-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Management

p-ISSN: 2162-9374 e-ISSN: 2162-8416

2013; 3(6): 292-303

doi:10.5923/j.mm.20130306.02

Lean as Universal Approach: False or True?

Aleksandr Miina

Tallinn School of Economics and Business Administration, Tallinn University of Technology, Talinn, 12618, Estonia

Correspondence to: Aleksandr Miina, Tallinn School of Economics and Business Administration, Tallinn University of Technology, Talinn, 12618, Estonia.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

Lean thinking approach was reported in many papers to be very efficient and straightforward way towards process improvements in terms of productivity and value adding activities ratio. Also, lean thinking has been implemented in many fields other than manufacturing. On other hand, it was also discovered that the system which is working very well in Toyota might not give similar effective results in other companies.Current study is trying to find answer to the question of universality of lean approach. One of the proposals is that lean thinking implementation process in general should be performed the same way in any company. The difference might appear only on certain tools or method implementation in particular company. Such proposal is based on comprehensive literature study and based on example of Scaniacompany.Study results indicate that every company could approach lean thinking implementation framework the same way and no limitations are existent.

Keywords: Lean Thinking, Universal, Continuous Improvement

Cite this paper: Aleksandr Miina, Lean as Universal Approach: False or True?, Management, Vol. 3 No. 6, 2013, pp. 292-303. doi: 10.5923/j.mm.20130306.02.

Article Outline

1. Introduction

- Lean thinking principles have been widely and deeply studied for more than 30 years. The bestseller “Machine, that changed the world”[73] introduced the concept to the world and since then numerous academic articles and practical books have been published on the topic of lean. Despite on this, till the present moment there is no common understanding of what is lean and what is lean not. Again and again many authors try to find arguments and evidences pro and cons lean. Modig and Åhlström[49]in their book “This is lean” once more go through all the basics of lean and explain them using different set of words. Several researches have indicated that there are problems of lean application due to inappropriate understanding of the lean concept[65], and due to the taking the philosophy as “black box”, which has many dangers inside[75] and due to the usage of lean initiatives as a fad[63]. Arlbjørn and Freytag[7]in recent study again find that in many cases lean concept seems to be unclear and vague, and also is taken as toolbox. Based on this it seems that lean is some kind of enigmatic approach which is still unclear irregardless of all the papers written on the topic.Additionally, prerequisites for starting lean implementation are indicated as follows ([13],[39],[18],[8]): production of standard goods/services, large volume, and relatively long product lifecycle. This leads to another conclusion of non-suitability of lean for high-mix low volume(or similar) types of processes.Per contra, a lot of evidence is existent about implementation of lean principles in other areas than manufacturing. As investigated by academic researchers, lean usage has spread from a focused application in manufacturing to service companies ([1],[62],[68]), healthcare ([43],[17],[44]), administrative processes[8], education ([21],[24]) and public administration ([9],[59]).It is well known that the roots of lean thinking come from Toyota Production System (TPS). Ohno[54]defines it as the system of organising production processes in efficient and effective manner. Though lean seemed to work very well in Toyota factories, companies outside of Toyota were not able to achieve the same results. Lean was developed in Toyota and thus is natural thing for Toyota[48]. Other companies had to find their personal way to implement those ideas in a successful manner and it turned out to be very complicated. Since then lean topic was studied very widely and different aspects of lean implementation were investigated, though still there is no standard framework or roadmap of successful lean implementation ([38],[60],[63]). At the present time the similar examples of TPS could be found almost in all automotive companies. Scania is known as one of the best examples of lean implementation outside Toyota corporation. The focus of Scania Production System is on continuous improvement in order to maintain strong, sustainable and efficient production. SPS is developed in-house by company’s employees based on Toyota Production System. SPS together with Scania Retail System (SRS) are the parts of philosophy at Scania – to focus on methods rather than results and results will come as a consequence of doing right things right. Scania started to develop and implement new approach to the trucks and bus production in mid 1990s and still continues this way[48]. It could be found on Scania web page: “In the early 1990s, when Scania had exhausted traditional production and management methods, it sent a team to the Toyota car company in Japan to study what was behind that company’s high productivity and quality. Scania engineers returned with important new knowledge that they had not been able to glean from the literature on Japanese car production methods. As it turned out, the success of the Japanese was primarily a matter of management and people rather than industrial robots. Toyota’s leadership system was based on a few clear basic values shared by all employees. The company also worked with a set of principles that the employees knew and understood.”The purpose of the current research is to investigate the universality of lean thinking approach to the different areas. For this the following things will be done: first, the investigationof academic literature about the approaches of lean thinking implementation; second, the study of Scania approach of SPS implementation; third, the creation of general framework of lean thinking implementation based on studied literature and SPS; and then, discussion of applicability of the general framework to other areas than manufacturing as well as to high mix low volume manufacturing. Author proposal is that lean approach is universal for any company if it is looked from high level of abstraction. This means, that general steps the company need to take in order to achieve successful lean application are the same in all cases. The difference will come in details: how one or another lean tool will be implemented in the particular company. The target of current study is to identify whether indicated proposal is true or false. Research was done as a part of doctoral thesis which in general was focusing on development of standard framework of lean thinking implementation process.Main contribution of the study to the theory is identification of the importance of company’s own production system model in the form of lean house. Practice is contributed by straight direction for companies who wish or are implementing lean. Each company who is starting its lean road (or already going that road) should focus on its own production philosophy creation in the form of lean house. By this the results of lean implementation in the companies could be higher and more successful.

2. Methodology

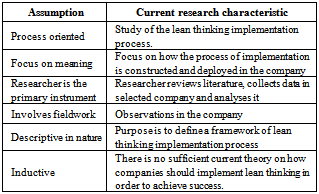

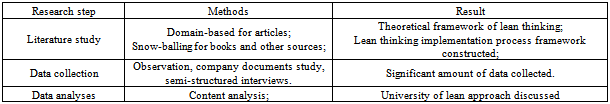

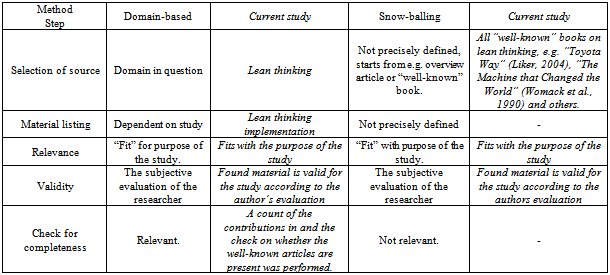

- In general, the two primary research paradigms are qualitative and quantitative studies. The process by which the researcher follows in studying the questions raised is shaped by those paradigms. Creswell[22]defines qualitative study as a process of inquiry that is based on building a complex picture, formed with words and conducted in a natural setting. Also same author alternatively defines quantitative study as a process of inquiry that is based on testing a theory composed of variables, measured with numbers, and analysed with statistical procedures. The data for this study are qualitative in nature; therefore, a qualitative design is most appropriate for the current. Creswell[22] lists six assumptions of qualitative research that should be addressed when conducting qualitative research. The following Table 1 lists the assumptions and how current research addresses them.

|

|

|

3. Theoretical Framework

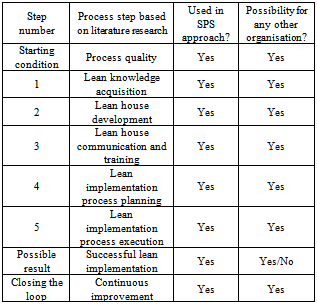

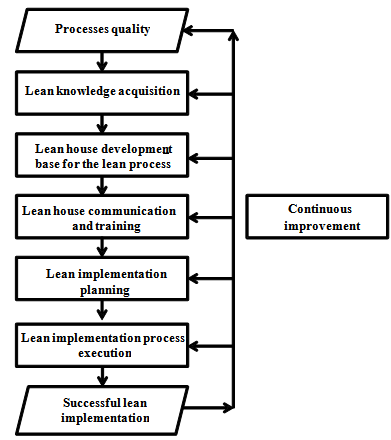

- Deep investigation of literature allows us to highlight the aspects of lean thinking implementation for constructing the general framework. First, as a basis for manufacturing process improvement, many authors ([53],[34],[75],[64] and others) point out standards. TaiichiOhno ([54]) stated very clearly: “You have to have standards, even if they are bad standards”. Standard process means that the same process is performed each time exactly the same way, independent of who is performing the process. And if process is performed every time the same way, we can easily predict how much time it will take and what the result will be. We can also call such a process controlled or a quality process ([6],[49],[34]). It is impossible to improve non-quality process due to the fact that it is not possible to measure it and therefore to define value non-adding activities. A lack of standard processes will make hard work to improve them ([29],[20],[36]).Furthermore, many studies show that companies do not really understand what is lean and how it could be implemented. For example, only 10 per cent or less of companies succeeds at implementing lean manufacturing practices[14]. Furthermore “only 10 per cent has the philosophy properly instituted” ([65], p. 8). On the other side, new paradigms and best practices are often taken as a “black box”, which has many dangers inside[75]. Also, if companies use lean initiatives almost as a fad, most of their efforts will fail to produce significant results ([63],[38]). Consequently, lean knowledge should be present in the company and disseminated, so that each employee understands what is lean thinking and for what it is used. Lean knowledge acquisition could be done in many different ways: books, articles, trainings, consultancy help, benchmarking other companies and many other ways. Based on gathered lean knowledge, a company has to construct their own model of the new production system it will take on – lean house. Question of either we should view lean concept as a philosophy of doing work or not is widely studied by different authors. They give ideas that lean should be viewed more as a philosophy or condition than as a process ([6],[14],[51],[55]). Laureani and Antony[45] advice is to accept lean more as a state of mind or philosophy, than just a process improvement tool. Toyota Production System (TPS) did not happen overnight but through a series of innovations during 30 years[54]. Lean philosophy means that all the company lives and thinks based on the lean ideas[69]. As soon as company and its personnel takes lean as “a new innovative project”, which is additional to the everyday work, then lean ideas do not work. Philosophical aspect of lean is giving an idea that each company might have its own understanding of lean, or, we could say, their own lean philosophy. Indeed, Toyota went this path by describing Toyota philosophy in the form of lean house[47]. Lean house shows how the particular company understands lean philosophy ([47],[61]). TPS house incorporates four basement blocks, or the foundation for the TPS: Toyota Way philosophy, Visual Management, Stable and Standardized Processes and Leveled Production. Next part of the Toyota house is two main pillars – Just-In-Time and Jidoka (In-station quality), or it is also called as right quality from the first time. Those pillars show very clearly why Toyota way achieves their goals, which are the roof of the house. Best Quality, Lowest Cost, Shortest Lead Time, Best Safety and High Morale are achieved do the focus to on time delivery and best quality, which as a result allow to shorter production time by eliminating the waste. Another good example of the similar lean house is the house of Scania Production System (SPS). Scania has its own vision and understanding of lean philosophy and this particular understanding is expressed in the form of SPS house.Exampled houses of lean are nothing else than companies approaches to their daily operations based on long-term thinking which is expressed by lean house. Changing the approach to the operations means changing the company’s manufacturing paradigm[64] and many authors see lean as new manufacturing paradigm. For example, James-Moore and Gibbons[39] and Cooney[18] discuss the relevance of lean manufacturing for all types of manufacturing. Harrison [33] and Drickhamer[25] study the concept of world class manufacturing, its meaning and implication to manufacturing strategy development. Finally, Papadopoulou and Özbayrak[58] and Drucker[26] find that all new manufacturing paradigms and systems, developed after lean, are always assessed towards lean. Also, their findings include interesting facts: despite on high interest toward lean topic the literature failed to follow the development of lean and therefore the big part of literature relies on antiquated view of lean.As was mentioned previously, lean house is an interpretation of the lean theory for the current company in the form of values, principles and tools. Lean house means that the company is rethinking lean principles through the company activities prism and decides in which way and how they will implement lean[61]. Lean house is the basis for the whole lean process and if it is missing, then the lean implementation process will not be continuous and sustainable in the long term ([61],[47],[64],[75]). Logically, a new form of lean knowledge should be spread around the company by the simple training of personnel. In lean house training, the company should focus on training in the way that the company understands lean[1]. As soon as lean house is created and communicated to the company, a lean implementation plan should be developed and executed. Without a long-term plan and its step-by-step execution, the whole lean implementation idea becomes a short project and it is inspired by momentary emotions[64]. As a result, nothing is achieved and the company is not changing its nature towards being lean ([4],[5],[14],[65]). Lean implementation could not be the project. Otherwise, the ultimate goal of continuous improvement will never be achieved – projects have their starts and ends; continuous improvement is endless ([54], [47] and others). The execution of plans constitutes a vital element for the success of the process ([34],[64]). The intended result of the discussed steps is successful lean thinking implementation.Finally, to close the loop, the continuous improvement (CI) step should be presented. CI shows a company’s ability to endlessly analyze processes in order to search for new wastes – since there is no ideal process due to continuous changes in the people, company, technology, world and so on, one can find wastes again and again. In Japanese, it is called kaizen. The tool or formal structure used for kaizen in manufacturing companies is called PDCA –Plan-Do-Check-Act – circle, also known as Deming cycle ([34],[47],[64] 2004 and others). PDCA is a simple framework for planning improvement activities in a continuous manner, not dependent on what kind of activity is being executed[63]. It could be the implementing of 5S ideas (the principle of creation of efficient and well organized workplace), or solving a practical problem of too high a scrap amount, or improving space usage in a particular production group and so on. Also, within each of the steps, different tools such as Value Stream Mapping (VSM) could be used. For example, if the target is to improve the space utilization and time, the VSM could be used as the focus of the circle.In addition to 5Why?, the technique of CI (to determine root cause, it is proposed to ask at least five ‘why’ questions after each answer) is used to find out the problem’s root cause and eliminate the problem. Companies often deal not with the root cause of the problem but with the consequences of the problem and eliminate those ([20],[43],[45]). As a result, it looks like a problem is solved now, but it is solved only for now – it could be repeated again and again since the root cause has not been eliminated ([51]). The summary of identified steps of lean thinking implementation framework is presented in (Figure 1).Hines et al.[37] says that lean paradigm was consequently focusing on topics arising in the field of operations management and, as it was already mentioned, moving from lean production status (improvement activities on shop-floor) through lean supply chain into lean thinking (system level). Despite on this major part of the companies, which are implementing lean thinking, are stuck in purely manufacturing process improvement part and forget about the philosophy. This may lead to the fail of lean implementation ([47],[75]). Every company has to have clear vision and target about lean implementation process. In other words they have to answer the question “Why are we doing this?” Thus, a systematic approach needs to be adopted, which optimizes systems as a whole, focusing the right strategies in the correct places.”[60].

| Figure 1. Lean implementation process |

4. Analysis of Scania Production System

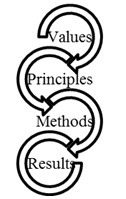

- Scania was founded in 1891 and since then has produced more than 1.4 million buses and trucks around the world. At present, Scania operates in more than 100 countries and has 32,000 employees. Scania has three core values, which are maintained in all activities: customer first, respect for the individual and quality.Scania’s objective is to deliver optimized heavy trucks and buses, engines and services, provide the best total operating economy for our customers, and thereby be the leading company in our industry. The foundation is core values together with a focus on methods and the dedicated people of Scania.(http://www.scania.com/scania-group/scania-in-brief/).Scania is focused on continuous improvement in order to maintain strong, sustainable and efficient production. This is achieved via developed Scania Production System. SPS has been developed in-house by the company’s employees based on the Toyota Production System. SPS together with Scania Retail System (SRS) are the parts of the philosophy at Scania – to focus on methods rather than results, and results will come as a consequence of doing right things right. There are three main values that are the foundations of the whole Scania Production System. All three values are equally important and are the foundation for everybody’s work in Scania. They are: Customer first – the customer is in focus during the work and when decisions are made. As says one of the workers, “the customer first means that we make sure we deliver with the right quality at the right time. The immediate customer to whom we deliver is the next link in the production chain. Scania’s final customer is our joint customer.” Respect for the individual – everybody is respected by managers and colleagues and can have an influence. Everyone has the opportunity for development based on personal preconditions. Elimination of waste – competitiveness is strengthened by the elimination of waste.The principles of SPS help to make decisions and provide guidance on how employees should think in order to achieve the goals of efficient and sustainable production. SPS has four main principles: normal situation – standardised working method, right from me, consumption controlled production and continuous improvement. Standardised working methods come from TPS and were discussed earlier in the paper. This method is also described in SPS house by smaller blocks:Standardisation – create standards on manual work; Tact – define customer need; Levelled flow – even out the production volumes and distribute labour-intensive units across the working day; Balanced flow – as far as possible the work is uniformly distributed between those resources that will be doing the work; Visual – where we are in relation to the normal situation; Real time – react and act here and now.Right from me is another interpretation of Toyota’s jidoka principle – right quality from the first time. In Scania, right from me means that nobody accepts, provides or passes on a deviation to the customer. Each next step is regarded as a customer. If the problem occurs, then everybody is required to stop production, give quick feedback about the problems and deal with the problems.Consumption controlled production is kanban– eliminating overproduction and starting things only when the customer (next step or final customer) gives a signal for need. Continuous improvement, as in lean thinking, is the head of everything and the ultimate target – constantly and continuously to examine the way the company works in order to define places for improvement via waste elimination.In the center of SPS house, one can find priorities – everybody has the same priorities in order to make right decisions quickly. Priorities are: 1. Safety/Environment; 2. Quality; 3. Delivery; 4. Cost. Scania sees the priorities as a compulsory menu. Which is: priority is safety at the same time as right quality, correct delivery and competitive cost. But the order of the priorities comes into play as well – when one should prioritise abnormalities over each other. Finally, we come to the practical application of the SPS. The general model of day to day working with the main parts of SPS is presented in Figure. SPS says that the company shares certain perceptions (values), agrees on basic ideas on how the work should be conducted (principles), therefore acting in a uniform way (methods) and achieving results.

| Figure 2. Practical application of SPS (SPS booklet, 20 March 2007 version 2) |

5. Research Result and Discussion

- Previous parts of the paper have discussed the problem of lean thinking implementation framework, then required steps in lean thinking implementation were identified through comprehensive literature study and at last Scania production system approach were under the loop. The final part of the paper is focusing on answering the question: is lean the universal approach or not?In general, the answer to the stated questions is that lean is universal approach, but universality of lean is limited by the general lean implementation framework. In other words, the process identified in part 4 is universal, though, if to dig into details of each step, the different companies could have specific needs or approaches of lean tools. Table 4 is comparing literature study based lean thinking implementation approach with Scania approach and indicates the possibility of using the same step in any other company (non-manufacturing companies and low volume-high mix manufacturing companies). The following discussion is explaining the Table 4.

|

6. Conclusions

- Proposed empirical model of lean thinking implementation process embody the start point - good process quality, and five steps: lean knowledge acquisition, lean house development, lean house communication and training, lean implementation planning and execution of lean thinking implementation plan. The argumentation hereinabove has indicated that proposed model of lean thinking implementation process is valid and could be used by companies first to analyze their current status of processes and second for constructing their lean implementation process and incorporating understanding of lean. Thus, the initial proposal is partly true – lean thinking implementation general framework is a universal approach, but detailed application of tools and principles could be different from company to company and from area to area. It has to be also mentioned that statement brought above is valid in terms of current research focus. Should the focus of the research be in more detailed investigation of lean thinking implementation of the companies, then the result would be different. More detailed means understanding how one or another practical tool or method of lean could be and are implemented in the companies of different field. Nevertheless, performed research is one more step in finding the final truth about universality of lean and there are still many of aspect to investigate.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML