-

Paper Information

- Next Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

American Journal of Materials Science

p-ISSN: 2162-9382 e-ISSN: 2162-8424

2017; 7(3): 53-58

doi:10.5923/j.materials.20170703.02

Sorption and Strength Properties of Thermally Modified Plantation Grown Leucaena Leucocephala (Lam) Wood Using Paraffin Wax

Owoyemi J. M., Olumuyiwa A. O., Oyeleye I. O.

Department of Forestry and Wood Technology, Federal University of Technology, Akure, Nigeria

Correspondence to: Owoyemi J. M., Department of Forestry and Wood Technology, Federal University of Technology, Akure, Nigeria.

| Email: |  |

Copyright © 2017 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Reduction in the supply of indigenous wood from natural forest called for investigation into the properties of plantation grown Leucaena leucocephala wood. Density of the treated samples reduced with treatment time. Water absorption, shrinkage and swelling values decreased with increase in treatment time using the same temperature. At a treatment time of 3hrs for thermal wax and 6hrs for thermally treated samples, higher values of 879.50 and 916.22 g/m3 were obtained for density compared with the untreated which is 874.21 g/m3 was obtained. Lower values of 2.13, 12.13% were obtained for water absorption at 180°C. Values of 2.78 and 8.73% were obtained for swelling. Values of 5.65 and 3.08% were obtained for shrinkage at 180°C which was lower to the untreated values. Treatments resulted in improved dimensional stability as indicated by the reduction in water absorption, swelling and shrinkage of treated materials. Mechanical properties as measured by modulus of rupture were significantly reduced while there were significant effects on the modulus of elasticity as a result of heat treatment.

Keywords: Density, Volumetric Shrinkage, Water Absorption, MOE, MOR

Cite this paper: Owoyemi J. M., Olumuyiwa A. O., Oyeleye I. O., Sorption and Strength Properties of Thermally Modified Plantation Grown Leucaena Leucocephala (Lam) Wood Using Paraffin Wax, American Journal of Materials Science, Vol. 7 No. 3, 2017, pp. 53-58. doi: 10.5923/j.materials.20170703.02.

Article Outline

1. Introduction

- The use of wood in day to day human activities is dated to time immemorial due to its excellent properties. Global demand for forest products is alarming worldwide, matching with decreasing forest production area and increasing human population. The high demand for wood and wood products in Nigeria has led to over exploitation of natural forest. The annual demand for wood as construction material exceeds the quantity of round log extracted from the forest reserve and plantation per annum. According to Olugbire [1], less than 10% of the required cubic meter of wood plantation is been used in Nigeria so more attention should be given to the lesser wood species particular on how to improve their properties. Wood being a hygroscopic and biodegradable material shrinks in service and swells due to varying humidity and its life span can be shortened as a result of fungus infestation when exposed to humid/wet conditions, and insects such as powder post beetles and termites [2]. An alternative way of protecting wood from decay and insects without the use of toxic preservatives is by improving its dimensional stability through thermal modification [3]. Thermal modification has long been known to increase the dimensional stability of wood by reducing its hygroscopicity and increasing resistance to biodegradation [4]. When wood is heated, its chemical and physical properties undergo permanent changes and its structure is transformed [5]. As a result, swelling due to its moisture absorption decrease, biological durability improves, and the density of the wood decreases [6]. Paraffin wax is a white or colourless soft solid derivable from petroleum, coal or oil shale that consists of a mixture of hydrocarbon molecules containing between 20 and 40 carbon atoms. It is solid at room temperature and begins to melt above approximately 37°C (99°F), its boiling points is greater than 370°C (698°F). Common applications include lubrication, electrical insulation and it is sometimes called paraffin [7]. Sorption properties are the quantitative characteristics of wood and its behavior to external influences other than applied forces. Familiarity with physical properties is important because they can significantly influence the performance and strength of wood used in structural applications [8].Strength properties are the characteristics of a material in response to externally applied forces. They include elastic properties, which characterize resistance to deformation and distortion, and strength properties which characterize resistance to applied loads. Mechanical property values are given in terms of stress and strain The mechanical property values of wood are obtained from laboratory tests of lumber of straight-grain clear wood samples (without natural defects that would reduce strength, such as knots, checks, splits, etc. [9]. The aim of this study is to investigate the effects of thermal modification using paraffin wax on sorption and strength properties of L. leucocephala wood.

2. Materials and Methods

2.1. Study Area

- This research was conducted at Central Research Laboratory, Forestry and Wood Technology Department Laboratory and Wood Workshop, Federal University of Technology, Akure, Nigeria. The climate is the humid sub-tropical indicating that it is basically within the tropical rainforest zone, dominated by broadleaved hardwood trees that form hard layered stands [10]. The mean annual temperature is about 26°C (min. 19°C and max. 340°C) and rainfall of 1500 mm with bimodal rainfall pattern [11].

2.2. Materials

- Freshly cut trees of L. leucocephala were obtained from the plantation of The Federal University of Technology Akure, Nigeria. Three trees were felled and samples were cut from the top, middle and base portions to specified dimensions. Equipment used were chain saw circular sawing machine, weighing balance, industrial grade paraffin wax, measuring tape, vernier calliper, universal testing machine and chamber for heating.

2.3. Preparation of Wood Samples

- The L. leucocephala logs were billeted for ease of evacuation and the outer and inner portions of the sampling height; top, middle and base portions along the grain pattern of tree length were used in preparation of samples. The sawn planks were machined and trimmed to standard size of 20 mm × 20 mm × 60 mm for determination of sorption properties and 20 mm × 20 mm × 300 mm for strength properties and the samples were replicated five times.

2.4. Thermal Wax Modification Process

- The heat treatment for the thermal wax samples were conducted in a constructed heating chamber and the steps in the process involve the following; Construction and setting up of the heating chamber, Cutting of paraffin wax into required sizes, Heating of the chamber with the paraffin wax, Inserting the samples and heating for three hours to a temperature of 180°C, cooling, Re-heat again to remove the wax, Removing the sample, drained and conditioned before laboratory test.

2.5. Thermal Modification Process

- A large-sized electric oven-dryer with temperature control at the Central Research Laboratory, FUTA was used as the treating chamber for thermal modification. The thermal modification process was performed using temperature of 180°C for 6h. The treatment time was recorded once the inside temperature of the oven reached target treatment temperature.

2.6. Determination of Sorption/Physical Properties

- The variation in the moisture content of the wood portions were determined and the hygroscopicity (measured by water absorption) and dimensional stability (measured by density, volumetric swelling and shrinkage), were determined following ASTM Vol. D.09 [9] with some modifications. Sample samples measuring 20 mm × 20 mm × 60 mm were used to carry out this experiment. Five replicates per treatment were prepared. Dimensions and weight were taken using a digital vernier calliper and weighing balance submerged in water for 24 hours and samples removed for measurements. The amount of water absorbed and volumetric swelling were calculated by using the difference of the weight and dimensions before and after submersion expressed as percentage of the initial weight or dimensions.

2.7. Determination of Strength Property

- Modulus of Elasticity and Rupture (MOE and MOR) in accordance with ASTM Vol. D. [9]. Samples dimension of 20 mm x 20 mm x 300 mm of five replicates for each treatment combinations were tested using a Universal Testing Machine. The actual width and thickness of each sample were measured prior to testing. Center loading of the 230 mm span of the sample was used. Speed of test was 20mm/min. At the point of failure the force exerted on the sample that caused the failure was recorded and the MOE and MOR were calculated.

3. Results and Discussions

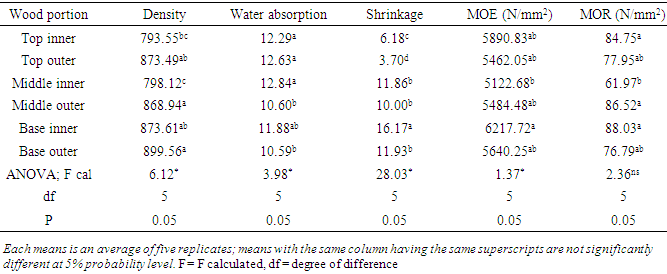

3.1. Hygroscopicity and Dimensional Stability

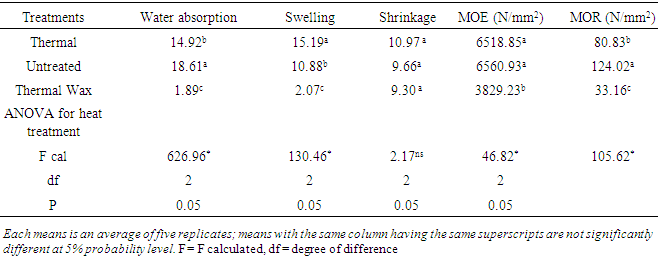

- The values of the moisture content of freshly felled L. leucocephala wood from the top to the bottom of the untreated wood samples ranged from 32.47 to 49.93% (Figure 1). The fiber saturated point (FSP) of L. leucocephala is 28% at room temperature. There was no significant difference within the wood portion at 0.05% probability level. It was observed in the experiment that there was no variation in the moisture content of the L. leucocephala wood from the top to the base [12].

| Figure 1. Mean values for the variation in the moisture content of untreated L. leucocephala wood |

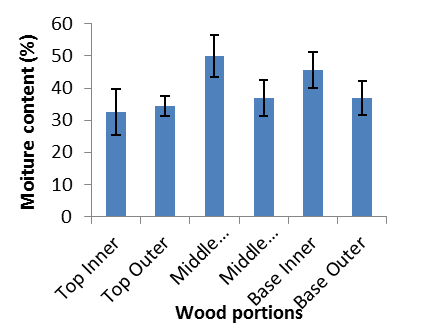

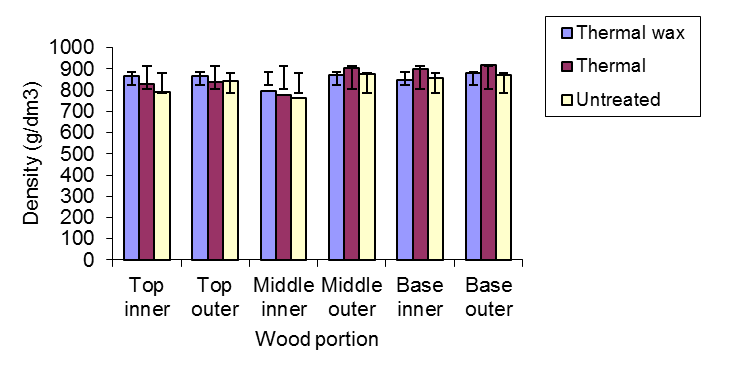

3.2. Density

- The mean values for the wood density from the top to bottom of the treated and untreated wood samples ranged from 762.11 to 916.22 gm/m3 at 180°C for 6 h for the thermally treated sample and 3 h for the thermal wax samples (Figure 2). There was no significant different between the treatments and also the interaction between the treatments and the wood portion while significant different was observed within the wood portion at 0.05% probability level (Tables 1 and 2). It was observed from the study that the wood density of the treatment samples increases slightly with the treatment time. The thermally treated samples have the highest density which is a good predictor of strength, and stiffness, the density of thermal wax was higher compared to the untreated which was lower. Hence, thermal modification increases the density of wood, [13]. Similar result was reported that thermal treatment influenced the wood density only in a small extent as can be seen in Bracatinga wood showed a small increase in wood density after the heat-treatment [14].

| Figure 2. Density of thermal, thermal wax and untreated L. leucocephala |

|

|

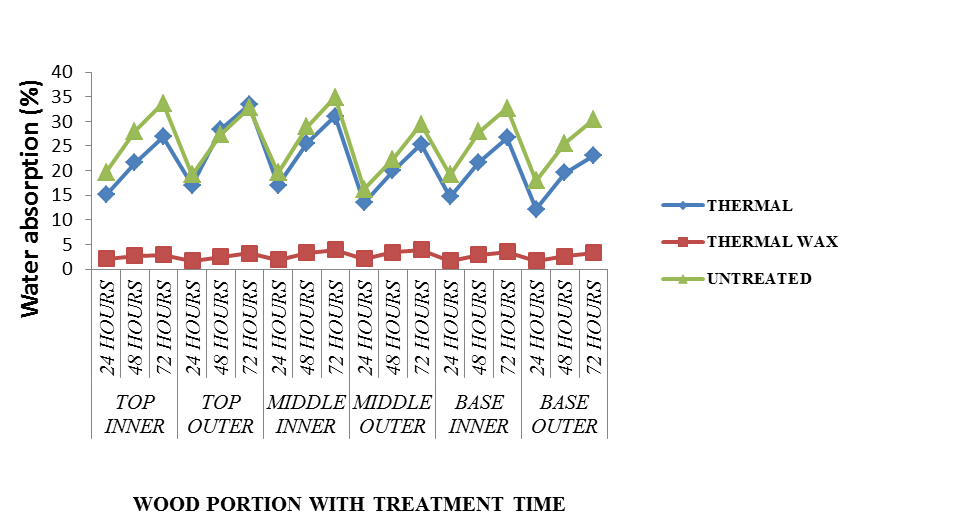

3.3. Water Absorption

- The water absorption values for the treated and untreated L. leucocephala wood samples after immersion in water for 24, 48 and 72hrs are presented in Figure 3. As immersion time increases, absorption rate increases; thermal wax and thermally treated samples absorb less water compared to the untreated sample which was greater. The mean values for the water absorption of the wood from the top to the bottom of the treated to the untreated wood samples ranged from 1.73 to 19.66% at 180°C for 3hrs for the thermal wax samples and 10hrs for the thermally treated samples. Significant different was observed between the treatment and the wood portion while there was no significant different in the interaction between the treatment and the wood portion at 0.05% probability level (Table 1 and 2). Heat treatment reduced the water intake of cells thereby attract less moisture as a result of reduction in hydroxyl group while for the thermal wax treated samples, the pore spaces has been blocked by wax preventing water from entering the wood [15-18].

| Figure 3. Percentage water absorption for thermal wax, thermally treated and untreated samples of L. leucocephala wood |

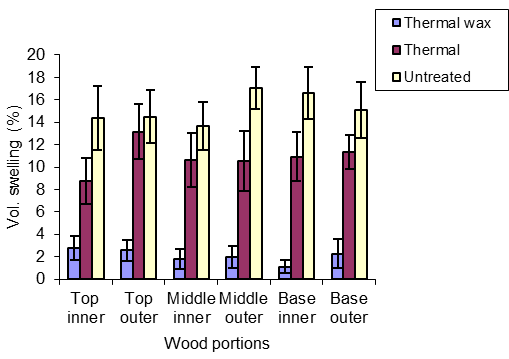

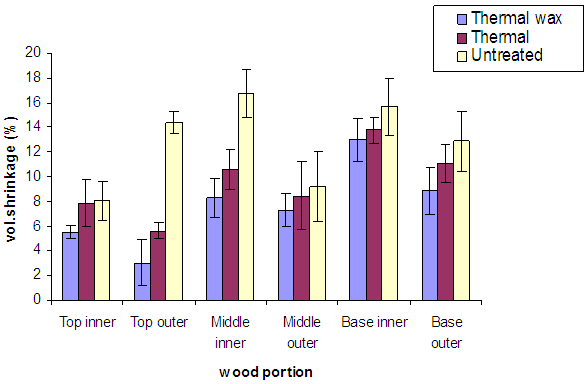

3.4. Volumetric Swelling and Shrinkage

- The value obtained from volumetric swelling ranged from 1.11 to 17.02% (Figure 4) at 180°C for 3hrs for the thermal wax samples and 10hrs for the thermally treated samples. The volumetric swelling coefficient of treated samples decreased with increased treatment temperature and duration. The highest reduction was noted with the thermal wax sample at 180°C for 3hrs. The mean values for the shrinkage of the wood from the top to the bottom of the treated and untreated wood samples ranged from 3.04 to 16.71% (Table 2) at 180°C for 3 to 10hrs for the thermal wax and thermally treated samples respectively. The lowest volumetric shrinkage was found in the thermally treated sample while the highest shrinkage was observed in the untreated samples (Figure 4 and 5). The analysis of variance carried out at 95% probability level showed that thermal wax and thermally treated had significant effect on volumetric swelling but does not have effect on the volumetric shrinkage (Table 1) while within the wood portion there was significant difference on the volumetric shrinkage (Table 2). The decrease in volumetric swelling and increase in dimensional stability of heat treated wood is attributed to a decrease in moisture absorption. Heat reduces swelling and shrinkage of wood because it reduces the hydroxyl group thereby reducing the hygroscopicity [19].

| Figure 4. Volumetric swelling of thermal, thermal wax and control L. leucocephala |

| Figure 5. Mean values for the shrinkage of thermal, thermal wax and control L. leucocephala |

3.5. Mechanical Properties

3.5.1. Modulus of Elasticity (MOE) and Modulus of Ruputre (MOR)

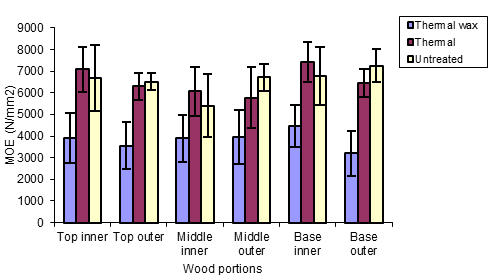

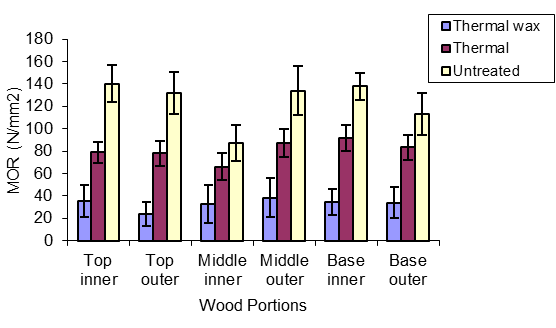

- The mean values for the MOE of L. leucocephala wood from the top to the bottom of treated and untreated wood samples ranged from 3200.73 to 7407.56 N/mm2 at 180°C for 3 and 10 hrs for the wax and thermally treated samples respectively (Figure 6). ANOVA (Table 1) showed that temperature factor and time duration contributes to the variation in MOE. This corroborates with the work of Claude, et al., (2017) density was correlated with MOE, which showed wood density increase is of benefit to the wood MOE due to the decrease in the void volume thereby leading to enhanced strength [20]. Among the treatments, the thermally modified samples have higher bending strength than the thermal-wax modified samples. The mean values for MOR from the top to bottom of the treated and untreated L. leucocephala wood samples (Figure 7) ranged from 23.97 to 140.25 N/mm2 at 180°C for 3 and 10 hrs for the wax and thermally treated samples respectively. The lowest MOR was found in the wax treated samples while the highest MOR was observed in the untreated samples (Table 1 and 2). MOE increases in heat-treated wood. Ellison, et al., 2000 explained this result that increased lignin cross-linking makes the structure around the cellulose microfibrils and the middle lamella more rigid [7]. [16] explained this increase in MOE with increasing crystallinity of the cellulose and the reduction of moisture content equilibrium. It was reported that the results of modulus of elasticity (MOE) determination confirm the fact that thermal modification has an adverse effect on the mechanical properties mainly due to the thermal degradation of hemicelluloses [21, 22].

| Figure 6. Volumetric swelling of thermal, thermal wax and control L. leucocephala |

| Figure 7. Volumetric swelling of thermal, thermal wax and control L. leucocephala |

4. Conclusions

- In general, sorption and strength properties of L. leucocephala wood showed significant modifications using temperature of 180°C. The hygroscopicity and dimensional stability improved as measured by reduced volumetric swelling, shrinkage and water absorption while there was increase in the density of the wood. Hence thermal wax and thermal modification of wood reduced the affinity of the wood to moisture thereby improved the dimensional stability which is an advantage for wood used in moisture prone environment. The thermal wax treated wood revealed that the wax filled the cell lumen as evident increased density which made the wood suitable for places like swimming pool, river banks.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML