-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Management

p-ISSN: 2162-9374 e-ISSN: 2162-8416

2015; 5(2): 25-33

doi:10.5923/j.mm.20150502.01

The Supply Chain’s Strategic Importance for AZADEA Group

Atef H. Harb 1, Lina Bou Chaaya 2

1Faculty of Business Administration and Economics, Notre Dame University (NDU), Lebanon

2Business Consultant, Ph.D. Candidate, Lebanese University (UL), Lebanon

Correspondence to: Atef H. Harb , Faculty of Business Administration and Economics, Notre Dame University (NDU), Lebanon.

| Email: |  |

Copyright © 2015 Scientific & Academic Publishing. All Rights Reserved.

In general and through the three functions of Marketing, Operations and Finance, value for the customer is created. However, firms seldom create this value by themselves. Instead, they rely on a variety of suppliers who provide everything from raw materials to accounting. These suppliers when taken together can be thought of a supply chain. AZADEA Group is one of the retail business leaders in the Middle East welcoming shoppers at its different stores formats spread through almost 40 brands and many different sectors. Being so diversified, AZADEA had a huge challenge in setting a unified supply chain process, thus, the Group and through its professional team was able to set a detailed list of requirements to be followed in order to consolidate its data and to manage properly the flow of merchandise from the source to the destination. This research will describe how it is done through a vast literature review. The purpose of the research is to provide insights into the importance of the supply chain strategy and ERP integration for AZADEA group. This will ensure a proper integration and will highlight the flow of information of the supply chain helping the group to minimize the inventory cost and being a competitive Advantage. Also, The Electronic Data interchange (EDI) will contribute in the replenishment during the season and the analysis done over the historical data identify the best/worst selling items per shop and define the forecasted order of the upcoming season. The optimization is highly recommended to maintain a sustainable workflow of the supply chain along to the forecasted expansion. To achieve our goal, a secondary data will be used. Results found showed that Although AZADEA Group has developed an ERP system within its community, where a clear vision is possible at all stages to improve the communication between different parties internally and with the supplier externally, the Group is still in need to go further in the development of applications to optimize its resources.

Keywords: Supply Chain Strategy, Enterprise Resource Planning (ERP), AZADEA, e-Business, Networking, Technology, Workflow, Electronic Data Interchange (EDI)

Cite this paper: Atef H. Harb , Lina Bou Chaaya , The Supply Chain’s Strategic Importance for AZADEA Group, Management, Vol. 5 No. 2, 2015, pp. 25-33. doi: 10.5923/j.mm.20150502.01.

Article Outline

1. Introduction

- AZADEA Group, a company owned by the DAHER brothers origin from Lebanon grew during the last 10 years aggressively in the Middle East operating in more than 15 countries such as Lebanon, United Arab Emirates, Bahrain, Qatar, Kuwait, Jordan, Oman, Turkey, Erbil, Kingdom of Saudi Arabia, Kazakhstan, Algeria, Egypt, etc…, by integrating as well new brands within several sectors covering almost 167,000 SQM within 409 shops.Azadea Group is one of the retail business leaders in the Middle East welcoming shoppers at its different stores formats spread through almost 40 brands and six different sectors.● Sporting goods: Decathlon● Fashion: Bershka, Boggi, Calzedonia, Grain de Malice, Gymboree, Intimissimi, Jules, Mango, Marella, Marina Rinaldi, MD, Maxmara, Oysho, Penny Black, Piazza Italia, Pimkie, Prenatal, Promod, Pull & Bear, Punt o Roma, Salsa, Stradivarius, Tezenis and Zara● Accessories: I AM, Mango Touch, Oculis, Sunglass Hut, and Uterque● Food and Beverages: Columbus Café, Paul Café, Pulp Juice, Kosebasi and the Butcher Shop and Grill.● Home Furnishings: Mood, Singways and Zara Home.● Multimedia: Virgin Megastore.Being so diversified, AZADEA had a huge challenge in setting a unified supply chain process, thus, the Group and through its professional team was able to set a detailed list of requirements to be followed in order to consolidate its data and to manage properly the flow of merchandise from the source to the destination.

2. Literature Review

- The term Supply Chain Management has been created early in 1982 by two consultants: Oliver and Webber – The supply chain is defined as a mission of logistics to become a top management concern since “….only top management can assure that conflicting functional objectives along the supply chain are reconciled and balanced…. And finally, that an integrated systems strategy that reduces the level of vulnerability is developed and implemented” [1].The constituents of the Supply Chain Management are:- The management philosophy- The target - The objectives- The tools used to achieve these objectives“In a broad sense a Supply Chain consists of two or more legally separated organizations, being linked by material, information and financial flows” [2].Competitiveness and customer service are considered as the highest standards to be followed for an ultimate achievement of a supply chain set goal. The reduction of the cost, increase of flexibility with respect to changes in customer demands or by providing high quality of products and services, are to be considered for a competitiveness improvement. The network integration along to the coordination of information material and financials workflow is selected as main components of the Supply Chain Management. According to a survey conducted by [3] there are 3 elements of customer service:- Pre-transaction, Transaction and Post transaction elements.The integration is the collaboration in the long term of the below main building blocks:- Selection of partners, Network organization and Leadership and inter-organizational.The stability of a supply chain depends economically on its entities. Even if they are legally independent, the structure of a supply chain will stay steady, only if there is a win-win situation for each member at least in the long run. At short term, it should be compensated through a compensation schemes based on the usual price mechanisms. To implement the consistency of the supply chain members, several types of relationships may be used:- “Technical bonds which are related to the technologies employed by the firms.- Knowledge bonds related to the parties knowledge about their business- Social bonds in the form of personal confidence- Administrative bonds related to the administrative routines and procedures of the firm.- Legal bonds in the form of contracts between the firms” [4].The main actor forming a supply chain is “Leadership”; it is a fragile topic in light of the supreme of self-organizing; Regardless of the advantages attributed to a supply chain, we should keep in mind that its structure is susceptible- the exit of one collaborator may put at risk the survival of the supply chain as a whole; Also, an associate may run the threat of becoming unappealing and to be substituted by a competitor once he identified how he has been distributed within the supply chain. The organization of information includes 3 main processes:Communication technology and information dispatch, Process direction and advanced planning.The progresses in the information technology (IT) made the procedure of information at different phases in the supply chain possible; the large storage space devices allow the storage and the retrieve of historical group data; therefore, the Data Warehouses may now be used for a better analysis. The communication through the electronic data interchange (EDI) can be recognized through private and public networks, the most known one being the Internet. The communication links are distinguished according to the below 3 parties: Business, Consumer and Administration. Two communication links are defined:1. Business-to-Business (B2B), it allows the companies to redesign and automate processes, the enterprises might use the network such as the internet as based marketplaces; the latter can be categorized through 4 characteristics: ● The specifications of the supplies● The period of the relationship● Pricing matrices● The unfairness if an e-hub, which may support either the seller, the buyer or take a neutral position.2. Business-to-Consumer (B2C), it releases a new marketing channel to end consumers and offers a funds for incorporating end users within a supply chain, as long it is friendly used through the access to the information related to the goods and services , mode of payments, cost of carrying, shipping and customer services after sale.The orientation method manages all the activities involved in the customer order in the most efficient way. “Key performance indicators (KPI) can reveal weaknesses, bottlenecks and waste within a supply chain, especially at the interface between its members [5].As [5] puts it “streamlining cross-company processes is the next great frontier for reducing costs, enhancing quality, and speeding operations”.The advanced planning system includes long-term, mid-term and short-term planning levels. An Advanced Planning System (APS) is divided into several elements; efficient information run between these modules to make it a coherent software system. The Enterprise Resource Planning (ERP) system sculpts the different planning tasks insufficiently. These planning jobs are executed successively without allowing for reviews to upper-level decision makers.Even though the APS modules are separated in several modules, APS are planned to adjust the imperfections of ERP systems through a closer combination of modules, adequate redesigning of bottleneck capacities, a hierarchical scheduling concept and the use of the latest technical developments.To operate successfully a supply chain, the below components are highly required:- Logistics and transportation- Marketing- Operations Research and Development- Organizational performance, industrial association and operation cost - Procurement- Inventory ControlThe below mechanisms contributes in the incorporation and coordination of different functional elements that existed before the creation of the term Supply Chain Management in 1982.- Channel research (Alderson, 1957)- Collaboration and cooperation (Bowersox, 1969)- Location and control of inventories in production-distribution networks (Hanssmann, 1959)- Bullwhip effect in production-distribution systems (Forrester, 1958)- Hierarchical production planning (Hax and Meal, 1975)Over the past decade, companies across a large range of industries have been focusing their competitive strategies on leveraging the competencies and inventive capabilities to be found in the groups of customers and suppliers constituting their business supply chains.Today academics, consultants and practitioners alike have come to understand that the capacity of companies to continuously reinvent competitive advantage depends on the ability to look outward to their supply chains in the search for resources to persuade the right mix of competencies that will resound with their own organizations and core product and process strategies.Competitive advantage in tomorrow’s environment will go to those enterprises that can consistently anticipate and implement customer-winning supply chain competencies, while discarding those that have become commodities or easily copied by the competition.In today’s business environment, no enterprise can expect to build a successful product, process, or service advantage without integrating their strategies with those of the supply chain systems in which they are inextricably entwined.In the past what occurred outside of the four walls of the business was of secondary importance in comparison to the execution of strategies designed to effectively manage internal engineering, manufacturing, marketing, sales, and finance activities.The measure of success in a company, it is its ability to look out of its channel associations to gain admittance to sources of unique competencies, physical resources, and marketplace value.“What has caused this awareness of the “interconnectiveness” of once isolated and often adversarial business occupying the same supply chain? What forces have obsolete long-practiced methods of ensuring corporate governance, structuring business, and developing strategies? What will be the long-term impact on the fabric of business ecosystems of an increasing dependence on channel partnership? What are the possible opportunities as well as the liabilities of channel alliances? How information technology tools like the Internet should be integrated into supply chain management, and what new sources of market winning product and service value will be identified? [6].The supply chain event management (SCEM) offers timely event-related information that can be used to recognize and adjust disorder and malfunctions in operational supply-chain processes. A proactive SCEM system that sticks to necessities resulting from the insufficiencies of current SCEM solutions can considerably reduce supply-chain troubleshooting costs. “Several mechanisms for proactive SCEM are proposed, encompassing concepts to gather data on suborders in inter organizational settings, focus on proactive monitoring activities with classified critical order profiles, and analyze, interpret and distribute information employing fuzzy logic. Agent technology is shown to be suitable for implementing proactive SCEM concept is evaluated by means of a prototype implementation for a logistics service provider. The results show that the costs of information and monitoring processes can be reduced substantially”. Proactive Supply-Chain Event Management with Agent Technology [7].Abnormalities and troubles produced by the active situations and doubts of fulfillment processes threaten the benefits of optimized plans for supply chains. Inescapable variances in processing time and processing quality may be the cause of delays in the production processes and other irregularities. The interruption due to the machines’ malfunctions, failures in handling it, the inaccurate picking in the warehouses, or any other external reasons like traffic overcrowding have a serious impact on the fulfillment of orders within a supply chain. There is a tremendous need for proactive assembly and communication of information to overcome such events across supply chains. This would take place as part of an inter organizational information exchange so significant for today’s forms of collaboration in supply chains. Supply chain event management (SCEM) systems assure the beating of these problems. The term “supply chain event management” coined by AMR Research in 2000 [8], refers to systems that monitor events in supply chains (e.g. milestones, disruptions) and react according to predefined business rules (e.g., sending e-mail alerts).Traditional tracking systems, the predecessors of SCEM systems, are widely implemented in logistics service provider (LSP) networks. They follow orders within the borders of a single corporation and generally do not offer practical alert mechanisms. Similar approaches to production control are also characterized as inaccessible systems without event-management competences.Current SCEM systems from companies like SAP, I2 and Manugistics, and specialized vendors like Saltare or Velocity have additional capabilities for reacting to critical events. “An overview of SCEM functions is given by AMR Research in 2000:● Monitoring: Identification of events during fulfillment processes (e.g. production, warehousing, transportation).● Notification: Generation of alerts and communication with actors or systems based on event information.● Simulation: Simulation of effects of disruptive events on supply-chain performance, and simulation of consequences due to managerial reactions.● Measurement: Supply-chain performance measurement over a longer period.”SCEM software collects input from the planning and execution fields of supply chain processes. It controls the status of these processes and feeds back information to planning applications such as Advanced Planning Systems (APS). “An APS covers several aspects of planning, such as long, mid and short term planning. SCEM systems like the SAP Event Manager (EM) are not designed to substitute planning applications like the Advanced Planning and Optimization (APO) APS solution offered by SAP. The SCEM approach complements the planning functions by providing feedback capabilities from the execution processes of a supply chain to the planning domain. As a result, SCEM tools, if integrated with APS tools, enable closed-loop supply-chain management. Existing SCEM systems mainly perform monitoring and notification functions. What with their lack of simulation, control, and measurement functions, current implementations offer a huge potential for improvement [9].Having the logistics service provider (LSP) as a business partner, the LSP performs the warehouse operations and assign borders for transportation to different carriers.The LSP is part of a large international enterprise and mainly serves its customers. The products are small to medium sized, and orders may include large volumes of products. Deliveries are to national and international destinations across the world. The focus of the prototype implementation is on international transports because these exhibit more operational problems [10].For transportation, the LSP coordinates with carriers with a regional focus. The supplementary of the LSP examined in detail places about 200,000 orders per year with these carriers.The completion processes consist of warehousing operations conducted by the LSP and transportation processes. The warehousing process begins with the arrival of consumers orders. Such orders are generally fulfilled directly from stock. Therefore, procurement activities [11] are decoupled from the main order-fulfillment process. After significant order items are picked and packaging activities are completed, the order is dispatched to a carrier. From there on the carrier is accountable for the whole transportation process, covering trans-shipment and delivery to the customer. This may include activities to clear customs during international transport. Subcontractors or local carriers in the destination country are sometimes integrated into the process. If so, they have contracts with the carriers.The milestones defined by the LSP for the completion process include, for example, “Order released for picking” during warehousing processes and “Arrival at customs” during transportation. Severe deviations from predefined milestones and associated planned dates indicate problems in the fulfillment process that have to be managed actively. A proactive SCEM system located at the LSP needs to integrate information both from its internal data sources (especially its ERP system) and from the tracking systems run by the different carriers.Standard Event Detailed Information (EDI) messages for every order are generated externally by the carriers at certain intervals or milestones and sent to the LSP. The resulting databases at the LSP are filled with information on orders that in most cases do not encounter any serious problems during fulfillment. This situation calls for a decentralized storage of data at the carriers’ sites and on demand queries for information when needed. Late orders are the one having different problems, the information on their status is postponed due to different reasons, including batch-wise transmission of status information. In addition, information on critical situations is often lost in large databases because there are no well-organized methods in place to extract the relevant information in a timely manner. A proactive system focusing on potentially critical orders can help to facilitate a focused operational management.The transferred data is not compatible with the he needs of a decision-maker who has to respond to a difficulty because they do not identify the types of problems encountered or the harshness or criticality of events. This situation calls for advanced self-directed interpretation support and quick innovation.The supply chain performance measures have two central effects [12] and work in two directions. They can be used to describe the current situation by describing the past and present of the process being considered, on the other hand they can be used to set performance goals. This allows to establish a focal point on the future. The focus in this research will be on the components and elements used within Azadea management to serve the organization and its diversification along to optimizing its cost and increasing its efficiency. Within our below study, we will highlight the action plan set between Azadea Group and the source / supplier to have a successful supply chain flow while exploring new market or integrating a new brand specifically for the Retail Fashion, since it contribute around 65% from the total turnover of AZADEA [13].Knowing that Azadea is working with different suppliers sources, Spain, France, China, Italy…, the group should have a systematic workflow to maintain the extending of the business while saving the environment.AZADEA Group receives goods from different regions, what would be the followed process that optimized the lead time between the order, production and the distribution phases?What is the supply chain strategy pursued by Azadea that made of this company a success story at all levels?

3. Research Methodology

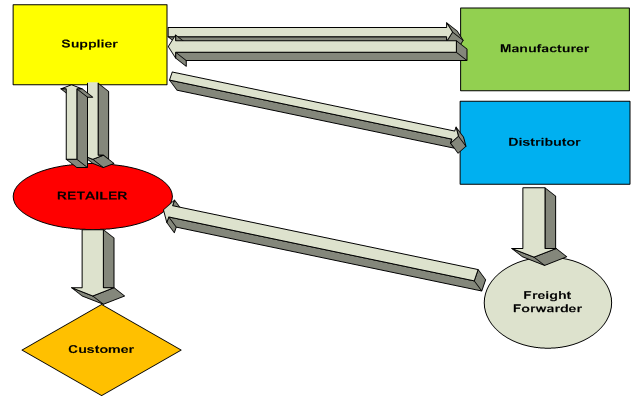

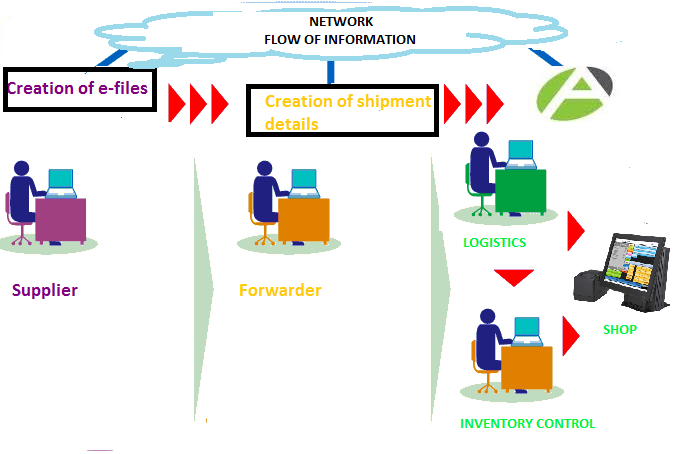

- The analysis of this research is based on secondary data, including online databases related to e-files communicated and interchanged with the foreign suppliers covering the retail fashion sector since it contributes around 65% from the total group business.As mentioned in the previous sections, due to the diversification in AZADEA’s business, the Group has established a list of requirements to be applied while integrating a new brand or a new country.AZADEA Group follows a simple work flow (Figure 1) from upstream to downstream of its supply chain.

| Figure 1. Supply chain work flow |

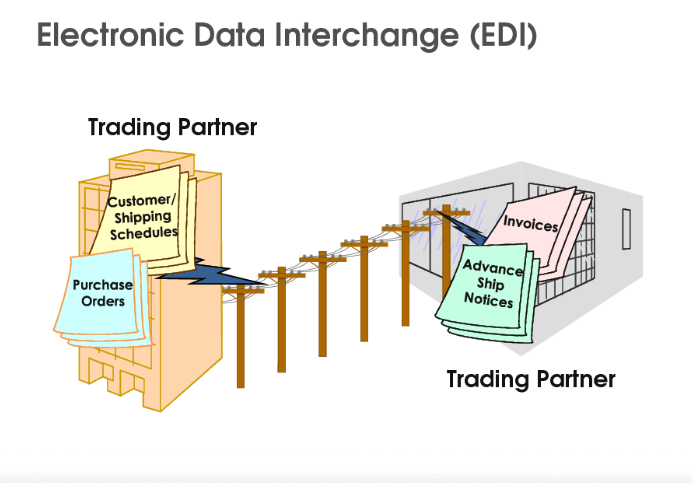

| Figure 2. Electronic Data Interchange flow |

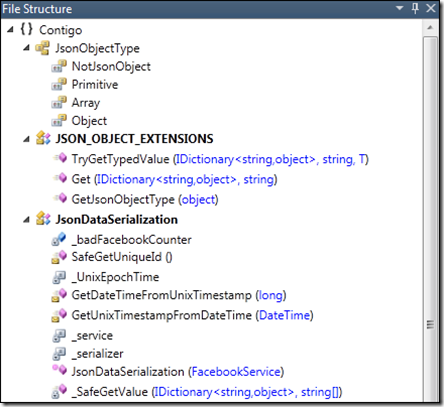

| Figure 3. Point of Sales |

| Figure 4. File structure sample |

4. Findings

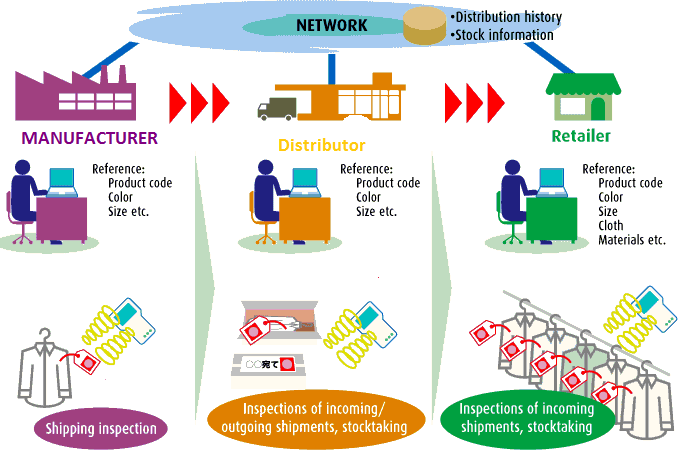

- Azadea Group has an ERP system implemented within its organization, where all the data is automatically integrated without human intervention. The Group is continually communicating with the foreign suppliers to ensure a proper integration, mainly due to its brands and areas diversification. Below findings highlight the flow of information within Azadea Group from upstream to downstream of the supply chain. Foreign supplier identified at certain stage as franchisor has clear access to the data of the retailer (Shop) either the Point of Sale (POS) is set from his side or from AZADEA’s side. The Electronic Data Interchange (figure 5) contributes in the replenishment during the season and the analysis done over the historical data identify the best/worst selling items per shop and define the forecasted order for the coming season. Once the order is placed, information is automatically transferred to the manufacturer for production. The time line for manufacturing differs from supplier to another; Inditex produce and launch new items within 4 weeks maximum whereas Promod will produce and launch new products within 2 months time. Worthy to mention, some of the orders are cancelled due to the limited quantity required or due to shortage in stock.

| Figure 5. Flow of merchandise |

| Figure 6. Flow of information |

5. Conclusions and Recommendations

- Although AZADEA Group has developed an ERP system within its community, where a clear vision is possible at all stages to improve the communication between different parties internally and with the supplier externally, the Group is still in need to go further in the development of applications to optimize its resources. The optimization is highly recommended to maintain a sustainable workflow of the supply chain along to the forecasted expansion; Azadea will reach approximately600 stores by end of 2015. Having said that, I believe the main area for development should be at the forwarder stage where an EDI application should be integrated. The forwarder company has to input all the information related to the shipment along to its status, at the other end, the logistics team will not be obliged to create manually the shipment into the ERP system to input the related data. On the other hand, Azadea Group should look into the technology of the future which is the RFID and start the communication with its main franchisor to install it at their end. AZADEA will receive all the merchandise tagged with RFID labels, once the system is implemented, the Group is not anymore obliged to do physical receiving nor cycle counts in order to update its stock level on daily basis. The stock movement will be real time updated and monitored at all levels. Moreover, the paper work will decrease tremendously as it will be replaced by e-data. This application would also help the supplier to monitor the stock movement and identify the best and worst selling items for future orders.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML