followed by “explosion” (score 4). The others scored 1. The emergency nominated as "intoxication" was scored as lower environmental impact, followed by the "spill" and "explosion". If a fire occurs in the building of gases, this would cause a major environmental impact, because combustion reactions of gases in the cylinders are able to generate solid and gaseous waste.For this activity was given a vulnerability index equal to 51. With the results in Table 7 and the above discussions, it is observed that emergencies that most influenced the increased vulnerability of activity were "fire" and "explosion".Table 7. Determination of IVI for activity 1

|

| |

|

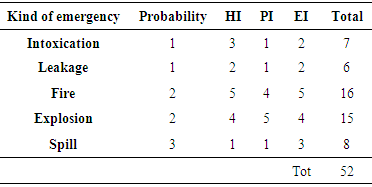

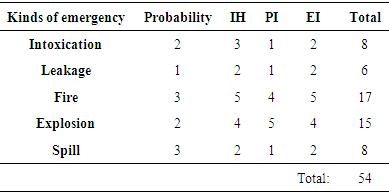

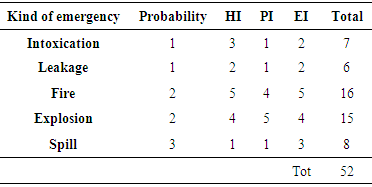

6.3.2. Activity 2 - Adsorption on Bench Unit

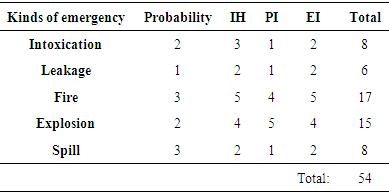

The "spill" was considered as the emergency with high probability for occurrence. It scored 3, this classification is due to the higher relation with human mistake: A little carelessness in the storage or handling can cause spill. Fire and Explosion scored 2, because these activities have diesel as main product manipulated. According to the magazine SIND TRR, static electricity is a risk of fire and explosion in activities involving the handling of diesel or any other petroleum product. Poisoning and leakage scored 1. About the human impact, the emergencies nominated "fire" and "explosion" scored 5 and 4, respectively. For this, the large number of people in the lab (about 10) and the location of the laboratory (on a floor, with several class rooms and others labs) were taken into account. Emergencies indicated as "fire" and "explosion" received the highest values (4 and 5, respectively) for damage to goods. The first received a lower value since it is easier to be controlled (the lab has fire extinguishers within the validity and they are submitted to periodic maintenance). The environmental impact in case of fire or explosion involving diesel was rated high. This fossil fuel generates CO2 and can produce NO, NO2, SO2 and SO3.The spilling of this fuel would cause serious environmental troubles, reaching the sewer system, for example. This activity was classified with an index of vulnerability of 52. With the results shown in Table 8 and the above discussions, it is observed that emergencies that most influenced the increased vulnerability of activity were "fire" and "explosion".Table 8. Determination of IVI for activity 2

|

| |

|

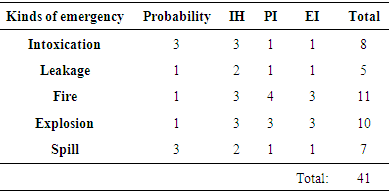

6.3.3. Activity 3 - Determination of Total Nitrogen and Sulfur

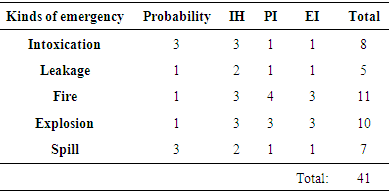

Comparing this activity with activity 2, it is observed that the first one has the same values as described above in relation to "leakage" and "explosion" and higher values of poisoning, fire and spill. This occurs because the two activities use diesel. Furthermore, the activity 3 also uses toluene, which is a flammable liquid, be harmful if inhaled and harmful if inhaled or absorbed through skin. These reasons justify the higher values obtained at: probability of poisoning and fire and human impact if it occurs intoxication or spill.This activity received a vulnerability index equal to 57. With the results in Table 9 and the above discussions, it is noted that emergencies that most influenced the increasing vulnerability of activity were "fire", "explosion" and "poisoning".Table 9. Determination of IVI for activity 3

|

| |

|

6.3.4. Activity 4 - Determination of Viscosity

This activity is related to acetone handling. This solvent is flammable, toxic by inhalation, and penetrates quickly into the skin. This explains the high values in the human impact parameter and on emergency nominated "fire".This activity had a vulnerability index equal to 54. With the results in Table 10 and the discussion above, it is observed that emergencies that most influenced the increasing vulnerability of activity were "fire" and "explosion".Table 10. Determination of IVI for activity 4

|

| |

|

6.3.5. Activity 5 - Transfer of Liquid Nitrogen

When the liquid nitrogen evaporates, it lowers the oxygen concentration in the air and can act as an asphyxiant agent, especially in confined spaces. Nitrogen is odorless, without color or taste, and may produce asphyxia without any sensation provided warning. Therefore, the higher value found for the emergency nominated "poisoning".This activity had an index of vulnerability equals to 41. With the results in Table 11 and the discussion above, it is observed that emergencies that most influence in increasing the vulnerability of the activity were "fire" and "explosion".Table 11. Determination of IVI for activity 5

|

| |

|

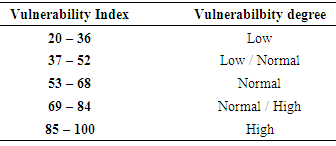

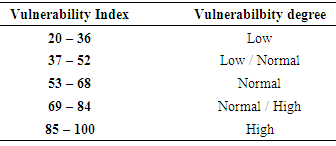

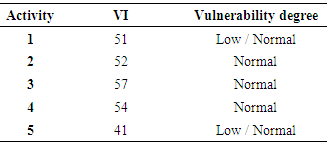

6.3.6. Analysis of the Degree of Vulnerability for Each Activity

For individual vulnerability index (IVI), the lowest value that could be obtained would be 20 (if all parameters analyzed receive value 1) implying a safe activity without some vulnerability. The higher value possible for IVI was 100. In this case, all parameters would be scored as 5. And the activity would be considered completely unsafe.Thus, to classify the degree of vulnerability of each activity it was distributed values between 20 and 100 into five major groups, as shown in Table 12. The results obtained for the IVI and the ranking of the degree of vulnerability of each activity are shown in Table 13.Table 12. Vulnerability degree for the VI range

|

| |

|

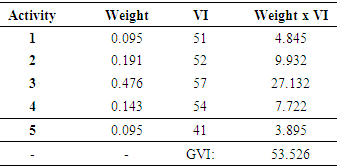

Table 13. Vulnerability degree for the each activity

|

| |

|

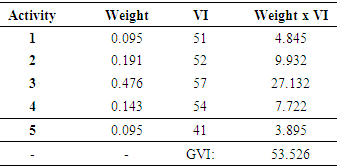

6.4. Determination of GVI and Its Analysis for the LETPP Lab

With the values previously obtained for "weight" and for individual vulnerability index (IVI), the global vulnerability index was calculated as 53.526, as shown in Table 14.Table 14. Determination of GVI for the LETPP lab

|

| |

|

The minimum value possible for GVI is 20 and the maximum, 100. Therefore, the table 12 can be used to classify the degree of vulnerability. Not only for the activity but also for the laboratory. So the GVI for the lab is in average degree of vulnerability. According to table 14, the activity 3 had more influence over GVI, presenting most weighting as also the highest individual vulnerability. Therefore, this activity can be considered as the most dangerous of the lab and hence requiring greater attention to the management of quality, health, safety and environment, followed by activities 2 (bench unit), 4 (viscosity), 1 (align and misalign of cylinders) and 5 (liquid nitrogen transfer).

7. Conclusions

It was possible to propose successfully, a global vulnerability index for the LETPP laboratory. It is noted that the determination of this index is an important step in quality, health, safety and environment management systems to be applied in the lab. This tool allowed to identify the most vulnerable activity, facilitating the determination of corrective and preventive actions in order to reduce its occurrence.

Future Works

With the relevant informations about the vulnerability of the risks in LETPP lab, it is recommended to conduct simulated activities to address the events of risks pointed by the global vulnerability index.

ACKOWLEDGMENTS

The authors are very thankful to chemical technicians Alessandra Dias and Fábio for technical support and to CENPES/Petrobras for financial support.

References

| [1] | Hendershot, Dennis. Do you believe in Murphy’s Law? Journal of Chemical Health and Safety, 21(5), 2014. |

| [2] | Langerman, Neal. Expand process safety management. Journal of Chemical Health and Safety, 22(2), p.41-42, 2015. |

| [3] | Ashbrook, Peter. Chemical waste management. Journal of Chemical Health and Safety, 22(2), p. 40, 2015. |

| [4] | Vuksic, Vesna, Bach, Mirjana Pejic, Tomicic-Pupek, Katarina. Process performance management in higher education. International Journal of Engineering Business Management, 2014. |

| [5] | Brasil, Ministério de Integração Nacional. Secretaria Nacional de Defesa Civil (SEDEC). Política Nacional de Defesa Civil - PNDC. 2004. 88p. |

| [6] | phifer, Russel. Security vulnerability analysis for laboratories and small chemical facilities. Journal of Chemical Health and Safety, 14(6), p.12-14, 2007. |

| [7] | Frosini, L. H., Carvalho, A. B. M. Segurança e Saúde na Qualidade e no Meio Ambiente, in: CQ Qualidade, nº 38, p. 40-45, São Paulo, 1995. |

| [8] | International Organization for Standartization. ISO 9011 – Quality management systems, 2008. |

| [9] | Federal Emergency Management Agency. Emergency Management Guide for Business & Industry. FEMA 141, USA, October 1993. Available: <http://www.fema.gov/pdf/business/guide/bizindst.pdf>. Accessed in 2009 April. |

| [10] | Sullivan, Dennis. Higher education emergency management survey. Journal of Chemical Health and Safety, 19(4), p.36-43, 2012. |

| [11] | Kotlas, Maureen. Lions, tigers, and bears – managing research security in academia. Journal of Chemical Health and Safety, 20(3), p.21-29, 2013. |

Each emergency was analyzed following these parameters: probability of occurrence, human impact (HI), property impact (PI) and environmental impact (EI). Each parameter, in turn, was rated on a scale from 1 to 5. The interpretation of the values is shown in Table 4.

Each emergency was analyzed following these parameters: probability of occurrence, human impact (HI), property impact (PI) and environmental impact (EI). Each parameter, in turn, was rated on a scale from 1 to 5. The interpretation of the values is shown in Table 4.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML