-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

American Journal of Materials Science

p-ISSN: 2162-9382 e-ISSN: 2162-8424

2020; 10(2): 42-47

doi:10.5923/j.materials.20201002.03

Received: Nov. 6, 2020; Accepted: Nov. 26, 2020; Published: Dec. 15, 2020

Study on Preparation and Mechanical Characterization of Blended Pineapple and Jute Fiber/Unsaturated Polyester Resin (UPR) Based Composite and Effect of Alkali on Composites

Solaiman1, Mohammad Bellal Hoque2, Zahid Mahmud1, Asraful Aman1, Asif Hassan1, Ruhul A. Khan3, Nazrima Sultana2

1Pabna Textile Engineering College, Bypass, Pabna, Bangladesh

2Department of Textile Engineering, Fareast International University, Banani, Dhaka, Bangladesh

3Polymer Composite Laboratory, Institute of Radiation and Polymer Technology, Bangladesh, Atomic Energy Commission, Dhaka, Bangladesh

Correspondence to: Solaiman, Pabna Textile Engineering College, Bypass, Pabna, Bangladesh.

| Email: |  |

Copyright © 2020 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

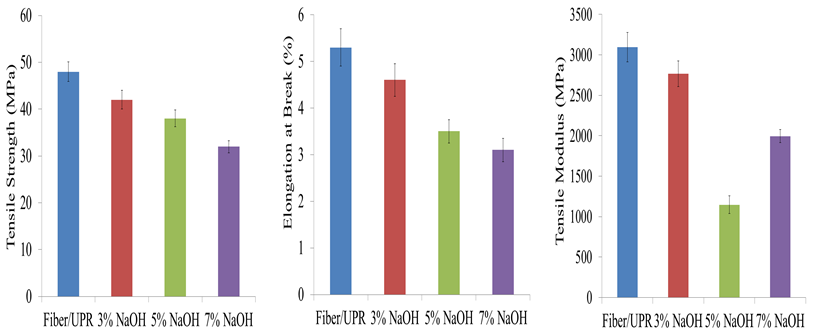

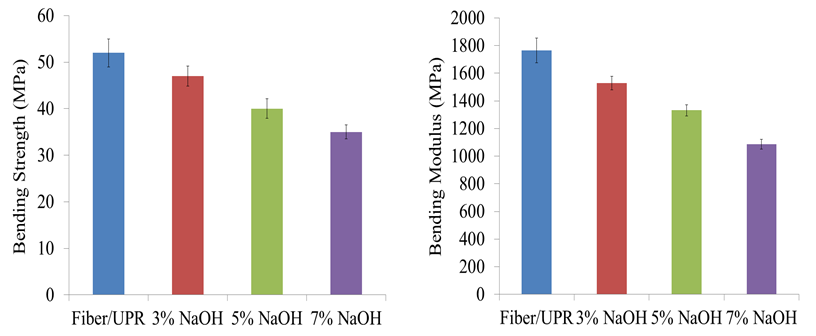

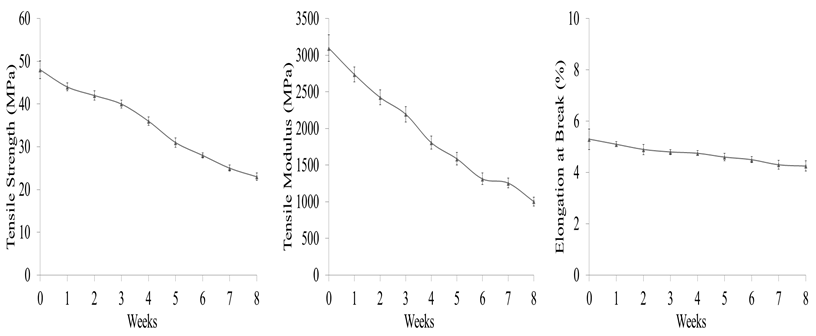

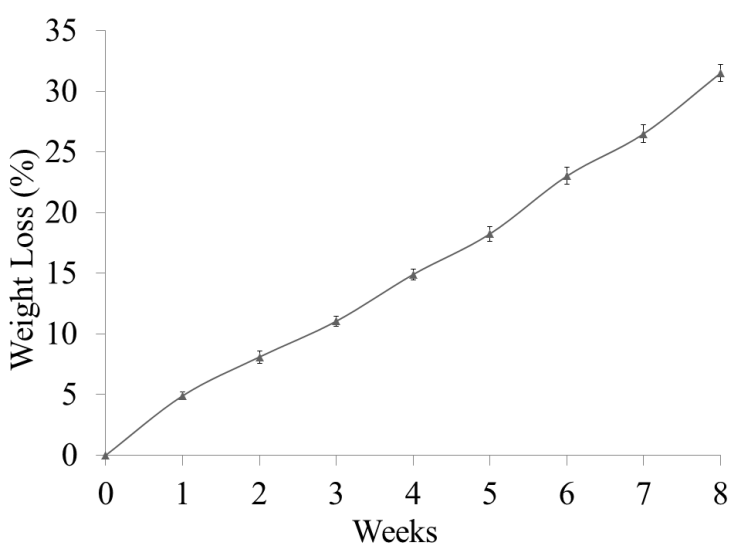

In this study, blended pineapple and jute fiber reinforced unsaturated polyester resin (UPR) based composites were made by simple hand lay-up technique. The quantity of fibers were 50% by weight. The tensile strength (TS), tensile modulus (TM), elongation at break (Eb%), bending strength (BS) and bending modulus (BM) of the composites were found to be 48 MPa, 3096 MPa, 5.30%, 52 MPa and 1764 MPa respectively. Results revealed the increased percentage of TS, TM, BS and BM were 33%, 34%, 18% and 26% respectively. Reduced Eb% was noticed due to addition fo fibers. Water uptake test was executed by immersing the composites in deionized water and water uptake was higher. The composites were sunk in 3%, 5% and 7% solution of sodium for 1 hour to investigate the effect of alkali and reduced mechanical properties were evaluated. Soil degradation test was carried out on composites for 8 weeks and found that fiber/UPR composites retained about 48% of their original mechanical properties.

Keywords: Natural fiber, Unsaturated polyester resin (UPR), Composite, Hand lay-up technique, Mechanical properties

Cite this paper: Solaiman, Mohammad Bellal Hoque, Zahid Mahmud, Asraful Aman, Asif Hassan, Ruhul A. Khan, Nazrima Sultana, Study on Preparation and Mechanical Characterization of Blended Pineapple and Jute Fiber/Unsaturated Polyester Resin (UPR) Based Composite and Effect of Alkali on Composites, American Journal of Materials Science, Vol. 10 No. 2, 2020, pp. 42-47. doi: 10.5923/j.materials.20201002.03.

1. Introduction

- A composite material can be defined as a solid material which is fabricated by sandwiching a core layer by two or more other materials which are known as matrix material. The uses of natural fibers as a core layer for fabricating composites have been increasing day by day. Fiber reinforced composite materials are using in various fields such as aerospace, civil construction, medical sector, furniture and many more [1-9]. Nowadays, composites made from synthetic fibers are mostly used but they are expensive and not environmental friendly. For overcoming these problems, cellulose based natural fibers especially for high volume and cost effective applications are replacing them. Polarity and hydrophilicity properties are involved with natural fibers but non polar matrix material can be solved these problems. Besides, the natural fibers are available, cost effective and most importantly environmental friendly. [10–14]. Researchers have been giving their concentration for replacing synthetic fibers by natural fibers as a raw material that have similar physical and mechanical properties compared to synthetic fiber. There things need to be considered during the selection of raw materials are inexpensiveness, effect on environmental and human health, high flexibility, availability which are directly related with the suitability of natural fibers. Natural fibers are renewable source, besides they are durable, economical and hygienic [15].Pineapple leaf fiber (PALF) is a natural fiber and considered as an agricultural wastage. It has chemical composition of 70–82% holocellulose, 5–12% lignin and 1.1% ash. For having higher percentage of hollocellulose in pineapple fiber, it shows excellent mechanical properties. For this reason it has been used for making of reinforced polymer composites. Jute is another important natural fiber. It is cultivated in Bangladesh, India, China, Uzbekistan, Bhutan, Vietnam and Thailand. Bangladesh and India produce 93% jute of the world. Clothes, ropes, gunny and shopping bags, floor coverings etc. are produced from jute fiber. Jute fibers can also be used with matrix material like low density polyethylene, unsaturated polyester resin, polypropylene, polyethylene etc. as filler or core layer of composites. It provides advantages such as low weight, density and elongation at break, high tensile modulus, availability and economic [16]. It has 82%-85% hollocellulose in which 58%-63% alpha-cellulose which make it more compatible for composite fabrication [17]. Matrix material is the most important part of composite material. Unsaturated polyester resin (UPR) has been widely used as a matrix material with natural fibers in composite preparation. UPR can also be used as sheet molding compounds. A good range of mechanical properties can be achieved by using UPR in composite fabrication. Besides, it has advantages such as low cost, good corrosion resistant and light weight [18]. In this study, the mechanical behaviour of fiber reinforced UPR based composites were reported. Water absorption profile and effect of alkali on mechanical properties of fiber/UPR composites were also investigated.

2. Materials and Methods

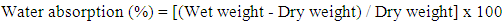

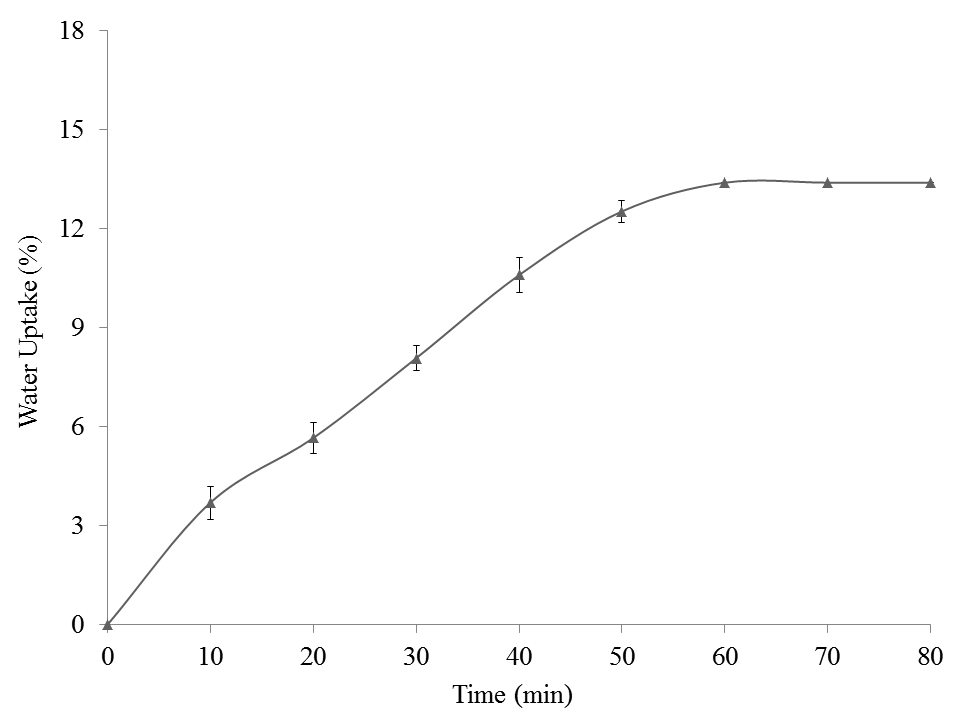

- MaterialsBleached PALF and jute fibers were purchased from two different places of Bangladesh. PLAF were bought from Modhupur, Tangail and jute fibers were from Bangladesh Jute Research Institute (BJRI), Dhaka, Bangladesh. Jute and pineapple fibers were opened mechanically in Bangladesh Jute Research Institute (BJRI), Dhaka, Bangladesh. The matrix polymer unsaturated polyester resin was supplied by Shakubal Kagaku Kogyo Company Limited, Chou-ku, Osaka, Japan and curing agent methyl ethyl ketone peroxide (MEKP) was brought from Tokuyama Corporation, Japan.Making of Blended Pineapple and Jute Fiber/ Unsaturated Polyester Resin (UPR) Based CompositeSimple hand lay-up technique was used for fabricating composites. For easy removal of composites from the mylot paper, the mylot paper was treated with waxes and kept it on metal plate. At the beginning of the fabrication process, a solution containing 97% UPR and 3% MEKP as hardener was made at room temperature. After placing equal amount of fibers closely on mylot paper, the solution was laid down on the fibers. Then the fibers were covered with another mylot paper and rolled it by hand roller. Finally covered it with another metal plate and kept it for six hours under a weight of 15 kg. After six hours, the composites were uncovered and cut it into desired size. 25% pineapple and 25% jute fibers were in composites and the rest 50% was unsaturated polyester resin. The fabricated composites were then collected in polyethylene bags for further evaluation. Mechanical Properties of CompositesThe mechanical properties such as tensile and bending properties of the composites were assessed by using Hounsfield series S testing machine (UK) according to ASTM-D638-01. The initial separation of clamp was 20 mm and the loading force was 1 mm/sec. (60×10×3) mm was the dimension for mechanical tests of fiber/UPR composites. All the tests were carried out for five times and their average values were taken.Water absorption Profile of the CompositesThe investigation of water uptake percentage of fiber/UPR composites was performed to find out the water absorption profile. Three cut samples of different weight of fiber/UPR composites were used to determine the water uptake behaviour. The weights of the samples were measured initially. The samples were immersed in 500 ml deionized water at room temperature (25°C). After certain time interval they were brought out from the beaker, wiped by using tissue papers and again weighted. In this case, no considerable water uptake was noticed after 1 hour. That was the reason for conducting water uptake test for 1 hour. The percentage of water absorption was calculated by-

| (1) |

3. Result and Discussion

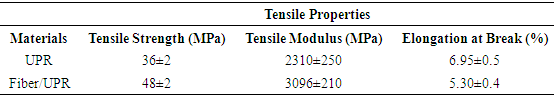

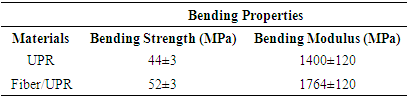

- Mechanical Properties of CompositesThe effects of pineapple and jute fiber on tensile and bending properties of the composites are shown in table 1 and 2. From the table it is seen that the mechanical properties such as the tensile strength (TS), tensile modulus (TM), elongation at break (Eb%), bending strength (BS) and bending modulus (BM) of the UPR were found to be 36 MPa, 2310 MPa, 6.95%, 44 MPa and 1400 MPa respectively. And the TS, TM, Eb%, BS and BM of fiber/UPR composites were 48 MPa, 3096 MPa, 5.30%, 52 MPa and 1764 MPa respectively. By analyzing the values of the table, it is seen that fiber/UPR composites gained increased mechanical properties. Due to addition of pineapple and jute fibers with the UPR, 33% increased in TS, 34% in TM, 18% in BS and 26% in BM were observed. In this study, reduced Eb% was observed though the other mechanical properties were improved. Incorporation of pineapple and jute fibers into composites was the main reason of resucing Eb%.

|

|

| Figure 1. Water uptake % of Blended Pineapple and Jute Fiber/Unsaturated Polyester Resin (UPR) Based Composite |

| Figure 2. Effect of alkali on tensile properties of the composites |

| Figure 3. Effect of alkali on bending properties of the composites |

| Figure 4. Effect of soil degradation on tensile properties of fiber/UPR composites |

| Figure 5. Effect of soil degradation on bending properties of fiber/UPR composites |

| Figure 6. Effect of soil degradation on weight of fiber/UPR composites |

4. Conclusions

- Pineapple and jute fibers/UPR composites were successfully fabricated by simple hand lay-up technique and characterized in this study. Use of blended pineapple and jute fiber can be a new source of composite material in sense of environmental issue. Under this study, 50 wt% PALF and Jute fiber/UPR composites were studied throughout. Acceptable values of mechanical properties were achieved at this composition. The tensile and bending properties of the composites were increased significantly in this study. Diminished tensile and bending properties were also investigated by alkali treated PALF and Jute fiber/UPR composites. The soil degradation test was conducted for a time period of 8 weeks and after 8 weeks the composites lost about 52% of their original mechanical properties which indicated the biodegradability of PALF and jute fiber/UPR composites. PALF and jute fiber are water susceptible natural fiber. Initially, the rate of water absorption of fiber/UPR composites was higher but after 60 minute the composites were absorbed no water. Further research on PALF and jute fiber reinforced unsaturated polyester resin based composites is needed to achieve improve knowledge about the topic.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML