Athirah Mansor1, Suzaini Abdul Ghani2, Muhamad Faizul Yahya2

1Faculty of Applied Sciences, Universiti Teknologi MARA (UiTM), Malaysia

2Textile Research Group, Faculty of Applied Sciences, Universiti Teknologi MARA (UiTM), Malaysia

Correspondence to: Suzaini Abdul Ghani, Textile Research Group, Faculty of Applied Sciences, Universiti Teknologi MARA (UiTM), Malaysia.

| Email: |  |

Copyright © 2016 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Abstract

This paper reports on an investigation of physical properties on some of the clothing comfort properties of knitted fabrics. Fabric parameters such as fabric density, fabric thickness and fabric weight have been considered to be correlated to air and water vapor permeability, and also moisture management properties which includes accumulative one-way transport index and overall moisture management capacity. This is important in order to determine the overall thermophysiological comfort performance of knitted fabrics. The results suggested that all of the fabric parameters stated before appeared to affect the fabric comfort properties.

Keywords:

Knitted fabric, Clothing comfort, Air permeability, Water vapour permeability, Moisture transport

Cite this paper: Athirah Mansor, Suzaini Abdul Ghani, Muhamad Faizul Yahya, Knitted Fabric Parameters in Relation to Comfort Properties, American Journal of Materials Science, Vol. 6 No. 6, 2016, pp. 147-151. doi: 10.5923/j.materials.20160606.01.

1. Introduction

Clothing comfort is a subjective matter as it depends on the wearers’ perception. It is usually measured with the interaction between human body with its surrounding microclimate and also the clothing [1]. In hot and humid country, it is important to maintain heat balance of the body to achieve thermo-physiological comfort state which the process is called homeostasis and in this case it is temperature homeostasis. In order to achieve that, the heat production by the body must be in equilibrium with the exchange of environment heat [2]. During activities, sweating and evaporation are the key for heat loss due to the sweat carries away the heat as it evaporates away from the skin. However, clothes can be the barrier to optimum body heat and moisture loss. The moisture and heat loss from the body and the feeling of comfort state in a certain environment affected by the clothing worn.Knitted fabrics are widely used due to their easy care properties and possessed high degree of clothing comfort. Liquid moisture transport and breathability of the fabric are two significant factors that affects the thermo-physiological comfort of garment. It is said that thermo-physiological comfort properties of fabric are mainly influenced by fiber type, yarn parameters, fabric characteristics and finishing processes [3-5]. Due to that, the first part of this study is dedicated to verify some of the thermo-physiological comfort properties of selected knitted fabrics in terms of air permeability, water vapor permeability and liquid moisture transport properties with objective evaluation. In general, liquid moisture transport in textile materials are mainly affected by the moisture absorbency of the fiber content and wicking ability which are determined by the capillary action , pathways and surface tension [6]. Many researchers worked on the improvement of thermal comfort performance in clothing. Özkan et al, measured the thermal and moisture management properties of polyester knitted fabrics used in cycling clothes and it is aimed to compare to find the fabrics that were more convenient for the cyclists [7]. Objective fabric evaluations were conducted on thermal resistance, water vapor resistance, air permeability and moisture management properties and it is said that fabrics with good moisture comfort, low water vapor resistance and good moisture management properties were preferred.Nazir investigated the effect of changes on knitting parameters on the moisture management and air permeability of interlock fabrics [1]. It was found that the fabric weight, the thickness of the fabric and fabric porosity increased when the machine gauge increased and the stitch length decreased. It was further concluded that loosely knitted fabric samples with higher amount of entrapped air shows good air permeability property but poor moisture management properties.

2. Materials and Methods

Ten knitted fabrics with different fiber and knit structures were used. The physical parameters of the fabrics were measured with the related standards (MS ISO 5084-2003; ASTM D3776/ D3776M-2009a; MS ISO 7211/2-2003). Fabrics were medium weight to heavy weight in the range of 120 g/m2 to 400 g/m2. All of the samples were tested for air permeability, water vapor permeability, and moisture transport and the average value was given for the discussion of the results.

2.1. Air Permeability

Air permeability is the rate air flowing passing perpendicularly through a known area under a prescribed air pressure between two surface of the material used [5, 8]. All the samples were measured using MESDAN Air-Tronic Air Permeability tester according to ASTM D737-04/2008 standard. The measurement details are: test area = 10 cm2, test pressure = 100Pa, and air volume = 10 liters.

2.2. Water Vapor Permeability

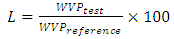

The samples were measured by SDL Atlas Water Vapor Permeability Tester according to standard BS 7209. There are two ways of water vapor diffuses through a textile material, the first one is a simple diffusion through the air spaces between fibers and yarns and also along the fiber itself [8]. The method used in this study is the straight forward one, involving the determination of weight loss with the evaporation time of water contained in a cup. The method compares the rate of water mass transfer through fabric from eight cups, two of them covered with reference fabric and the other six with test samples. The water vapor permeability index calculated by expressing water vapor permeability (WVP) of the fabric sample as a percentage of the WVP of the reference; | (1) |

Where, M is the loss in mass (g), t is the time interval (h), and A is the area of exposed sample that equal to the internal area of the test cup (m2). Water vapor permeability index (L) was calculated by; | (2) |

2.3. Moisture Transport Properties

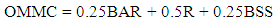

For moisture transport within fabrics, wettability and wickability must be accounted. The moisture management tester (MMT) was used to measure liquid moisture transport capability of textiles [9]. According to AATCC Test Method 195 (2009), a solution containing NaCl was introduced to top surface of the sample to simulate sweating. A series of indices were calculated to describe the moisture management performance of a fabric such as wetting time (sec), absorption rate (%/sec), spreading speed (mm/sec), maximum wetted radius (mm), one-way transport capacity also known as accumulative one-way transport index (AOTI) and lastly overall moisture management capacity. Overall moisture management capacity (OMMC) indicates the overall capability of fabric to manage liquid moistures’ transport that includes three aspects of performances: moisture absorption rate at bottom (BAR), one-way liquid transport ability (R), moisture drying speed at bottom side (BSS) which calculated using formula; | (3) |

OMMC range values are compared with the grading scale given by the manufacturing company which is according to the 5 grade scale (1-5). The grades of the indexes are: 1(0~0.2) = very poor, 2(0.2~0.4) = poor, 3(0.4~0.6) = good, 4(0.6~0.8) = very good, 5(>0.8) =excellent.

2.4. Analysis

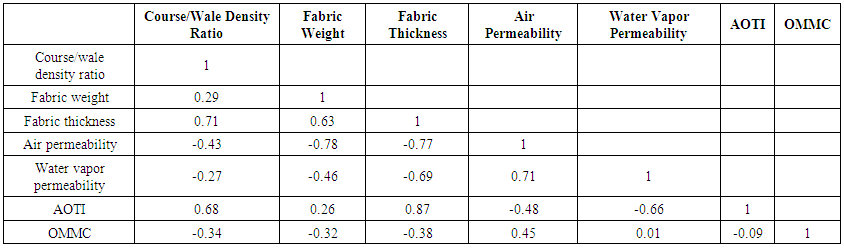

Correlation coefficient analysis was conducted to determine the relationships between fabric parameters and fabric comfort properties. The correlation coefficient value (r) was derived by the value R2. The absolute r-value higher than 0.3 was considered to be related but weak relationship and the absolute r-value higher than 0.6 was considered to have moderate to strong relationship [10].

3. Results and Discussions

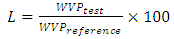

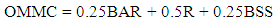

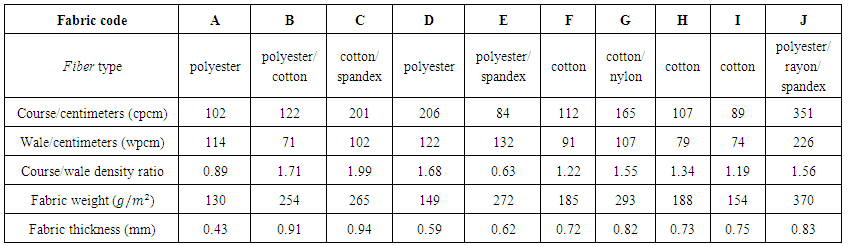

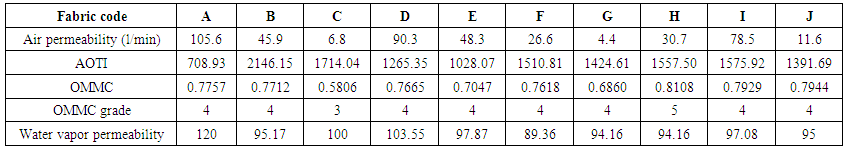

The physical parameters and properties results of ten selected sample of knitted fabrics, which were measured in accordance to standards are tabulated in Table 1 and Table 2. The correlation coefficient analysis results (r-value) shown in Table 3. | Table 1. Parameters of Knitted Fabrics |

| Table 2. Properties of Knitted Fabrics |

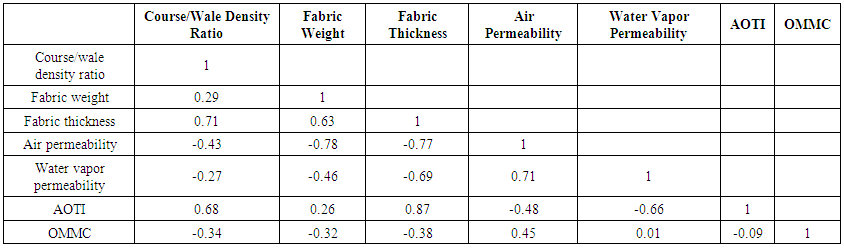

| Table 3. Correlation Coefficient Analysis (r-value) |

3.1. Air Permeability

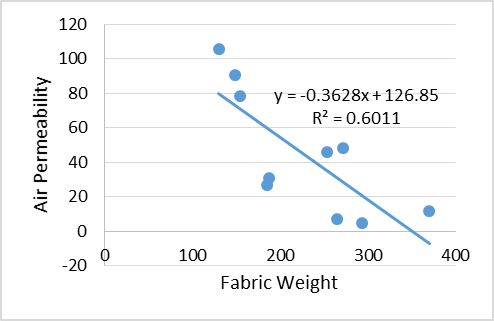

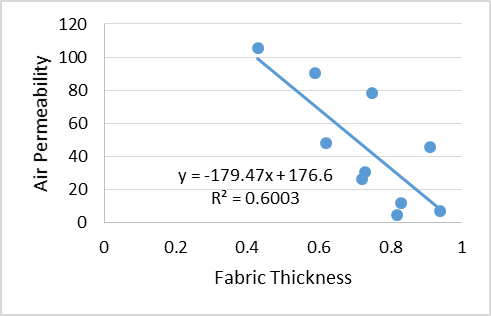

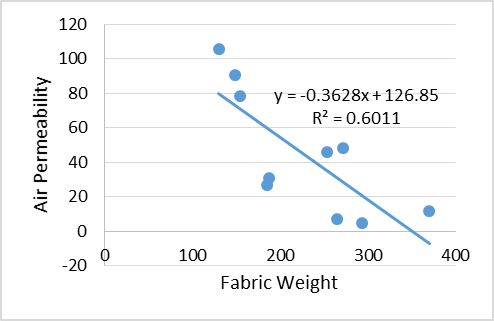

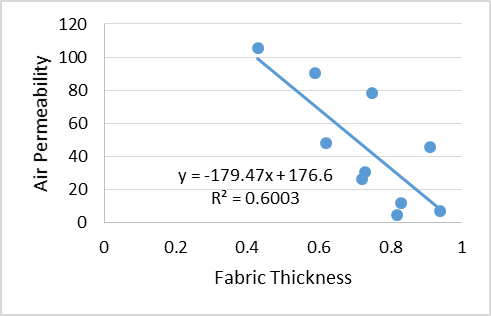

Table 2 shows the results for all the knitted fabric samples used. It shows that the fabric A has the highest air permeability value then followed by fabric D and fabric G has the lowest air permeability value. According to Table 1 and 2, although fabric A and D both made from polyester fiber, fabric A has higher air permeability value compared to fabric D. This is due to fabric A has lower course/wale density ratio, fabric thickness and fabric weight and also the contribution of difference in fabric structures and this case is also applies to the fabric F, H and I which all of them made from cotton. Figure 1 and 2 which according to the correlation coefficient analysis in Table 3, air permeability has strong negative relationships with fabric weight and fabric thickness parameters. However there is a negative correlation coefficient between air permeability and course/wale density ratio but it is not strong enough. Thus, as the fabric weight and fabric thickness increased, it causes the fabric volume per area to increase which representing porosity. This results in decreased in air permeability as the fabric volume per area increased which tells that porosity that plays an important role in air permeability. This can be further concluded that air permeability of the fabrics are mainly affected by porosity and type of fabric structures.  | Figure 1. Correlation of air permeability and fabric weight |

| Figure 2. Correlation of air permeability and fabric thickness |

3.2. Water Vapor Permeability

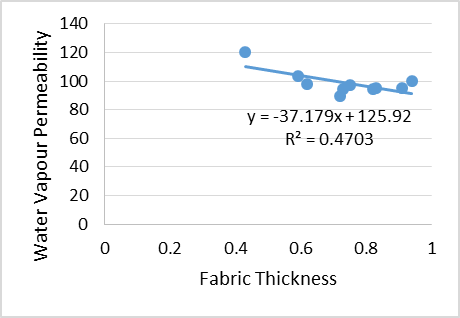

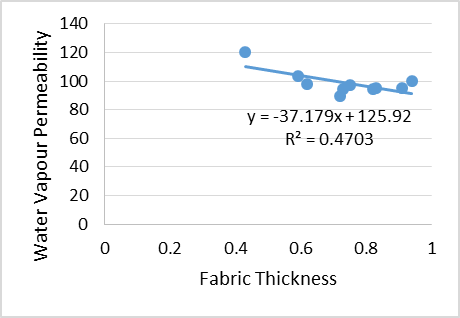

Water vapor permeability properties is one of the crucial factors in determining clothing comfort as it represent the ability of transferring perspiration. According to the SDL Atlas Water Vapor Permeability Tester test results (Table 2), fabric A has the highest water vapor permeability index value which was in parallel with its highest air permeability result. In other words, fabric A able to allow the air and water vapor to pass through the other side of the fabric better than other samples of knitted fabrics. According to Table 2, fabric A and D are both made from polyester but fabric A has higher index value compared to fabric D and this is due to fabric D is more compact as its’ course/wale density ratio, fabric thickness and fabric weight higher value than fabric D. This also applies to the fabric made from cotton which are fabric F, H, and I. Although fabric I is the thickest among fabric F, H, and I, it still the least compact fabric. In Figure 3 which according to correlation coefficient analysis (Table 3), water vapor permeability has a strong negative relationship with fabric thickness. According to Table 3, there is negative relationship with fabric weight but it was not strong enough meanwhile r-value of water vapor permeability and course/wale density ratio less than 0.3 hence it is not related. Thus, in this case water vapor permeability properties does not significantly influenced by the course/wale density ratio and fabric weight. | Figure 3. Correlation of water vapor permeability and fabric thickness |

3.3. Moisture Transport Properties

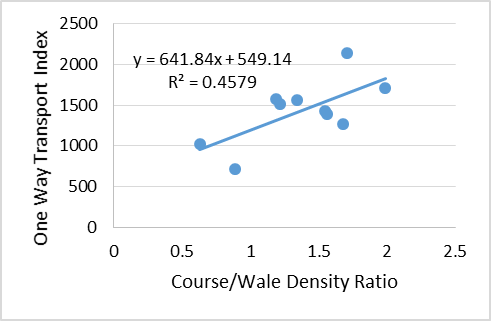

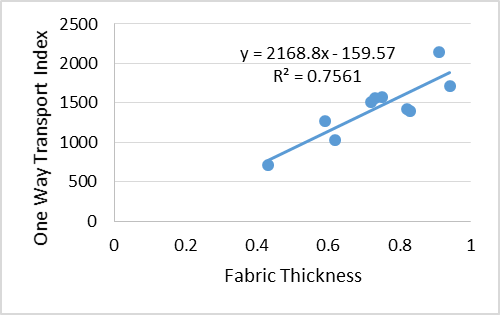

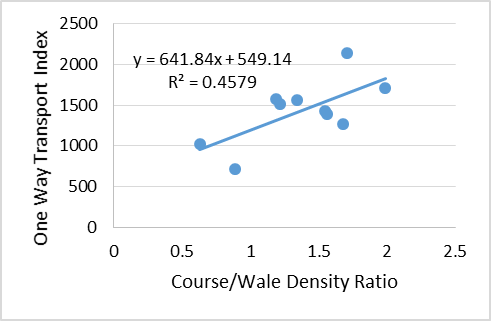

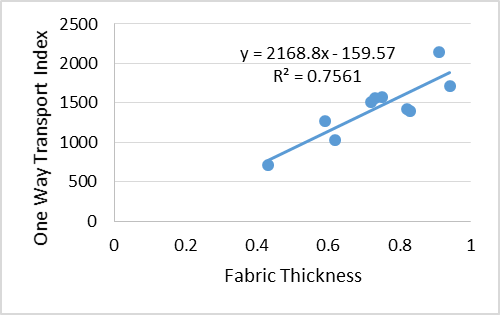

According to moisture transport properties test results (Table 2), fabric B has the highest accumulative one-way transport index value and fabric A has the lowest index value. Both fabric A and D made from polyester but fabric D has higher index compared to fabric A though fabric D has higher fabric thickness and fabric weight and this is due to difference in fabric structures. For fabric made out from cotton which are fabric F, H, and I, fabric I has the highest index and this is due to its’ lowest density ratio, fabric thickness and fabric weight among three of them.For overall moisture management capacity (OMMC) in Table 2, fabric H has the highest OMMC index value which was graded 5(excellent) and fabric C has the lowest OMMC index value which was 3(good). Fabric F, H and I are made from cotton but only fabric H graded as 5 and this is due to fabric H is made from combed cotton yarn.In Figure 4 and Figure 5 which according to the correlation coefficient analysis in Table 3, accumulative one-way transport index (AOTI) have strong positive relationships with course/wale density ratio and fabric thickness parameters which represented compactness of the fabric. This shows that AOTI is strongly affected by compactness of the fabric. The r-value between AOTI and fabric weight is less than 0.3 therefore it is not related.  | Figure 4. Correlation of AOTI and course/wale density ratio |

| Figure 5. Correlation of AOTI and fabric thickness |

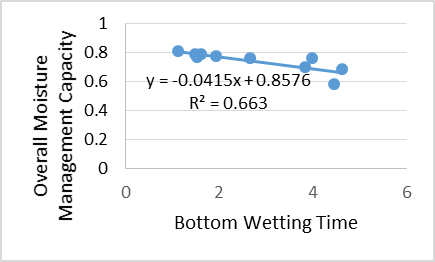

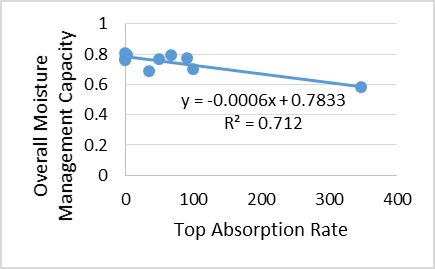

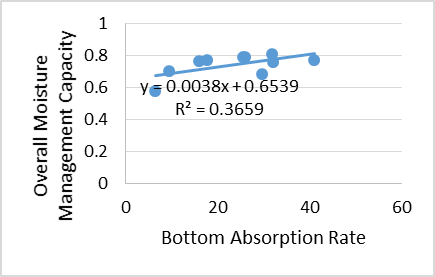

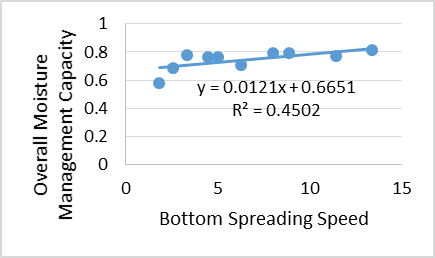

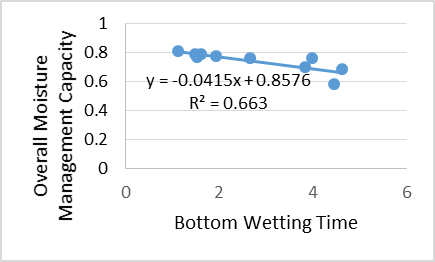

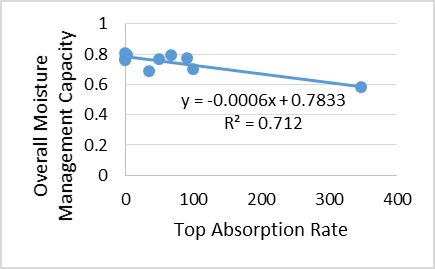

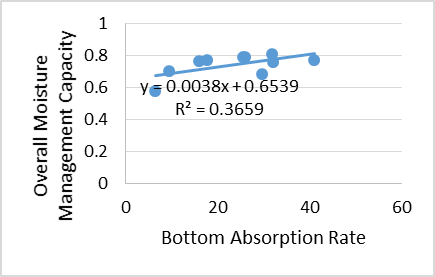

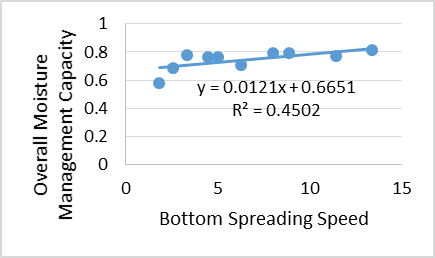

According to the correlation coefficient analysis (Table 3), overall moisture management capacity have negative relationships between course/wale density ratio, fabric weight and fabric thickness and all of them was not strong enough. Thus, OMMC does not significantly influenced by the fabric parameters tested which are course/wale density ratio, fabric thickness and fabric weight. Despite the weak relationships between the overall moisture management capacity with course/wale density ratio, fabric weight and fabric thickness in correlation coefficient analysis, OMMC have strong negative relationships with bottom wetting time with r-value = 0.81 and top absorption rate with r-value = 0.84 as shown in Figure 6 and 7. OMMC also have strong positive correlation coefficients with bottom absorption rate with r-value = 0.6 and bottom maximum wetted radius with r-value = 0.67 as shown in Figure 8 and 9. All of the results mentioned showed that OMMC of the fabrics naturally more reflected on the ability of the type of the fiber, fibers’ composition and moisture regain, and of the fabric structure. | Figure 6. Correlation of OMMC and bottom wetting time |

| Figure 7. Correlation of OMMC and top absorption rate |

| Figure 8. Correlation of OMMC and bottom absorption rate |

| Figure 9. Correlation of OMMC and bottom spreading speed |

4. Conclusions

The implication of the study provides knowledge and a better understanding of the degree of clothing comfort. It enables the parties who used the outcome as market tools to improvise products that is not restricted to knitted fabrics only. Ten types of knitted fabrics were selected as raw materials for the purpose of this study. The correlation coefficient analysis was done to identify the how strong the relationship and how it affects the others. From the results, fabric thickness has the most effect on accumulative one-way transport which shows that fabric thickness has impact on wickability of fabric. It is expected that OMMC and water vapor permeability have relatively low correlation coefficient values than the others as OMMC and water vapor permeability more influenced by the properties of the fiber content and fabric structure. The study may be continued by testing including other properties and other parameters.

ACKNOWLEDGEMENTS

The authors wish to thank the Ministry of Education, Malaysia (MOE) for the Fundamental Research Grant Scheme (FRGS) and the Research Management Institute (RMI) of UiTM for the management of the fund.

References

| [1] | A. Nazir, T. Hussain, F. Ahmad, and S. Faheem, "Effect of Knitting Parameters on Moisture Management and Air Permeability of Interlock Fabrics," AUTEX Research Journal, vol. 14, pp. 39-46, 2014. |

| [2] | K. Stevens and M. Fuller, "Thermoregulation and clothing comfort," Textile-led Design for the Active Ageing Population, p. 117, 2014. |

| [3] | S. H. Ravandi and M. Valizadeh, "Properties of fibers and fabrics that contribute to human comfort," Improving comfort in clothing, pp. 61-78, 2011. |

| [4] | N. Oglakcioglu, "Design of functional knitted fabrics for medical corsets with high clothing comfort characteristics," Journal of Industrial Textiles, p. 1528083714551438, 2014. |

| [5] | G. Bedek, F. Salaün, Z. Martinkovska, E. Devaux, and D. Dupont, "Evaluation of thermal and moisture management properties on knitted fabrics and comparison with a physiological model in warm conditions," Applied ergonomics, vol. 42, pp. 792-800, 2011. |

| [6] | R. Bagherzadeh, M. Gorji, M. Latifi, P. Payvandy, and L. Kong, "Evolution of moisture management behavior of high-wicking 3D warp knitted spacer fabrics," Fibers and polymers, vol. 13, pp. 529-534, 2012. |

| [7] | E. T. Özkan and B. Meriç, "Thermophysiological comfort properties of different knitted fabrics used in cycling clothes," Textile Research Journal, p. 0040517514530033, 2014. |

| [8] | E. Onofrei, A. M. Rocha, and A. Catarino, "The influence of knitted fabrics’ structure on the thermal and moisture management properties," Journal of Engineered Fibers and Fabrics, vol. 6, pp. 10-22, 2011. |

| [9] | M. Manshahia and A. Dasa, "Thermo-physiological comfort of compression athletic wear," Indian Journal of Fibre & Textile Research, vol. 39, pp. 139-146, 2014. |

| [10] | M. Mukaka, "A guide to appropriate use of Correlation coefficient in medical research," Malawi Medical Journal, vol. 24, pp. 69-71, 2012. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML