-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Management

p-ISSN: 2162-9374 e-ISSN: 2162-8416

2012; 2(5): 232-250

doi: 10.5923/j.mm.20120205.12

Lean Problem: Why Conpanies Fail with Lean Implementation?

Aleksandr Miina

Tallinn School of Economics and Business Administration, Tallinn University of Technology, Talinn,12618, Estonia

Correspondence to: Aleksandr Miina , Tallinn School of Economics and Business Administration, Tallinn University of Technology, Talinn,12618, Estonia.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

Lean thinking approach was reported in many papers to be very efficient and straightforward way towards process improvements in terms of productivity and value adding activities ratio. On other hand, it was also discovered that the system which is working very well in Toyota might not give similar effective results in other companies. Many manufacturers have failed in achieving success of lean thinking implementation. Current study is seeking the reasons of failures in lean thinking implementation. One of the proposals is that companies have to interpret their lean knowledge into own vision in form of lean house. Such proposal is derived from example of Scania, which is one of the best examples of lean thinking implementation outside the Toyota corporation. Study results indicate that success or failure of lean initiatives strongly depends on companies approach to it and on whether company has created they own philosophy towards lean – lean house.

Keywords: Lean Thinking, Lean House, Success of Lean Thinking

Cite this paper: Aleksandr Miina , "Lean Problem: Why Conpanies Fail with Lean Implementation?", Management, Vol. 2 No. 5, 2012, pp. 232-250. doi: 10.5923/j.mm.20120205.12.

Article Outline

1. Introduction

- Studies of lean thinking phenomena have indicated the difficult and intricate nature of it. The ideas of lean were studied extensively for more than 30 years, but there are still a lot of difficult and unclear aspects to understand. Several problems regarding lean implementation process in manufacturing companies are identified in literature: about 10 per cent or less of companies succeeds at implementing lean manufacturing practices[7]; “only 10 per cent has the philosophy properly instituted”[46]; new paradigms and best practices are often taken as a “black box”, which has many dangers inside[55]; if companies use lean initiatives almost as a fad, most of their effort will fail to produce significant results[44]; finally, there are evidence that “no standard framework for lean or its implementation exists. A systematic approach needs to be adopted, which optimizes systems as a whole, focusing the right strategies in the correct places.”[42].Based on above on of the problems of the lean implementation could be formulated as weak understanding of lean thinking philosophy of manufacturing companies and as a result fail of lean thinking implementation in manufacturing companies.Lean thinking (often expressed as just “lean” of “lean concept”) is defined as the systematic elimination of waste [45]. Ohno[37] saw lean as a time line, where company must look to it from the moment the customer gives it an order to the point when company collects the cash. Additionally, Womack et al.[53] define lean as shortening lead time by eliminating waste in each step of a manufacturing process what in turn leads to best quality and lowest cost, while improving safety and morale. And finally, Liker[32] writes that company must see the value from customer perspective, remove then all unnecessary activities and then make process better and better, producing as much as customer wants, no more or less. Under the waste lean understands everything which does not contribute to the final product or service value and value is regarded from customer’s point of view. Customer value is all activities during the manufacturing of products, which are paid by the customer[53]. In academic literature lean thinking is regarded as cost reduction and productivity improvement technique worldwide ([1-4],[8-9],[52-53]), new efficient paradigm for the operations ([29],[51]), many companies use lean principles in developing their corporate strategies[54] and as a result it could be used as a powerful weapon in more globally competing world[48]. To conclude, lean thinking could be defined as philosophy of manufacturing process organisation and management, which incorporates a set of tools and methods for waste elimination with the focus on people development and continuous improvement.The roots of lean thinking lie in Toyota Production System (TPS) – the system of organising production processes in efficient and effective manner which is used in Toyota Motor Corporation. Development of the system started from the end of nineteenth century at the time when Toyoda family (the owner of Toyota company) owned Toyoda Automatic Loom Works company. System development continued in twentieth after starting Toyota Motor Corporation. Focused development of TPS started after Second World War and as a result bringing Toyota to the top of automotive industry. After discovering the TPS and introducing the term lean in the famous bestseller “Machine that changed the world”, the idea spread all around the world very fast, starting from automotive industry first and then entering all other industries and sectors (services, healthcare, construction, public services)[45].Though lean seemed to work very well in Toyota factories, companies outside of Toyota were not able to achieve the same results. Lean was developed in Toyota and thus is natural thing for Toyota. Other companies had to find their personal way to implement those ideas in a successful manner and it turned out to be very complicated. Since then lean topic was studied very widely and different aspects of lean implementation were investigated, though still there is no standard framework or roadmap of successful lean implementation ([26],[42],[44]). One of good examples of creating clear targets of lean thinking implementation is Scaniacompany with its Scania Production System (SPS). Scania is known as one of the best examples of lean implementation outside Toyota corporation. Scania is focused on continuous improvement in order to maintain strong, sustainable and efficient production. This is achieved via developed Scania Production System. SPS is developed in-house by company’s employees based on Toyota Production System. SPS together with Scania Retail System (SRS) are the parts of philosophy at Scania – to focus on methods rather than results and results will come as a consequence of doing right things right. Scania started to develop and implement new approach to the trucks and bus production in mid 1990s and still continues this way. This what Scania says in its webpage: “In the early 1990s, when Scania had exhausted traditional production and management methods, it sent a team to the Toyota car company in Japan to study what was behind that company’s high productivity and quality.Scania engineers returned with important new knowledge that they had not been able to glean from the literature on Japanese car production methods. As it turned out, the success of the Japanese was primarily a matter of management and people rather than industrial robots. Toyota’s leadership system was based on a few clear basic values shared by all employees. The company also worked with a set of principles that the employees knew and understood.” Simply put, SPS is relying on values, principles and priorities which are expressed in the form of lean house – the same as have Toyota, though in Scania way.Author’s proposal based on above is that each manufacturing company which is implementing lean thinking ideas should first to gather as much knowledge about lean as possible and then to interpret it into own values and principles in the form of lean house – to create own lean philosophy. Thus, lean house, or company’s production system, will represent company specific way of implementing lean principles and will lead to the success of implementation. The target of current study is to identify whether indicated proposal is true or false. For purpose of that twelve manufacturing companies were investigated and they general approach towards lean thinking implementation initiative were studied. Research was done as a part of doctoral thesis which in general was focusing on development of standard framework of lean thinking implementation process and creation of lean house was regarded as central for the whole process.Main contribution of the study to the theory is identification of the importance of company’s own production system model in the form of lean house. Practice is contributed by straight direction for companies who wish or are implementing lean. Each company who is starting its lean road (or already going that road) should focus on its own production philosophy creation in the form of lean house. By this the results of lean implementation in the companies could be higher and more successful

2. Theoretical Framework

- Question of either we should view lean concept as a philosophy of doing work or not is widely studied by different authors. They give ideas that lean should be viewed more as a philosophy or condition than as a process ([5],[7],[34],[38-42]). Laureani and Antony[31] advice is to accept lean more as a state of mind or philosophy, than just a process improvement tool. Toyota Production System (TPS) did not happen overnight but through a series of innovations during 30 years[37]. Lean philosophy means that all the company lives and thinks based on the lean ideas[49]. As soon as company and its personnel takes lean as “a new innovative project”, which is additional to the everyday work, then lean ideas do not work. The lean manufacturing is philosophy because before end of 19th century craft production was the philosophy of doing work – companies and workers lived by it; then in the start of 20th century mass production became a new philosophy – companies and workers also lived by it, while, yes, craft philosophy remained in some place; and then lean ideas came out and again became the philosophy of doing work and exist in parallel with craft and mass production. Toyota success is based on its philosophy.Philosophical aspect of lean is giving an idea that each company might have its own understanding of lean, or, we could say, their own lean philosophy. Indeed, Toyota went this path by describing Toyota philosophy in the form of lean house[32]. Lean house shows how the particular company understands lean philosophy ([32],[43]). TPS house incorporates four basement blocks, or the foundation for the TPS: Toyota Way philosophy, Visual Management, Stable and Standardized Processes and Levelled Production. Next part of the Toyota house is two main pillars – Just-In-Time and Jidoka (In-station quality), or it is also called as right quality from the first time. Those pillars show very clearly why Toyota way achieves their goals, which are the roof of the house. Best Quality, Lowest Cost, Shortest Lead Time, Best Safety and High Morale are achieved do the focus to on time delivery and best quality, which as a result allow to shorter production time by eliminating the waste. Another good example of the similar lean house is the house of Scania Production System (SPS). Scania has its own vision and understanding of lean philosophy and this particular understanding is expressed in the form of SPS house.Exampled houses of lean are nothing else than companies approaches to their daily operations based on long-term thinking which is expressed by lean house. Changing the approach to the operations means changing the company’s manufacturing paradigm[45] and many authors see lean as new manufacturing paradigm. For example, James-Moore and Gibbons[27] and Cooney[10] discuss the relevance of lean manufacturing for all types of manufacturing. Harrison[21] and Drickhamer[14] study the concept of world class manufacturing, its meaning and implication to manufacturing strategy development. Finally, Papadopoulou and Özbayrak[41] and Drucker[15] find that all new manufacturing paradigms and systems, developed after lean, are always assessed towards lean. Also, they findings include interesting fact: despite on high interest toward lean topic the literature failed to follow the development of lean and therefore the big part of literature relies on antiquated view of lean.Despite on many good words said towards lean, there is still a lot questions around this topic[51]. Many authors ([32],[37],[52-53] and others) point out that implementing of lean principles have to be continuous in order to bring desired results and thus cannot be used as a fire fighting mechanism. This sets certain limitations to the process of implementation and requires step by step planned approach ([5],[34],[37-39],[48]). Additionally, some authors view lean as a philosophy ([7],[32]) and divide into two human aspect of the paradigm: culture and people development. From the cultural perspective two sides could be defined. One of the understandings is that management systems can be transferred regardless of the cultural differences: the development of the management is based on the general logic[20]. Other side is opposite: management systems are difficult to transfer aboard because the environmental context is different from one country to another and one company to another ([18],[36],[50]).Hines et al.[25] gives rather deep overview of lean paradigm development. He says that lean paradigm was consequently focusing on topics arising in the field of operations management and, as it was already mentioned, moving from lean production status (improvement activities on shop-floor) through lean supply chain into lean thinking (system level). Despite on this major part of the companies, which are implementing lean thinking, are stuck in purely manufacturing process improvement part and forget about the philosophy. This may lead to the fail of lean implementation ([32],[55]). Every company has to have clear vision and target about lean implementation process. In other words they have to answer the question “Why are we doing this?” Thus, a systematic approach needs to be adopted, which optimizes systems as a whole, focusing the right strategies in the correct places.”[42].Literature gives us different strategies of lean thinking implementation, while no research about leanimplementation results depending on used methodology was identified in literature. As example, three main references are found[13]: Lean Thinking[52], Going lean[25]and the Procedures Manual from lean Aerospace Initiative[12]. Those strategies are giving very general steps and are not pointing out the critical aspects of lean implementation process – the steps which defines the overall success of lean thinking implementation. Many authors ([32],[37][52-53], and others) point out that implementing of lean principles have to be continuous in order to bring desired results and thus cannot be used as a fire fighting mechanism. This sets certain limitations to the process of implementation and requires step by step planned approach ([6],[34],[37-39],[48]). Additionally, there are evidence that “no standard framework for lean or its implementation exists. A systematic approach needs to be adopted, which optimizes systems as a whole, focusing the right strategies in the correct places.”[42]. Also, organizations are realizing the fact that it takes more than quality, cost, and delivery commitments to ensure survival. Organizations are recognizing the need for extra efforts in terms of ability to adjust quickly and effectively to demand fluctuations as well as product diversification according to the requirement of customer[33]. Those mentioned additional efforts mean than companies have to focus on certain steps of lean implementation process more than on others. Such steps are named as critical steps or critical success factors.Achanga et al.[4]in their research investigation has brought four main key factors that are fundamental or even critical for the implementation of lean manufacturing: leadership and management, finance, skills and expertise, and culture of the organisation. Leadership stands for 50%, finance for 30%, organisation and culture for 10% and skill and expertise also for 10% of influencing the results of lean implementation. They suggest that “leadership and management commitment are the most critical ones in determining the success of a lean project. Strong leadership ethos and committed management support is the cornerstone to the success of implementing any idea within an organisation”. Output of management is correctly organised and controlled process[22]. Thus, strong management of lean implementation results in a correct and effective lean implementation process. Also other authors show that management support and commitment to problem solving are the main factors for successful lean implementation ([5],[11],[16],[23]).Oprime et al.[40]in their study bring the summary of critical success factors of continuous. This study focuses on factors themselves and do not investigate the process of lean implementation. Factors of lean implementation are divided into three groups: organisational and operational, incentive systems and support tools. The process of lean thinking implementation is left aside and only factors facilitating the process or used during the process are considered.Hilton and Sohal[24]in their investigation again relay on factors of lean itself, not on factors of process of implementation. They find that those success factors are: leadership, communication, behaviour and awareness of Six Sigma; policies, culture and organizational support and strategy; education, training and competency of the Six Sigma experts; project improvement teams and project management; and performance evaluations based on quality criteria, information systems, data and measurement.To conclude that point it is important to notice that so far studies in academic literature mostly focus either on very general lean implementation process ([12],[25],[52]) or on general organisation’s characteristics which should facilitate the process of lean implementation([4-5],[11],[16],[23],[40]). Additionally, companies are taking lean as a popular thing and do not properly study the issue. As a result, the process of lean implementation is not achieving desired results and resources are wasted for nothing.

3. Main Proposals

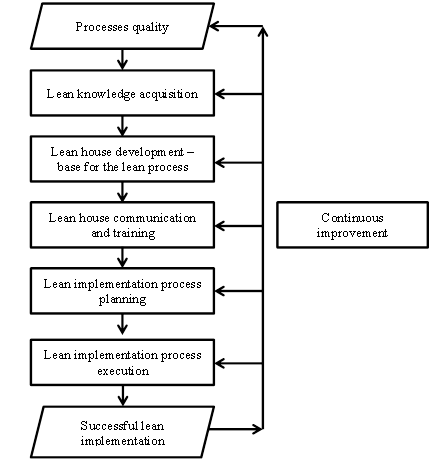

- The research is focusing on identification of importance of lean house for lean thinking implementation process in connection with the whole process of lean thinking implementation (Figure 1). Since lean house cannot be created based on empty space, certain actions have to be taken before. Also, the process of lean thinking does not stop after lean house creation. Thus, author has developed the process flow describing lean thinking implementation process and latter connection with lean house. Process consists of 5 implementation process steps (from Lean knowledge acquisition to Lean implementation process execution), start and end conditions (Process quality and Successful lean implementation respectively) and 1 step creating closed loop (Continuous improvement). Inevitably starting condition of lean implementation process is process quality - all processes in the company are under control, or, in other words, there are standardized and those standards are strictly followed. If the process is not standardized, then it is impossible to improve it. TaichiOhno said: “You have to have standards, even if they are bad standards”[37]. Additionally, as it comes from lean theory, standard processes are base for the improvements.Further, is lean knowledge acquisition step. The idea is to understand what is lean before lean implementation will start. As we have seen a lot studies show that companies do not really understand what is lean and how it could be implemented. Author’s proposal is that collecting and working through as much as possible of lean theory is essential before starting lean journey and is vital for its success.

| Figure 1. Lean implementation process |

4. Data Collection and Analysis

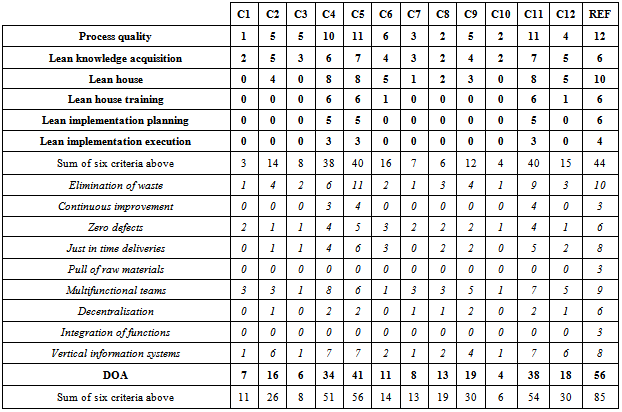

- Twelve companies from different industries and of different size were chosen for the study purposes. The selection was made based on company’s own statements about that they are implementing lean practices and principles to improve their operations, and lean is not taken as a “popular thing” in those companies. Companies selection was based on multiple case study method. Case study method was chosen due to the qualitative nature of current study. Also, case study method does not require control over the activity or process being studied and is focused on contemporary events[56]. Lean thinking implementation processes were going on in the company at the moment of study and thus were contemporary events. Author had no rights to decide what to do and how to do in the process of lean thinking implementation in the company and thus does not had control over it.Single case study requires usage of the theory; multiple case study analysis requires replication logic and benchmarking of cases from different industries[56]. Exactly the same tactics was used in current research, where companies from different industries were benchmarked against each other and findings replicated. According to the multiple case study method the sufficient number of the cases is 10[56]. To assess the companies approaches and results of lean thinking implementation, data collection step was performed. The types of data collected were text, narrative data and visual data. Assessment of the companies consisted of two main parts: assessment of lean thinking implementation process steps (proposed process described above) and results of that process – degree of adoption of lean (DOA).DOA was assessed based on the simplified model of Karlsson and Åhlström[28]. According to this model nine criteria of lean adoption are assessed:- Elimination of waste- Continuous improvement- Zero defects- Just in time deliveries- Pull of raw materials- Multifunctional teams- Decentralization- Integration of functions- Vertical information systemsEach criterion has determinants. Determinants describe the results of implementation of corresponding criterion. Determinants are assessed as 2 – implemented, 1 – partly implemented and 0 – not implemented. Those grades are not taken directly from DOA and are brought in by author. Such grades are chosen from simplicity point of view. Assessment is made by comparing the initial state before lean initiative started and the state of each area by the time of assessment. For assessment of starting point – process quality – and of five steps of empirical model author modified the same Karlsson and Åhlström[28] model by developing determinants for each path. Similar to the assessment of lean implementation results, determinants of starting point and five steps were graded from 0 to 2. The results of assessment as well as the names of determinants of each criterion are shown in Appendix 1. The summary of the results are shown in Appendix 2Collected qualitative content (text, narrative and visual) was analysed by using content analysis method. According to Neuendorf[35] “content analysis is a summarising, quantitative analysis of messages that relies on the scientific method and is not limited as to the types of variables that may be measured or the context in which the messages are created or presented”. Content analysis method could incorporate the various kinds of analysis where communication content is categorised and further classified[30] and is a systematic, replicable technique for compressing many words of text into fewer content categories based on explicit rules of coding”[47].Data analysis in current thesis used emergent coding approach with application of recording units. In emergent coding categories are established following some preliminary examination of the data: material is reviewed and a set of features in the form of checklist is created, further applied for coding[19]. Recording units are defined syntactically, that is, to use the separations created by the author, such as words, sentences, or paragraphs[47]. Additionally, the question of validity is very important. As such, validation of the inferences made on the basis of data from one analytic approach demands the use of multiple sources of information. Meaning, the researcher should try to have some sort of validation study built into the design, for example in the form of triangulation, which is often used in qualitative research. By triangulation the credibility of the findings could be achieved by incorporating multiple sources of data[17]. In current research three main types of data were used.Based on the content analysis method, the data was naturally categorised based on criteria from Karlsson and Åhlström[28] model and furthermore subcategorised into categories derived from determinants of each criterion. Next, subcategorised data were analysed and concentrate of needed information were brought out based on data type – text (company documents), narrative (questionnaire and interviews) and visual (photos, video and field notes). Further, grades were given to the each determinant based on data availableAssessment of the companies based on the proposed model should prove or disprove the main proposal of importance of lean house for the success of lean thinking implementation process.

5. Research Result and Discussion

5.1. Process Quality

- Results of assessing the companies towards success of lean thinking implementation are presented in Appendix 1. The starting point of lean thinking implementation model – process quality – showed interesting results not only in terms of lean, but also in term of general manufacturing process management. Process quality is aspect which has to be on place in any company and despite on the fact whether this company is going to implement lean or not. Standard processes are the foundation for controlled environment in production and thus are must for any manufacturing company. In our case, 3 companies out 12 got almost maximum scores, another 4 companies got medium results (5-6 points) and others were on the lowest part of scores (1-4 points). Such result is indicating that only one fourth of companies have their manufacturing environment under control, all others have minor or major disturbances with controlling the manufacturing process, thus keeping those processes under standards. Also, those companies which are subsidiaries of foreign companies tend to have better process quality level that local owned. Especial nature of starting point allows us to say – companies without good process quality are not able to improve anything. They just have nothing to improve due to the reason that most of the processes are performed differently each time there are done. Consequently, the unified base (standard process) for improvement implementation is missing. At last, this means that companies with non-controlled manufacturing processes are not able to implement lean thinking by default.Contrarily, one of the tools within lean thinking is standard work, which adds more controlled environment and thus better manufacturing process quality. This means that lean thinking implementation could be used also to correct the process quality aspect. First determinant of process quality (further PQD1) aspect is indicating whether the number of standardized processes increased or not during lean thinking implementation. Within this criterion the results are the almost the same as general results of process quality aspect: 4 companies out of 12 get score 2 (implemented), another seven get score 1 (partly implemented) and one company get 0 (not implemented). Score 2 in the aspect of process quality indicates that during lean thinking implementation process quality (and thus the number of standard processes) increased, score 1 means that it stand more or less on the same level as before the implementation and 0 means that either it became worse or the starting situation was bad and nothing significant happened during the implementation. Result of PQD1 indicates that 3 companies which get higher scores in process quality are using the standard work tool appropriately, also one company with medium results of process quality are also using latter tool for process quality improvement and others are not. It is important to notice, that the medium process quality score company which uses standard work tool got the highest score out of medium score companies.Having standard processes on place does not mean yet that those standards are strictly followed in daily operations. Second determinant of process quality (further PQD2) is indicating the number of deviations between real life and documented process standards. Here the situation is that only two companies (those with highest scores of process quality) have good situation (score 2) – the number of deviations between real life and standards are decreasing during lean thinking implementation. With others (three companies with score 1 and seven companies with score 0) it means that either set standards are not followed and there are deviations and number is not decreasing or there is nothing to follow (no standard process as indicated in PQD1).Deviations between standards and real life usually results in high scrap and rework costs[18] and this is indicated by the third determinant (further PQD3). Correspondingly, companies with good results in PQD1 and PQD2 have also higher score in PQD3. In practice it means that those companies which have standards on place and are following them are able to decrease the scrap and rework costs and others (without any standards or having standards, but not following them) are not.Furthermore, the overall process quality is also dependent on where and how process standards are created. The better (more practical and from different functions) input to the process standards creation, the better output – process standard is indicating real life and thus easier to follow. The forth determinant (PQD4) is indicating that either standards are created by functional manager (meaning single person is doing those) or responsibility for standards is lying on cross-functional teams consisting of lower level managers and line workers. Assessment results shows that mainly responsibility for creating process standards in studied companies is lying on functional managers (eight companies get score 8) or functional managers sometime discuss those standards with others (score 1 for another three companies). Only one company has implemented cross-functional teams for process standard creation.Finally, all mentioned above activities should results in a smaller amount of non-value added activities in processes (PQD5) and in a higher number of improvement suggestions per employee (PQD6). In case of PQD5 situation is different from possible logical conclusion: six companies out of twelve have indicated score 2 and another six scores 1 or 0 (respectively three and three companies). Such result is indicating that despite of not satisfying work with improving of process quality some companies are still able to improve the manufacturing process in terms of value adding, but this is done on non-controlled manner, not saved in new process standards and thus is of short-term nature. In other words, achieved improvement in non-controlled manner could be lost soon and the same work should be repeated (meaning, eliminating the same non-value adding activities again in changed processes since the optimal process to date were not saved in process standard).The situation with PQD6 score are following the logical pattern: those companies with existing and followed standards, controlled and multi-functional approach of process quality improvement are increasing the amount of improvement suggestions coming from employees. Scania as reference company is indicating excellent scores in all six determinants, showing that strong process quality is on place. Without that it would be impossible for it to achieve such significant results in overall operations and in lean thinking implementation.To conclude the analysis of process quality criterion (and starting point for lean thinking implementation) the following statements could be derived. Companies with good process quality has better possibilities to achieve desired results in lean thinking implementation since they have good ground to start the implementation process, they save already done improvements and thus creating next solid step for further improvements and they get improvement suggestions from daily operations. Those companies with low process quality are missing (or not controlling) the ground to start the process of lean implementation and most likely planned results will not be achieved since they do not know what they are going to improve. Lean thinking implementation are giving the possibility to improve the process quality by using the standard work tool and taking this into account it could be said, that also companies with low process quality on start have the possibility to improve latter and to achieve intended results of lean thinking implementation. Thus, good process quality as a starting point of lean thinking implementation is important factor to the companies, but is not critical.

5.2. Lean Knowledge Acquisition

- Gathering as much knowledge about lean as possible is a first step in lean thinking implementation process, and received results from study at this step are indicating the same pattern as in process quality aspect. Same three companies get almost maximum scores: C4 get 6 points out of 8 maximum, C5 – 7 points and C11 – 7 points. Another five companies get medium scores (3-5 points) and other 4 were at low level (2-3 points). Current step in general is indicating how well the company and its personnel are trained against lean thinking knowledge. Gathered results open the picture where we can see than again only one fourth of the studied companies are investing time and money into lean training and others are not perfect in this aspect.Lean knowledge acquisition step of lean thinking implementation process is focusing on four main determinants: number of personnel trained in lean should increase (LKAD1); number of topics deeply trained to personnel should increase (LKAD2); number of benchmarked companies should increase (LKAD3): and number of books mandatory to read to all employees should increase (LKAD4). The detailed results of those four determinants are indicating that in general all studied companies are doing trainings to the personnel in different lean topics (LKAD1 and LKAD2), though benchmarking and books reading (LKAD3 and LKAD4) are at weak position. Eight companies out of twelve are constantly increasing the number of trained personnel (score 2 in LKAD1) and others four keeping it on the more or less same level (score 1 in LKAD1). This is good result and gives strong opportunities for all companies to achieve successful lean implementation. The more employees know what is lean and how to implement it, the easier it could be done. On other hand, the situation with number of topics trained is not so excellent. Only six companies are constantly training new topics to the employees (score 2 in LKAD2) and others stay on the same level (score 1 in LKAD2). The situation, where new topics are not trained to the employees, means that the lean knowledge of the company is not developing and the lean thinking implementation process stays on the same level of progress (in terms of ultimate goal to become as lean as Toyota).In two last determinants of this criterion the situation is even worse. Only two companies are constantlybenchmarking other companies implementing lean (score 2 in LKAD3), another five have done it some when and never repeated (score 1) and last five have never done it (score 1). On one hand, there might be no need to benchmark others since no one company is similar to another and in each company one can find such a level of uniqueness, which is enough for implementing lean in its own way, without any understanding of how it is done in others – the theoretical knowledge is required and that is it. Per contra, the logic of operations and lean remains the same, also transferring theoretical lean knowledge into practical way of its implementation in the company requires hands-on experience and lessons learned, even if this is experience of others. Those latter aspects ultimately require benchmarking and thus understanding the experience of others. From this insight received results indicate weak point in lean knowledge acquisition.Training and benchmarking is good, though even more additional knowledge could be received from the huge number of books on lean. At least main and worldwide known bestsellers on lean have to be mandatory to read for the employees towards understanding lean thinking in wider context with examples of abroad. In current study only three companies have had some books to read (score 1 in LKAD4) and other nine have never used this approach (score 0). In case of Estonia such picture is explainable very easy: there is only one main lean book translated into Estonian language and some articles in local magazines are available. All other literature is in English and thus is usable only by top management with fluent English. On other hand, Estonian manufacturers have a significant part of employees with native Russian language and thus the same lean literature translated into Russian could be used (all main lean books are translated in Russia). This is one possibility to improve the situation with fourth determinant.As to about reference company, then situation indicated that Scania is doing very well in terms of personnel training on different topics and is keeping moderate level on benchmarking and books reading. The need of constant training is very well placed there. Situation with benchmarking is so due to the reason that Scania itself is already the object of benchmarking for others and also has achieved a lot of self-experience in terms of lean implementation that could easily live with self - benchmarking (intra-company benchmarking).Findings in lean knowledge acquisition step shows that in general major part of companies is dealing with personnel trainings, understanding that without of those the lean thinking implementation is not possible. Though, in some companies the need for extended number of topics is required. Furthermore, situation with benchmarking of other’s experience as well as getting more global view on lean from books could be improved significantly. Those last two determinants are defining the importance of lean knowledge acquisition in successful lean implementation. There is need to hurry up a bit at this point and to say that lean knowledge acquisition (all four determinants) are critical in terms of next step of proposed model – lean house development. If company has focused only on trainings of lean, then the picture of lean house, the picture of successful lean companies interpretations of lean in the form of their own production system could be missed. Thus, studied companies will not be able to see this important next step and will not focus on creating their own lean house. Contrarily, LKAD3 and LKAD4 might be covered by trainings, if trainers are aware about the need of interpretation of lean into companies own production system in the form of lean house. On this point it could be said, that lean knowledge acquisition step is one of critical success factors for the successful lean thinking implementation as it gives ultimately required base for the lean house development.

5.3. Lean House Development

- The concept of lean house was introduced in point 1.3 and it represents the central part of lean thinking implementation. First, it is topmost understanding and interpretation of lean thinking philosophy in a company. Second, it demonstrates the main road of lean thinking implementation in a company. And finally, it enables the move from add-on to daily operations lean principles implementation towards way of working based on lean principles. In current study five determinants help to assess it: attitude to lean implementation should move from project type (principle by principle) towards company’s own production system based on lean principles approach (LHDD1); lean principles integrated into company values are increasing (LHDD2); lean principles integrated into daily work is increasing (LHDD3); attitude towards lean philosophy should move from waste elimination techniques to the way of working (LHDD4); as a result, lean house (or own production system) is created (LHDD5).The result of assessment of studied companies represents the picture where good starting point in process quality and strong focus on lean knowledge acquisition gives the possibility for the lean house creation. Process quality indicates structured approach to all process in a company, including lean thinking implementation process. Meaning, lean thinking implementation is also a process, thus it has to be standardized and constantly improved, but, again, should be started from solid base – lean house. Good understanding on lean theory, insights into other companies practice in lean and broad view of worldwide experience allows to create own interpretation of lean theory suitable for the current company in given conditions. Companies C4, C5 and C11, which have highest scores in process quality and lean knowledge acquisition, get highest scores in lean house development step: all three get 8 points out of 10 maximum. Other studied companies have more moderate results: another three get medium results (4-5 points) and rest six are on lowest level (0-3 points), where three companies get 0. Generically, results are indicating that only three companies understand what is lean and how they would implement it. Rest either have only some generic understanding of lean or have not at all.First determinant give evidence about overall approach on lean thinking implementation: whether it is project type (company is implementing one principle at once, for example 5S, as a single project and does not have longer insight about what is next) or it is approach of step-by-step incorporation of lean principles into daily routines. When companies have project approach of lean thinking tools implementation, then employees see them (tools) as some additional task to perform and thus are not taking them as necessary, but normal routine. “Tasks, additional to normal” are not performed and as a result lean thinking tools are not working properly. Results are as follows: four companies get 2 points, three companies get 1 point and rest five get 0. Maximum points in LHDD1 indicate that companies approach is to achieve such condition where employees use lean tools as normal daily routines and do not see them (lean principles) as some addition to work tasks. In contradiction, lowest points mean that daily tasks and usage of lean tools is separated and employees do it as some additional, thus disturbing, duty. Medium score is indicating that companies are moving from one approach (add-on tools) towards another approach (incorporating tools into daily routines). The outcome of activities assessed in LHDD1 is consequently graded in LHDD2, which is indicating the increase of the number of lean tools integrated into companies values. In this field scores divided evenly between companies: 2, 1 and 0 points are given each for fourth companies. Situation is logical compared to the LHDD1 scores: C4, C5 and C11 have being adding lean principles to company’s values due to existence of long term plan of lean thinking tools implementation. Main tools discovered in companies values are 5S (visual and efficient organisation of workspace), SMED (single minute exchange of dies – method for reducing setup times on machines), 5Why? (searching for the root cause of the problem asking at least five times question why) and standard work. Consequently, the scores of LHDD3 are showing similar path: same three companies get 2 points in LHDD2 get also 2 points in LHDD3. It means that tools added to the company’s values are also integrated into day-to-day operations as normal routines. Since the length of lean implementation to the date of study is not very big (maximum 5 years), then number of tools indicated in values itself is not big – 3 to 4 tools. Despite on that, the important issue is that those three companies are constantly increasing the number and on date of study had clear plan on what is next.In case of C12, it has no well approach on moving from project type of lean implementation towards “lean in daily routines” (LHDD1 score 1), though even with project type approach it managed it keep results of performed projects on lean thinking implementation, and thus achieved increasing in lean tools integrated into values and day-to-day activities (LHDD2 and LHDD3 scores 2). So far they have only tool of 5S (implementation length of lean is around 2 years) and result of keeping it is due the local initiative of implementing those. Since company itself (locally) decided to start lean implementation process, then it is not worthwhile to spent resources on implementing one or another tool and then to though away achieved results. It could be said that C12 has strong potential in further lean implementation. The situation with C6 is wise versa. Strong initiative from headquarters put it to create vision of lean thinking implementation which follows the path of integration of tools, though it is lacking the passion of keeping those working as a “philosophy of doing the work”. C12 still has an approach of add-on lean tools to their normal operations. Tools of 5S and kaizen are present, but the real outcome is not achieved yet. If the strong initiative from the headquarters will stay, then situation with LHDD2 and LHDD3 might change into positive side. The situation of other companies with LHDD2 and LHDD3 is weak. Due to the strong nature of project type approach in lean thinking implementation tools are not incorporated into companies values and are not the part of daily routines. This indicates that weak process approach in general and weak lean knowledge acquisition results in weak results on practical integration of lean thinking tools into company’s operations. Fourth determinant submits the overall approach in the company towards lean thinking. Companies are either focused on pure waste elimination without philosophical aspect or building the strong system of being lean company as such in the very heart. In other words, lean thinking has to be the way of working in a particular company, but not just the panacea against problems and faults. The ultimate result should be continuous improvement everywhere and always. Assessed scores in LHDD4 indicates that five companies – C2, C4, C5, C6 and C11 – get medium score of 1 point and other seven get 0 points. Results of companies C4, C5, C6 and C11 are predictable based on previous discussion and indicating that those are on their way towards achieving the situation where “we, company, act as lean everywhere and always”. Integration of lean tools into values and day-to-day operations on constant basis should give such result. The more important is to look into result of C2. It has medium results in all four determinants in lean house development criterion, indicating that though it is not yet well doing with integration of lean principles, but the direction is right. C2 is subsidiary of foreign company and it is lean initiative is from headquarters. It is using a lot of consultancy help and keeping already integrated tools working (5S, OEE and KPIs), personnel attitude towards improving manufacturing processes is positive. This is strong indication of correct path and strong potential, but only in case if company will keep this path. In this case it much depends on how strong the initiative from headquarters will be in the future.Last determinant (LHDD5) of lean house criterion is summarizing all activities of latter and indicating whether company was able to transform all its knowledge, ideas and wishes about lean into one formal structure – lean house. The grading is simple: 2 points mean that lean house is created; 0 points mean that not; and 1 point mean that there is some structural representation of company’s view on lean and its implementation, but not exactly in the form of lean house. Results are indicating that companies C4, C5 and C11 get 1 point and others 0 points. Company C4 has very good formal approach to kaizen groups (KG) and continuous improvement (CI) – the system which describes in very detail how to apply KG and CI in all levels of an organisation, the responsibility of managers and other employees, results to be achieved. One important point is that approach has start point, but has no end point – company is going to apply it as long as feasible. On other hand, this approach is not a lean house as such, with clear values, priorities and lean tools. Employees are divided into KG, but each KG is free to choose which tool to use and what to improve. It looks effective, flexible and reasonable, but such approach tends to be uncontrolled and does not give the same base for whole organisation. KGs are rarely communicating with each other. Consequently, such system could not be called as company’s production system, but only some form of it.Company C5 has simpler approach than C4, but the same effective. C5 has long term plan on which tools and when to implement and how to sustain already implemented tools. This approach is additionally supported by the corporation certification system. At the moment of study C5 had implemented three tools (5S, kaizen groups and operator’s maintenance) and was certified by the corporation on one of those. Conversely, kind of approach does not fit into picture of lean house and actually is not a lean house. Company C5 is implementing tool by tool in long term approach and by this is building the foundation for the possible future lean house. Similar approach is used in company C6, which has also long-term plan (at least next 10 years) for the lean thinking tools implementation, not with corporate certification system, but plan is the same for all companies within the corporation. Approaches of that sort allow companies to create the attitude, where lean tools are implemented and sustained continuously. It could be resumed, that companies with discussed way of lean tools implementation is more leaner that those without any long term view, but are less leaner that those with existent lean production system in the form of lean house.Approach of lean house is fully realised in reference company Scania as is get maximum points. Scania Production System’s lean house represents the foundation of work culture in the company. Every decision, every action and movement is based on values, priorities and tools derived from lean house at Scania.As we see from result number 2, the DOA is much dependent on score of lean house development criterion score. This dependence is explained as follows. Lean house is the result of good starting point and first step of lean thinking implementation process model. As it was said in the start of that point, without systematic approach to process management, the process of lean thinking implementation will not be addressed constitutionally as well, and due to this company will not see the requirement of elaborating the frame for latter process. Thereafter, reverse approach will naturally lead company to the necessity of company’s lean framework either in the form of lean house (preferably), or in any other analogous form. Furthermore, requirement for lean house establishment will lead to the need of good comprehension of lean and such need could be realised only via thorough lean knowledge acquisition. Onward, existence of lean house (or similar form of that) guide the process of lean thinking implementation first, towards the need of training about lean house, and next, together with systematic approach to all process, towards lean implementation thorough planning and execution of that plan. Correspondingly, absence of lean house will not require the training of lean house at all. Additionally, the planning of lean thinking implementation is not needed very much because of deficiency of long-term vision about lean thinking and without plan there is no plan execution. In other words, good scores of lean thinking implementation process start point and first step gives good score of lean house criterion and consequently derives good scores of proximate steps of the process. In the issue, DOA is high. Absence of lean house and good scores of process quality and lean knowledge acquisition might exist simultaneously, but non-availability of lean house will certainly lead to poor scores of next steps (meaning, weak lean thinking implementation), which will give in outcome insignificant DOA score. Based on all above the conclusion of criticality of lean house step for the successful lean thinking implementation could be made.

5.4. Lean House Communication and Training, Lean Implementation Process Planning and Execution

- It was explained in the conclusion to the last point that lean house existence directly influences the scores of the next steps of the model: lean house communication and training, lean implementation process planning and execution of that plan. This influence exists because any kind of philosophy or production system concept is valid only when whole organisation uses it as basis for daily work. For attainment of such condition philosophy has to be trained to the whole organisation and further implementation should be based on principles, values and priorities which are expressed in this trained philosophy.Consequently, lean house communication and training criterion indicates how well company’s lean framework is spread around the employees by usage of three determinants: number of employees trained should increase (LHTD1); number of employees able to train lean house to others should increase (LHTD2); and amount of information about lean house should increase (LHTD3). After company personnel is aware of company’s lean house and is well trained, the planning of lean implementation process could start. This step of empirical model is defined by three determinants as well: lean implementation approach is moving from project type towards way of doing work based on lean house (LIPD1); lean implementation plan is long term with clearly defined small steps and targets (LIPD2); continuous improvement, also improvement of lean implementation plan, is built in into lean implementation plan (LIPD3). The last step of empirical model, the execution of lean implementation plan is assessed with the help of two determinants: lean implementation execution approach is moving from project type towards way of doing work based on lean house (LIED1); lean implementation follows the plan and is continuously improved based on achieved targets (LIED2).Constitutionally, in the mentioned above three criteria only companies C4, C5 and C11 get scores in all criteria and companies C6 and C12 in lean house training criterion. Companies C4, C5 and C11 get maximum points in lean house training criterion (6 points) and almost maximum points in last two criteria (5 and 3 consequently). Companies C6 and C12 get only points from the LHTD1 – each company get 1 point. Other companies get 0 points in all three criteria mentioned in this point.The interpretation of those results indicates that companies which are leading in our assessing (C4, C5 and C11, further LC – leading companies) get high scores mainly due to the existence of lean house. The absence of lean house immediately removes the need for its training – no lean house, no training. Thus, since LC has lean house (or similar form of it, as discussed in previous point), they have to train it to the personnel to get the practical use of it. Again, the existence of lean house does not necessarily mean that lean house is trained in proper manner. It is important to notice, that training of lean house is not the same as training of lean principles. Training of lean house assumes that principles used in it are already similar (or mostly similar) to the audience and is focused on explaining the way lean principles will be implemented and sustained in the company – exactly the thing which is coded in the lean house. Thus, results of LC in lean house training step of the process show that those companies are constantly training the personnel, achieving the situation where the increasing part of employees are able to teach lean house to others and due to continuous development of lean house the more information about it is coming.Thereinafter, the existence of lean house allows the creation of the plan for the lean thinking implementation. Important point is that under the plan the long term plan of implementing and sustaining of several lean principles, tools and approaches are meant. Without the lean house the plan usually means the plan of the next project for some lean tools implementation (the case we have with other companies out of LC). As well, LC has the form of lean house which is expressed as long term plan of introducing and using of tools and principles. Thus LC gets maximum points for two first determinants of lean implementation planning criteria (LIPD1 and LIPD2) – lean implementation plan incorporates the view that this is not only the plan of lean principles and tools implementation, but the plan of changing the way of working with clearly set goals and targets for long term as well as for short term. Since the lengths of implementations of LC were not long to the date of study, the plan was not much improved and due to this the last determinant (LIPD3) obtained one point.At the end, the presence of the plan infers itsimplementation and absence of the plan requires no actions. Therefore, LC get 2 points for the LIED1 and other companies 0 points. Again, due to the short history of lean implementations in LC it is hard to assess the continuous manner of plan improvements and based on this the score for LC for LIED2 is 1 point.As for companies C6 and C12, they get each 1 point for LHTD1 and 0 points for LHTD2 and LHTD3 due to the fact that they had some training on their ideas and vision about lean thinking implementation, but this training was attended by limited number of people, never repeated and had no major impact on overall process of lean implementation to the date of assessment. Also, as it was discussed before, the lack of long term vision for lean thinking implementation deletes the need for latter planning and execution of plan. Thus, results of C6 and C12 in last two determinants are 0 points.All other companies get 0 points for because of the situation highlighted in the previous point and the beginning of current point – absence of lean house creates the condition where training and further planning together with implementation is not required. Due to the latter studied companies are not doing those activities and thus achieving no points.Reference company get maximum points. Scania has department dedicated to the development of SPS, which has main tasks as training of SPS, follow-up of its implementation, continuous improvement of SPS and consequent planning of implementation of new tools, value or principles from SPS and execution of those plans. Those tasks fit ideally into the determinants of last three steps of the model of lean thinking implementation and accordingly maximum scores are awarded.Relying on discussion in present point the conclusion of critical nature of last three steps could be made. The presence of lean house is critical as well, but, as it was pointed out earlier, lean house does not necessarily mean that training of it will be performed. Without the understanding of lean thinking approach of the company, employees will not be able to achieve the way of working relied on lean principles instead of project type of lean application. Furthermore, without the thorough planning of lean house (and thus lean thinking) implementation and the execution of the plan the existence of lean house is needless. Therefore successful lean thinking implementation critically requires the understanding of lean house throughout the organisation, the thorough planning of its implementation and step by step execution with clear goals and objectives.

5.5. Degree of Adoption

- The performing of lean implementation process model steps resulted in degree of adoption – the indication of how good results were achieved by each company in adapting lean principles. The highest score out of studies companies in DOA is achieved by C5 (40 points) and it also has one of the highest scores in sum of model starting point and steps (40 points). Next two companies are C11 (with 38 points in DOA and 40 points in process) and C4 (respectively with 34 and 38 points). All other companies have significantly smaller results in DOA and also in process stepsDegree of adoption is identified by nine criteria and corresponding determinants of the criteria. In general, assessed twelve companies are focused on waste elimination, zero defects, just in time deliveries, multifunctional teams and vertical information system criteria–almost all companies get points in those criteria, though mentioned above three companies are inevitable better than others: C4, C5, and C11 achieve high or medium points, though other respectively medium and low. The focus to criteria referred above is explained first by the nature and second by the length of lean implementation processes in the companies. Studied companies due to the starting kind of processes are mostly dealing with pure waste elimination and not in building the system of continuous improvement and way of working based on lean. Though our score leading companies have lean houses, which are actually focused on continuous improvement and building sustainable lean system, they still have not being doing that for long time and thus big signs could not be seen. Again, lean houses lead to better application of first lean tools, meaning better results and assessed scores are higher. Such things as reducing set-up times of machines, decreasing the amount of work in progress, improving transportation due to the changes in the layout, reducing amount of scrap, creating more focused quality control system, achieving higher delivery performance, creating improvement teams and providing more data for employees are the first results of 5S, SMED, kaizen group, standard work and VSM (value stream mapping – visualisation of the process in order to identify the amount of value non adding work) tools. All those results are indicated in respective scores. More, C4, C5 and C11 have much better and sustainable results of mentioned improvements than others. The latter – sustainability – is the main indicator of solid system of lean implementation and it was find only in those companies which have understood lean and created their own vision for implementing in the company. Lean house forms the visual basis for implementing lean, thus employees physically see what is lean for their company. Tangible nature of such visual approach enable the attitude towards the building presented lean house in the company and sustainability of the system arises.Continuous improvement, pull of raw materials, decentralisation and integration of functions are criteria in which assessed companies mainly failed to achieve scores. In two criteria of those – pull of raw materials and integration of functions – all companies achieved 0 points. The latter is indicator that none of the studied companies is improving the supply chain (pull of raw materials) or eliminates functional approach of company structure (integration of functions). True, those two aspects of degree of adoption are rather difficult and require much more powerful lean systems, and thus powerful companies, to start those. In continuous improvement criterion the only companies which get some points there again the same C4, C5 and C11. This is due to the existence of future sights in those companies – long term vision of how the company should implement lean. In last criterion in this section–decentralisation–almost all companies get points (except three) and mainly due to the reason, that companies create kaizen teams (multifunctional teams) and give them some responsibility.At the end it is important to notice once more, that C4, C5 and C11 has higher DOA since the creation of their vision of lean thinking implementation allows to achieve the sustainability of the results and to enter into the loop of continuous improvement. Contrarily, the absence of vision of others creates unsustainable environment which merely deletes first results of 5S, SMED and standard work tools, and thus not allowing to achieve high results of lean thinking implementation over time.

6. Conclusions

- Proposed empirical model of lean thinkingimplementation process embody the start point - good process quality, and five steps: lean knowledge acquisition, lean house development, lean house communication and training, lean implementation planning and execution of lean thinking implementation plan. The argumentation hereinabove has indicated that process quality is important, but not critical factor and all process steps are critical success factors. Per contra, it was clearly seen that the basis for the proposed lean thinking implementation process is lean house step. In case of missing lean house all other steps could even remain as critical, but they lose their major purpose and are insufficient for achieving successful lean implementation. The latter was shown on the example of all other companies except LC (C4, C5 and C12). Hence, it could be concluded that main critical success factor for successful lean implementation in the proposed empirical model is lean house creation step and the criticality of others are driven by it.Finally it could be stated that proposed model of lean thinking implementation process is valid and could be used by companies first to analyse their current initiative and second for constructing their lean implementation process and incorporating understanding of lean philosophy into it by creating their own vision in form of lean house. The initial idea says that correct starting point and performing the steps in certain sequence and to the certain depth are the critical success factors of successful and continuous lean implementation. By performing current research author has proved that if mentioned above aspects are taken into consideration and are actually done then company has all prerequisites to achieve its desired targets in terms of lean – meaning successful lean implementation. At last, creation of the lean house is the central part of the model; it drives all other steps and thus is main critical success factor for the successful lean thinking implementation. Thus, the initial proposal is true – on of the reasons of failure of lean thinking implementation process is absence of company’s vision of its lean initiative in the form of lean house. Performed research is only the top of the iceberg. There are a lot of questions which should be answered in this area. How to study Toyota Production System? In Scania web page it is written that in 90’s Scania people went to Toyota to study the TPS – is it still relevant today? Are there other ways to study lean system without visiting the Toyota – traveling to Japan might be expensive for the SMEs and there is a question of what will be the output of such travel. Another question which might arise is how to create own lean house – where and how to start. And there are more such questions. To answer all of them the ultimate goal has to be achieved – development of the general model of successful lean implementation. This model should incorporate Process, People and Culture aspects for all manufacturing process types with possibility of assessing the financial feasibility of implementation.

Appendix 2. Summary of companies assessment results

References

| [1] | Achanga, P., Shehab, E., Roy, R. and Nelder, G. (2005a). Lean manufacturing to improve cost-effectiveness of SMEs. Proceedings of the Seventh International Conference on Stimulating Manufacturing Excellence in Small and Medium Enterprises, University of Strathclyde, Glasgow. |

| [2] | Achanga, P., Shehab, E., Roy, R. and Nelder, G. (2005b). Lean manufacturing for SMEs: enabling rapid response to demand changes. Paper presented at the 15th International Conference on Engineering Design, Melbourne. |

| [3] | Achanga, P., Taratoukhine, V., Roy, R. and Nelder, G. (2004). The application of lean manufacturing within small and medium sized enterprises: what are the impediments? Paper presented at the 2nd International Conference on Manufacturing Research (ICMR 2004), Sheffield Hallam University, Sheffield. |

| [4] | Achanga, P., Shehab, E., Roy, R., Nelder, G. (2006). Critical success factors for lean implementation within SMEs”. Journal of Manufacturing Technology Management, Vol. 17, No. 4, pp. 460-471. |

| [5] | Antony, J., Banuelas, R. (2001). A strategy for survival. Manufacturing Engineer, Vol. 80 No. 3, pp. 119-21. |

| [6] | Bateman, N. (2002). Sustainability. Lean Enterprise Research Centre Publication, Cardiff, April, pp. 2-24. |

| [7] | Bhasin, S., Burcher, P. (2006). Lean viewed as a philosophy. Journal of Manufacturing Technology Management, Vol. 17, No. 1, pp. 56-72. |

| [8] | Bicheno, J., (2000). Cause and Effect Lean. Lean Operations, Six Sigma and Supply Chain Essentials, PICSIE Books, Buckingham. |

| [9] | Bicheno, J., (2004). The New Lean Toolbox Towards Fast and Flexible Flow. PICSIE Books, Buckingham. |

| [10] | Cooney, R. (2002). Is lean” a universal production system? Batch production in automotive industry. International Journal of Operations & Production Management, Vol. 22, No. 10, pp. 1130-1147 |

| [11] | Coronado, R.B., Antony, J. (2002). Critical success factors for the successful implementation of six sigma projects in organisations. The TQM Magazine, Vol. 14, No. 2, pp. 92-9. |

| [12] | Crabill, J., Harmon, E., Meadows, D., Milauskas, R., Miller, C., Nightingale, D., Schwartz, B., Shields, T. &Torrani, B. (2000). Production Operations Level Transition-To-Lean Description Manual. WP, Center for Technology, Policy, and Industrial Development, Massachusetts Institute of Technology |

| [13] | Cuatrecasas, L., Cuatrecasas, O., Fortuny, J., Olivella, J., (2007). Notes for the implementation of lean production approach in medium sized manufacturing companies. Proceedings of 14th International Annual EurOMA Conference |

| [14] | Drickhamer, D. (2000). Manufacturer of automotive climate-control systems follows lean. International Journal of Operations & Production Management, Vol. 17, No. 7 |

| [15] | Drucker, P.F. (1992). Managing for the Future: The 1990s and Beyond. Butterworth-Heinemann, London, UK |

| [16] | Eckes, G. (2000). The Six Sigma Revolution. Wiley, New York. |

| [17] | Erlandson, D.A., Harris, E.L., Skipper, B.L., & Allen, S.D. (1993). Doing Naturalistic Inquiry: A Guide to Methods. Newbury Park, CA: Sage Publications. |

| [18] | Fukuda, K. J. (1988). Japanese-style management transferred: the experience of East Asia. Rouledge, London. |

| [19] | Haney, W., Russell, M., Gulek, C., and Fierros, E. (1998). Drawing on education: Using student drawings to promote middle school improvement. Schools in the Middle, 7(3). |

| [20] | Harbison, F. H., and Myers, C. A. (1959). Management in the industrial world: An international analysis. McGraw-Hill, New York |

| [21] | Harrison, A. (1998). Manufacturing strategy and the concept of world class manufacturing. International Journal of Operations & Production Management, Vol. 18 No. 4, pp. 397-408 |

| [22] | Heizer, J., Render, B. (2011). Principles of OperationsManagement, Pearson Education. |

| [23] | Henderson, K., Evans, J. (2000), Successful implementation of six sigma: benchmarking general electric company. Benchmarking: An International Journal, Vol. 7, No. 4, pp. 260-81. |

| [24] | Hilton, R., Sohal, A. (2012) A conceptual model for the successful deployment of Lean Six Sigma, International Journal of Quality & Reliability Management, Vol. 29 Iss: 1, pp.54 – 70. |

| [25] | Hines, P., Taylor, D. (2000). Going Lean. Lean Enterprise Research Centre. Cardiff Business School. Cambridge, MA |

| [26] | Hogg, T.M.(1993). Lean Manufacturing. Human System Management, Vol. 12, pp. 35-40 |

| [27] | James-Moore, S., and Gibbons, A. (1997). Is lean manufacturing universally relevant.International Journal of Operations & Production Management, Vol. 17 No. 9, pp. 899-911. |

| [28] | Karlsson C. and Åhlström P. (1996). Assessing changes towards lean production.International Journal of Operations & Production Management, Vol. 16, No. 2, pp. 24-41. |

| [29] | Katayama, H. and Bennett, D. (1996). Lean production in a changing competitive world: a Japanese perspective. International Journal of Production and Operations Management, Vol. 16 No. 2, pp. 8-23. |

| [30] | Krippendorff, K. (2004). Content Analysis: An Introduction to Its Methodology. 2nd edition, Thousand Oaks, CA: Sage |

| [31] | Laureani, A., Antony, J. (2011). Standards for lean six sigma certification. International Journal of Productivity and Performance Management, Volume: 61 Issue: 1. |

| [32] | Liker, J., (2004). The Toyota Way: 14 Management Principles from the World’s Greatest Manufacturer. McGraw-Hill. |

| [33] | Mohan A. and Sharma S. (2003). Lean approach: some insights.Journal of Advances in Management Research, Volume: 1 Issue: 1 |

| [34] | Moore, R. (2001). Comparing the major manufacturing improvement methods. Plant Engineering, September, pp. 1-3. |

| [35] | Neuendorf, K.A. (2002). The Content Analysis Guidebook. Thousand Oaks, CA: Sage Publications |

| [36] | Oberg, W. (1963). Cross-cultural perspectives on management principles. The Academy of Management Journal, Vol.6, No.2, pp.129-143. |

| [37] | Ohno, T. (1988). The Toyota Production System: Beyond Large Scale Production. Productivity Press, Portland. |

| [38] | Olexa, R. (2002a). Freudenberg – NOK’s lean journey. Manufacturing Engineering, January, pp. 2-8. |

| [39] | Olexa, R. (2002b). Manufacturing lite with lean. Forming and Fabricating, Vol. 9, pp. 1-6. |

| [40] | Oprime, P., de Sousa Mendes, G.H., Lopes Pimenta, M. (2011). Continuous Improvement: Critical Factors in Brazilian Industrial Companies. International Journal of Productivity and Performance Management, Volume: 61 Issue: 1 |

| [41] | Papadopoulou, T.C. and Özbayrak, M (2005), Leanness: experiences from the journey to date. Journal of Manufacturing Technology Management, Vol. 16 No. 7, pp. 784-807 |

| [42] | Pepper M.P.J. and Spedding T.A. (2010). The evolution of lean Six Sigma, International Journal of Quality & Reliability Management, Vol. 27 No. 2, pp. 138-155. |

| [43] | Philips, T. (2000). Building the lean machine. Advanced Manufacturing, January |

| [44] | Repenning, N., Sterman, J. (2001). Creating and sustaining process improvement. California Management Review. |

| [45] | Santos, J., Wysk, R., Torres, J.M. (2006). Improving production with Lean Thinking. John Wiley and Sons. |

| [46] | Sohal, A., Eggleston, A. (1994). Lean production: experience amongst Australian organizations. International Journal of Operations & Production Management, Vol. 14, pp. 1-17. |

| [47] | Stemler, S. (2001). An overview of content analysis. Practical Assessment, Research & Evaluation, 7(17) |

| [48] | Söderkist, K. and Motwani, J. (1999). Quality issuses in lean production implementation. Total Quality Management, Vol. 10, No. 8. |

| [49] | Teresko, J. (2002). A partnership in excellence: Boeing Co.’s success in long beach celebrates a commitment to employee involvement and lean manufacturing (best plants). Reprint from Gale Group, October |

| [50] | White, M., and Trevor, M. (1983). Under Japanese management: The experience of British workers. Heinemann, London. |

| [51] | Williams, K., Haslam, C., Williams, J., Cutler, T., Adcroft, A. and Johal, S., (1992). Against lean production. Economy and Society, vol. 21 no. 3. |

| [52] | Womack, J.P. & Jones, D.T. (1996). Lean thinking: banish waste and create wealth in your corporation. New York, Free Press. |

| [53] | Womack, J.P., Jones, D.T., Roos, D. (1990). The Machine that Changed the World, Macmillan Publishers. The Massachusetts Institute of Technology, Woodridge, IL/Cambridge, MA. |

| [54] | Womack, J.P. and Jones, DT. (2005). Lean Solutions: How Companies and Customers Can Create Wealth Together. New York, Simon & Schuster |

| [55] | Voss, C. (2007). The evolution of best practices in operations. Proceedings of 14th International Annual EurOMA Conference. |

| [56] | Yin, K. (2003). Case Study Research: Designs and Methods. Thousand Oaks CA: SAGE Publications, 2003. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-Text HTML

Full-Text HTML