-

Paper Information

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

American Journal of Materials Science

p-ISSN: 2162-9382 e-ISSN: 2162-8424

2018; 8(3): 51-57

doi:10.5923/j.materials.20180803.02

Comparative Analysis of the Friction and Microstructural Properties of WC-10Co-4Cr and Cr3C2-25NiCr Coatings Sprayed by High-Velocity Oxy-fuel (HVOF)

Angela Selau Marques, Rafael Luciano Dalcin, Leonardo Fonseca Oliveira, Lucas Alves Vitor da Silva, Giovanni Rocha dos Santos, Alexandre da Silva Rocha

Department of Metallurgical Engineering, UFRGS - Federal University of Rio Grande do Sul, Porto Alegre-RS, Brazil

Correspondence to: Angela Selau Marques, Department of Metallurgical Engineering, UFRGS - Federal University of Rio Grande do Sul, Porto Alegre-RS, Brazil.

| Email: |  |

Copyright © 2018 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

In this study, coatings WC-10Co-4Cr and Cr3C2-25NiCr were deposited on the AISI H13 steel by oxy-fuel Thermal spraying (HVOF). This coating increases the wear resistance of surfaces subjected to severe conditions, such as: abrasive wear, thermal fatigue and plastic deformation. The coatings microstructure, hardness and wear resistance are investigated through friction and wear tests performed through a pin-on-disc type tribometer following the procedures defined in ASTM G99-04. It was verified that both materials used in the spraying have high resistance to wear, however, in the sample coated with Cr3C2-25NiCr there was a greater removal of material during the test.

Keywords: Wear, Friction, Thermal Spraying

Cite this paper: Angela Selau Marques, Rafael Luciano Dalcin, Leonardo Fonseca Oliveira, Lucas Alves Vitor da Silva, Giovanni Rocha dos Santos, Alexandre da Silva Rocha, Comparative Analysis of the Friction and Microstructural Properties of WC-10Co-4Cr and Cr3C2-25NiCr Coatings Sprayed by High-Velocity Oxy-fuel (HVOF), American Journal of Materials Science, Vol. 8 No. 3, 2018, pp. 51-57. doi: 10.5923/j.materials.20180803.02.

Article Outline

1. Introduction

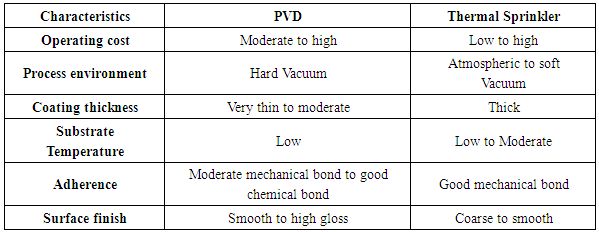

- Chromium and Tungsten Carbide coatings are used to improve wear resistance in industry various segments and recently it has also been applied in the mechanical forming industry to prevent premature damage to the die caused by the hot forging process [1]. Coatings based on cermets can be applied by High-Velocity Oxy-fuel Spraying (HVOF), which is a promising technique and has stood out from the rest due to its characteristics [2]. Table 1 presents a comparison between the main characteristics of PVD coatings used by the metalworking industry. The choice of coating to be used depends greatly on the application, however the versatility of coatings applied by thermal spraying has made its use increase considerably in recent years [3].

|

2. Experimental Procedures

- In the present study, WC-10Co-4Cr and Cr3C2-25NiCr coatings were deposited via HVOF. The coatings were characterized by X-ray diffraction, optical microscopy, scanning electron microscopy (SEM) and microhardness. Finally, both coatings wear resistance is compared through a pin-on-disc type tribometer, following the procedures defined in ASTM G99-04. This test provides friction and wear resistance information under dry sliding conditions.The specimens used in the test were fabricated from AISI H13 steel by the conventional machining process. The dimensions are 60 mm in diameter and 15 mm in thickness. After the parts were manufactured, the tempering and tempering treatment was carried out according to the material specifications, reaching a hardness of 51 HRC.

2.1. Coating Materials

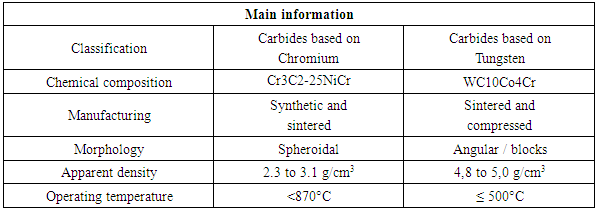

- The method of manufacturing the material determines the powders morphology and may vary according to the supplier. This characteristic has a great influence on the heat exchange between the particles and the combustion gases, since the size and shape of the powder influence the ability to absorb thermal energy during the deposition process [11, 12]. The powders morphology also determines the lamellar structure, by the way the particles settle when they collide with the substrate [13]. In this study, two types of powders were used, supplied by Oerlikon Metco. The main characteristics of each one are represented in Table 2.

|

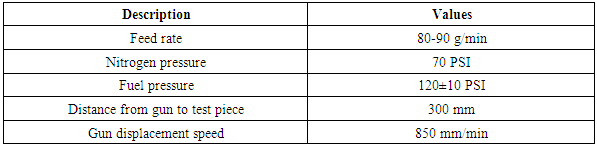

2.2. Spraying HVOF

- The coatings were applied on H13 samples. Prior to the coating application, the samples undergo a blasting process with aluminum oxide. This procedure has the purpose of increasing the surface roughness to improve the adhesion of the coating to the substrate [15]. The coating deposition was performed by the company Rijeza Metallurgy. This company is specialized in the development and application of wear coatings on machines, equipment and parts in different segments of the metalworking industry. For application of the coating the TAFA JP 5000 HP / HVOF System Model 5120, from the manufacturer PRAXAIR and a TAFA GUN Model 5220 pistol, was used as shown in Fig. 1.

| Figure 1. Application of the coating on the specimens |

|

2.3. Characterization Tests

- After application of coating via HVOF, the samples were cut and sanitized for the assays. Scanning electron microscopy (SEM) analysis was performed in Zeiss Scanning Electron Microscope EVO MA 10, which allows analyzing the grain morphology used in the spray and the surface after the coatings were applied. X-ray diffraction analyzes were performed using a Charon XRD Mcom X-ray diffractometer with Cr-K rad radiation. The model GE Meteor1D detector, of the linear type of 20° was used. In addition, the sample was rotated around the PHI axis at an angular velocity of 0.5 / s with an amplitude of 45° and displaced in oscillatory movements with respect to the X and Y axes at a speed of 0.5 mm / s and amplitude of 5 mm. Measurements were taken for 2 ân angles ranging from 35° to 166° with a pitch of 0.02° and a measurement time per step of 200 seconds. Vickers microhardness measurements were performed in accordance with the international standard ASTM E92 [17]. The Vickers HV0.01 microhardness profiles were constructed using an ISH-TDV 1000 microdurometer model - Micro Hardness Tester - INSIZE. The charge penetration time was 10 seconds. Measurements were taken in the cross section of the sample.

2.4. Pin-on-disc Test and Wear Track Measurement

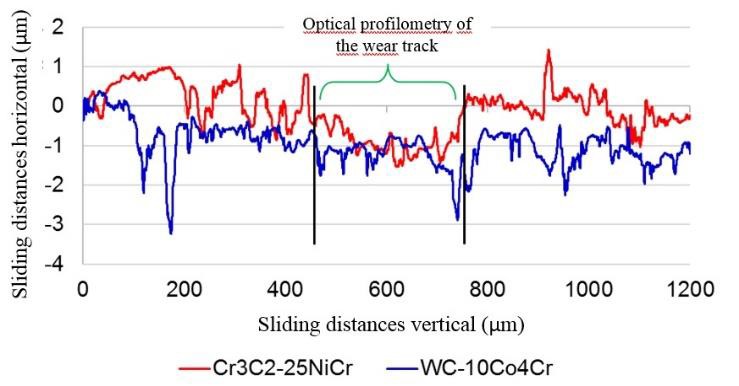

- The standard governing the pin-on-disc test is designated by ASTM as G99-04 [18]. This regulation provides a standard, laboratory-level method for conducting material wear tests during sliding using the pin-on-disc configuration. A ceramic ball (Al2O3) of 6 mm with an average hardness of 1528 HV was used, applying a normal force (F) of 30N. During the test, the linear velocity produced was 0.47 m/s in a radius of 18 mm, with a total distance of 1000 m. For each coating three replications were performed. The measurements of width, depth of wear tracks, and consequently the coatings volume loss produced by this test were obtained by means of profilometry. The roughness of the coated surface was characterized by a BRUKER 3D Optical Profileometer and the Vision64® analysis software from the Multi-user Surface Analysis Laboratory (LAMAS) at UFRGS.

3. Results and Discussion

3.1. X-ray Diffraction Analysis

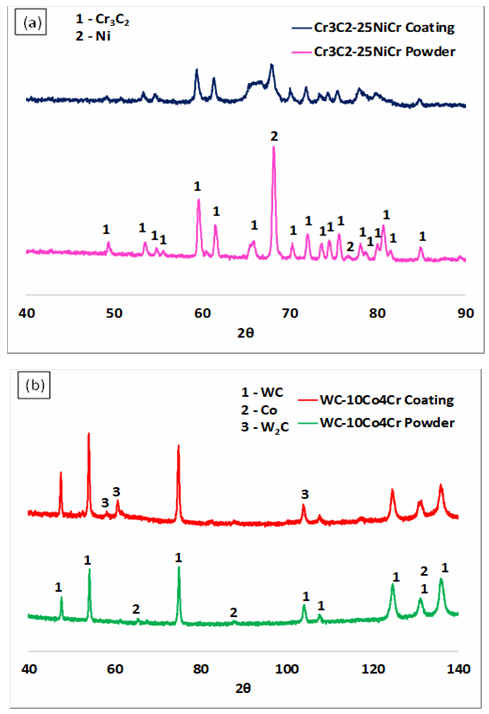

- Fig. 2 (a) shows the diffractogram for Cr3C2-25NiCr powder and the coated surface. In the standard obtained for the powder several peaks of the Cr3C2 phase and an intense Ni peak are present. After the powder is sprayed the Ni peak becomes less intense and closer to one of the peaks of Cr3C2, becoming wider, characterizing an amorphous phase. Similar results were also obtained by Murthy & Venkataraman [19]. Other peaks defined in the powder were less evident after the sprinkling process. The increase in the formation of non-crystalline amorphous phases occurs due to very fast cooling during the spraying process [20].The results obtained for the WC-10Co4Cr powder and for the coated surface are presented in the difatogram of Fig. 2 (b). The presence of the WC and Co. phases can be observed. After the coating deposition, characteristic peaks and "elbows" of the W2C phase are formed. This dewaxing of WC in W2C may impair some coating properties due to the formation of brittle carbides [15, 19]. Studies developed by Stewart, Shipway & Mccartney demonstrate that the amount of different phases and the proportion of each depends greatly on the process conditions at the time of spraying the particles under the substrate. [21].

| Figure 2. XRD patterns of coatings and powder. (a) Cr3C2-25NiCr and (b) WC-10Co4Cr |

3.2. Microstructural Characterization

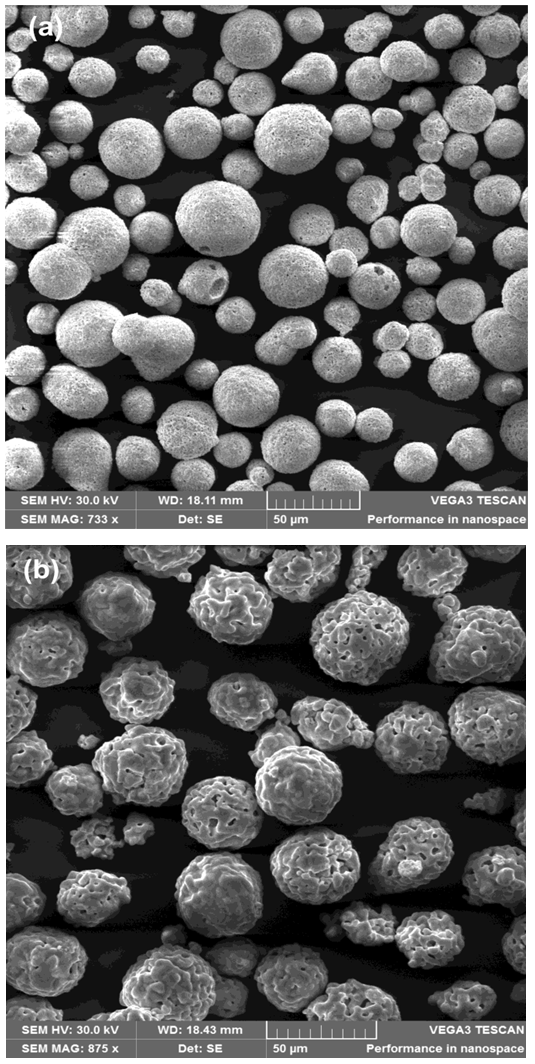

- Fig. 3 (a) shows the scanning electron microscopy (SEM) analysis of the morphological characteristics of WC-10Co4Cr powder. This material has a dense grain, which forms a more homogeneous layer, because material spreads better on the surface [22]. This morphology is desirable for the Thermal spraying y process by HVOF, as it allows a better flow of the powder in the spray gun during the application of the coating [23]. The average diameter of the beads of WC-10Co4Cr powder is 30 μm. In Fig. 3 (b) it is observed that the morphology of Cr3C2-25NiCr powder presents a hollow sphere shaped structure with porosities and spaced particles, the grain diameter varies around 40 μm.

| Figure 3. Morphology of the powder used in the coating based. (a) Cr3C2- 25NiCr and (b) WC-10Co4Cr |

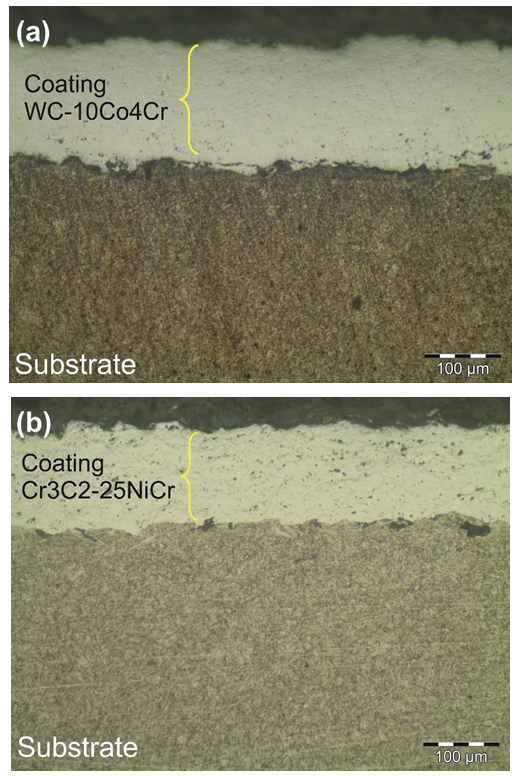

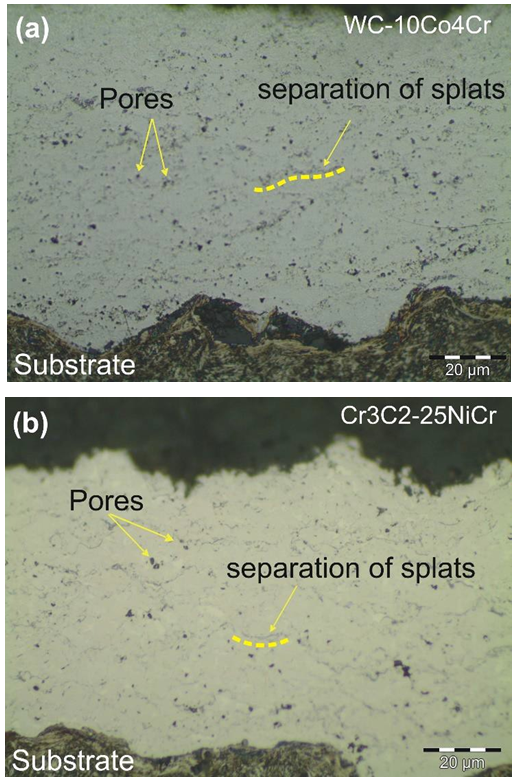

| Figure 4. Microestrutura dos revestimentos. (a) WC-10Co4Cr. (b) Cr3C2- 25NiCr |

| Figure 5. Pores and voids in coatings. (a) WC-10Co4Cr. (b) Cr3C2- 25NiCr |

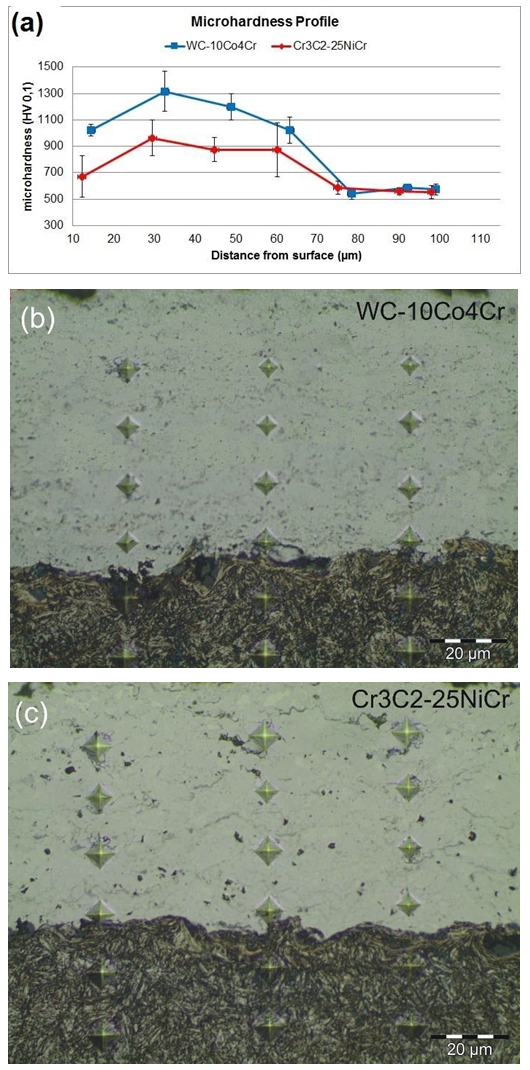

3.3. Microhardness

- The average Vickers microhardness results and the standard deviation of each coating are shown in the graph of Fig. 6 (a). The microhardness values of the layer sprayed with Cr3C2-25NiCr are lower than WC-10Co4Cr values. This behavior is compatible with both researched literature and material supplier indications [28]. It will be appreciated that both coatings have high hardness variations along the cross section, this is due to non-uniformity of the layer. Fig. 6 (a) and (b) shows that each indentation point is located in different microstructures, such as carbides, oxides, inclusions and finally the substrate. The substrate measurements do not have values as discrepant as those found in the sprayed layer, which confirms the variation due to the coating characteristics.

| Figure 6. Microhardness profiles of the coatings |

3.4. Tribological Behavior - Pin-on-Disc

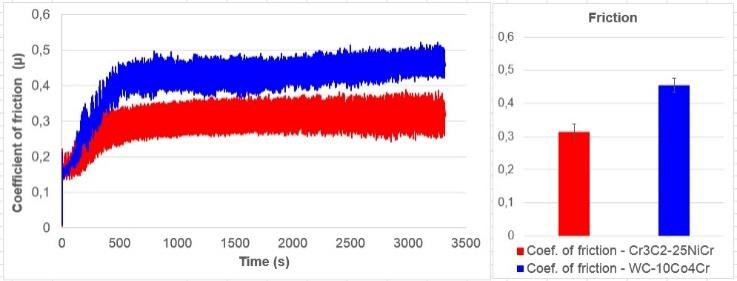

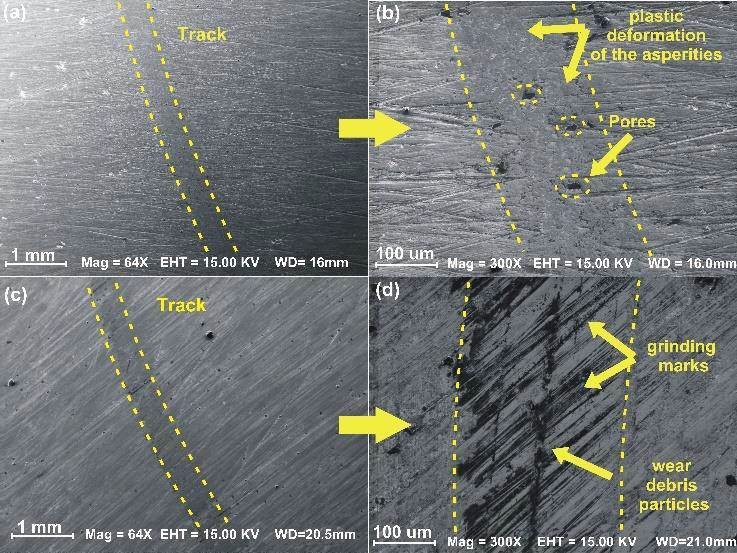

- The behavior of the coefficient of friction for both coatings is shown in Fig. 7. It is observed that the friction coefficient of the sample coated with WC-10Co4Cr is greater than the sample coated with Cr3C2-25NiCr. Initially there is a zone of instability, which occurs due to the detachment of particles from the sphere and the coating [15]. Then, the coefficient of friction reaches a steady value, but there is a maximum and minimum fluctuation that remains constant for both coatings, this phenomenon indicates the wear stabilization on the coating [29, 30].

| Figure 7. Average coefficient of friction obtained in the pin-on-disc test |

| Figure 8. Profilometry of worn tracks after pin-on-disc tests |

| Figure 9. Topography of surface after pin-on-disc tests |

4. Conclusions

- Based on the results obtained it is possible to conclude that the Cr3C2-25NiCr and WC-10Co4Cr coatings on the AISI H13 steel substrate are morphologically well constituted and may contribute to the reduction of surface wear. Through the microscopy analysis, the coatings were found to be homogeneous without defects, such as cracks and / or microchips, and with low porosity. Regarding the coefficient of friction, the coating of WC-10Co4Cr is approximately 58% higher when compared to the coating of Cr3C2-25NiCr. However, the volume loss was more pronounced for Cr3C2-25NiCr coating, this is due to the lower hardness, lower adhesion and higher porosity of this coating.For the WC-10Co4Cr coating, which had a high hardness, there was no significant volume loss to calculate the wear rate. The adsorbed layers with Cr3C2-25NiCr and WC-10Co4Cr presented satisfactory results in the analyzes carried out in this work, showing a promising future for their application in industry components, especially regarding wear resistance.

ACKNOWLEDGEMENTS

- We would like to thank the Rijeza Company from São Leopoldo for the availability to perform production tests and laboratory analysis. We acknowledge the financial support by the Brazilian agencies CAPES, CNPq (process number CNPq 311348/20157) for research grants.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML