-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

American Journal of Materials Science

p-ISSN: 2162-9382 e-ISSN: 2162-8424

2016; 6(1): 35-43

doi:10.5923/j.materials.20160601.03

Using Cost Effective Natural Fibre to Build Environment Friendly Brick

Kazi Tauhidul Alam , Alexander Büsgen

Department of Textile and Clothing Technology, Niederrhein University of Applied Science, Germany

Correspondence to: Kazi Tauhidul Alam , Department of Textile and Clothing Technology, Niederrhein University of Applied Science, Germany.

| Email: | kazitauhidul.alam@gmail.com |

Copyright © 2016 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Now-a-days the world is having immense threat of global warming due to bad impact of CFC emission in the earth. It is a well know fact that air conditioner plays a crucial role in this development. Fortunately, there is a growing trend of corporate-social responsibility to mitigate this problem by designing more environmentally sustainable product. In this paper, we provide the theoretical analysis of making an environment friendly brick by the use of natural fibre, jute, which is as strong as normal brick and a possible competitor to the air conditioner. Our proposed product, jute based brick can help in the movement of reduced CFC emission, which is also very cost effective.

Keywords: Chlorofluorocarbon, Global warming, Environment friendly, Natural fibre, Jute, Innovative Product development

Cite this paper: Kazi Tauhidul Alam , Alexander Büsgen , Using Cost Effective Natural Fibre to Build Environment Friendly Brick, American Journal of Materials Science, Vol. 6 No. 1, 2016, pp. 35-43. doi: 10.5923/j.materials.20160601.03.

Article Outline

1. Introduction

- During the process of developing a new product, consciously or unconsciously, a number of decisions are made that affect the environment, thus making a product not only for the technical performance and economic performance but also for the environmental impact of a product. The greenhouse gases i.e. carbon dioxide, methane, nitrous oxide, ozone and chloro-fluoro-carbon (CfC) are responsible for altering the global climate. Scientists believe that this effect may be the result of the temperature rise of 1.5 to 5.5 degree Celsius by the middle of this century. The necessity [1] of environmental friendly product is a crying need in the world. Now a days the world is having immense threat for the global warming effect so, we need to produce those kind of product which will be environmental friendly and sustainable. As a matter of fact we are focusing to produce our product by natural fibre to compete against the air condition in the global market. Previously we have got the knowledge about the emission of green house gases for the use of [2] air conditioner and refrigerator.Reason behind using jute fibre to form our product:As per the previous and recent resources we have known that after the Coir fibre Jute is the most cost effective natural fibre [3] in the world but the use of jute fibre in the modern aspects is hardly be seen.Reasons behind the selection of [4] Jute fibre:v Jute fiber is 100% bio-degradable and recyclable and thus environmentally friendly. v It is the cheapest vegetable fiber procured from the bast or skin of the plant's stem. v It is the second most important vegetable fiber after cotton, in terms of usage, global consumption, production, and availability. v It has high tensile strength, low extensibility, and ensures better breathability of fabrics. v It helps to make best quality industrial yarn, fabric, net, and sacks. It is one of the most versatile natural fibers that has been used in raw materials for packaging, textiles, non-textile, construction, and agricultural sectors. Bulking of yarn results in a reduced breaking tenacity and an increased breaking extensibility when blended as a ternary blend.v Advantages of jute include good insulating and antistatic properties, as well as having low thermal conductivity and a moderate moisture regain. Other advantages of jute include acoustic insulating properties and manufacture with no skin irritations. v Jute has the ability to be blended with other fibers, both synthetic and natural, and accepts cellulosic dye classes such as natural, basic, vat, sulphur, reactive, and pigment dyes. Jute can also be blended with wool. By treating jute with caustic soda, crimp, softness, pliability, and appearance is improved, aiding in its ability to be spun with wool. Liquid ammonia has a similar effect on jute, as well as the added characteristic of improving flame resistance when treated with flame proofing agents.Relation of eco- friendliness and the corporate social responsibility:Previously we have mentioned that our intention is to produce an environmental friendly and cost effective product. The word environment friendly is very much close towards the word [5] ECO friendly. Eco-friendly means the things which is not harmful for the earth or the product which is really environmental friendly. It is uniformly refers to the items that intend to green living and that helps to conserve the resources like water and energy. Environmental friendly items also contributes to air, water and land pollution. We can engage in environmental friendly practices by being extra conscious of how we use our resources. In our product we tried to find out the advanced use of jute fibre with a high technological impact. Our product will be much more cost effective and environmental friendly than air condition. Currently the use of bricks in the building hardly be seen to secure the impact of global warming effects for the future generation but we have always in our mind to produce a product, which will be able to decrease the global warming impact from the world to achieve the environmental sustainability. Our intention is to show that corporate social responsibility that defines the [6] environmental sustainability.Purpose and the approach of the project:v To form a new innovative product by a eco friendly and natural material. v To introduce a new eco-technology for maintaining the room temperature constant on 25 degree Celsius. v To decrease the use of existing technology against controlling the temperature.v To be a leader in the market position. v To introduce a cheap but productive material against the highest innovation of technology. Objectives:v To make economical and eco-friendly product by Jute fibre.v To reduce the use of machine and the reduction of CFC. The word environment is very much close towards the word [5] ECO friendly. Eco-friendly means the things which is not harmful to the earth or the product which is really environmental friendly. It is uniformly refers to the items that intend to green living and that helps to conserve the resources like water and energy. Environmental friendly items also contributes to air, water and land pollution. We can engage in environmental friendly practices by being extra conscious of how we use our resources. Usually air condition is the competitive product and it is very much famous for those countries whose are having the high temperature and at a stake very low temperature. If we want to define this product then it can be called as the process or a device that lower or higher the temperature to achieve more favourable conditions to an occupied space to feel comfort.Content of our paper:In our report there are two major sections like product development section and cost calculation. PDS is made of idea screen, conceptual design and rating calculation of technology and cost effectiveness of the product. In the cost calculation section we have decorated the costing in three different tables like: table 1 (fabric consumption), table 2 (material cost) and table 3 (Cost of manufacturing). In the product development section we have tried to show how to develop our product and in the costing section we have tried our best to make a cost comparison of our product with the competitive product air conditioner.

2. Related Works

- Now-a-days people who belong the world gradually facing a great problem i.e fast depletion of our natural resources due to mechanization and high demand of materials for construction. If it continues like this it will really become a great problem and it is affecting our environment to a great extent i.e. drastic climate change. Hence it is high time to go for alternate building materials especially for sand, stone aggregates, stone, brick etc. In the recent past the Spanish and Scottish researchers have added wool fibres to the clay material used to make bricks and combined these with an alginate, a natural polymer extracted from seaweed. The result is brick that are stronger and more environmentally-friendly, according to the study published recently in the journal Construction and [7] Building Materials. We all know wool is a natural fiber but which is much more expensive than jute fibre. In the recent research of Spanish and Scottish researchers there was no information of the bricks to be used with more technological index. Previously we have got the idea of making [8] Green Building. There people tried to reduce the use of power to achieve environmental sustainability which is very much important for corporate social responsibility. One of the famous e-retailer Alibaba is an example for the buying and selling place of fibre made jute brick. Alibaba made us much more enthusiastic to know the marketing and selling knowledge [9] from itself. World Academy of Science, Engineering and Technology has made a research in the ground of natural fibre inclusion in clay bricks and the author was Mr. Chee-Ming Chan in 2011. This study examined the physical and mechanical properties of clay bricks made by adding two natural fibres to a clay-water mixture with baked and non-baked conditions. In 2013 there was a publication by Hindawi for the experimental behavior of natural fiber based composites used for strengthening masonry structures. That gives us the knowledge of how to strength a fibre to form [10] strong product. Recently in a reputed online news journal called “The Constructor’’ has published “ECO Friendly building materials” for the betterment of the future development of civil engineering. Here we have the knowledge of how we can differentiate the eco friendly materials, categorization, source of materials and also with the [11] environmental impact. Here we have also the knowledge of using bamboo which is a natural material. Using of bamboo encourages us to use Jute as a natural fibre to make our product. In our report we tried to make our product by jute fibre and which is a natural fibre also the brick which to be made has also a great technological index. These bricks can perform also as the alternative use of air condition in the building inner face. Our jute made brick will much more environmental friendly because it is made of one of the most [3] cost effective natural fibre and it also reducing the emission of CFC. Our intention is not only to make a product which has a great cost effectiveness and technological index but also to maintain the corporate social responsibility that defines the [6] environmental sustainability.

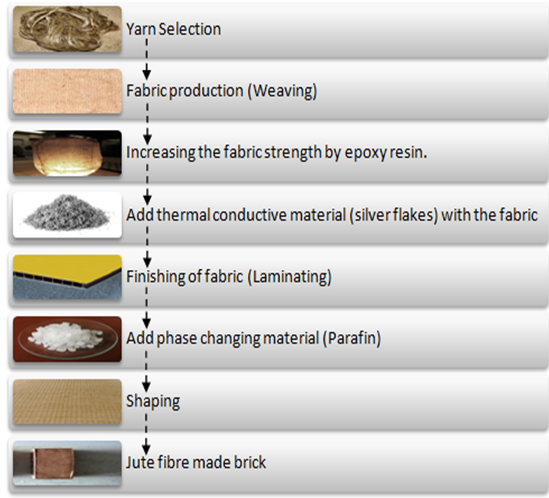

3. Product Development

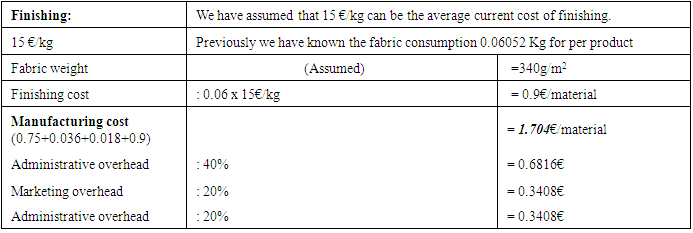

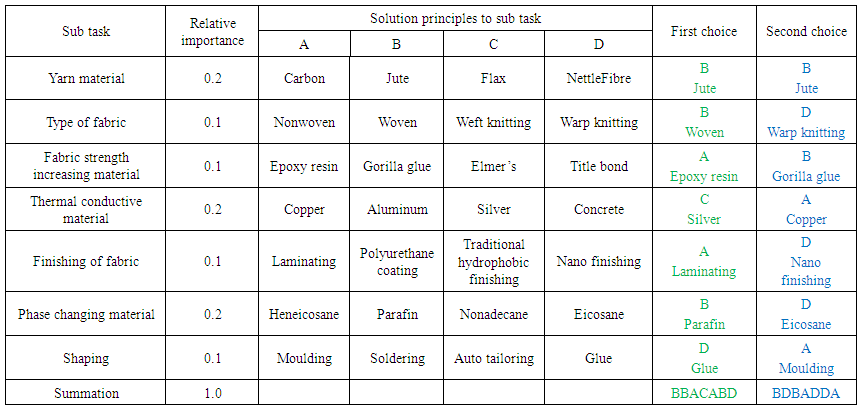

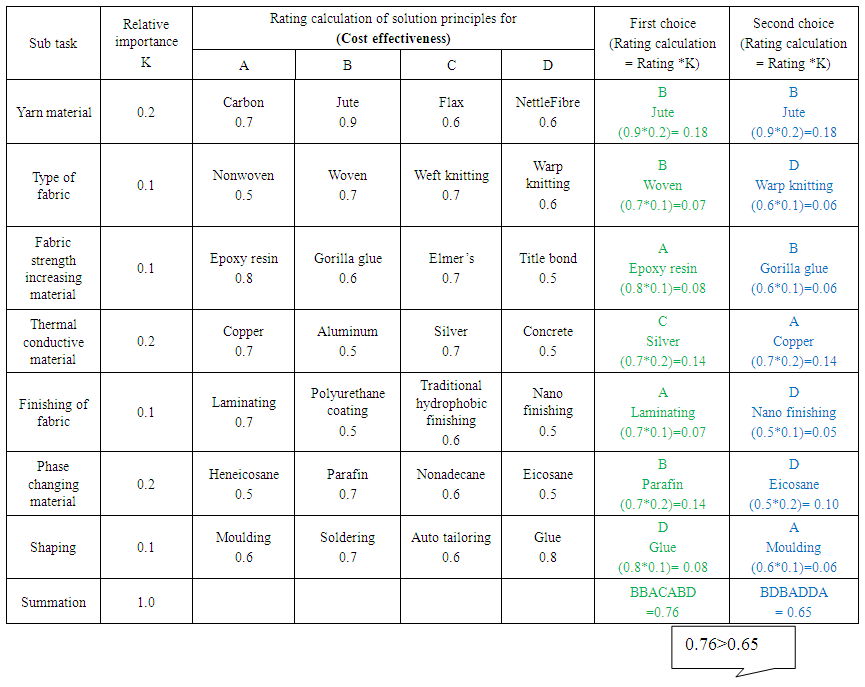

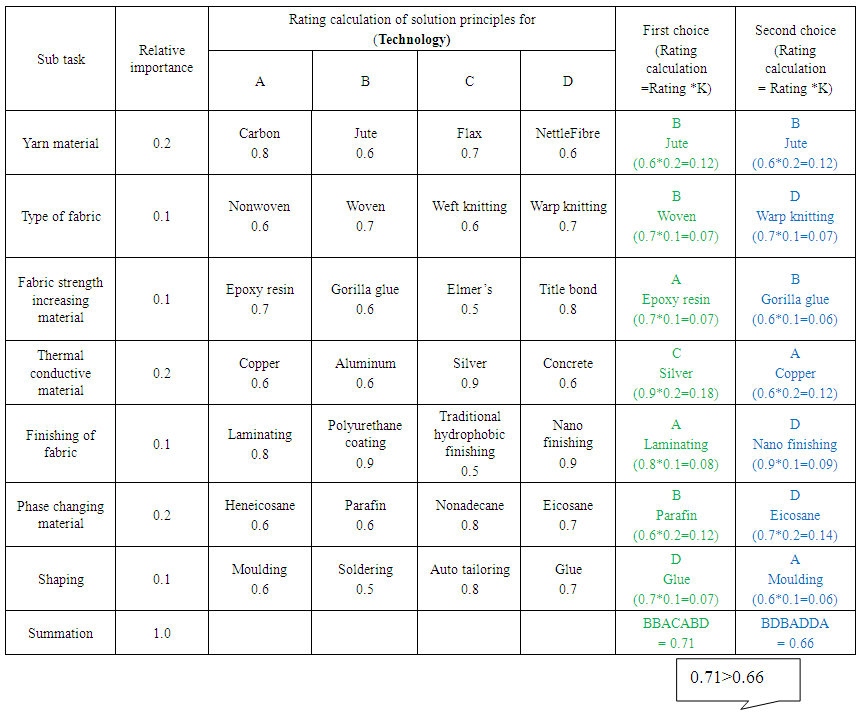

- At first we have to select the yarn which will be perfect for our product. For our product we have selected Jute fibre to produce the yarn. After having the yarn from Jute fibre we have to produce the fibre as a woven fabric from weaving procedure. Then we can use epoxy resin in the produced fabric and add the thermal conductive materials called silver flakes with the fabric. Then we will have the finishing of the fabric and laminate the fabric to add the phase changing material Parafin. At the last we have to shape the fabric to make our product and further marketing aspects.Here is the flow chart of our product development:

| Figure 1. Product development procedure before marketing |

| Figure 2. Idea rating of new product |

| Figure 3. Conceptual design of new product |

| Figure 4. Rating calculation of cost effectiveness |

| Figure 5. Rating calculation of technology |

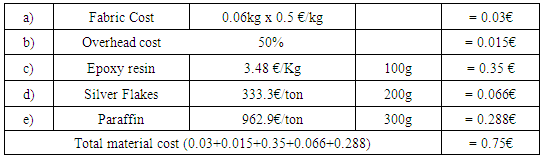

4. Cost Calculation

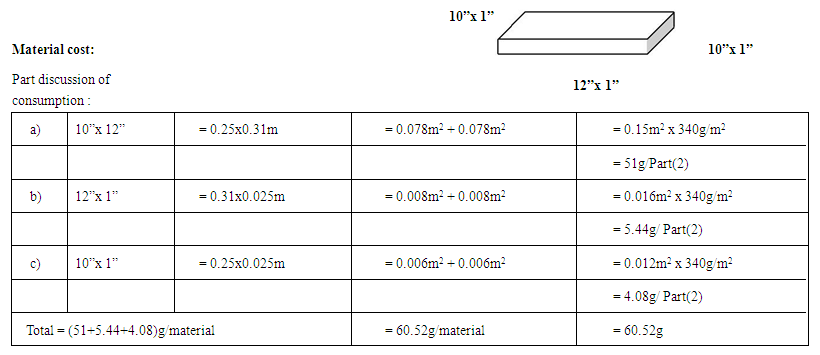

- The length of the brick is 10”x 1” and the width of the brick is 12”x 1”.

| Table 1. Consumption of the total fabric used to develop our product |

|

|

|

= 700/324 euro= 2.16049383 euro.Brick: Calculation of the area of a brick = 12*10*1’’

= 700/324 euro= 2.16049383 euro.Brick: Calculation of the area of a brick = 12*10*1’’ = 120’’square (Ignoring the little height because of 1’’limit)

= 120’’square (Ignoring the little height because of 1’’limit) = 3.0480 square mtr (assuming)

= 3.0480 square mtr (assuming)  = 3.0480*10% + 3.0480 (Add 10% allowance to solve height limit)

= 3.0480*10% + 3.0480 (Add 10% allowance to solve height limit)  = 3.3528 euro. Area of 1 brick is = 3.0480 square mtr. So, As per our

= 3.3528 euro. Area of 1 brick is = 3.0480 square mtr. So, As per our  previous measurement, 3.3528 square mtr = 3.37392 euro

previous measurement, 3.3528 square mtr = 3.37392 euro  1 square mtr = 3.37392/3.3528 euro

1 square mtr = 3.37392/3.3528 euro = 1.00629 euro. (which is less than 2.16049383 euro)So, here is a clear over view that our product is near about 2 times cost effective than air condition.Existing market of our product:We are focusing for the expanded and the rising building construction in the global world. Our product is very new and the environmental friendly. Especially focusing for those countries where the temperature is very much high but economically and geographically they have some limitations to focus for the environmental impact of the earth. Our cheap materials and unique innovation will go ahead via promotional activities towards them. Western market will also acquire this technology to justify the new innovation against global warming and to achieve the environmental friendless. Those countries who are facing the problem of high and low temperature in a stake they are in need of this kind of permanent solution. Our product will also focus to reduce the consumption of power to build a green house [8].

= 1.00629 euro. (which is less than 2.16049383 euro)So, here is a clear over view that our product is near about 2 times cost effective than air condition.Existing market of our product:We are focusing for the expanded and the rising building construction in the global world. Our product is very new and the environmental friendly. Especially focusing for those countries where the temperature is very much high but economically and geographically they have some limitations to focus for the environmental impact of the earth. Our cheap materials and unique innovation will go ahead via promotional activities towards them. Western market will also acquire this technology to justify the new innovation against global warming and to achieve the environmental friendless. Those countries who are facing the problem of high and low temperature in a stake they are in need of this kind of permanent solution. Our product will also focus to reduce the consumption of power to build a green house [8].5. Conclusions

- We all know that, the world is in a great threat for the global warming condition. We need to step forward for producing environmental friendly product. Actually we have selected the jute yarn because it is famous as a cost-effective natural fibre. We also focused for the environmental impact of our product. We used the natural weaving process as a concern of cost effectiveness of our product. To increase the strength we have used the epoxy resin because we are not only focusing the environmental impact but also the physical strength of our product as a brick. Silver flakes as a thermal conductive material we can have the performance of thermal productivity. For finishing we have used laminating process because it has both cost effectiveness and technological index. We also used paraffin as a phase changing material for the better insulation system. Shaping of the product as like as brick is also an important for us. At last we can have our product and via intellectual knowledge and with the promotional activity we can launch a very good product which have also an excellent eco-friendly impact. Environmental friendliness is also a special identification of our product. We hope our product will be the most innovative product in the upcoming market and hope that we launch it very soon. Our earth is getting more and more warm day by day only for us. We should try from our own position to reduce the global warming condition of the world. As a matter fact our product which is made of a natural fiber called jute with only some additional chemicals it can be a green product. We all know about the emission of CFC gases from the air condition and it is the burning question in our society. We tried our level best to make an initiative to reduce the electricity consumption and also the usage of air condition by producing a particular product which will be identified as a green product in the world.

ACKNOWLEDGEMENTS

- The authors would like to thank Kazi Masudul Alam, University of Ottawa for his excellent efforts to organize the content of this paper. It was quiet impossible for us to shape this paper without the appropriate direction of him. I am really grateful towards him for the kind direction he has provided we would also like to thank the anonymous reviewers for their comments in improving the quality of the paper.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML