Santi Setyaningsih , Mursyid Hasan Basri

School of Business Management, Institut Teknologi Bandung, Bandung, 40132, Indonesia

Correspondence to: Santi Setyaningsih , School of Business Management, Institut Teknologi Bandung, Bandung, 40132, Indonesia.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

Abstract

Hospital is one of the public facilities that can support human health. Hospital quality system is the main thing to consider in order providing satisfaction to the customers, especially in terms of logistics, not only medicine but also foods which always have a direct contact with the patients. Inventory management system in supply chain management is one factor to control the quality of the food. This research aim is to select the appropriate method in demand forecasting to determine the number of products purchased for use and stored in the warehouse. The results showed the nutrition installation department should use simple exponential smoothing (SES) method for Anlene, Ensure FOS, Hepatosol and Peptamen product, while the product Pediasure and Neosure should use the moving average method, because the error was less significant and the method was really fit, according to product demand compared to the other forecasting methods. This research is not only using time series for demand forecasting, but also tries to apply the calculation of average inventory value. It uses for inventory management system to improve the warehouse system of nutrition installation department effectively and efficiently. The calculation is using periodic review method, yielding an average inventory value is much smaller than the current situation.

Keywords:

Forecasting, Enteral, Formula Food, Public Hospital, Inventory Management

Cite this paper: Santi Setyaningsih , Mursyid Hasan Basri , The Evaluation of Forecasting Method for Enteral and Formula Food Supply to Support Inventory Management System Hospital, Management, Vol. 3 No. 2, 2013, pp. 121-127. doi: 10.5923/j.mm.20130302.09.

1. Introduction

Inventory is one factor in SCM and Inventory system is one aspect that is very important for small business owners. This is because most of the business activities related to the storage of products from raw materials to finished goods. Each item represents a certain amount of money stock and the stock is bound to leave the company as a product that was purchased by the customer[1]. Food is one of the products that must be maintained about the freshness in inventory system for sale to the customers. Supply chain of perishable products is generally referred to as “cold chain”. Any disruption in that product such as time, distance and temperature in the supply chain and also the inventory management can inhibit the value added of cold chain[2].This study aim is to provide the information about the problems of inventory management system that occurs in enteral and formulas food supply (BMF&E) in one of the public hospital in Bandung city. It is also expected to provide input on appropriate forecasting method and provide feedback for improvement of the problem in inventory management system BMF&E.Research of demand forecasting system foodstuffs BMF&E at this hospital is one kind of new research in health management. It is expected that the research will contribute on the improvements to the method of forecasting the BMF&E which is expected to stabilize the stock of goods in warehouses so it will not happen the overstock or under stock situation and also the development of operation in BMF&E inventory management system so that the system will increasing stability on demand forecasting if there is an uncertain demand.There are several limitation in this study such as the focus just on nutrition installation department which has 4 types of foods and this study is just only observed six products which considered important to the BMF&E inventory management system. This study does not take into account the provision of food at Parahyangan Building in this public Bandung Hospital because the provision of food in the building was done by outsourcing.

2. Literature Review

The following parts are some of the literature that supports this research which consists of inventory management systems, demand forecasting and hospital food as one of the perishable product.

2.1. Inventory Management

Inventory management is a small part in the Supply Chain Management which is contain in internal company. A system of inventory resulting from the possibility of purchasing a product or system to produce large-scale supply chain systems that can lower operating costs[3]. In the other sense, inventory refers to stock that is required in doing business. Good stock management will maximize the profits of a business. Failure to control the inventory will result in a loss to the company[1].Based Hedrick, et al. (2012), there are some aspects of a successful inventory management. Many companies that failed due to lack of detail in recording inventory costs, including direct costs of storage, insurance and taxes and the cost of money tied up in inventory. In the present study, we will clarify some of the studies conducted both in the inventory of products, both in manufacturing products or services. The end goal is to see how it performed on the inventory. Other aspects of success include:● Maintain many stocks ● Increase the turnover of inventory ● While maintaining the stock with a low value ● Obtain lower prices of goods with a certain volume ● Have an adequate amount of suppliesA good inventory system needs to be able to keep perishable products as needed so as to minimize the time the warranty expires[4]. Many companies are not able to do, so it will result in increased costs and wastage is quite high. Inventory management challenges in one of which is to store perishable products, the fear of running out of product or products that accumulate too much and it will expire and will increase the cost.

2.2. Demand Forecasting

Forecasting is an attempt to predict the future. Demand forecasts form the basis of the overall supply chain planning. There are some characteristics of forecasting that companies should be aware of[3], those are:1. Forecast is not always accurate and thus should include the expected value of the estimate and the size of the forecast errors.2. Long-term forecasts are usually less accurate than short-term forecast because the long term forecast has a larger standard deviation of the error relative to the average than the short-term forecast.3. Aggregate forecast is usually more accurate than disaggregate forecast, because they tend to have a smaller standard deviation of the error relative to the mean4. Further and further up the supply chain of the company, the greater of distortion of the information it receives.Food services in hospitals or commonly known as a nutrition installation hospital in general have a tight budget. Thus, the need of forecasting for food is very important in their activities. Research from Chandler, Norton, Hoover, and Moore[5] explains that the simple exponential smoothing forecasting method and the simple moving average is the most practical method to produce a reliable forecasting. The other study by Miller and Shanklin[6] evaluate the status of the production menu item forecasting in healthcare foodservice operations. They found that hospital mostly using naive method rather than mathematical methods. The employee has acknowledged that mathematical forecasting is important and the implications of educational development of teaching materials should be implemented.Research by Veiga, et al.[7] conducted a study on the ex-post facto by using 2004-2008 data and choosing the appropriate method for each product group that could affect the company's profit. Comparing methods of quantitative time series which consist of 4 methods, such as simple exponential smoothing, holt's model, winter's models, and ARIMA models. Each product has a different match on forecasting method used.

2.3. Hospital Food as Perishable Product

Hospital food is very closely linked with the service provided by the hospital. Service includes the provision of food choices for all patients who are prepared to secure a balanced nutrition, of course, with the fulfilment of hygiene and access 24 hours a day. Important factor for hospital food is the nutritional adequacy of inpatients, high-quality food supply, provision of adequate services for patients, staff and visitors are served at the proper temperature and satisfactory quality[8].Hospital food is currently divided into the two options which is done by catering or arranged by the hospital itself. If the system was done by catering, the problem that often arise health policy[9] and if it done by the hospital itself, the problem that often arises is the point of sale and managing the product. Those are 4 factors that important for the point of sale, include increase throughput and revenue, employee badge scanning with payroll deduction capabilities, enhance employee and guest convenience and make menu changes a breeze[10].Based on the research which conducted by Silverman, et al.[11], they said that the hospital food service environment has changed. It would draw more revenue in the future by serving meals to fewer inpatients, employ fewer staff and reduced budget. However this is not approved because it will impact on customer satisfaction that will affect the reputation of the hospital itself.

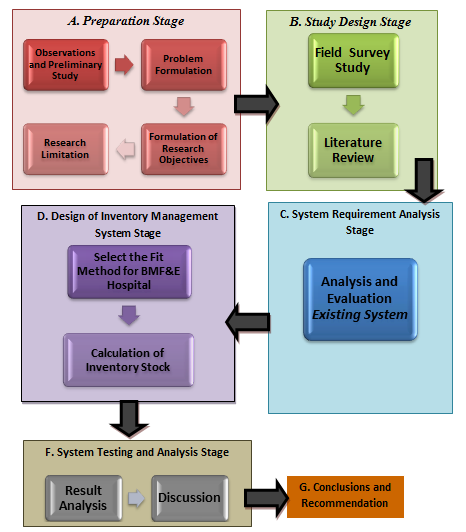

3. Research Methodology

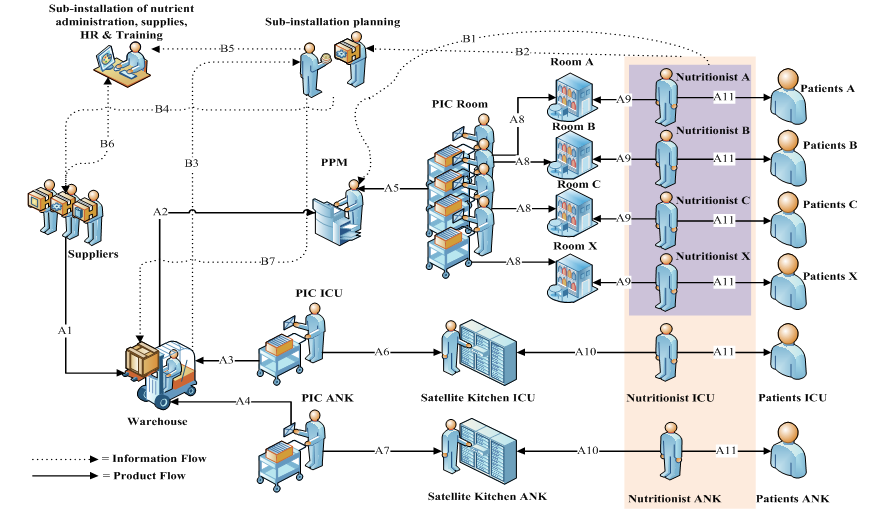

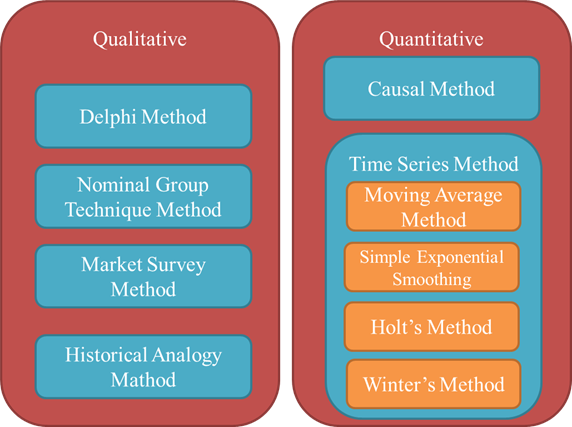

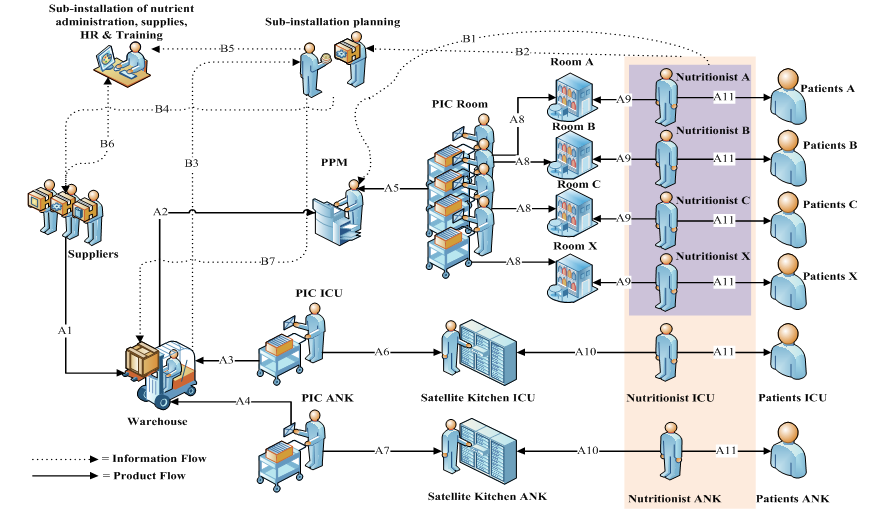

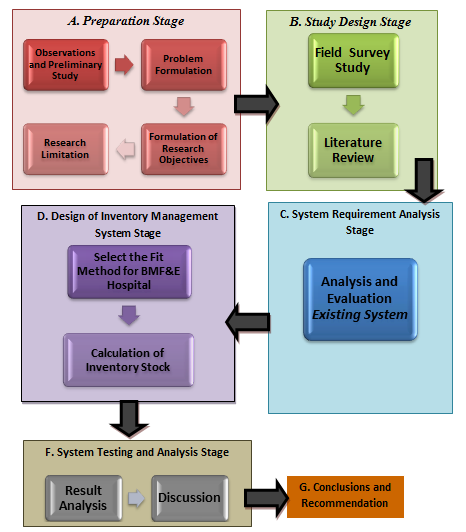

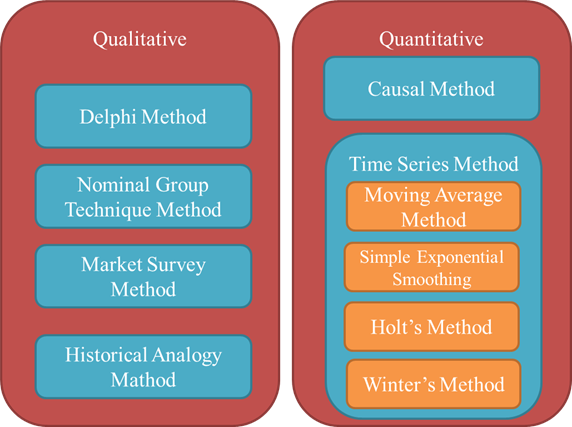

This research was using a set of data which collected in 2009-2012. Research methods which used in this study use field survey research to the one of the public Bandung hospital, as a government’s hospital. Field surveys conducted research in order to avoid manipulation or make changes to the data and problems that occur on the subject of research. Field experimental research was carried out in an area where the work takes place, but can applied to one or more groups[12]. This chapter contains of the research methods to answer the objectives and research questions. There are six stages in the conceptual framework of this research which shown at the image.Based on that flow of the research, figure 2 describes the BMF&E procurement mechanisms that will affect the inventory in the warehouse nutrition installation. This mechanism connecting four areas of work in the company internally, such as Sub-installation planning, sub-installation administration, supplies, HR & training, warehouse and also every room that needs BMF&E as consumption. These activities are the responsibility and authority of the nutrition installation. It can be seen in the picture that between one part and the other part inside of this department give each other important information. If one party does not exist, then the activities of the business process will not be balanced.This section objective is to choose the most suitable method for the data demand of BMF&E hospital, because it has certain characteristics, such as the need of these product was so rapid, demand was unstable and there was a special warehouse adjacent to the patient which makes forecasting for the product will be different from other food products. Forecasting methods are grouped into two main groups, those are qualitative methods and quantitative methods. Selection methods will refer to these methods.Quantitative forecasts typically use mathematical models and historical data or causal variables to forecast future demand. While Qualitative forecast in general combine intuition of the practitioners, emotions, personal experiences and value systems in predicting future needs. To get more accurate results, there are more research refers to the use of quantitative forecasts, because qualitative forecast would be better used if there are less historical data and the company cannot use complex mathematical models[13]. Based on the explanation of Veiga, et al.[7] said that it is better to use a quantitative method to forecast in the food industry.Causal forecasting method assumes that the demand forecasts are highly correlated with certain factors in the environment[3]. This method is most often used because the person in charge usually has a limited mathematical skill. According to Hanke, Winchern and Reitsch[14], a simple causal forecast methods was inexpensive, easy to implement, and easy to understand. Meanwhile, the disadvantage is that they do not consider any causal relationships that may underlie the forecasted variable[15]. Time series methods are statistical methods that use historical data with the assumption that the historical patterns will repeat themselves in the future. It will contain a level, a trend and a seasonal factor. In contrast to the causal method, this method will take into account more variables involved in the forecast[3]. Thus, this method has the accuracy of perceived close to the actual data. In the time series forecasting method, there are several methods, so that the appropriate method to forecast the demand of BMF&E depends on the methods that have less error results with the actual data. | Figure 1. Research Methodology |

| Figure 2. Product and Information Flow |

| Figure 3. Forecast Method |

4. Data Calculation

4.1. Demand Time Series Forecasting Enteral and Formula Food Supply (BMF&E)

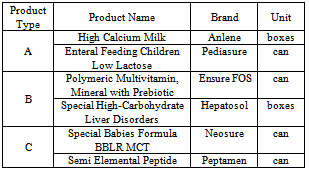

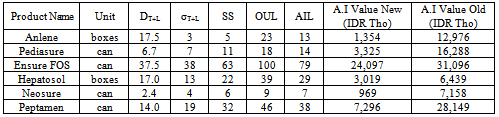

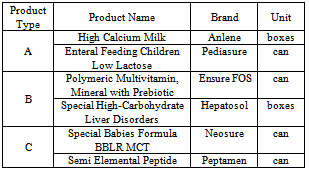

Based on the analysis conducted to the data in 2012, there are 6 pieces of products which categorized in three types of inventory and usage. Type A product is a product with high usage and high inventory, type B is a product with medium usage and inventory and type C is a product with low usage and high inventory. The third type has a high cost inventory. The six products are:Table 1. BMF&E Under Study

|

| |

|

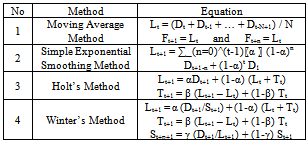

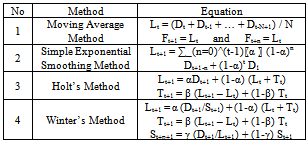

Research conducted on four methods of time series forecasting by using the following formula:Table 2. Equation of Time Series Forecasting Method

|

| |

|

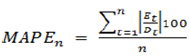

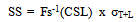

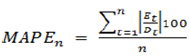

This is the definition of a few terms:Lt = Estimate of level at the end of Period tTt = Estimate of trend at the end of Period tSt = Estimate of seasonal at the end of Period tFt = Forecast of demand for Period t (made in Period t-1 or earlier)Dt = Actual demand observed in Period tα = Smoothing constant for the level, 0<α<1β = Smoothing constant for the trend, 0<β<1γ = Smoothing constant for the seasonal, 0<γ<1Et = Error forecast in Period tTo perform the calculation of the forecast error made by using mean absolute percentage error (MAPE) with the formula: | (1) |

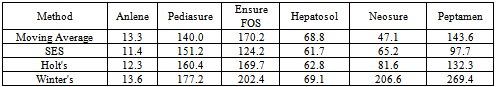

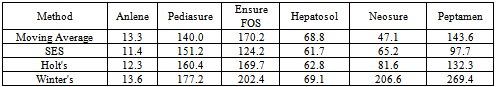

Based on calculations for the six product BMF&E using 2009-2010 data and made forecast for 2011-2012, the table below was the result of forecast error value when compared one method with other methods for time series method.Table 3. MAPE Result Forecasting Method

|

| |

|

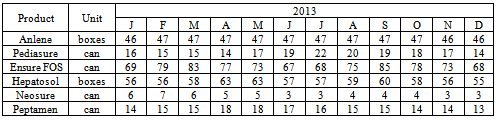

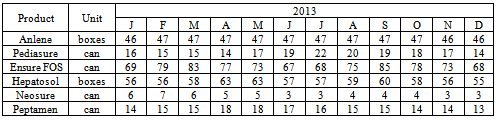

Table 4. 2013 Forecasting

|

| |

|

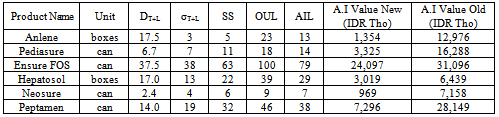

Table 5. Proposed Method Inventory Management System

|

| |

|

From the results, there are 2 products that better use of moving average method forecast, those are Pediasure and Neosure. The other products better to use simple exponential smoothing method (SES). Those products are Anlene, Ensure FOS, Hepatosol and Peptamen product. Then it conducted the demand forecast for 2013 by using appropriate methods for each product.

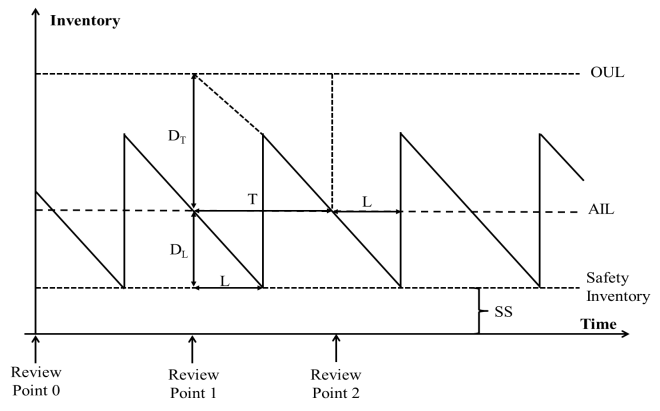

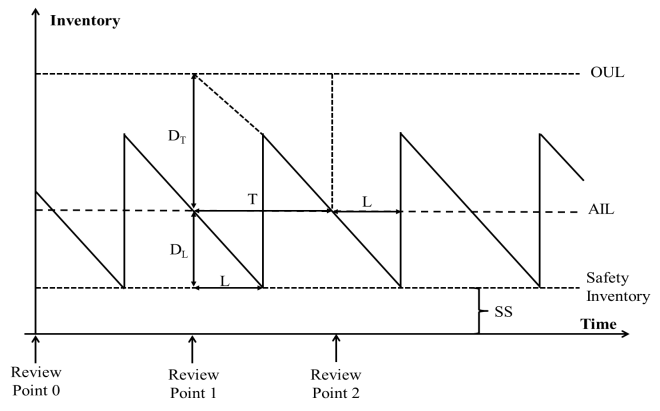

4.2. Inventory Management System

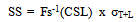

There was an absence of inventory management system which applied in the warehouse of nutrition installation department of public Bandung Hospital. Thus, this research proposed strategy of average inventory level at the warehouse BMF&E using periodic review policies. The formula of inventory management system that used was: | (2) |

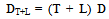

| (3) |

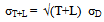

| (4) |

| (5) |

| (6) |

This is the definition of a few terms:SS = safety stockCSL = cycle service levelFs-1 = normsinvσT+L = standard deviation of demand during T+LT = review intervalL = lead timeD = average demand per periodσD = standard deviation of demand per periodDT+L = mean demand during T+LOUL = order up to levelAIL = average inventory levelThe results of the calculation for proposed basic method of inventory management system using periodic review BMF&E products are as follows:Based on the results of the calculation of demand forecasting and inventory management system, it can provide an overview on nutrition installation department to keep maintain inventory in the main warehouse at the point of OUL and purchase of goods in accordance with the 2013 demand forecast which has been done.

5. Data Analysis and Discussion

5.1. Demand Forecasting Analysis

Forecasting which already done in this public Bandung hospital initially relied on estimation from nutritionist in each room, using naïve method. They refer to the usage in the prior period to the future demand periods. Sub installation planning that has the responsibility to make a forecast of the demand future of any product, rely on the calculations performed by nutritionist. Through this research, it will give the suggestion that sub-installation can do the forecasting without waiting for the estimation of the nutritionist. That data can be used as an additional data and references to order the product to the suppliers.Forecasting of data in the business world generally uses historical data to predict future market behaviour. Time series method is one of the forecasting methods that used historical data. In contrast to the other methods, time series method more clearly and predictable in its calculation and also easy to predict the error rate calculation. This research did calculation to the historical data to see about which method was suitable to use on BMF&E products. So it can be analysed more about precise method that can be used for a particular product. This study also proves the previous research from Chandler, Norton, Hoover, and Moore (1982) in Ryu (2002) that using simple exponential smoothing or moving average method was generally fits for healthcare food products in forecasting system. It can be seen in this study that the calculation of error in MAPE for that method was smaller than the other methods and it means that the error value using those method are better than the other methods.

5.2. Inventory Management System Analysis

Existing method of inventory management system at this public Bandung hospital did not use any particular calculation, only reached the stage of fulfilment of demand without seeing the other side of the inventory management system such as warehouse capacity, safety stock of each product, and others. In this research presented some basic calculations of the factors that affect the inventory of BMF&E.These data were considered important to be owned by nutrition installation department because it can solve the problems that occur, the problems which occurring today is the products that had expired on a large scale. It is not only damaging in terms of financial but also show them the less organized planning of inventory management system. In addition, by using the proposed method's inventory management system, it would give the expected positive impact so that nutrition installation department can keep the capacity of warehouse, may reduce the value of inventory cost, reduce the amount of inventory that can decrease the level of expired products and also to improve the performance of this department itself. This proposed method was still referring to the periodic review which they already did without calculation of inventory management system.Calculations performed in this study will have the result in an inventory profile with safety stock in accordance with the figure 4 for each product. It can be used as a reference for nutrition installation department to implement it for other BMF&E products in their warehouse. Apart from calculating inventory system and demand forecast, there are some inputs to the recording system of the product. It can be seen in the existing system that all records done manually by each party such as the satellite kitchen, warehouse and PPM. With a manual recording, there will be a probability of recording errors data and data discrepancies between one party and the other party and also it will be possible to not carrying very large data. So it will be better to record it using computer system. The goals are to control the inventory management system, neatness the records, traceability and it would be easy to clarify the errors. Other problems arise from the different records between the warehouse and the PPM. It is better to do data binding between the PPM and the warehouse so that the data given in the sub-installation planning will become more clear and organized. This suggestion need to explore and analyse more in the future research to improve the performance of nutrition installation department. | Figure 4. Inventory Profile with Safety Stock using Periodic Review |

6. Conclusions

Based on the problem of nutrition installation department on BMF&E which is about the large scale of products that had expired, it impacts to the financial loss and ineffectiveness of the inventory management system that become the reason of this study. This research provides advice to the hospital to perform time series forecasting demand on products that have a high level of inventory as well as having a high inventory cost. The result showed that Pediasure and Neosure were better to use moving average method and Anlene, Hepatosol, Ensure FOS and Peptamen better using Simple Exponential Smoothing to demand forecasting. Beside of demand forecasting, then it was also suggested that using basic mathematical calculations in managing inventory management systems such as calculating order up to level, safety stock in order to minimize the losses that have occurred. The result showed about savings in inventory cost of each product. Savings of average inventory value proposed method on Anlene is 90%, Pediasure 80%, Ensure FOS 23%, Hepatosol 53%, Neosure 86% and Peptamen 74%. For the further analysis is still required to design this system such as make a simulations of inventory management system using such variables that match to the characteristics of BMF&E products, try to use different method of review and change the number of period time. Thus, the better method of inventory management system can be implemented to the BMF&E products of nutrition installation public Bandung hospital and it supposed to make the performance of the department more effective and efficient.

References

| [1] | Hedrick, F.D, et al., “Inventory Management”, Purchasing for Owners of Small Plants, Buying for Retail Stores and Inventory Management, 2012. |

| [2] | Joshi, R., et al., “Indian Cold Chain: Modeling the Inhibitors” British Food Journal, Vol. 111 No. 11, p. 1260-1283, 2009. |

| [3] | Chopra, S. and Meindl, P., “Supply Chain Management Strategy, Planning and Operation”, Pearson, 4th Ed, 2010. |

| [4] | Stanger, S.H.W., et al., “What Drives Perishable Inventory Management Performance? Lessons Learnt from the UK Blood Supply Chain”, Supply Chain Management: An International Journal, p.107–123, 2012. |

| [5] | Chandler, S.J., Norton, L.C., Hoover, D.W., Moore, A.N., “Analysis of Meal Patterns for Forecasting Menu Item Demand”, Hospitality Foodservice Management, 80, pp. 317-323., 1982. |

| [6] | Miller, J.L. and Shanklin, C.W., “Forecasting Menu-Item Demand in Foodservice Operations”, Journal of the American Dietetic Association, 88(4), pp. 443-449, 1988. |

| [7] | Veiga, C.R.P, et al., “The Accuracy of Demand Forecast Models as a Critical Factor in the Financial Performance of the Food Industry”, Future Studies Research Journal: Trends and Strategies, San Paulo, v.2, n.2, pp. 81-104, 2000. |

| [8] | Online available:http://www.nbt.nhs.uk/sites/default/files/filedepot/incoming/Hospital%20Food.pdf |

| [9] | Baum, T., “Food or facilities? The changing role of catering managers in the healthcare environment”, Nutrition & Food Science, Vol. 36 Iss: 3, pp.138 – 152, 2006. |

| [10] | Online available:http://www.arbapro.com/PDF/HOSPITAL%20FOOD%20SERVICES%20BOOKLET.PDF |

| [11] | Silverman, M.R., et al., “Current and Future Practices in Hospital Foodservice”, Journal of the Academy of Nutrition and Dietetics, ProQuest Agriculture Journals, No. 100, 1 pp. 76, 2000. |

| [12] | Sekaran, U. and Bougie,R, “Research Methods for Business. A Skill Building Approach”, 5th edition, 2010. |

| [13] | Ryu, K., “The Evaluation of Forecasting Methods at an Institutional Foodservice Dining Facility”, Texas Technique University, Master of Science Thesis, Texas, 2002. |

| [14] | Hanke, J.E., Wichern, D.W, Reitsch, A.G., “Business Forecasting”, 7th Ed, Upper Saddle River, NJ: Prentice Hall, 2001. |

| [15] | Shim, J.K., “Strategic Business Forecasting”, Boca Raton, FL: St. Lucie Press, 2000. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML