Md. Shak Sadi1, Nazmun Nahar2, Md. Shakhawat Hossain2, Sirajul Haque Sajib3

1School of Textile Science & Engineering, Wuhan Textile University, Wuhan, China

2College of Chemistry & Chemical Engineering, Wuhan Textile University, Wuhan, China

3Department of Apparel Manufacturing, Bangladesh University of Textiles, Dhaka, Bangladesh

Correspondence to: Md. Shak Sadi, School of Textile Science & Engineering, Wuhan Textile University, Wuhan, China.

| Email: |  |

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Abstract

Quality is of prime importance in any aspect of a business. Customers demand and expect value for money. Quality and reputation are interlinked with each other; a low-quality product can lead to the damage to the brand image which will be an immeasurable loss for any company. So in that regard quality is the money. Since the popularity of knitted fabric is increasing consistently it is really important to maintain the quality of the supplied product (ex. Garment). Without maintaining high quality there is no other way to survive in this competitive market. In this study, the quality of the finished fabric of a knit factory was observed for the period of 12 months. The Frequencies of different faults on Different Types of finished knitted fabric i.e. Single jersey, Lycra Single jersey, Rib (1*1, 2*1, 2*2, 4*2 etc.), Lycra rib, Interlock, Terry, Fleece, Pique, Lactose, Mesh, Waffle etc. were analyzed. According to the Pareto chart, it was found that 90.10% of the defects were caused by only 4 types of defects i.e. Hole, Contamination, Dirty Spot, Oil Spot and lycra out among 20 types of defect. The root causes for all types of defects were analyzed and their improvement technique discussed.

Keywords:

Weft Knitted fabric, Quality, Defect, Pareto analysis, Cause & Effect

Cite this paper: Md. Shak Sadi, Nazmun Nahar, Md. Shakhawat Hossain, Sirajul Haque Sajib, Amendment of Finished Knitted Fabric Quality by Reducing the Intensity of Defects and Improvement Techniques, American Journal of Materials Science, Vol. 8 No. 1, 2018, pp. 6-14. doi: 10.5923/j.materials.20180801.02.

1. Introduction

Weft Knitted fabrics are gaining more popularity day by day Due to higher production rate, lower cost and easy installment [1]. The high degree of stretch and comfort that knit cloth brings to close-fitting garments, coupled with excellent wrinkle resistance, ease of care, resilience, soft draping qualities, good air porosity and relatively low cost makes them demands eminently suitable to the modern consumer [2, 3]. To meet the demands of an increasingly discerning market, the defect-free high-quality product should be manufactured and supplied by the manufacturer. Quality is the main ingredient in a product that delights the customer either by meeting or exceeding his expectations. Quality can be defined as a combination of the characteristics or properties of a product that makes the product usable [4]. Users estimate the qualities of textile products in many different ways. Designers primarily focus on visual appearance, which has, however, lately become more and more connected with the handle and behavior of a textile fabric as a finished product, for example, in a garment [5]. The quality of the finished fabric is really important because the finished fabric is the raw material for the final product i.e. garment. A defect in the finished fabric will appear in the garment which will lead to the rejection of the end product. Defects in the fabric can occur right from raw material selection to the finishing stage, because of improper input parameters with respect to material, machine and man [6]. Fabric inspection system is important to maintain the quality of fabric [7]. Human inspection by using knitted fabric inspection machines remains today the most used way to classify faults after knitting and after finishing [8]. Generally, faults are classified by type and by frequency in the inspected knitted roll. The inspection assessment permits to appreciate fabric quality. The judgments of fabric quality depend on faults tolerance levels fixed by each knitter and could be in some cases subjective because it is often based only on the number of faults and not on fault size and gravity [9]. In this study faults in the knitted fabric are identified by human inspection using knit fabric inspection machine. The faults in the fabric were calculated by using 4 point system and categorized by the supplier quality acceptance limit. A pareto analysis was performed to identify major defects. Root-cause of the defects was identified and their possible remedies & improvement technique were also analyzed.

2. Materials & Methods

The research was carried out at Meghna Knit Composite Limited located at Gilarchala, Sreepur, Gazipur, Bangladesh.

2.1. Fabrics

The quality of the different types of weft knitted fabric produced by the factory in 2016 was analyzed. Major types of fabric produced in 2016 were Single jersey, Lycra Single jersey, Rib (1*1, 2*1, 2*2, 4*2 etc.), Lycra rib, Interlock, Terry, Fleece, Pique, Lactose, Mesh, Waffle etc.

2.2. Machinery

All the knitted fabrics were produced by Fukuhara (Japan) knitting machine, The factory has a capacity of dyeing 20 tons/day and dyeing machine brand was Fong's (Hong Kong), Slitting Machine brand was Bianco (Italy), Stenter machine brand was Bruckner (Germany) and the brand of compacting machine was Tube Tex (USA). The finished fabrics were inspected using UZU (Thailand) fabric inspection machine.

2.3. The Operation Involved in the Knitted Finished Fabric

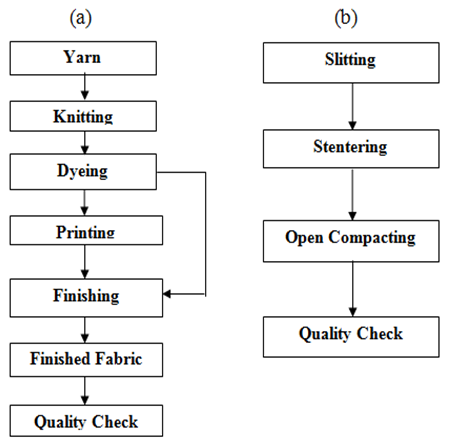

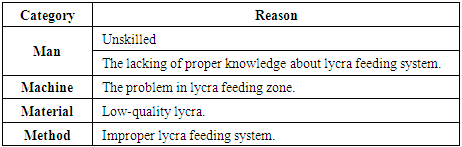

The defects in the finished fabric can come from every single operation involved (Figure 1a) from raw material to finished fabric.  | Figure 1. (a) Flowchart of the process involved from the raw material (yarn) to the finished fabric & (b) Flowchart of open knit finishing |

In Meghna knit composite limited, knit fabric is finished in open form (Figure 1b) rather than tube form. Once the grey fabric is made from raw material (yarn) by knitting (Figure 2a), then dyeing/coloration process (Figure 2b) is carried out, if the end product contains any printed design/motif than the dyed fabric goes for printing and finally after finishing (Figure 2c) desired finished fabric is obtained. The next step is quality checking (Figure 2d) which is a very crucial step because checking results will determine whether the finished is okay for making the end product (garment) or not. | Figure 2. Picture of the different process involved from the yarn to the knitted finished fabric |

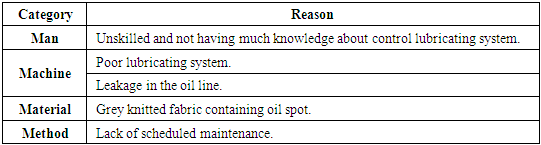

2.4. Fabric Inspection

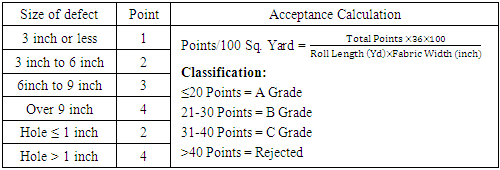

Quality inspection is an important aspect of industrial manufacturing. In textile industry fabric defect detection plays an important role in the quality control [10]. For the inspection of finished fabric international 4 point system (Table 1) was used. The 4-point inspection system is the most common and widely used fabric quality inspection system for all types of fabrics in textile and apparel industry. The 4-point system, also called the American Apparel Manufacturers (AAMA) point grading system for determining the fabric quality, is endorsed by the AAMA as well as the ASQC (American Society of Quality Control) [11].Table 1. International 4 Point System

|

| |

|

Pareto analysis is performed to identify the major defects on the knitted finished fabric and for analyzing their root causes cause and effect diagram also performed.

3. Result & Discussion

3.1. Characterization of Defects

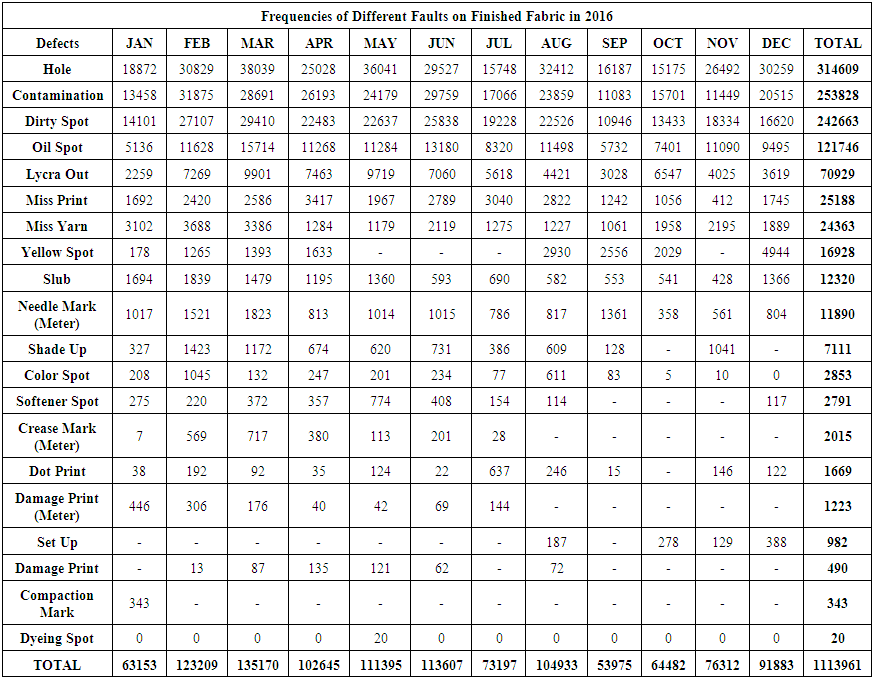

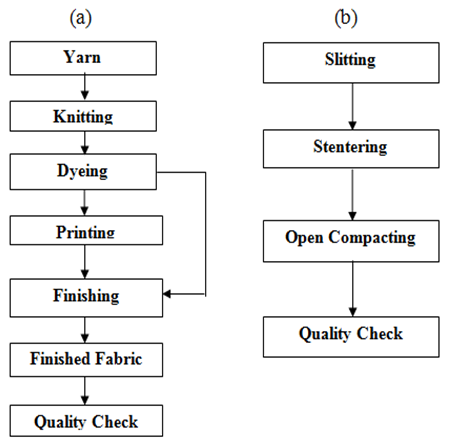

Total 20 types of defect found (Table 2) in different types of finished knitted fabric. The frequency of defects varied in every month but over the year. It was observed that the top 3 defects found in the finished fabric were Hole, Contamination and dirty spot. | Table 2. Different types of defects found in 2016 |

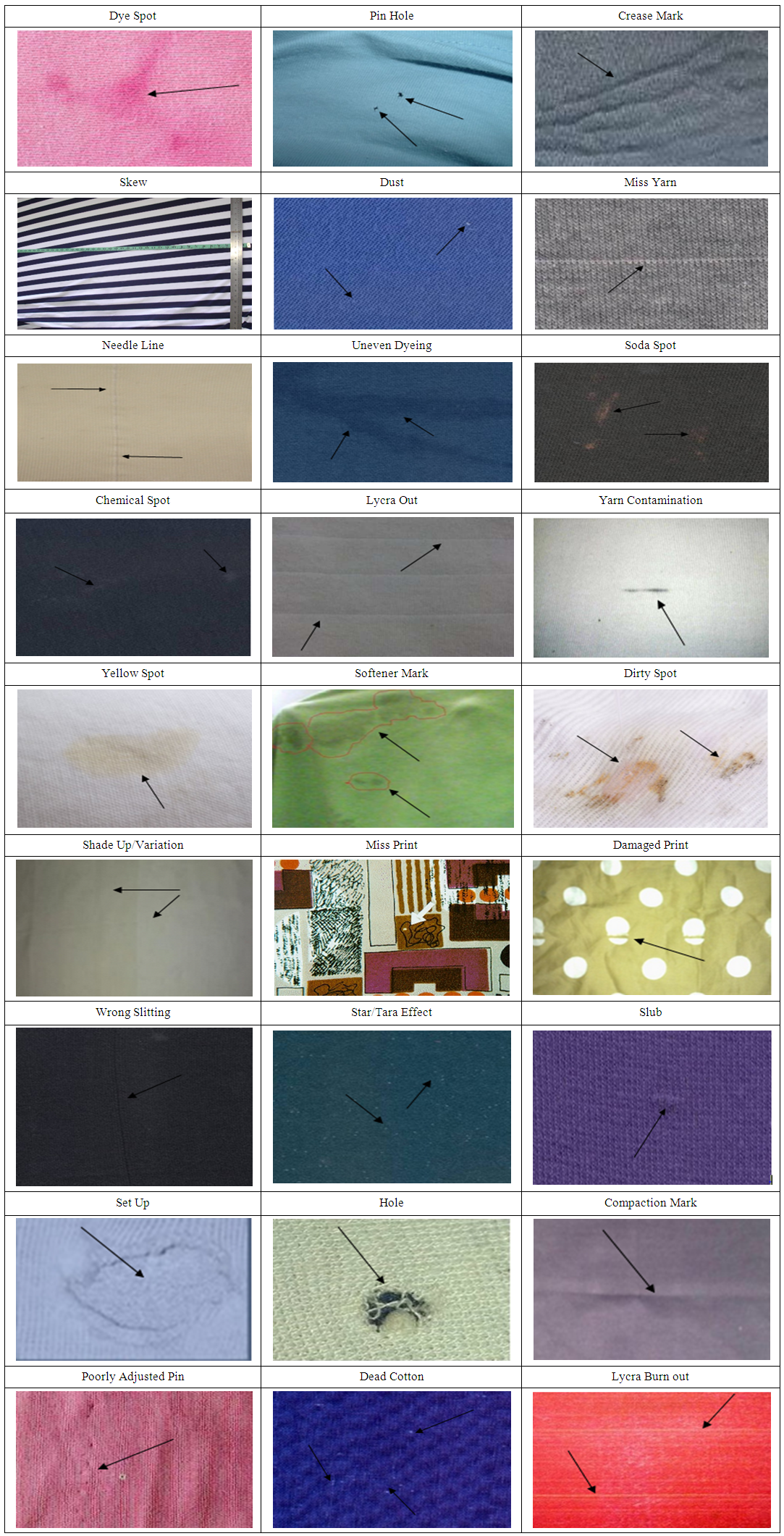

3.2. Different Type of Defects Found in Finished Fabric

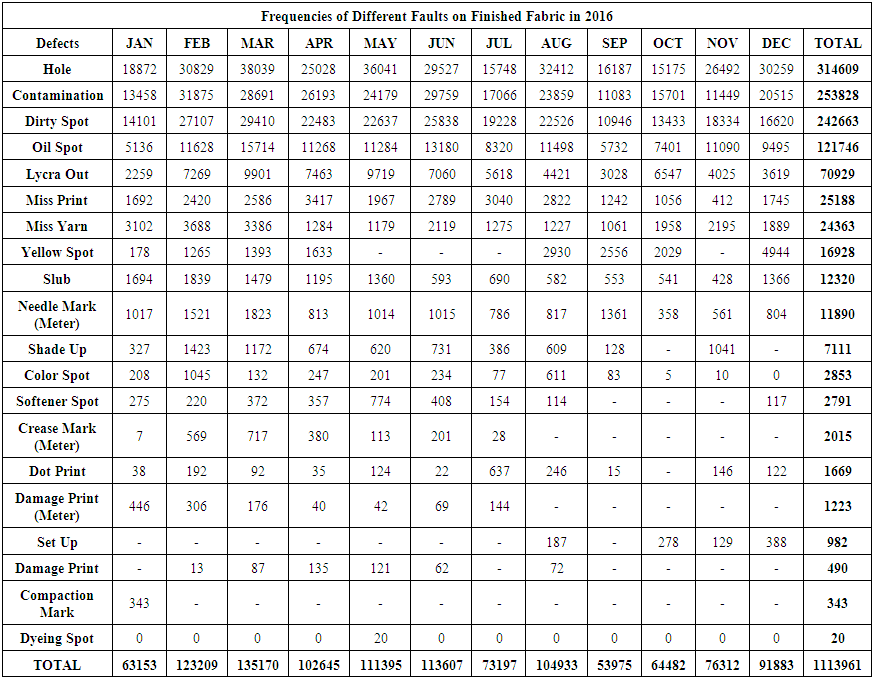

Every defect was apparently different from each other and related to particular processing action. For example, miss print & damage print only appeared in the printed fabric rather than in dyed fabric. The most commonly appeared defects on the finished fabric shown in figure 3.

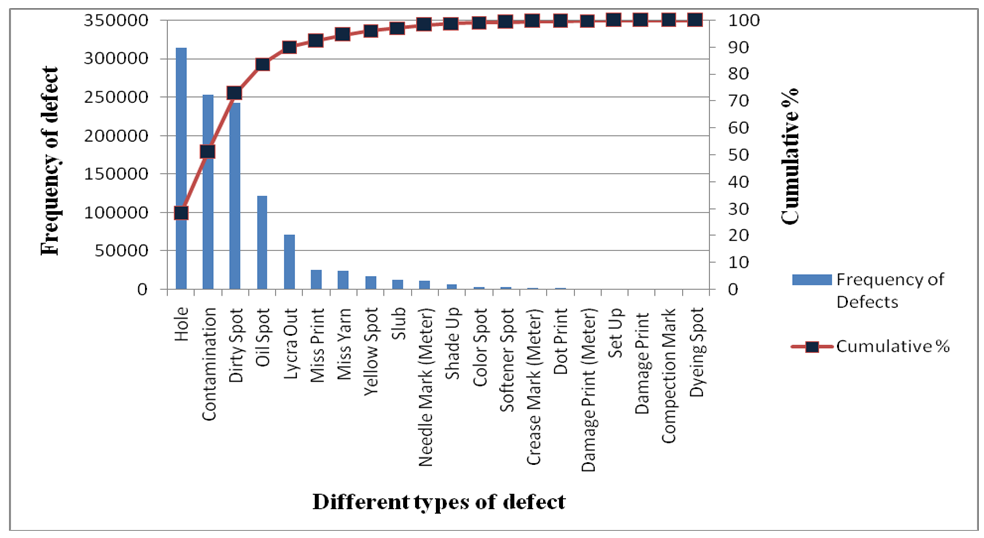

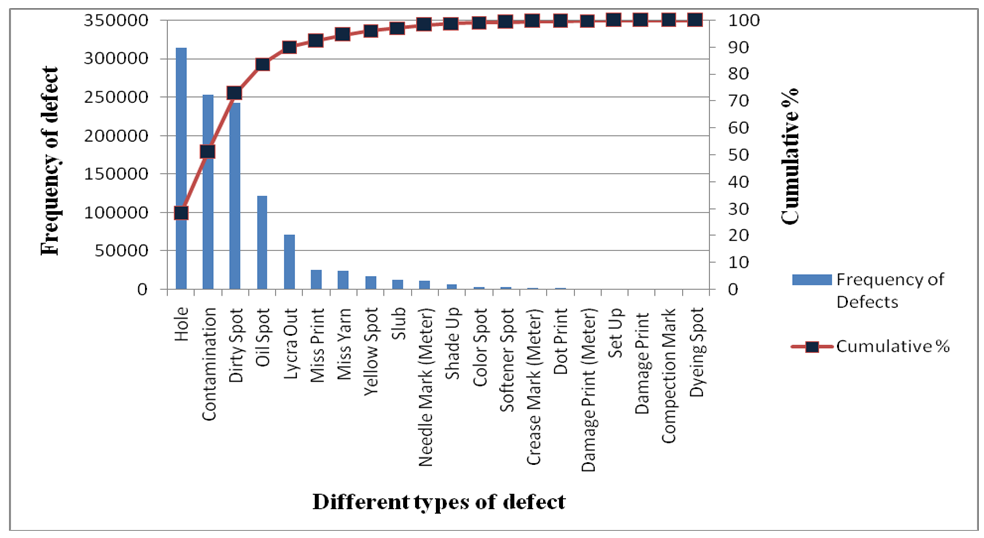

3.3. Pareto Analysis

In case of quality control, the identification of these major causes allows determining directions of actions that may very effectively contribute to the improvement of processes and product quality enhancement [12]. Pareto analysis is a technique used to identify quality problems based on their degree of importance. This concept has often been called the 80/20 rule [13]. We have performed our Pareto Analysis based on 12 months combined defect data of the weft knitted finished fabric. The analysis is shown in figure 3. Here horizontal axis represents different types of defect, the Primary vertical axis at left side represents defect frequency and secondary vertical axis at right side represents cumulative defect percentage.According to the Pareto analysis, major defects in the finished fabric were the hole, contamination, dirty Spot, oil spot and Lycra out. These faults were contributed to 90% of the total defects. If these 5 defects can be minimized almost 90% defects will be gone. The rest of 15 defects contribute only 10% to the total defects. | Figure 3. Different types of knitted finished fabric defects |

| Figure 4. The Pareto analysis for identifying major defects |

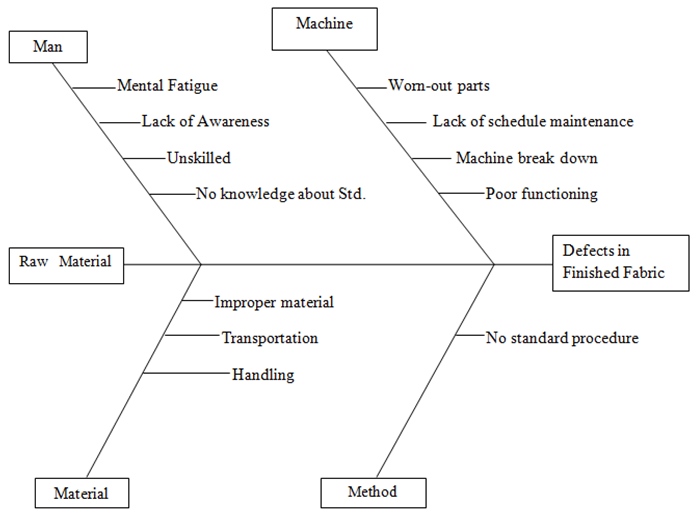

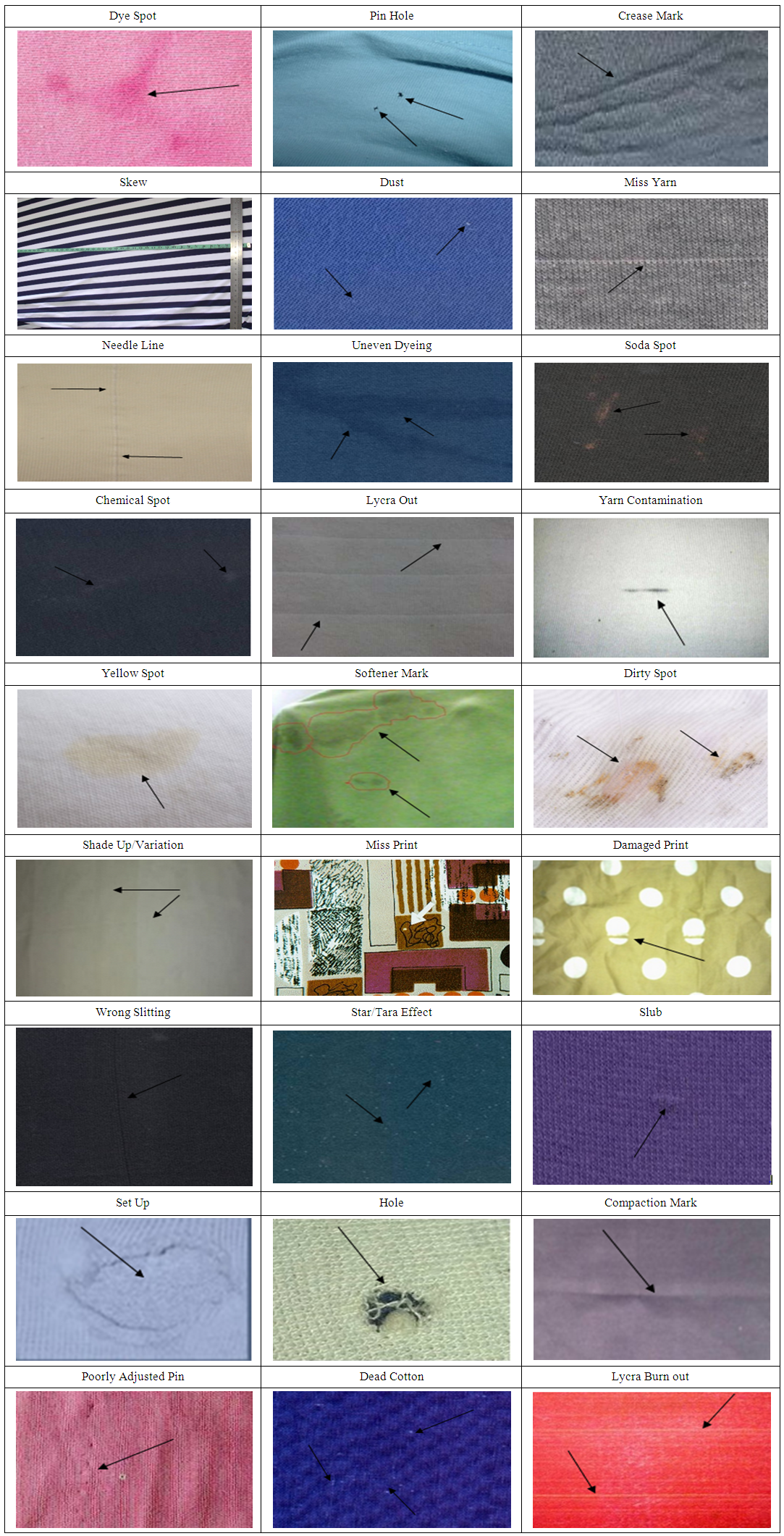

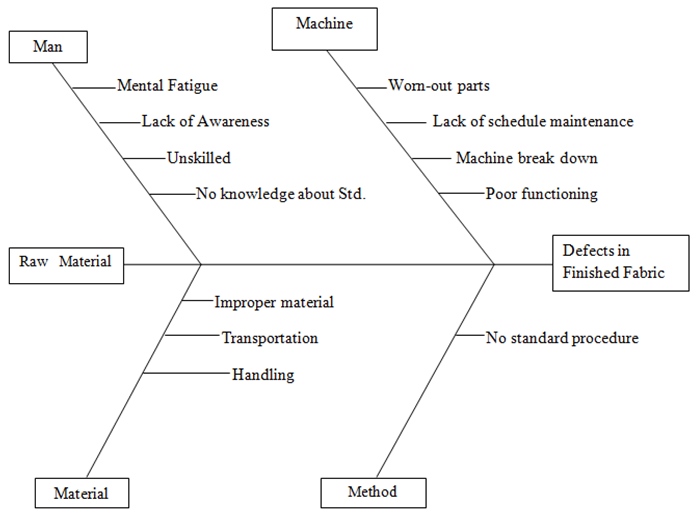

3.4. Cause & Effect Diagram

To determine possible root causes of rejection, Cause-and-Effect Diagram is a very useful tool. It helps to identify, sort, and display the causes of a specific problem or quality characteristic. It graphically illustrates the relationship between a given outcome and all the factors that influence the outcome and hence to identify the possible root causes i.e. basic reasons for a specific effect, problem, or condition [14]. The cause & effect diagram for finished fabric defects shown in figure 5. | Figure 5. Cause & Effect diagram for defects in finished fabric |

Every operation involved from raw material to finished fabric has a certain influence on the quality of the finished fabric. We have classified those influence in four categories i.e. Man, Man, Machine, and Material.

3.5. Reasons for the Major Defects & Their Improvement Techniques

3.5.1. Hole

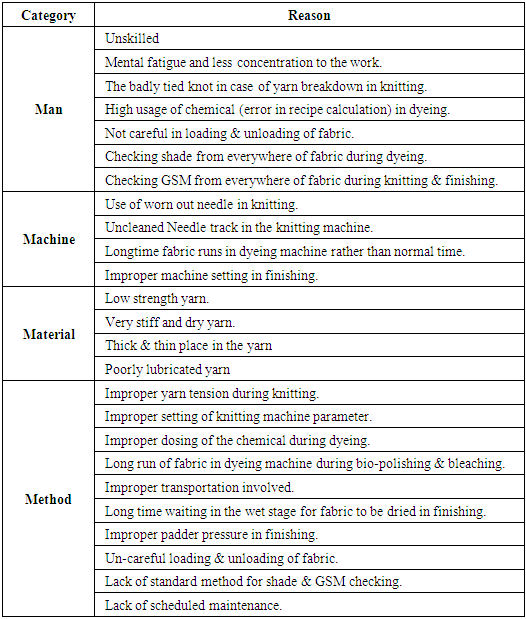

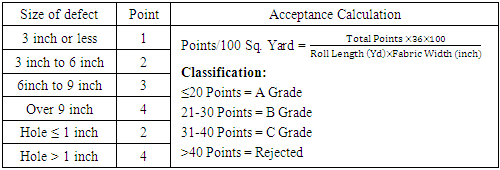

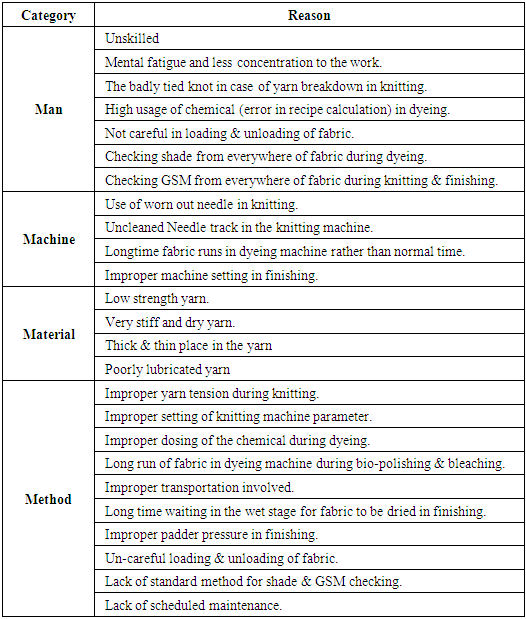

Among 20 types of different defect top, most defects were hole & its contribution to the total defect was 28.24%. The reason of hole related to Man, Machine, Material & Method are discussed below (Table 3). Table 3. Reasons for the hole in the finished fabric

|

| |

|

Holes in the finished fabric can come from knitting, dyeing, and finishing. The possibility of holes coming from knitting is quite higher than rather than dyeing & finishing. The number holes in the finished fabric can be reduced greatly by taking care of the process involved in grey fabric i.e. raw material selection & knitting. All of the improvement techniques are analyzed below from raw material selection to the finished fabric. Improvement TechniquesØ Machine operator should be skilled or there should be some arrangement of training at least once in a month to improve their skill.Ø The Standard working hour by labor law should be followed to improve fatigue.Ø Yarn strength must be sufficient to withstand the stretch.Ø Proper count of yarn must be used.Ø Yarn feeder should be set properly.Ø In case of yarn break down knot should be given properlyØ Use of worn out needle should be strictly avoided.Ø Raw material (yarn) with proper strength must be ensured while purchasing.Ø Properly lubricated yarn must be ensured so that yarn can pass easily through the needle.Ø Yarn without any thick & thin place, slub, Neps and less hairiness must be used.Ø Yarn feeder must be set correctly in position.Ø Yarn guide might be clean so that yarn can pass easily.Ø RPM of the knitting machine & fabric take-up tension must be set properly. Ø Schedule maintenance of knitting, dyeing and finishing machinery should be performed.Ø Properly dosing of the chemical during dyeing should be done. Ø Fabric in the dyeing machine should be kept for the standard hour not more than that.Ø During dyeing shade sample should be cut besides the magnet area or around that. Ø Proper temperature & speed should be maintained during fabric finishing.Ø Optimum use of the chemical & the padder pressure should be ensured in finishing.Ø During finishing GSM should check random basis rather than checking every roll.Ø The fabric transportation, loading, and unloading should be done carefully.

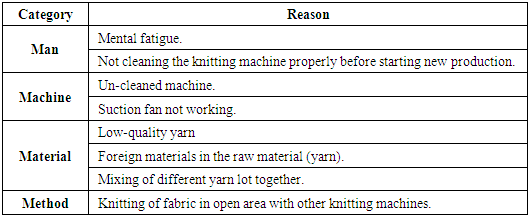

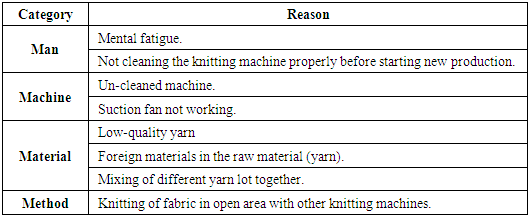

3.5.2. Contamination

Contamination was the second most defects found in finished fabric its contribution to the total defect was 22.78%. The reason of hole related to Man, Machine, Material & Method are discussed below (Table 4).Table 4. Reasons for Contamination in the finished fabric

|

| |

|

The main possible source of contamination is yarn and knitting. The number of contamination can be reduced greatly by taking proper care of yarn selection & knitting environment. All of the improvement techniques are analyzed below;Improvement TechniquesØ Raw material (yarn) used should be free from contamination.Ø Yarn Lot mixing in knitting should be avoided.Ø Use of more suction fan can be fruitful.Ø Knitting floor should be kept neat & clean.Ø Knitting machine can be covered by polyethylene so that fly fiber cannot come in the knitting zone.

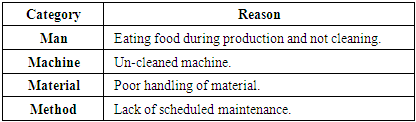

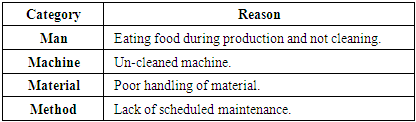

3.5.3. Dirty Spot

The dirty spot was the third most defects found in finished fabric its contribution to the total defect was 21.78%. The reason of hole related to Man, Machine, Material & Method are discussed below (Table 5).Table 5. Reasons for the Dirty spot in the finished fabric

|

| |

|

Dirty spots in the finished fabric can come from knitting, dyeing, and finishing. All of the improvement techniques are analyzed below;Improvement TechniquesØ Proper care should be taken during fabric transportation.Ø Cleaning of the machinery before production must be ensured.Ø Schedule maintenance should be performed to avoid poor lubricating system from which dirty spot may come.Ø Poor handling should be avoided.

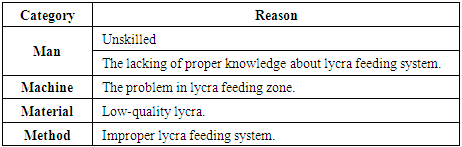

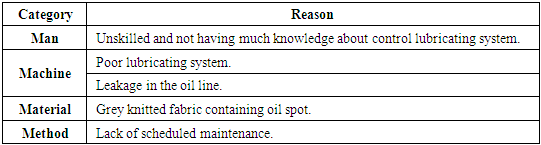

3.5.4. Oil Spot

Oil spot was the 4th most defects found in finished fabric its contribution to the total defect was 10.92%. The reason of hole related to Man, Machine, Material & Method are discussed below (Table 6).Table 6. Reasons for Oil spot in the finished fabric

|

| |

|

The main possible reason for oil spot in the finished fabric is because of oil spots in grey fabric. All of the improvement techniques are analyzed below;Improvement TechniquesØ Before starting production in the knitting machine lubricating system should be checked.Ø The lubricating system should be kept clean. Ø Good quality lubricant should be used.Ø The lubricating system should be changed if there is any leakage in the oil line. Ø Make sure no fibers & fluff accumulated in the needle tricks.Ø Optimum supply of lubricant to the needle bed must be ensured.

3.5.5. Lycra out

Oil spot was the 5th most defects found in finished fabric its contribution to the total defect was 6.36%. The reason of hole related to Man, Machine, Material & Method are discussed below (Table 7). Table 7. Reasons for Oil spot in the finished fabric

|

| |

|

All of the improvement techniques are analyzed below; Improvement TechniquesØ Uniform tension must be maintained.Ø Checking lycra feeding system.Ø Ensure uniform flow of lycra up to the needle.

4. Conclusions

Quality is of prime importance in any aspect of a business. Customers demand and expect value for money. Minimizing defect is very important for ensuring the quality of products. The importance of the Apparel industry in the economy of Bangladesh is very high. As producers of apparel, there must be a constant endeavor to produce work of good quality. Defects in finished fabric have a great influence on the quality of the garment. So, reducing the number of defects in the finished fabric is really important. The amounts of defects in the finished fabric are interlinked with the every processing action involved. In this study, it was observed that only five defects are responsible for almost 90.10% of the defects observed in the finished fabric. If these five defects i.e. hole, contamination, dirty spot, oil spot and lycra spot can be reduced than the quality of the finished fabric will improve significantly. Defects are something like that we cannot completely remove it but the optimized care during processing can minimize the possibility of defects in the finished fabric. Cause and Effect Diagram of the finished fabric defects helped us to find the reason of defects from the different origin in relation to man, machine, material, and method. Finally, we have provided some suggestions so that the management can apply them to minimize the frequency of defects. Thus they can effectively minimize rejection of fabric by increasing quality & productivity. This will certainly help them to increase their profit margin.

ACKNOWLEDGEMENTS

Authors are grateful to the authorities of Meghna Knit Composite Ltd, Gilarchala, Sreepur, Gazipur for their permission to conduct this study in their factory.

References

| [1] | Ripon Kumar Prasad, A New Approach for Machine Gauge & Production Calculation of Various Kinds of Rib and Interlock Knitted Fabric Structure, Journal of Textile Science and Technology, 2016, 2, 31-36. |

| [2] | A.K.M. Mobarok Hossain and Dr. A.B.M. Zohrul Kabir, Customization of Starfish Technology in the Production of Cotton-Knit Fabrics: A Practical Approach, International Journal of Engineering & Technology IJET-IJENS, February 2011, Vol: 11 No: 01. |

| [3] | Md.Solaiman, Elias Khalil, Mostafizur Rahman, Joy Sarkar, Efficiency Losses Calculation and Identify Causes of Losses of Circular Knitting Machine during Knit Fabric Production, Manufacturing Science and Technology 2(5): 93-96, 2014. |

| [4] | Amare Matebu, Model Development of Quality Management System for Ethiopian Textile Industries, AAU, Technology faculty, thesis, 2006. |

| [5] | Simona Jev Nik, Darinka Fakin, Lea Heikinheimo, and Zoran Stjepanovi, Changes in a Knitted Fabric's Surface Properties Due to Enzyme Treatments, Fibers and Polymers 2012, Vol.13, No.3, 371-379. |

| [6] | Md. Anwar Jahid and Md. Nahid Pervez, Amending of Finishing Quality of Different Knit Fabrics through Process Control Parameters by Optimizing Visualizing Defect’s, American Journal of Materials Science 2015, 5(3): 57-65, DOI: 10.5923/j.materials.20150503.01. |

| [7] | Bithika Mallik, Asit K Datta, “Defect Detection in Fabrics with a Joint Transform Correlation Technique Theoretical Basis and Simulation”. Textile Research Journal, vol.69, pp829-835, November 1999. |

| [8] | Spencer, D. J., Knitting technology: a comprehensive handbook and practical guide, Vol. 16. 2001: CRC Press. |

| [9] | Johnson-Laird, P.N., The computer and the mind: An introduction to cognitive science. 1988: Harvard University Press. |

| [10] | M. PM, K. SR, and P. PM, A review of automatic fabric defect detection techniques. Advances in Computational Research, 2009. 1: p. 18-29. |

| [11] | Automation in Garment Manufacturing, edited by Rajkishore Nayak, Rajiv Padhye. |

| [12] | K. Gawdzinska, Application of the Pareto chart and Ishikawa diagram for the identification of major defects in metal composite castings, ARCHIVES of FOUNDRY ENGINEERING, ISSN (1897-3310) Volume 11 Issue 2/2011 22–28. |

| [13] | Md. Syduzzaman, Md. Mahbubor Rahman, Md. Mazedul Islam, Md. Ahashan Habib and Sharif Ahmed, Implementing total Quality Management Approach In Garments Industry, European Scientific Journal December 2014 edition vol.10, No.34 ISSN: 1857 – 7881 (Print) e - ISSN 1857- 7431. |

| [14] | Mohiuddin Ahmed and Nafis Ahmad, An Application of Pareto Analysis and Cause-and-Effect Diagram (CED) for Minimizing Rejection of Raw Materials in Lamp Production Process, Management Science and Engineering, Vol.5, No.3, 2011, pp.87-95, DOI:10.3968/j.mse.1913035X20110503.320. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML