Mbuh Moses Kuma1, 2, Penka Jules Bertrand2, Nsahlai Leonard Nyuykongi2, Lepahle Stephanie Isha2, Patrick Bame Che1

1Department of Civil Engineering and Forestry Techniques, Higher Technical Teacher Training College, University of Bamenda, Bambili, Cameroon

2Department of Civil Engineering and Architecture, National Higher Polytechnic Institute, University of Bamenda, Bambili, Cameroon

Correspondence to: Mbuh Moses Kuma, Department of Civil Engineering and Forestry Techniques, Higher Technical Teacher Training College, University of Bamenda, Bambili, Cameroon.

| Email: |  |

Copyright © 2026 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Abstract

Concrete is commonly employed in construction because of its tremendous compressive strength, despite its low tensile strength. The main purpose of the research work was to study the properties of concrete cured under different environmental conditions. Laboratory experimental method used for the characterization of the constituent materials’ physical and mechanical properties assessment of concrete employed Dreux method which was carried out for the concrete mix design. The research was conducted by varying the concentration of sodium chloride salt and varying the concentration of 10M HCl acid. Sixty-four (64) concrete cubes were casted for this, the results showed that the compressive and flexural strength of concrete cubes cured in different concentration of acid decreased with increase acid concentration and gradually increased with curing age. The concrete cubes cured in 15ml HCl acid drastically dropped its 60 days’ strength while the concrete cubes cured in different concentration of salt (25g, 30g and 35g) solution increased at its early stages that is 7 and 14 days of curing more than the control sample, that is, the 0% and gradually dropped during the 28 and 60days curing. Conclusively, the strength of concrete dropped with increase salt concentration (40g and 45g) but increased with curing age.

Keywords:

Acid, Curing, Durability, Salts, Strength

Cite this paper: Mbuh Moses Kuma, Penka Jules Bertrand, Nsahlai Leonard Nyuykongi, Lepahle Stephanie Isha, Patrick Bame Che, Investigating the Properties of Concrete Made with Sanaga River Sand and Cured in Various Environmental Conditions, American Journal of Materials Science, Vol. 16 No. 1, 2026, pp. 1-10. doi: 10.5923/j.materials.20261601.01.

1. Introduction

Concrete is one of the most frequently used building material in the world [1] Concrete has a relatively high compressive strength but low tensile strength. The potential strength and durability of the concrete is fully developed only if the concrete is properly cured [2]. Curing is the process of maintaining satisfactory temperature and moisture conditions in concrete long enough for hydration to develop the desired concrete properties [3].Concrete properties are highly influenced by the water type used to cure and the concentration of the corrosive agent in the concrete mix [4]. Almost any natural water that is drinkable (potable) and has no pronounced taste or odour is satisfactory as mixing water for making and curing concrete [5]. But in some arid areas, local drinking water is saline or acidic in nature. There is no sufficient clean water in some industrial areas due to the contamination of clean water by industrial wastes and forcing the ready-mixed concrete industry to review the logistics of raw material supply [6]. There are many sources of salt water. Among these Sources, Sea is the predominant one. The primary chemical constituents of salt water are the ions of chloride, sodium, magnesium, calcium and potassium [7]. The concentration of major salt constituents of salt water is given in weight % of salt as 78%NaCl, 10.5% MgCl2, 5% MgSO4, 3.9% CaSO4, 2.3% K2SO4, and 0.3% KBr (Akinkurolere, 2007). It is evident from the above sodium chloride is by far the predominant salt component of seawater. Sea water has a total salinity of about 3.5% (78% of the dissolved solids being NaCl and 15% MgCl2 and MgSO4). Generally, the effects on setting are unimportant if water is acceptable from strength consideration. Water containing large quantities of chlorides (sea water) tends to cause persistent dampness and surface efflorescence. Such water should, therefore not be used where appearance is important, or where a plaster- finish is to be applied [8].Typically, concrete is made out of Portland cement, supplementary cementitious material, water, aggregates, and depending on its application and the requirements of a specific project, different types of chemical and mineral additives may be used in its production [9]. When it comes to resistance to different types of chemicals, the durability of concrete is quite influenced by its manufacturing process (curing methods, finishing, etc.) and the materials that are used [10]. It is well known that concrete deteriorates when exposed to chemical attack under acidic environments. Concrete structures may be subjected to acidic environments under variety of conditions such as acid spills, acid rains, drainage sewers, chemical factories, hot springs, industrial effluents, etc [10]. In above cases, the acid that affects concrete may be different. Also, the duration of attack may range from few seconds to years. Acidic attack usually originates from industrial processes, but it can even be due to urban activity. Even natural exposure conditions may cause acid attacks. Free acids in natural waters are rare. Exceptions are carbonic waters and sulfurous and sulfuric acids in peat waters. Soils may contain huminous acids. Several organic and inorganic acids may occur in shallow regions of sea-water as a consequence of bacteriological activity. Significant quantities of free acids in plants and factories may be found. In these cases, the concentration of acid, which comes in contact with concrete structures, may reach to high values. In actual environment, the acid exposed on concrete is not a pure acid but a diluted or type of mixed acid [10]. Concrete is susceptible to acid because of its alkaline nature. The components of the cement paste break during contact with acids. Acids such as nitric acid, hydrochloric acid and acetic acid are very aggressive as their calcium salts are readily soluble and removed from attack front [11].There are many research conducted on the effect of salty and acidic water on concrete strength especially on compressive strength. However, clear-cut conclusion has not been established until now. Therefore, laboratory tests are important to give clear-cut conclusions on the effect of salty and acidic water environments on the compressive strength of concrete.

2. Materials and Methods

2.1. Nature and Source of Materials

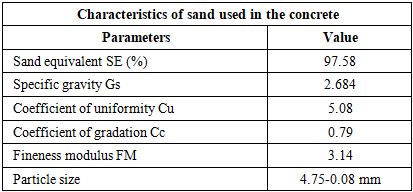

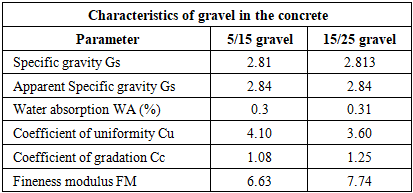

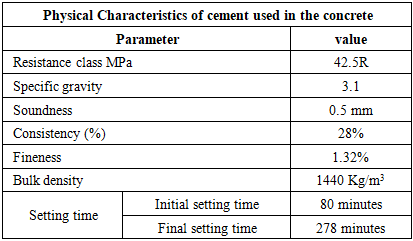

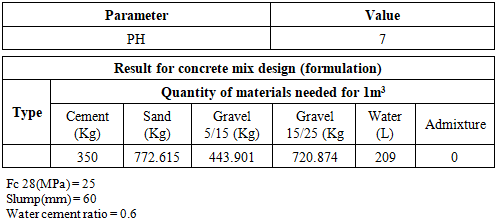

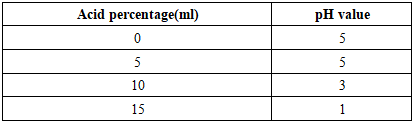

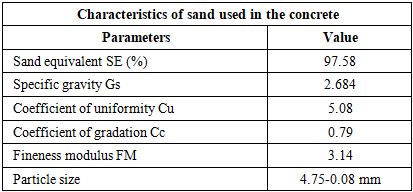

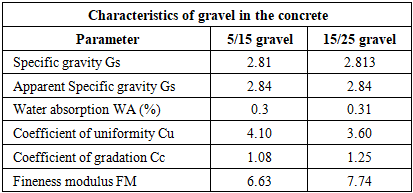

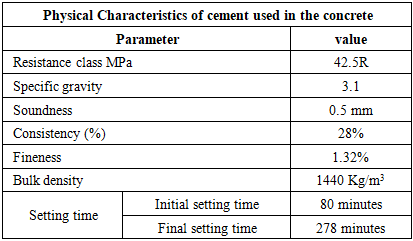

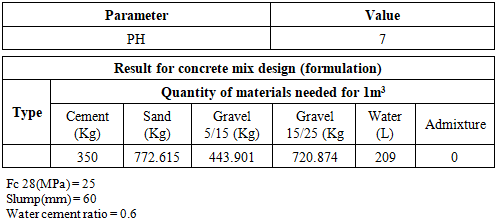

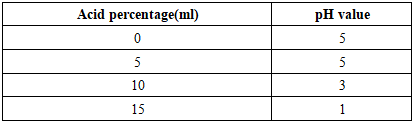

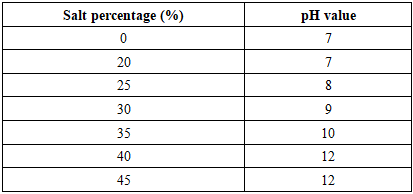

All the materials used in this research were cement, sand, gravel, sea salt, pH paper and hydrochloric acid (HCl). The 5/15 and 15/25 class gravel used for this study was obtained from the quarry of RAZEL Cameroon. The sand use was from River Sanaga. Dangote cement (DANGOTE CEM II, 42.5R), Type I general-purpose cement as per ASTM C 150 was used for this study. The sea salt, pH paper and hydrochloric acid used for this research were purchased from a chemical laboratory.ü SandSanaga sand was used for the study. The sand equivalence test was done in order to ascertain if the sand is clean or needs to be washed before used. The higher the sand equivalent SE, the cleaner the sand. According to the American standard test method [12], the sand equivalent of sand should be at least 35% to be an acceptable aggregate in construction. From the results obtained, the sand equivalent of the sand was 97% which indicates that the sand is good to be use as a construction material.The specific gravity or the unit weight of Sanaga sand is 2.684. According to the unified soil classification system ASTMD-2487, the specific gravity of sand used for construction should be greater than 2.65 which makes Sanaga sand a good construction sand. The coefficient of curvature of sands from River Sanaga is 0.79 while the coefficients of uniformity is 5.08. According to the unified soil classification system (USCS) and ASTMD-2487, for sand to be well graded, the coefficient of curvature, Cc must lie within the range 1 < Cc <3 and the coefficient of uniformity, Cu must be greater that 6; Cu > 6. The fineness modulus of Sanaga sand is 3.14. and according to the unified soil classification system, the acceptable range for the fineness modulus of sand is 2.2 to 2.8. ü GravelThe 5/15 and 15/25 class gravel were used for this study which was obtained from the quarry of RAZEL Cameroon. The 5/15 and 15/25 class gravel had specific gravity of 2.81 and 2.813 respectively and their water absorptions are respectively 0.3% and 0.31%. The specific gravity of aggregates normally ranges from 2.5 to 3 and the water absorption, ideally should not be more than 0.6%. this makes the above-mentioned gravel good for use in concrete [13].The coefficient of uniformity is respectively 4.1 and 3.6 respectively for 5/15 and 15/25 gravel and the coefficient of gradation are respectively 1.08 and 1. According to the unified soil classification system (USCS) and ASTMD-2487, for gravel to be well graded, the coefficient of curvature, Cc must lie within the range 1 < Cc <3 and the coefficient of uniformity, Cu must be greater that 6; Cu > 6.The fineness modulus of 5/15 and 15/25 gravel are respectively 6.63 and 7.74. According to the unified soil classification system (USCS) and ASTMD-2487, the fineness modulus of gravel varies from 5.5 to 8.0. this implies that the gravel used for the study follows USCS standard.ü CementDangote cement (DANGOTE CEM II, 42.5R) which is Type I general-purpose cement as per ASTM C 150 was used for this study and a secondary form of data was taken for its properties. It was important to have the properties of the cement to be used since some of its properties was needed during formulation.42.5R in Dangote cement defines the resistance class after 28 days. Which means it will attend 42.5 MPa strength in 28 days after mixing with water. This is one of the most important parameters of cement needed during formulation. Dangote cement 42.5R has a consistency of 30% which defines the quantity of water needed to form a cement paste of standard consistency. Dangote cement 42.5R has as initial and final setting time respectively 35 minutes and 348 minute which is slightly less than what is specified for ordinary Portland cement OPC 42R. [14].ü Water The water used for mixing was ordinary tap water having a pH of 7.The water used for curing was mixed with various percentages of sea salt and hydrochloric acid causing variations in the pH of water.[15], the pH of water for mixing in concrete should be in the range of 6 and 8. In this study, clean drinking water was used, which was obtained from the laboratory. Using another water with different pH might probably affect results.ü Sea SaltsThe water used for curing were mixed with different percentages of sea salt of 20%, 25%,30%, 35%,40% and 45% of sea salt which caused a difference in the pH of water.ü Hydrochloric acidThe acid was mixed into the curing water in different percentages of 0, 5, 10 and 15% of HCl which caused a pH change of 7, 5, 3 and 1 respectively.

2.2. Formulation

Concrete mix design also known as concrete formulation is the process of determining the quantities of the different materials needed to produce 1m3 of concrete [16]. Before doing formulation, we defined certain parameters which formed the basis of the properties of our concrete which include the design strength, the slump and the water cement ratio. The design strength is obtained after doing compressive strength testing and after a curing age of 60 days. For this study our designed strength was 25 MPa and that was the maximum strength obtained after crushing. The slump also matched the design slump when poured into the Abraham’s cone for slump testing. The water cement ratio together with the slump determined the quantity of cement and water for the mix.The harden samples used to assess the mechanical behavior of the concrete was obtained by mixing together the quantity of materials obtained during formulation for each case and cured in an acidic and salty environment.The results from the formulation indicated that, in order to produce 1m3 of normal concrete, it required 350Kg of cement, 772.615 Kg of sand, 443.901 Kg of 5/15 gravel, 720.874 Kg of 15/25 gravel and 209 liters of water with 0% admixture.

2.3. Laboratory Analysis

The laboratory experimental method was applied in this study. The research work involves formulation of concrete and curing the concrete cubes in different environmental conditions such as salty and acidic condition in varied concentrations. The quartering method was employed to select the samples for the various tests. The sand equivalent test, Specific gravity test and Grain size analysis test were conducted on the sand to ascertain its quality and for further use in the formulation of concrete using the Dreux method. The specific gravity, absolute density and grain size analysis was also performed on the course aggregate (gravel). The hydrogen potential of the curing environment was tested using the pH paper. A keen diagnostic test on aggregates was conducted to ensure a good quality of the materials used in formulating the concrete. The design characteristic strength was 25 MPa for concrete and all other materials kept constant while varying the different environmental conditions and their concentrations.

3. Results

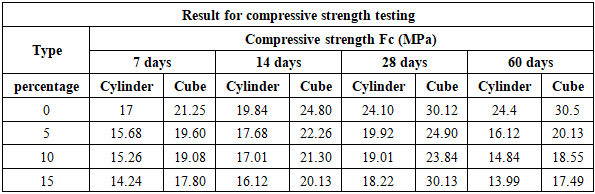

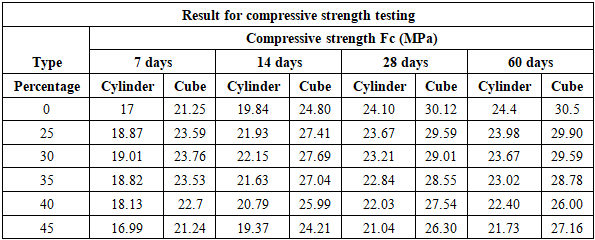

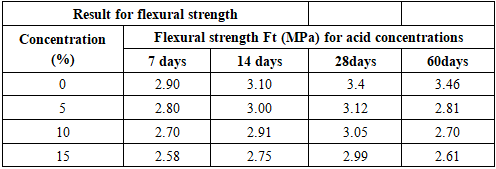

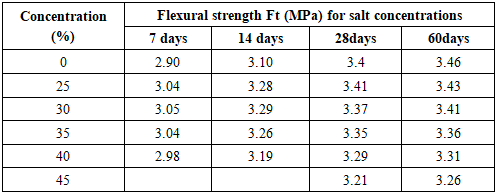

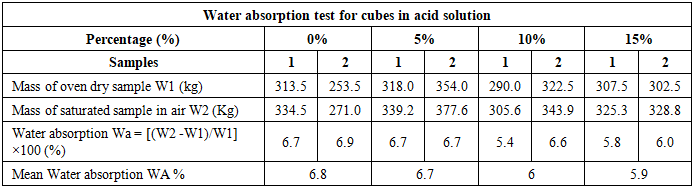

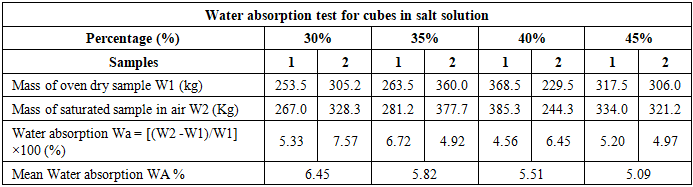

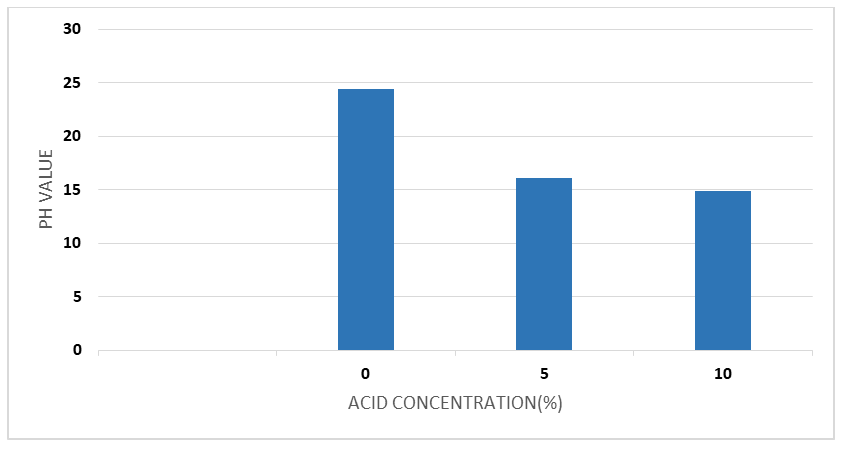

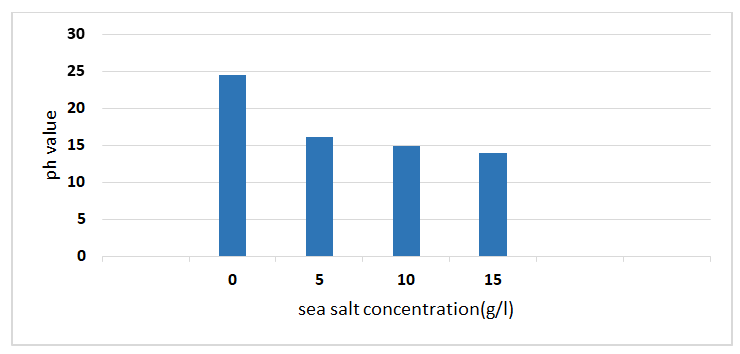

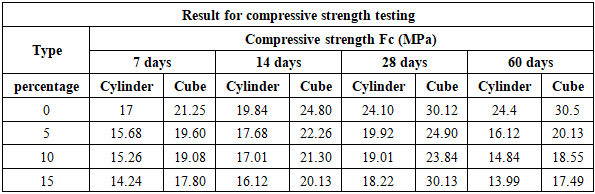

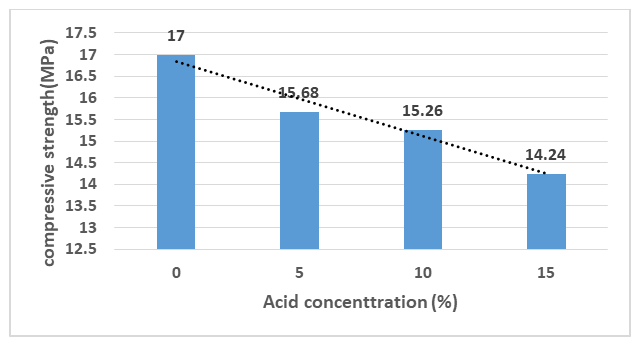

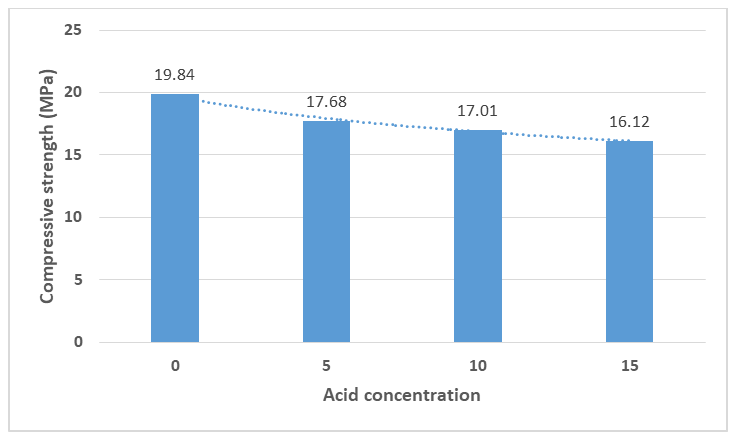

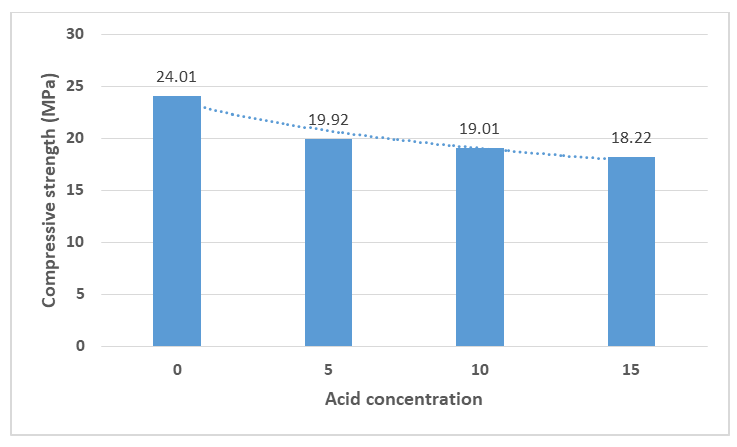

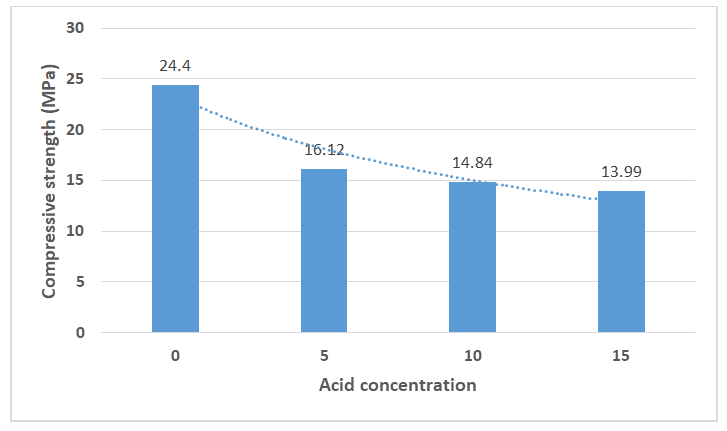

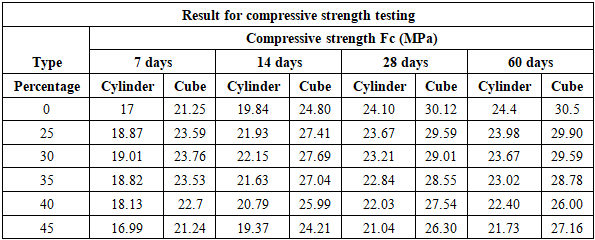

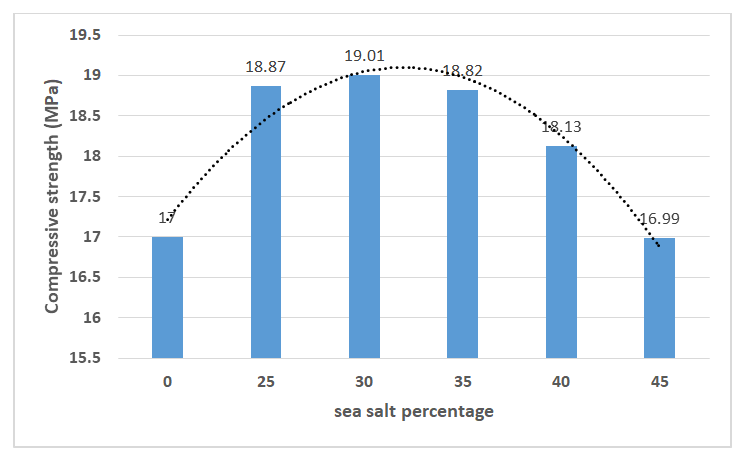

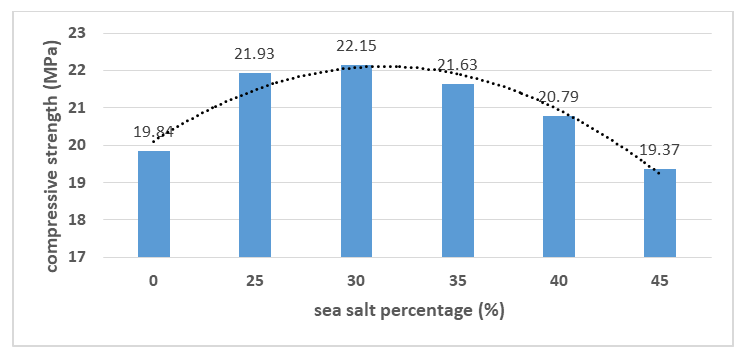

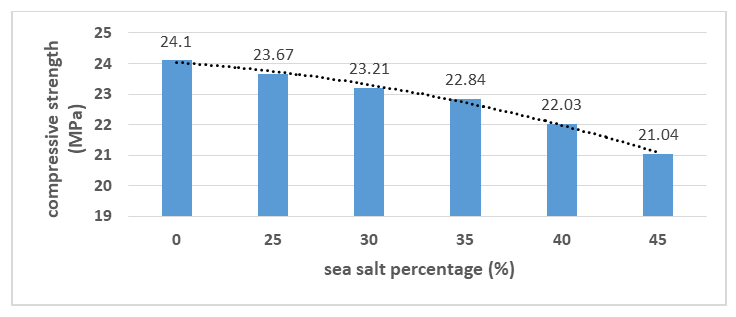

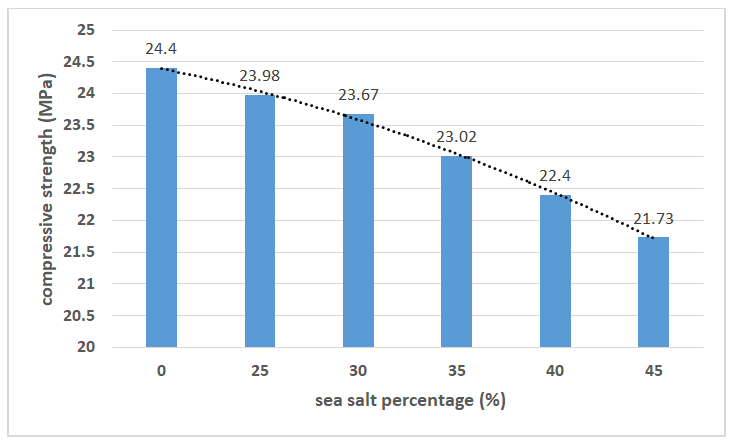

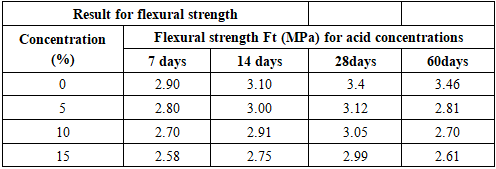

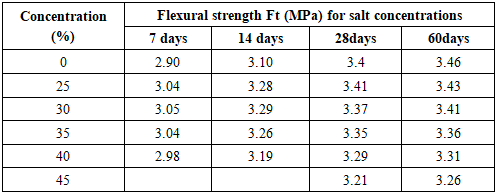

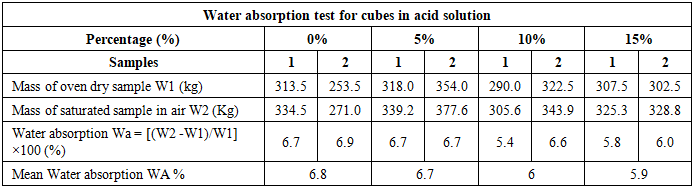

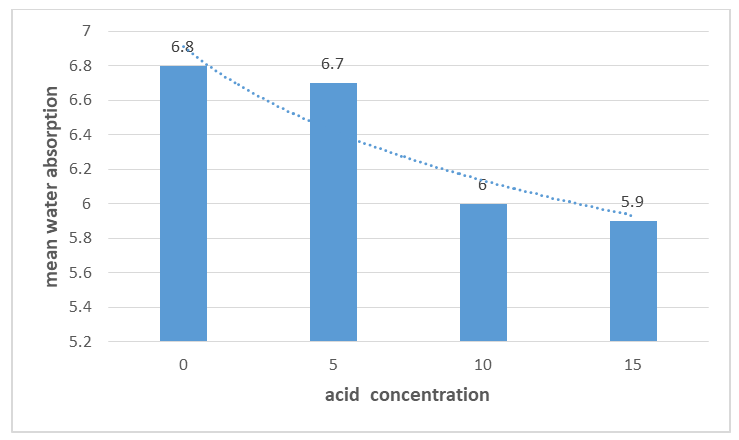

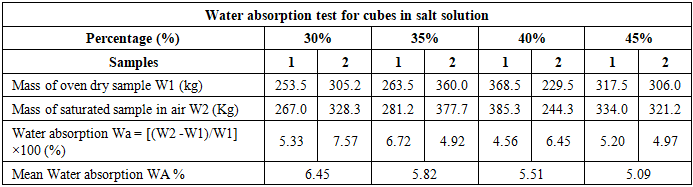

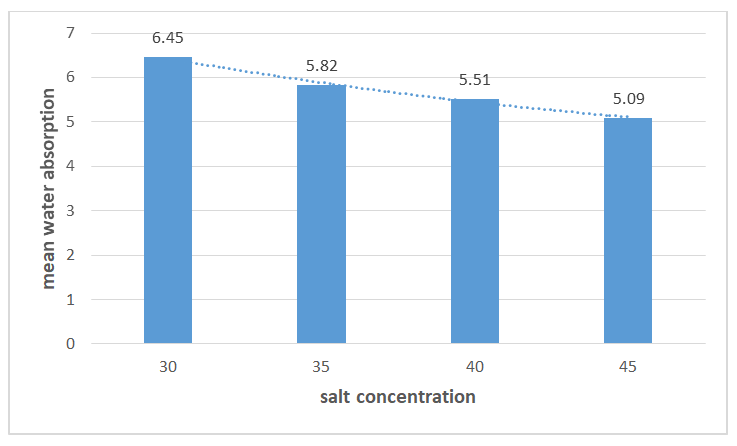

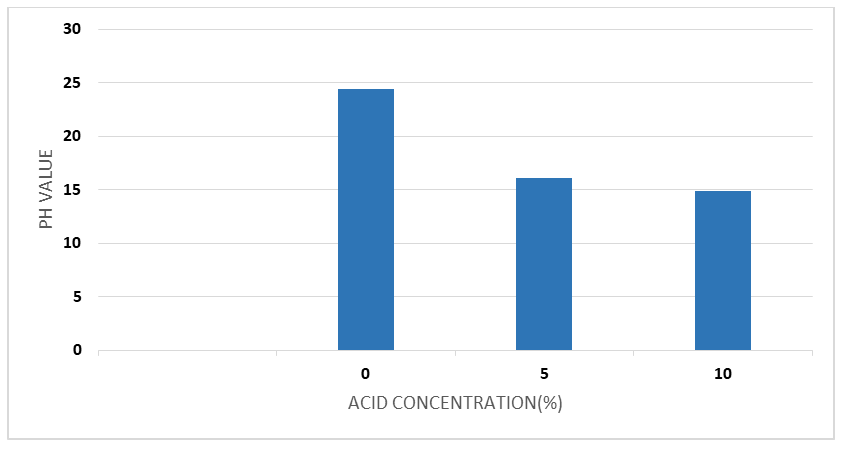

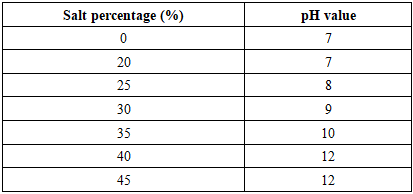

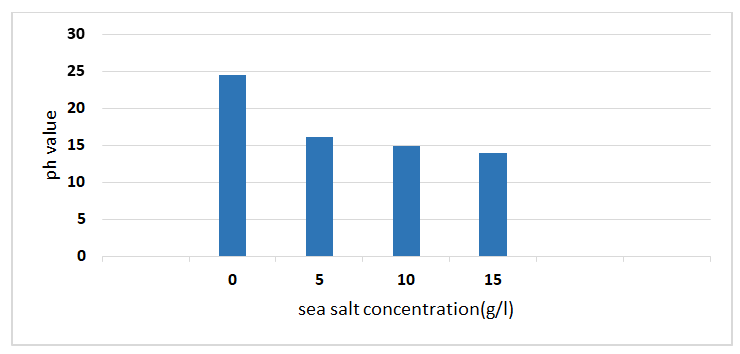

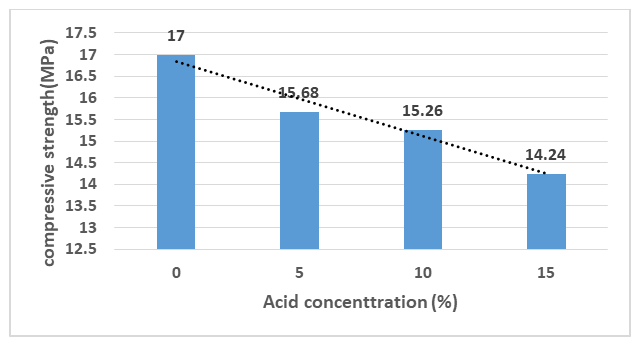

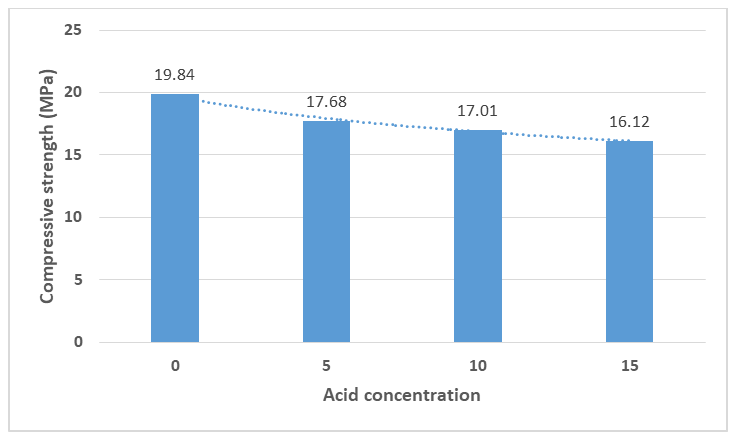

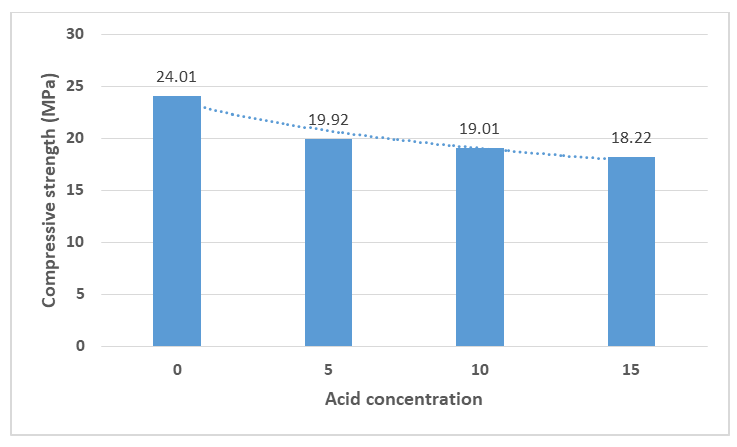

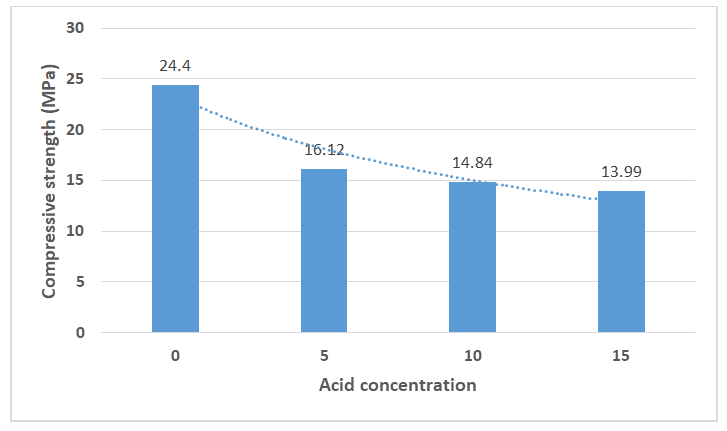

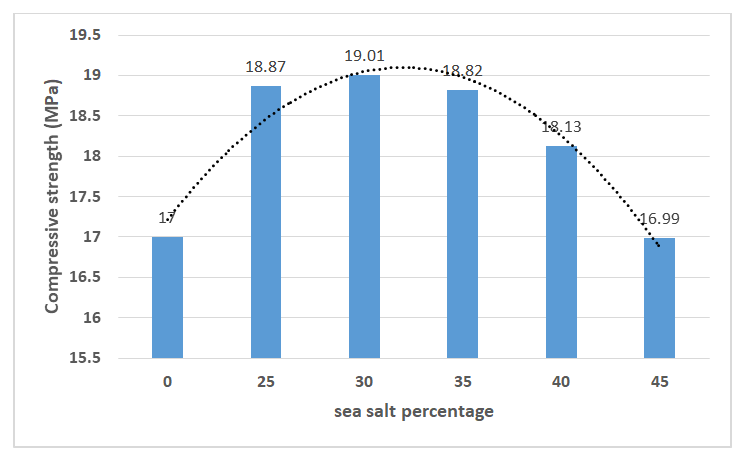

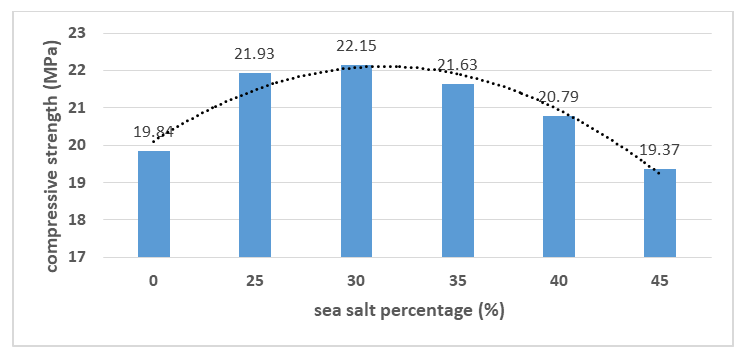

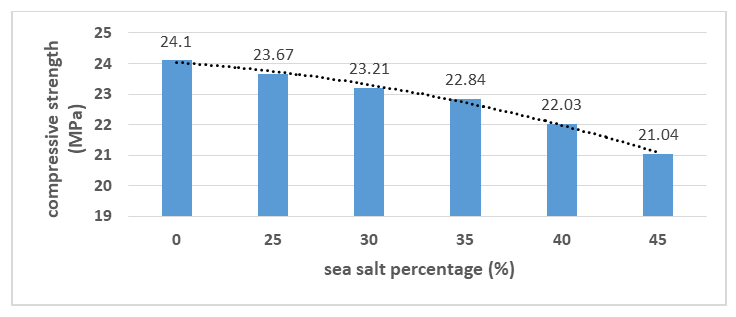

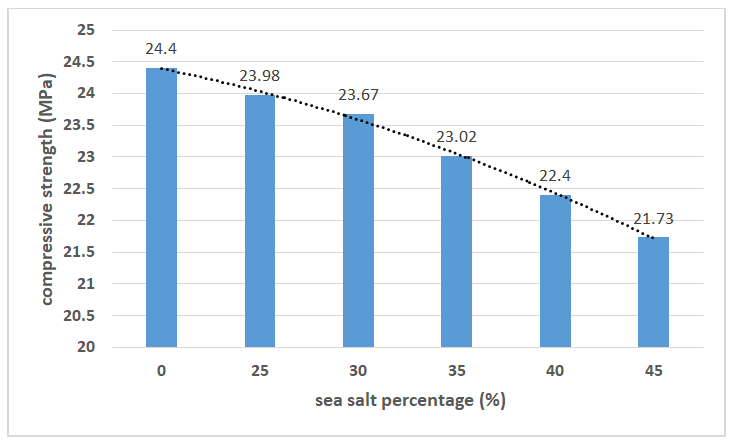

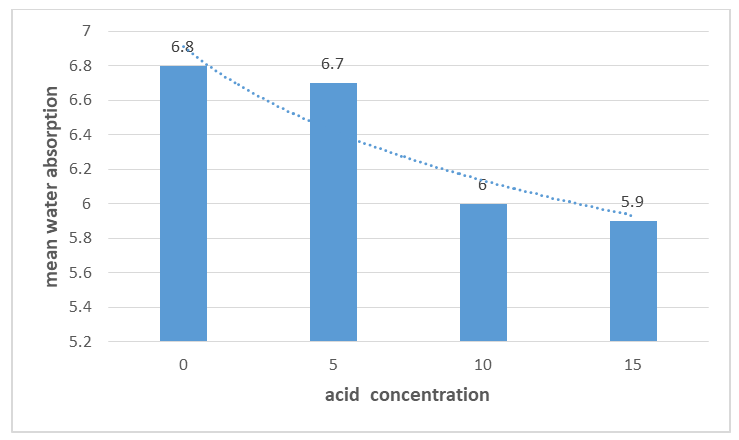

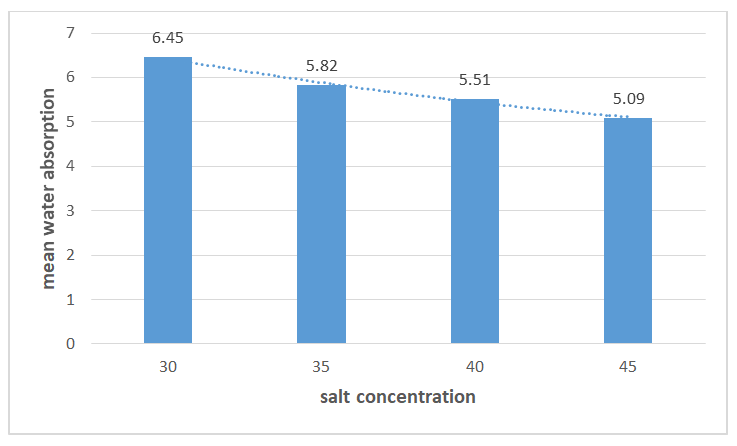

SandAccording to Table 1, the sand used in the concrete mix exhibited excellent quality:• Sand Equivalent (SE) = 97.58%: This high SE value indicates that the sand is clean and contains minimal clay and fines, essential for maintaining bond strength in concrete.• Specific Gravity (Gs) = 2.684: This value is typical for silica sand and suggests an average density, contributing to a balanced mix.• Coefficient of Uniformity (Cu) = 5.08 and Coefficient of Gradation (Cc) = 0.79: These show moderately graded sand. While Cu > 4 indicates well-graded sand, the Cc value near 1 suggests the gradation curve is slightly skewed but acceptable for concrete production.• Fineness Modulus (FM) = 3.14: Falls within the desirable range for concrete (2.3–3.1), suggesting medium sand suitable for workability and strength.• Particle size range = 4.75 mm to 0.08 mm: Indicates a well-sized distribution suitable for filling voids between coarse aggregates.GravelAs shown in Table 2, two size ranges of gravel were tested: 5/15 mm and 15/25 mm.• Specific Gravity = 2.81 and 2.813, Apparent Specific Gravity = 2.84: Suggests both gravel types are dense, typical of hard stones such as granite or basalt.• Water Absorption < 0.31%: Low absorption indicates the gravels are non-porous, supporting durable concrete.• Fineness Modulus = 6.63 (5/15 mm) and 7.74 (15/25 mm): Confirms the coarseness of the aggregates.• Cu and Cc values suggest moderately graded gravels, ideal for inter-particle packing in concrete.CementTable 3 details the characteristics of the cement used:• Resistance Class = 42.5R: Indicates a rapid-hardening cement with high early strength, crucial for fast formwork turnaround.• Specific Gravity = 3.1, Bulk Density = 1440 kg/m³: Normal for OPC, ensuring predictable behavior in mix calculations.• Consistency = 28%, Soundness = 0.5 mm: Indicates acceptable setting behavior with minimal expansion risk.• Setting Times (Initial: 80 min, Final: 278 min): Suitable for standard construction operations, providing ample workability.WaterFrom Table 4, the pH of the tap water used is 7, which is neutral and appropriate for concrete mixing.Concrete mix designThe mix design yielded a target compressive strength of 25 MPa at 28 days, with a water-cement ratio of 0.6 and slump of 60 mm (moderate workability). The mix components (Table 5) were well-balanced for structural concrete.Effects of acidic environment on concretepH VariabilityFigure 1 shows a clear reduction in pH with increasing acid concentration. At 15% acid, the pH drops to 1, indicating a highly corrosive curing environment.Compressive strength (Acid exposure)Referencing Table 6 and Figures 3 to 6, the data clearly demonstrates degradation in compressive strength over time under acid exposure:• At 0% acid, strength reached 24.10 MPa (cylinder) and 30.12 MPa (cube) at 28 days, confirming the mix met its design target.• With 15% acid, strength decreased to 18.22 MPa (cylinder) and 30.13 MPa (cube) at 28 days a 24% reduction in cylinder strength.• At 60 days, the degradation trend continued. For 15% acid, compressive strength dropped to 13.99 MPa, a ~42% decrease from the control (24.4 MPa).These reductions suggest that high acidity significantly impairs cement hydration and promotes leaching of calcium hydroxide, weakening the concrete matrix.Flexural strength (Acid exposure)From Table 7, flexural strength followed a similar declining trend:• Control (0%) = 3.4 MPa (28 days) vs. 15% acid = 2.99 MPa, indicating a ~12% drop.• At 60 days, 15% acid exposure led to a flexural strength of 2.61 MPa, down ~25% from the control (3.46 MPa).This confirms surface deterioration and cracking associated with aggressive acid attack.Water absorption (Acid exposure)Table 9 and Figure 11 illustrate increased permeability with acid exposure:• Mean absorption decreased from 6.8% at 0% acid to 5.9% at 15%. While this appears counterintuitive, it may reflect clogging of pores due to acid-induced recrystallization rather than improved impermeability.• The overall high absorption in acidic samples suggests ongoing microstructural degradation.Effects of Saline environment on concretepH variationFigure 2 confirms that as salt concentration increases, pH rises from 7 to 12, indicating a mildly to strongly alkaline curing environment at higher salt contents.Compressive strength (Salt exposure)From Table 6 (4.1.3) and Figures 7 to 10:• At 0% salt, 28-day cylinder strength = 24.10 MPa.• Peak strength occurred at 30% salt = 23.21 MPa, slightly below control but higher than more aggressive environments.• Even at 45% salt, strength remained 21.04 MPa, a ~13% drop, much less severe than acid exposure.Thus, saline curing has a milder negative effect, possibly due to salt-induced pore refinement at moderate concentrations.Flexural strength (Salt exposure)Table 8 shows relatively stable flexural strength:• Peak = 3.41 MPa (30%) at 28 days, nearly equal to control.• Even at 45%, it remained 3.21 MPa, a modest decline.Salt water appears to enhance early-age performance due to the potential densification of the microstructure.Water absorption (Salt exposure)Table 9 and Figure 12 show a clear trend:• Absorption decreased with salt concentration: 6.45% at 30% to 5.09% at 45%.• This suggests salt may aid in reducing porosity or filling micro-cracks, thereby enhancing durability to some extent, up to a certain threshold.Table 1. Result for characteristics of sand

|

| |

|

Table 2. Result for characteristics of gravels

|

| |

|

Table 3. Result for characteristics of cement

|

| |

|

Table 4. Result for pH of water

|

| |

|

Table 5. Results for pH of curing water solutions

|

| |

|

| Figure 1. Diagram showing the pH variation of the acid solution used for curing |

| Figure 2. Diagram demonstrating the variation in PH in the saline environment used for curing |

Table 6. Compressive strength of concrete for acids

|

| |

|

| Figure 3. Diagram demonstrating the variation in compressive strength of concrete cylinders in an acidic environment after 7 days |

| Figure 4. Diagram demonstrating the variation in compressive strength of concrete cylinders in an acidic environment after 14 days |

| Figure 5. Diagram demonstrating the variation in compressive strength of concrete cylinders in an acidic environment after 28 days |

| Figure 6. Diagram demonstrating the variation in compressive strength of concrete cylinders in an acidic environment after 60 days |

Table 7. Compressive strength of concrete for salts

|

| |

|

| Figure 7. Diagram demonstrating the variation in compressive strength of concrete cylinders in a saline environment after 7 days |

| Figure 8. Diagram demonstrating the variation in compressive strength of concrete cylinders in a saline environment after 14 days |

| Figure 9. Diagram demonstrating the variation in compressive strength of concrete cylinders in a saline environment after 28 days |

| Figure 10. Diagram demonstrating the variation in compressive strength of concrete cylinders in a saline environment after 60 days |

Table 8. Flexural strength results of concrete cured in acid water

|

| |

|

Table 9. Flexural strength results of concrete cured in salt water

|

| |

|

Table 10. Water absorption test results

|

| |

|

| Figure 11. Diagram demonstrating the variation in mean water absorption of concrete cylinders in a acid environment |

Table 11

|

| |

|

| Figure 12. Diagram demonstrating the variation in mean water absorption of concrete cylinders in a saline environment |

4. Discussion

ü Compressive and Flexural strengthThe compressive strength of concrete defines the maximum load that the material can carry per cubic meter. From the results, the compressive strength of concrete increased with increase in curing age for all normal water conditions. The compressive strength also increased with curing age for all acid concentrations from 0 to 28 day but witnessed a significant drop in strength from about 60 days in acidic water condition. It was also observed from the results that the compressive strength decreased with increase in acid concentration. This results indicate that the negative effect of structures placed or constructed in an acidic environment will not really be felt in the early stages after construction as compared to the late stages (about two months) after construction as the material will start to experience significant changes in its strength property. From 0 to 5% concentration of acid in water, for 60 days and above, the material experiences a significant drop in strength then decreases in a uniform manner for any further increase in acid concentration. Meanwhile according to According to [17], in a study on the deterioration of concrete Caused by Sulfuric Acid Attack, proposed a prediction method for the deterioration of concrete due to sulfuric acid. Concrete cylinder specimens were immersed in various concentrations of sulfuric acid. Also, sulfuric acid was circulated over the surface of concrete. It was found that the rate of concrete deterioration caused by sulfuric acid depended on pH value of acid solutions. Also, time of exposure of concrete to acid plays a crucial role in rate of deterioration. Paper also monitors depth of erosion.From our results, the compressive strength of samples cured in salt water increased for all concentrations of salt below 35%. The material starts experiencing a decrease in strength for all salt concentrations from 35% and above. In all cases observed, the compressive strength of concrete cured under salt water conditions increased with curing age even though there is a decreasing strength with salt concentration, it has an advantage of improving over time under any salt concentration. Meanwhile according to [18] on a research work on Salinity effect on properties of M20 Grade concrete in different normality condition. For this 24 concrete cubes and cylinders were casted using fresh water and saline water concentrations of 8g, 16g and 24g NaCl salt per one liter of clean water for a design mix of M-20 concrete, and 0.55 water cement ratio. Concrete specimens were casted and cured with fresh water and remaining specimens were casted and cured with saline water .The concrete cubes were tested for 7, 14 and 28 days respectively. The study reveals that there is some increase in the strength if salt water is used for casting and curing .This concrete can be used for mass concreting without any decrease in strength properties.It was observed that the flexural strength of concrete follows the same pattern with compressive strength. It increased with increase in curing age for all normal water conditions. The flexural strength just like the compressive strength also increased with curing age for all acid concentrations in the early stages after casting but witnessed a significant drop in strength from about 60 days in acidic water condition. It can also be observed from the results that the tensile strength decreased with increase in acid concentration. So, it can be inferred that, the negative effect of concrete in an acidic environment is not felt in early stages after construction as compared to the later stages (about two months) after construction as the material will start to experience significant changes in its strength property. From 0 to 5% concentration of acid in water, for 60 days and above, the material experiences a significant drop in strength then decreases in a uniform manner for any further increase in acid concentration.It was also observed from results that; the flexural strength also follows the same pattern of the compressive strength. The flexural strength of samples cured in salt water increased for all concentrations of salt below 35%. The material starts experiencing a decrease in strength for all salt concentrations from 35% and above. In all cases observed, the flexural strength of concrete cured under salt water conditions increased with curing age, even though it has a setback of decreasing in strength with salt concentration, it has an advantage of improving over time under any salt concentration. Failure of the concrete structure exposed to a corrosive environment is a widespread phenomenon and has been reported from different parts of world including Gulf countries [19]. Corrosive agents when present in significant concentration in plain cement concrete also form complex and expansive salts which result in a reduction in strength. The formation of expansive salt and its quantum may vary depending on the stage of hydrated cement paste. If the specimens are kept in an aggressive environment right from the time of demoulding, aggressive salt or acids may react with cement constituents more freely [20]. However, if the concrete is old when exposed to a corrosive environment, the picture may be different. It is normal practice to expose the structure for curing 24 hours after casting [21]. Therefore, in this study, specimens were exposed to a corrosive environment right from the time of demoulding and studies were carried out after 7 days, 14 days, 28 days and 60days of exposure to analyze the performance of the concrete in these environments to avoid deterioration and failure of structures. ü Water absorptionWater absorption is defined as the amount of water absorbed by a material and is calculated as the ratio of the weight of water absorbed to the weight of the dry material. From the results, it was observed that the effect curing concrete in a salty and acidic environment on the water absorption of the material is given below. Salty environmentFrom the result, it was observed that the water absorption of concrete decreases with increase in salt content. A material that absorbs more water will yield less strength and durability. A material will absorb more water if the porosity and void ratio is high. This also means that the material porosity and void ratio will decrease with increase in salt content. Acidic environmentFrom the result, it was observed that the water absorption of concrete decreases with increase in salt content for percentages of acid from 0% to 10%. The water absorption starts increasing with increase content of acid from 10% and above. A material that absorbs more water will yield less strength and durability. A material will absorb more water if the porosity and void ratio is high. This also means that the material’s porosity and void ratio will decrease with increase in acid content for smaller percentages of acid (0-10%) and will start increasing for higher percentages of acid (>10%).

5. Conclusions

By comparing the results of water absorption, compressive and flexural strength of concrete in each curing time for concrete cubes cured by using clean water with that of concrete cubes cured by using salt and acid water and also by comparing the results of compressive strength of non-control concrete cubes with each other in each curing time; the following conclusions were obtained;• The compressive and flexural strength of concrete cubes cured by using salt water were higher than that of concrete cubes cured by using clean water in the early curing days that is 7 and 14days.• The compressive and flexural strength of concrete cubes cured by using 25g, 30g and 35g sodium chloride salt per liter of clean water were increasing and dropped in the 40g and 45g of salt solution.• The 60 days compressive and flexural strength of concrete cubes cured by using 45g sodium chloride salt was smaller than that of the 60 days compressive and flexural strength of concrete cubes cured by all other salt water samples.• Acidic curing environment has a negative effect on the compressive strength, flexural strength and density of the concrete.• The rate of reduction of mass, compressive and flexural strength of the concrete cubes cured in lower concentration of acid (5%) increases as the concentration is raised from 5% to15%. Evidently, the compressive strength was lower at higher concentration of acid irrespective of the type of acid and method of attack.• Curing the concrete cubes in 15% HCl for 60 days causes maximum reduction in compressive and flexural strength.

ACKNOWLEDGEMENTS

Special thanks go to the staff of the Department of Civil Engineering and Forestry Techniques of Higher Technical Teacher Training College, the staff of Department of Civil Engineering and Architecture National Higher Polytechnic Institute of The University of Bamenda and the staff Mipromalo Laboratory for their inputs to this study.

Funding

This research work did not receive any funding.

Declaration of Interest Statement

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the findings reported in this paper.

Availability of Data and Materials

The data that support the findings of this study are available with the corresponding author, [Mbuh Moses Kuma], upon reasonable request.

Authors’ Contributions

Mbuh Moses Kuma, Penka Jules Bertrand, Nsahlai Leonard Nyuykongi, Lepahle Stephanie Isha were the investigators and drafted the manuscript. Mbuh Moses Kuma designed the study, Mbuh Moses Kuma read and approved the final manuscript.

List of Abbreviations

References

| [1] | Naik, T.R., Sustainability of the cement and concrete industries, in Sustainable construction materials and technologies. 2020, CRC Press. p. 19-25. |

| [2] | Ismail, S., W.H. Kwan, and M. Ramli, Mechanical strength and durability properties of concrete containing treated recycled concrete aggregates under different curing conditions. Construction and Building Materials, 2017. 155: p. 296-306. |

| [3] | Taylor, P.C., Curing concrete. 2013: CRC press. |

| [4] | Kucche, K., S. Jamkar, and P. Sadgir, Quality of water for making concrete: a review of literature. International Journal of Scientific and Research Publications, 2015. 5(1): p. 1-10. |

| [5] | Pierce, J.S., Mixing and curing water for concrete, in Significance of Tests and Properties of Concrete and Concrete-Making Materials. 2006, ASTM International. |

| [6] | Habert, G., et al., Environmental impacts and decarbonization strategies in the cement and concrete industries. Nature Reviews Earth & Environment, 2020. 1(11): p. 559-573. |

| [7] | Mondal, N., et al., Determining the interaction between groundwater and saline water through groundwater major ions chemistry. Journal of Hydrology, 2010. 388(1-2): p. 100-111. |

| [8] | Ekekezie, C., E. Nnadi, and F. Okeke, INVESTIGATION OF THE CAUSES, EFFECTS AND PREVENTIVE MEASURES OF DAMPNESS IN BUILDINGS IN ENUGU METROPOLIS. ONLY One Earth, 2022: p. 208. |

| [9] | Aprianti, E., A huge number of artificial waste material can be supplementary cementitious material (SCM) for concrete production–a review part II. Journal of cleaner production, 2017. 142: p. 4178-4194. |

| [10] | Umale, S. and G. Joshi, Study of effect of chemicals (acid) attack on strength and durability of hardened concrete. International Research Journal of Engineering and Technology (IRJET), 2019. 6(4): p. 548-552. |

| [11] | Surahyo, A. and A. Surahyo, Chemical Attack. Concrete Construction: Practical Problems and Solutions, 2019: p. 223-238. |

| [12] | D2419-22, A., Standard Test Method for Sand Equivalent Value of Soils and Fine Aggregate. 2022: https://www.astm.org/standards/C2419. Retrieved 1, July 2023 at 6:00 pm. |

| [13] | Neville, A.M., and Brooks, J. J., Concrete Technology, 2nd Edition. Edinburgh, England. 2010: Pearson Education Limited. |

| [14] | Kankam, C.K. and A. Thomas, Comparative Study of the Compressive Strength of Concrete made from Different Brands of Cements in Ghana. Journal of Engineering Research and Reports, 2022. 23(9): p. 41-49. |

| [15] | Zain, M.F.M., et al., Production of rice husk ash for use in concrete as a supplementary cementitious material. Construction and building materials, 2011. 25(2): p. 798-805. |

| [16] | Surahyo, A., L. Surahyo, and Luby, Concrete construction. 2019: Springer. |

| [17] | Kawai, K., S. Yamaji, and T. Shinmi, Concrete deterioration caused by sulfuric acid attack. Durability of Building Materials, 2005: p. 5-9. |

| [18] | Premchand, Experimental Study on Salinity Effect on Properties of M20 Grade Concrete In Different Normality Condition. Journal of Advances in Science and Technology, E-ISSN: 2230-9659, 2016. Volume 11, Issue No. 22, May 2016. |

| [19] | Qu, F., et al., Durability deterioration of concrete under marine environment from material to structure: A critical review. Journal of Building Engineering, 2021. 35: p. 102074. |

| [20] | Gosselin, C., Microstructural development of calcium aluminate cement based systems with and without supplementary cementitious materials. 2009, EPFL. |

| [21] | Gardner, D., et al., A survey on problems encountered in current concrete construction and the potential benefits of self-healing cementitious materials. Case studies in construction materials, 2018. 8: p. 238-247. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML