| [1] | B. Jaffe, and W.R. Cook Jr.. and H. Jaffe, “Piezoelectric Ceramics” Academic Press, New York, (1971). |

| [2] | T. Ibn-Mohammed, S. C. L. Koh, I. M. Reaney, A. Acquaye, D. Wang, S. Taylor and A. Genoves “Integrated hybrid life cycle assessment and supply chain environmental profile evaluations of lead-based (lead zirconate titanate) versus lead-free (potassium sodium niobate) piezoelectric ceramics” Energy & Environmental Science, (2016). |

| [3] | Ya-Ru Zhang, Jing-Feng Li , Bo-Ping Zhang, and Chun-E Peng “Piezoelectric and ferroelectric properties of Bi-compensated (Bi1/2Na1/2)TiO3–(Bi1/2K1/2)TiO3 lead-free piezoelectric ceramics” Journal of Applied Physics, (2008). |

| [4] | Yue-Ming Li, Zong-Yang Shen, Yi-Jun Liu, Wan-Cheng Shen and Zhu-Mei Wang “High piezoelectric response in KNNS–xBNKZ lead-free ceramics” Journal of Materials Science: Materials in Electronics, (2015). |

| [5] | Eric Cross “Materials science: Lead-free at last” Nature, (2004). |

| [6] | Yasuyoshi Saito, Hisaaki Takao, Toshihiko Tani, Tatsuhiko Nonoyama, Kazumasa Takatori, Takahiko Homma, Toshiatsu Nagaya, Masaya Nakamura “High performance lead-free piezoelectric material” Nature, (2004). |

| [7] | Kai Zhang, Yiping Guo , Di Pan, Huanan Duan, Yujie Chen, Hua Li, and Hezhou Liu “Phase transition and piezoelectric properties of dense (K0.48,Na0.52)0.95Li0.05SbxNb(1−x)O3-0.03Ca0.5(Bi0.5,Na0.5)0.5 ZrO3 lead free ceramics” Journal of Alloys and Compounds, (2016). |

| [8] | Amrita Singh and Ratnamala Chatterjee “Structural and electrical properties of BKT rich Bi0.5K0.5TiO3-K0.5Na0.5NbO3 system” AIP Advances, (2013). |

| [9] | Yongyong Zhuang, Zhuo Xu , Fei Li, Zhipeng Liao, and Weihua Liu “Fabrication of flexible energy harvesting device based on K0.5Na0.5NbO3 nanopowders” Journal of Alloys and Compounds, (2015). |

| [10] | Ting Zheng, Jiagang Wu, Dingquan Xiao, and Jianguo Zhu “Giant d 33 in nonstoichiometric (K, Na)NbO3-based lead-free ceramics” Scripta Materialia, (2015). |

| [11] | Zhiqiang Zhang, Jie Yang, Zhifu Liu, and Yongxiang Li “Evolution of textured microstructure of Li-doped (K,Na)NbO3 ceramics prepared by reactive templated grain growth” Journal of Alloys and Compounds, (2015). |

| [12] | Jialiang Zhang, Xing Tian, Yong Gao, Weizeng Yao, Yalin Qin, and Wenbin Su “Domain Structure of Poled (K0.50Na0.50)1−xLixNbO3 Ceramics with Different Stabilities” Journal of the American Ceramic Society, (2015). |

| [13] | Ying Lin, Jintao Zhang, Haibo Yang, and Tong Wang “Excellent piezoelectric and magnetoelectric properties of the (K0.45Na0.55)0.98Li0.02(Nb0.77Ta0.18Sb0.05)O3/Ni0.37Cu0.20Zn0.43 Fe1.92O3.88 laminated composites” Journal of Alloys and Compounds, (2017). |

| [14] | L. Egerton, and D.M. Dillon, “Piezoelectric and dielectric properties of ceramics in the system potassium—sodium niobate” Journal of the American Ceramic Society, (1959). |

| [15] | Tao Huang, Dingquan Xiao, Chao Liu, Fangxu Li, Bo Wu, Jiagang Wu, and Jianguo Zhu “Effect of SrZrO3 on phase structure and electrical properties of 0.974(K0.5Na0.5) NbO3–0.026Bi0.5K0.5TiO3 lead-free ceramics” Ceramics International, (2014). |

| [16] | Deqing Zhang, Feng Shi, Junye Cheng, Zhangjie Cheng, Xiuying Yang, Guangping Zheng, and Maosheng Cao “Modified hydrothermal synthesis and structural characterization of monoclinic (KxNa1− x)NbO3(0.05≤ x≤ 0.15) rods” Ceramics International, (2015). |

| [17] | Qiyi Yin, Zhaoqi Sun, Miao Zhang, Gang He, Yang Chen, Qing Wang, and Mingzhu Yan “Structure and electrical properties of K0.5Na0.5Nb0.94−xSb0.06SnxO3 lead-free piezoelectric ceramics” Journal of Alloys and Compounds, (2015). |

| [18] | Na Wei, Jin Wang, Bo Li, Yu Huan, and Longtu Li “Improvement of the piezoelectric and ferroelectric properties of (K, Na)0.5NbO3 ceramics via two-step calcination–milling route” Ceramics International, (2015). |

| [19] | Yunfei Chang, Zupei Yang, Lingling Wei, and Bing Liu “Effects of AETiO3 additions on phase structure, microstructure and electrical properties of (K0.5Na0.5)NbO3 ceramics” Materials Science and Engineering: A, (2006). |

| [20] | Xueyi Sun, Jun Chen, Ranbo Yu, Ce Sun, Guirong Liu, Xianran Xing, and Lijie Qiao “BiScO3 Doped (Na0.5K0.5)NbO3 Lead‐Free Piezoelectric Ceramics” Journal of the American Ceramic Society, (2009). |

| [21] | Fangyuan Zhu, T.A. Skidmore, A.J. Bell, T.P. Comyn, C.W. James, M. Ward, and S.J. Milne “Diffuse dielectric behaviour in Na0.5K0.5NbO3 – LiTaO3 – BiScO3 lead-free ceramics” Materials Chemistry and Physics, (2011). |

| [22] | Shujun Zhang, Jong Bong Lim, Hyeong Jae Lee, Ru Xia, and Thomas R. Shrout “(K0.5Na0.5)NbO3 based lead free piezoelectrics with expanded temperature usage range” 17th IEEE International Symposium on the Applications of Ferroelectrics, (2008). |

| [23] | Ruzhong Zuo, Xusheng Fang, Chun Ye, and Longtu Li “Phase Transitional Behavior and Piezoelectric Properties of Lead‐Free (Na0.5K0.5)NbO3–(Bi0.5K0.5)TiO3 Ceramics” Journal of the American Ceramic Society, (2007). |

| [24] | Masato Matsubara, Toshiaki Yamaguchi, Wataru Sakamoto, Koichi Kikuta, Toshinobu Yogo, and Shin-ichi Hirano “Processing and Piezoelectric Properties of Lead‐Free (K, Na)(Nb, Ta)O3 Ceramics” Journal of the American Ceramic Society, (2005). |

| [25] | Zhi Tan, Jianguo Zhu, Yuxing Zhang, Jie Xing, Qiang Chen, Bo Wu, Lingguang Sun, Jiagang Wu, Laiming Jiang, and Dingquan Xiao “Effects of Mo 2/3 Bi 1/3 doping on the phase structure, microstructure, and piezoelectric properties of KNNS–BNZ ceramics” Ceramics International, (2015). |

| [26] | Dai, Y., X. Zhang, and G. Zhou, “Phase transitional behavior in K0.5Na0.5NbO3–LiTaO3 ceramics” Applied Physics Letters, (2007). |

| [27] | Palei, P. and P. Kumar, “Dielectric, ferroelectric and piezoelectric properties of (1− x)[K0.5Na0.5NbO3] − x[LiSbO3] ceramics” Journal of Physics and Chemistry of Solids, (2012). |

| [28] | Jian Fu, Ruzhong Zuo, Xusheng Fang, and Kun Liu “Lead-free ceramics based on alkaline niobate tantalate antimonate with excellent dielectric and piezoelectric properties” Materials Research Bulletin, (2009). |

| [29] | Yuanyu Wang, Jiagang Wu, Dingquan Xiao, Jianguo Zhu, Ping Yu, Lang Wu, and Xiang Li “Piezoelectric properties of (Li, Ag, Sb) modified (K0.50Na0.50)NbO3 lead-free ceramics” Journal of Alloys and Compounds, (2008). |

| [30] | Sandeep Kumar, Neetu Ahlawat, and Navneet Ahlawat “Microwave sintering time optimization to boost structural and electrical properties in BaTiO3 ceramics” Journal of Integrated Science and Technology, (2016). |

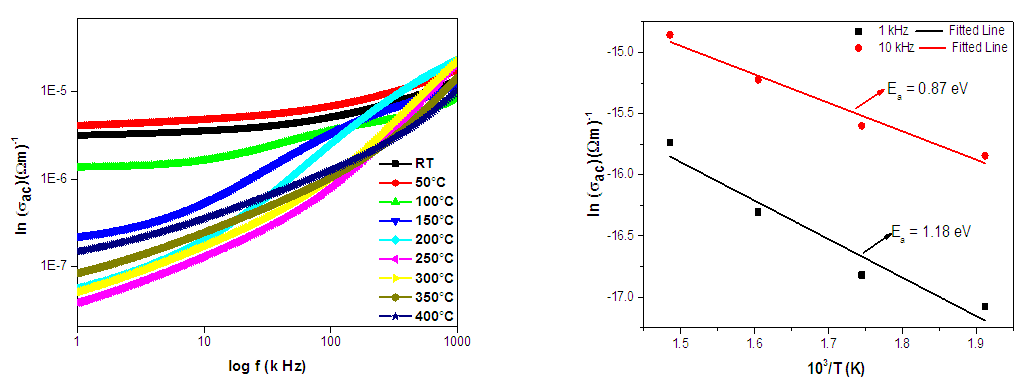

| [31] | Alexei A. Bokov and Zuo-Guang Ye “Dielectric relaxation in relaxor ferroelectrics” Journal of Advanced dielectrics, (2012). |

| [32] | P. Kumari, R. Rai, A. L. Kholkin , and A. Tiwari “Study of Ca doping on A-site on the structural and physical properties of BLTMNZ ceramics” Advanced Materials. Letters, (2014). |

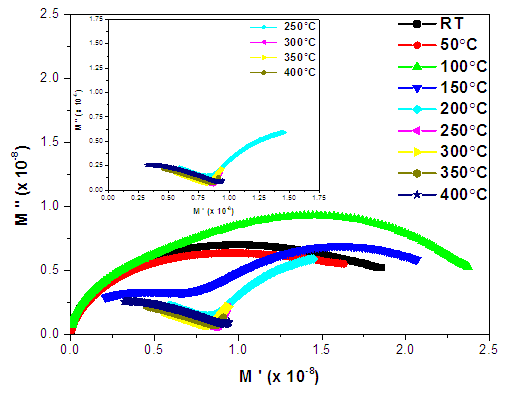

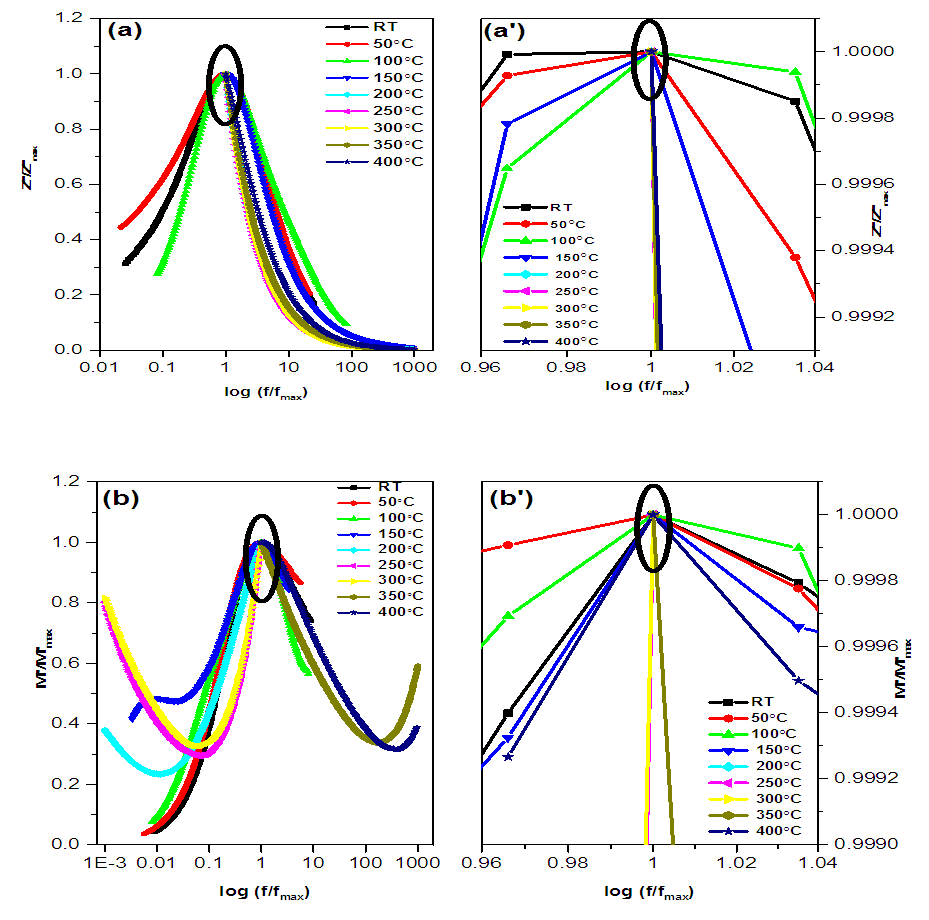

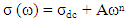

| [33] | D.C. Sinclair, and A.R. West, “Impedance and modulus spectroscopy of semiconducting BaTiO3 showing positive temperature coefficient of resistance” Journal of Applied Physics, (1989). |

| [34] | Karishma Kumari, Ashutosh Prasad, Kamal Prasad “Dielectric, Impedance/Modulus and Conductivity Studies on [Bi0.5(Na1-xKx)0.5]0.94Ba0.06TiO3(0.16≤x≤0.20) Lead-Free Ceramics” American Journal of Materials Science, (2016). |

| [35] | Seema Sharma, Kashif Shamim, Anand Ranjan, Radheshyam Rai, Poonam Kumari, and Sangeeta Sinha “Impedance and modulus spectroscopy characterization of lead free barium titanate ferroelectric ceramics” Ceramics International, (2015). |

| [36] | Shweta Thakur, Radheshyam Rai, Igor Bdikin, and Shashi Prakash Rai “Dielectric relaxation and ac conduction in multiferroic Bi0.8Gd0.1Pb0.1Fe0.9Ti0.1O3 ceramics: impedance spectroscopy analysis” Phase Transitions, (2016). |

| [37] | D.C. Sinclair, and A.R. West “Effect of atmosphere on the PTCR properties of BaTiO3 ceramics” Journal of materials science, (1994). |

| [38] | Li, H.-D., C.-D. Feng, and P.-H. Xiang “Electrical properties of La3+-doped (Na0.5Bi0.5)0.94Ba0.06TiO3 ceramics” Japanese journal of applied physics, (2003). |

| [39] | Ruzhong Zuo, Hongqiang Wang, Bing Ma, and Longtu Li “Effects of Nb5+ doping on sintering and electrical properties of lead-free (Bi0.5Na0.5)TiO3 ceramics” Journal of Materials Science: Materials in Electronics, (2009). |

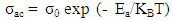

| [40] | A.K. Jonscher “Dielectric relaxation in solids” Journal of Physics D: Applied Physics, (1999). |

| [41] | J.C. Dyre. and T.B. Schrøder “Universality of ac conduction in disordered solids” Reviews of Modern Physics, (2000). |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML