-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

American Journal of Materials Science

p-ISSN: 2162-9382 e-ISSN: 2162-8424

2016; 6(3): 73-78

doi:10.5923/j.materials.20160603.02

Textural Characteristics of Fine Aggregate Efficiency on Concrete Strength

Abdulelah A. Bahabri

Faculty of Earth Sciences, King Abdulaziz University, Jeddah, Saudi Arabia

Correspondence to: Abdulelah A. Bahabri, Faculty of Earth Sciences, King Abdulaziz University, Jeddah, Saudi Arabia.

| Email: |  |

Copyright © 2016 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

The concrete aggregate has an effective function of concrete properties. Its final properties are controlled by the proportional of its components; aggregates, water and cement. It has known and deep settled that, its fine aggregates are used nearly as filling constitutes to reduce the cement percent with the concrete past. The current experimental study indicated that, the textural characteristics of fine aggregate are having a vital role of concrete properties at fixed FM-values of fine aggregates. This experimental study pointed out that, the mechanical properties of hardened cement concrete do not depend only on the characteristics of coarse aggregates but also on the characteristics of fine aggregates.

Keywords: Fine Crushed Aggregates, Textural Characteristics, Concrete Strength

Cite this paper: Abdulelah A. Bahabri, Textural Characteristics of Fine Aggregate Efficiency on Concrete Strength, American Journal of Materials Science, Vol. 6 No. 3, 2016, pp. 73-78. doi: 10.5923/j.materials.20160603.02.

Article Outline

1. Introduction

- From building materials point of view, concrete considered as one of the most manmade important building materials that passed through several stages since the ancient Egyptians and Romans, the availability of concrete components help us to stretch urbanization due to its hardness and higher stability against weathering processes. Compositionally, the present concrete was made of aggregates, cement and water. It must be stable with right proportion. The cement concrete is a mixture of cement, aggregates and water. These three main components became hard like a stone when hardened. It binds rapidly with steel and as it is weak in tension, the steel reinforcement is placed in cement concrete at suitable places to take up the tensile stresses. Its final strength and quality depend initially on quantity and quality of its components; aggregates, cement and water.Aggregates represent more than 75% of the total volume of cement concrete. The concrete aggregate plays an essential role of fresh and hardened properties of concrete. The percent of fine aggregate nearly makes about one third of the total amount of concrete aggregates, where the fine aggregate occupies the voids among coarse aggregates.Crushed aggregate represents the principle sources of construction aggregates in the western parts of Saudi Arabia, where wide outcrops of dioritic rocks are locating between Jeddah and Makkah. This type of hard rock was used as a vital resource of crushed aggregates for constructional uses (concrete, pavement). This experimental work is focusing to assess the effects of amount and granularity of fine crushed aggregate concrete strength.

2. Materials and Methodology

- The crushed fine and coarse aggregates were collected from a nearby crusher of diorite in north western Jeddah near Breman Bridge (Figs. 1 and 2). The admixture content methods have evolved from the arbitrary volumetric method (1:2:4:6- water: cement: fine aggregate: coarse aggregate). The fine natural aggregate was taken from sedimentary quarry of fine aggregates. Both fine natural and crushed aggregate are having the same FM-values and the same grain size destruction curve.

| Figure 1. Field photographs of Breman diorite aggregate crusher in NW of Jeddah |

| Figure 2. Field photographs show aggregate sampling and types of diorite aggregates (a and b respectively) |

3. Results and Discussion

3.1. Grain Grading

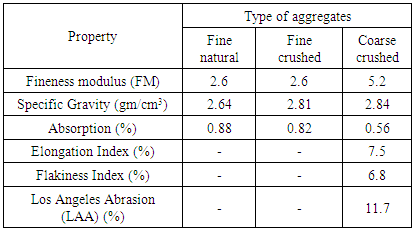

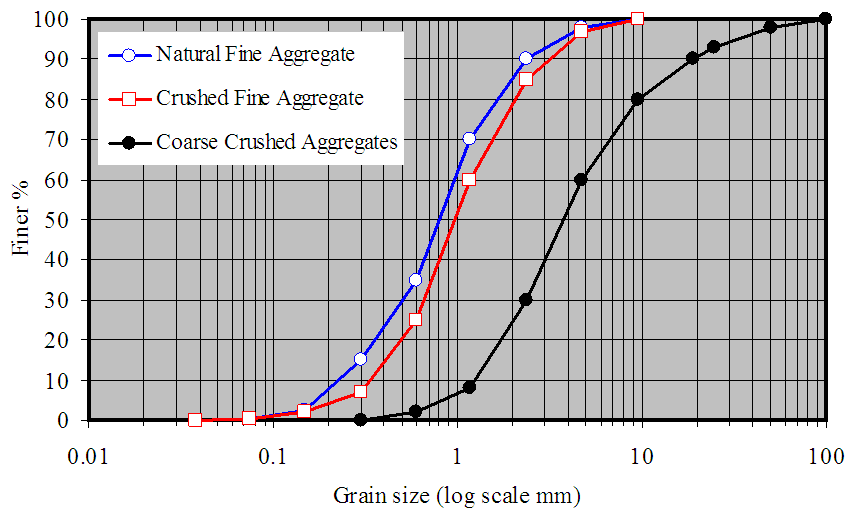

- The grain grading of concrete aggregate has an important control on the physical and mechanical of unhardened and harden concrete. Figure 3 illustrates the grain grading of the studied aggregates. It shows that, the studied fine (natural and crushed) and coarse crushed aggregates are characterized by more or less smooth well graded distribution curves. Consequently, little amount of inter-particle voids that must filled with cement past and the concrete mixes of different-sized particles will be enough stronger as well as will be more compacted when hardened [5]. The fineness modulus (FM) is most commonly computed factor for aggregates. It is used to determine the degree of uniformity of the aggregate gradation. Somewhat, smaller variations in fine aggregate grading can affect the aggregate workability due to the higher surface area.The FM (Fineness modulus) of the studied fine and coarse aggregates is 2.6 and 5.2 for fine and coarse aggregates respectively, Table 1). So that, the FM-value of fine aggregate does not have any effects on the properties of the studied concrete mixes.

|

3.2. Specific Gravity (GS) and Absorption

- In the evaluation processes of concrete aggregate, the value of specific gravity usually uses as a practical marker of its fitness. The specific gravity estimation of aggregate is very important during the concrete design. The specific gravity value of the studied aggregate is 2.64g/cm3, 2.81g/cm3 and 2.84 g/cm3 for fine natural, fine crushed and coarse crushed aggregates respectively (Table 1). That indicated that, the studied aggregate meets the standard characteristics of concrete aggregates [6]. The absorption values of the studied aggregates are 0.88%, 0.82% and 0.56% for fine natural, fine crushed and coarse crushed aggregates respectively (Table 1). These results are showing that, the studied concrete aggregates have standard limits for concrete aggregates absorption.

3.3. Textural Characteristics

3.3.1. Particle Roundness Degree of Fine Aggregates

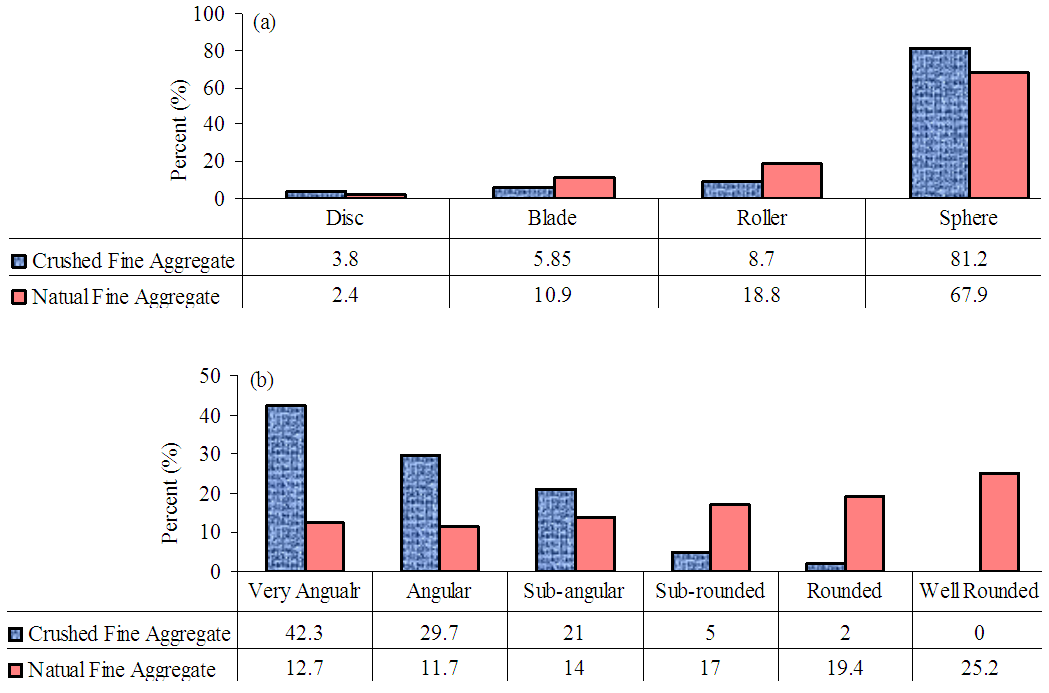

- Texturally, both shape and roundness degree of fine aggregate has an essential effecting on workability, strength and durability. Rounded and poorly graded grains tend to have higher void content than angular and well graded ones. So that, angular particles of aggregates tend to more packed, strength and durability in hardened mix of concrete and mortar. Figure 3 illustrates roundness degree of the studied fine aggregates. It shows nearly balanced amount of grain shape of both fine natural and crushed aggregates (Fig. 4a). Also, it indicated that, the crushed fine crushed aggregates are consisting mainly of very angular, angular, sub-angular and sub-rounded particles, whereas, fine natural aggregates are consisting of a balanced mixtures of both rounded and angular particles (Fig. 4b).

| Figure 3. Grain size distribution curves of the studied fine and coarse aggregates |

| Figure 4. Particle shape and roundness degree of the studied fine aggregates (a and b respectively) |

3.3.2. Elongation and Flakiness Index of Course Crushed Aggregates

- From constructional material point of view, it is believed that, the flat and elongated grains of concrete aggregates are undesirable owing to easily breaking under loads [10]. Whereas, the mostly equi-dimensional (cubical) particles tend to be more densified and stable under loads. The EI and FI values are 7.5% and 6.8% respectively (Table 1). That indicates that, the studied coarse crushed concrete aggregates are having a higher stability to shearing.

3.4. Los Angeles Abrasion (LAA)

- The main aim of LAA-test test was to evaluate abrasion resistance of the studied crushed coarse aggregates which can be used in cement concrete mixtures. Consequently, the obtained data will be very important in assessment the durability performance of the studied aggregates. Los Angles abrasion (LAA) value of the studied coarse crushed aggregates (larger than 2.36mm) is 11.7% to (Table 1). This result indicates strong resistance of the studied coarse crushed aggregates for abrasion [11]. The relative higher conflict to wear, as evaluated by a low abrasion loss percent, is desirable characteristics of aggregates to be used in cement concrete mix.

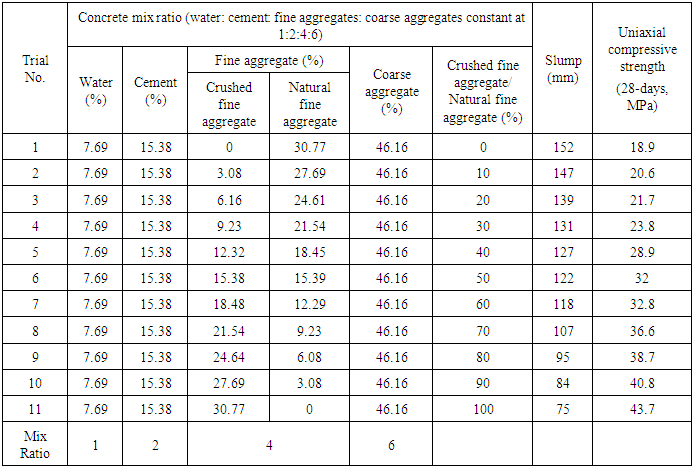

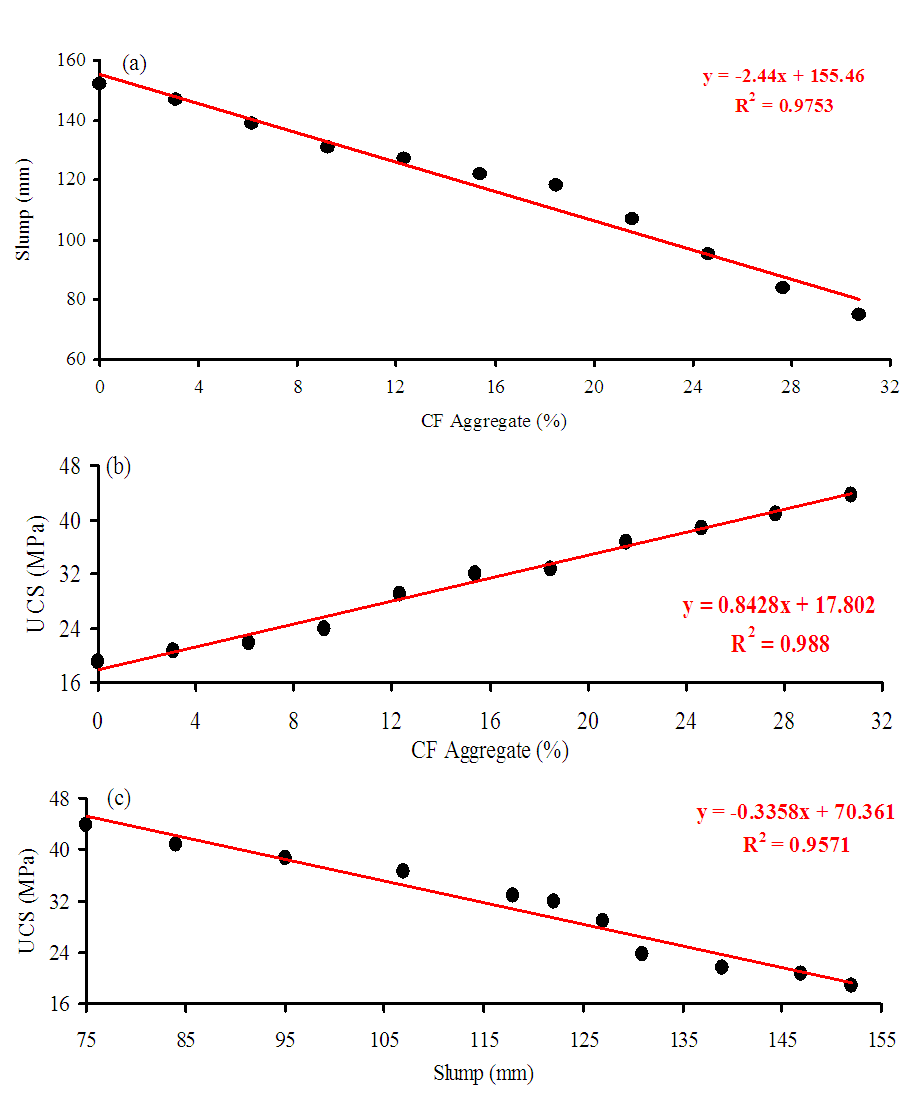

3.5. Workability Characteristics

- The workability degree of concrete mixture give an accurate indication about its component (aggregate, cement and water) homogeneity so that it plays an essential role in the mechanical properties of hardened concrete. The workability degrees (slump test, mm) give an indication of the water /cement ratio and thus the hardened strength of concrete [12]. Figure 4a shows the workability (slump test in mm) results; it is clear that the studied concrete workability decreases with increasing fine crushed aggregate percentages. The workability values are varying from 75mm to 152mm (Table 2). The workability of the studied concrete has indirect strong correlation with the fine crushed aggregate percent (r-vale = 0.988, Fig. 5a). That means that, the textural characteristics (especially roundness degree) of fine aggregates play an essential role in workability of concrete mixes.

|

3.6. Uniaxial Compressive Strength

- The compressive strength of concrete considered as the most common performance measurement used by engineers in designing buildings and other structures [13]. It depends essentially on two factors: the water-to-cement ratio and the degree of compaction. Even so, the shape of aggregates has an influence on the concrete strength [14]. Round, smooth sands require less mixing water in mortar and thus produce better strength at the same cement content. The mechanical properties of concrete are generally controlled by the strength of the cement-aggregate bond and by other factors such as texture and soundness of the rock [15]. Generally, the type of fine aggregate has a significant influence on both rheological and mechanical properties of concrete [16, 17]. The uniaxial compressive strength of the studied concrete samples was estimated by breaking concrete specimens (15x15x30 cm) in a compressive testing machine. The compressive strength was calculated from the failure load divided by the cross-sectional area resisting the load and repeated in units of megapascals.Figure 5b illustrates the compressive strength values for the studied concrete mix within 28 days (15x15x30cm). It shows that, the UCS-values are generally increasing with increasing fine crushed aggregate percent. This increasing in concrete strength was resulted from increasing rough surfaces of crushed aggregates that lead to well-packing with others aggregate particles. As well as owing to decreasing the surface area of crushed aggregates comparing with natural fine aggregates that having larger surface areas.It is found that the UCS-values of the studied concrete have a strongly direct proportional relation with fine crushed aggregate percent (r-value=0.99, Fig. 5b). Consequently, the UCS-values of the studied concrete and workability degree have a strongly indirect proportional relation (r-value=0.978, Fig. 5c).

4. Conclusions

- Based on the above mentioned results of this experimental study, the following conclusions could be drawn as the followings:1. The cement concrete properties are essentially controlled by the textural characteristics of both fine and coarse aggregates (at fixed FM-values).2. The roundness degree of fine aggregates has an effective role in both green and hardened cement concrete properties.3. The results of unconfined compressive strength test of the studied concrete aggregates indicated that the mechanical properties of hardened cement concrete do not depend only on the characteristics of coarse aggregates but also side by side on the characteristics of fine aggregates.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML