-

Paper Information

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Mining Engineering and Mineral Processing

p-ISSN: 2166-997X e-ISSN: 2166-9988

2014; 3(2): 28-31

doi:10.5923/j.mining.20140302.02

Characterization of the Jordanian Feldspar Raw Materials for Application in the Ceramic and Glass Industries

Mazen Amaireh, Mohammad Aljaradin

Department of Natural Resources and Chemical Engineering Tafila Technical University, Tafila, Jordan

Correspondence to: Mohammad Aljaradin, Department of Natural Resources and Chemical Engineering Tafila Technical University, Tafila, Jordan.

| Email: |  |

Copyright © 2014 Scientific & Academic Publishing. All Rights Reserved.

In this study, Jordanian feldspar from Wadi Al-Jayshiah area was invested to evaluate its applicability as raw material for ceramic and industries. The chemical analysis indicated that the average Fe2O3 content is 2.33%, which is very high, compared to commercial ceramic and glass grades feldspar. The SiO2 content in the Wadi Al-Jayshiah feldspar (67.96%) lies within the required amount in commercial ceramic grade feldspar (75%) and the in commercial ceramic glass feldspar (68.9 %). On the other hand it was found that the contents of K2O and Na2O are 4.13 and 4.12, respectively, which makes it suitable for the ceramic industry. However for glass in industry a beneficiation pre-treatment step is required to increase the amount of Na2O.

Keywords: Feldspar, Evaluation, Raw material, Ceramic, Glass, Wadi Al-Jayshiah

Cite this paper: Mazen Amaireh, Mohammad Aljaradin, Characterization of the Jordanian Feldspar Raw Materials for Application in the Ceramic and Glass Industries, International Journal of Mining Engineering and Mineral Processing , Vol. 3 No. 2, 2014, pp. 28-31. doi: 10.5923/j.mining.20140302.02.

Article Outline

1. Introduction

- Feldspar is the most plentiful group of minerals in the earth's crust, forming about 60% of earthly rocks. Most deposits offer sodium feldspar as well as potassium feldspar and mixed feldspars. Feldspars are primarily used in industrial applications for their alumina and alkali content. Feldspars are alumina silicates containing potassium, sodium, and a small amount of calcium, and usually are embodied in rocks such as granite or exist in large amounts, for example in pegmatite.Alkali feldspars are one of the basic raw materials of ceramic and glass industries. One of the most important feldspar contributions is the control of melting as it does not have a fixed melting point but it melts stage wise. Feldspar is distinguished by the low rate and balanced melting over the required range of temperature [1]. This is of great importance for both ceramics and glass manufacturing processes due to its role in helping the melting of quartz and clays. Moreover, feldspar is important for the inflection step of ceramic and glass formation. The glassy phases are formed at low temperatures due to the function of feldspar as a fluxing agent, thus it is the source of alkalies and alumina during the formation of these phases. Feldspars develop the mechanical properties [2, 3] of the ceramic and glass body such as strength, toughness, and durability. Also they bind the crystalline phase of their ingredients. The application of feldspar in ceramic and glass industries requires certain grade [4] and specifications in terms of its chemical and physical properties. In Jordan, the feldspar deposits are found in the alkali granite rocks, leucogranite, feldspar pegmatites and alkali-rich granite, which occurring as medium to coarse-grained, light colored igneous rocks such as aplites and alaskite, respectively, which have a granite composition and are characterized by low content of mafic of iron-bearing minerals [5]. These deposits located in the following areas [5]: Wadi Al-Jayshiah area, 6km south of Aqaba; Wadi Sadir Mulghan area, 25km north of Aqaba and 8 km to the west; Wadi Sadir Ashuqayri area, 40km north of Aqaba and in Ayn Al Hashim area, 45km south-east of Aqaba [6]. The objective of the current study is to investigate the characteristics of Jordanian feldspar ores and its suitability as raw material for ceramic and glass industries.

2. Methodology

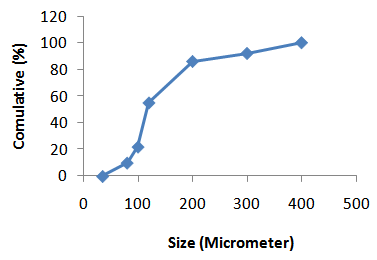

- Three samples of feldspar ore were collected from different areas at Wadi Al-Jayshiah deposits located six kilometres south of Aqaba in Jordan. The samples were obtained from the alkali granite rocks, which in the size range from medium to coarse grain brightness coloured igneous rocks. In the current examination, unprocessed samples were crushed by a jaw crusher, cone crusher and ball mill to separate to be prepared for the characterisation tests average time 3 minutes. All the samples (500g) were subjected to the same size reduction conditions. The average particle size distribution is presented in figure 1. Chemical composition of the dry samples was experimentally measured using x-ray diffraction system (ARL 9900). The laboratory equipment’s used for analysis (e.g., bottles, glassware) were washed carefully, rinsed with 1% HNO3 and finally cleaned with distilled water. The fine powder samples were fixed on special slides and then scanned between 2° and 65° 2 θ using Ni-filtered C° Kα radiation 40Kv/40mA, divergent and scattering slits of 0.02° mm, with stepping of 0.01° and scanning speed of 3°/min.

| Figure 1. Particles size distribution of samples after size reduction obtained from Wadi Al-Jayshiah |

3. Results and Discussion

3.1. Characterization of Feldspar Samples

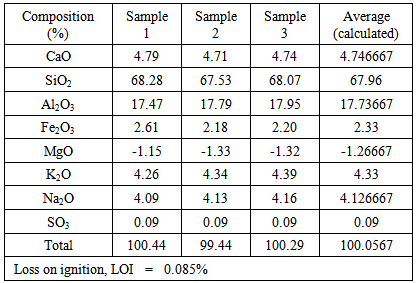

- The overall evaluation of the feldspar deposit at Wadi Al-Jayshiah was conducted by collecting three different samples of the original granitic rocks from different representative locations. The results of the chemical analyses are presented in Table 1.

|

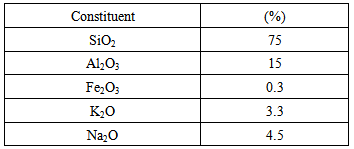

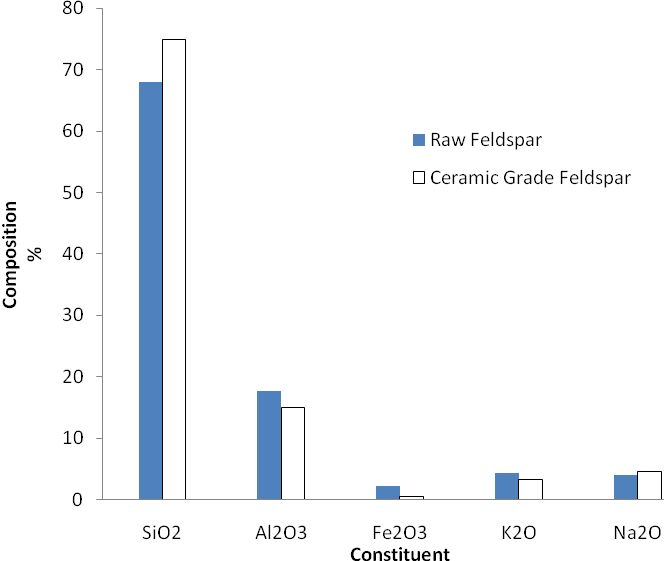

3.2. Comparing with Commercial Ceramic Grade Feldspar

- The main ingredients affecting the ceramic processing and the product quality are K2O, Na2O, Al2O3 , SiO2 and Fe2O3. The composition of commercial ceramic grade feldspar is given in table 2.

|

| Figure 2. Comparison between the percentage of the main ingredients of the raw feldspar at Wadi Al-Jayshiah deposit with the commercial ceramic grade feldspar |

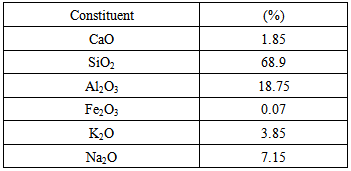

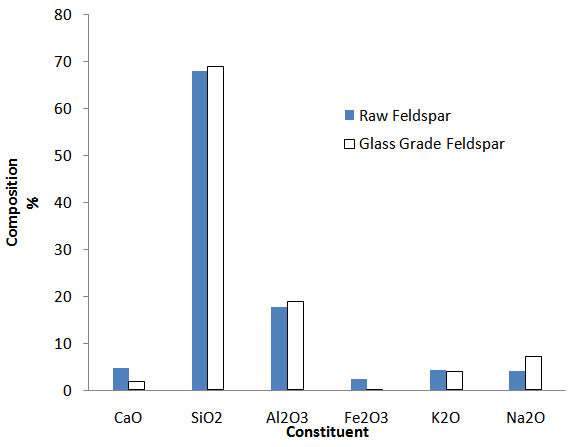

3.3. Comparing with Commercial Glass Grade Feldspar

- The main elements affecting the glass processing and the product superiority are K2O, CaO, Na2O, Al2O3, SiO2 and Fe2O3. The breakdown of commercial glass grade feldspar is arranged in table 3.

|

| Figure 3. Comparison between the composition of the raw feldspar at Wadi Al-Jayshiah deposit with the commercial glass grade feldspar |

4. Conclusions

- The chemical analysis of the feldspar samples obtained from Wadi Al-Jayshiah deposit can be used as a raw material for the ceramic and glass industries. However, a minor pre-treatment processes are required such as magnetic separation to reduce the Fe2O3 contents in case of ceramic and glass industries and froth floatation to increase the amount of Na2O in case of glass industries. The amount of feldspar deposits and its properties Wadi Al-Jayshiah indicate a promising economic production of feldspar as raw material for ceramic and glass industries.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML