-

Paper Information

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

American Journal of Materials Science

p-ISSN: 2162-9382 e-ISSN: 2162-8424

2014; 4(3): 150-158

doi:10.5923/j.materials.20140403.06

Crystallographic Texture Formation in Metals being Electrodeposited at the External Force Influence

Oleg B. Girin

Department of Materials Science, Ukrainian State University of Chemical Technology, Dnipropetrovsk 49005, Ukraine

Correspondence to: Oleg B. Girin, Department of Materials Science, Ukrainian State University of Chemical Technology, Dnipropetrovsk 49005, Ukraine.

| Email: |  |

Copyright © 2014 Scientific & Academic Publishing. All Rights Reserved.

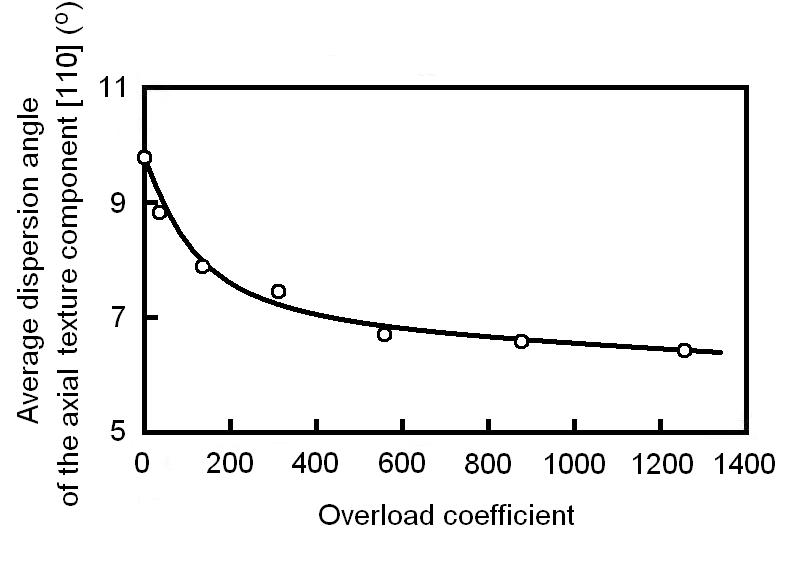

The aim of the work was the experimental verification of the validity of the phenomenon of phase formation through a stage of liquid state in metals being electrodeposited. For that the features of formation of crystallographic texture in metals being electrodeposited under the influence of external (centrifugal) force in the directions opposite and along the texture axis were investigated. As a result the effect of suppression of the process of texture formation in metals being electrodeposited up to the complete disordering of crystal lattices of grains under the influence of external force in the direction opposite to the texture axis was discovered. The effect of intensification of the texture formation process in metals being electrodeposited at the influence of external force directed along the texture axis was also found. The comparative analysis of the degree of texture perfection of electrodeposited metals obtained at different directions of the force action during their phase formation was accomplished. It was found that regardless to the direction of the force influence the most significant change of the degree of texture perfection occurs in metals being electrodeposited at relatively low overloads. It was discovered that the action of external force in the direction opposite to the texture axis results in the more significant influence on the texture formation process in metals being electrodeposited in comparison with the force action along the texture axis. The obtained results prove the validity of the phenomenon of phase formation through a stage of liquid state in metals being electrodeposited

Keywords: Crystallographic Texture, Metal being Electrodeposited, Centrifugal Force, External Force Influence

Cite this paper: Oleg B. Girin, Crystallographic Texture Formation in Metals being Electrodeposited at the External Force Influence, American Journal of Materials Science, Vol. 4 No. 3, 2014, pp. 150-158. doi: 10.5923/j.materials.20140403.06.

Article Outline

1. Introduction

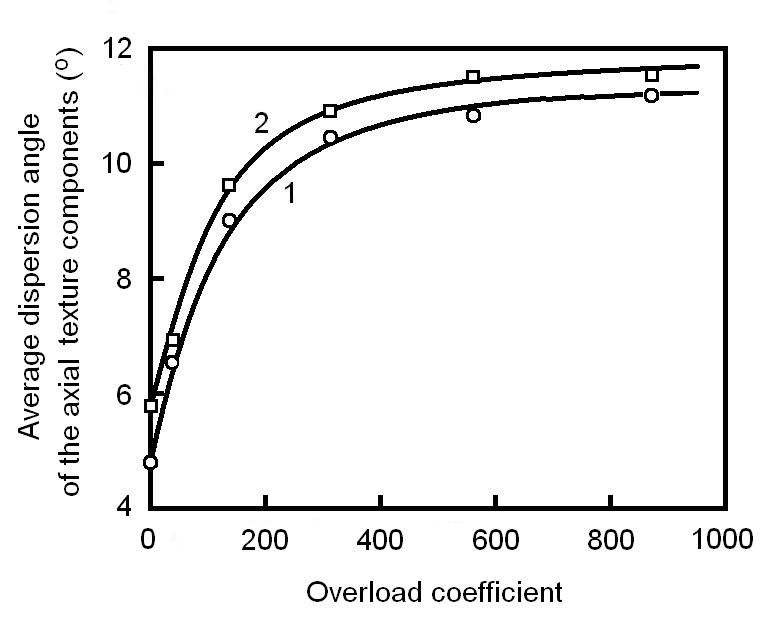

- The phenomenon of phase formation through a stage of liquid state in metals being electrodeposited was experimentally found in 1988 [1]. The essence of the discovered phenomenon is that during the electrochemical deposition of a metal onto a solid cathode in an aqueous medium a undercooled metallic liquid is being formed and superfast solidified at the deposition temperature in the form of a crystalline or/and an amorphous phase.Large volume of experimental materials proving the validity of the phenomenon of phase formation through a stage of liquid state in metals being electrodeposited has been obtained so far [2–8]. Nevertheless, the obtaining of additional data proving or contradicting the validity of this phenomenon was of interest. Therefore, the aim of this work was the further experimental verification of the validity of the discovered phenomenon.General idea for the arrangement of new experiments was based on the fact that the degree of perfection of crystallographic texture appearing in metals being solidified from liquid state at the action of the external force significantly depends on the direction of the force action. A change of the degree of perfection of texture in metals being electrodeposited with the change of the direction of minor force action (in comparison with the value of plastic deformation creating texture in solids) will be a proof of the validity of the discussed phenomenon.

2. Experimental Proof of Validity of the Phenomenon

2.1. Idea One and Its Realization

- It is known that texture formation of metal during its solidification occurs by oriented crystallization in the direction perpendicular to the crystallization front [9]. On the other hand, it is known that crystallographic texture of electrodeposited metal is the axial texture of growth with the axis perpendicular to the surface of a deposit [10]. Assuming that crystallographic texture of metal being electrodeposited is formed as a result of oriented crystallization of continuously renewed metallic liquid, the action of centrifugal force directed perpendicular to the crystallization front and opposite to the texture axis will obstruct the formation of texture. As a result of such action of centrifugal force the metal with more dispersed texture will crystallize and the further increase of the value of centrifugal force can even cause random grain orientation of metal being electrodeposited. In this regard the suppression of the texture formation process in metals being electrodeposited at the action of centrifugal force in the direction opposite to the texture axis will be a proof of the validity of the discussed phenomenon.

2.1.1. Materials and Methods

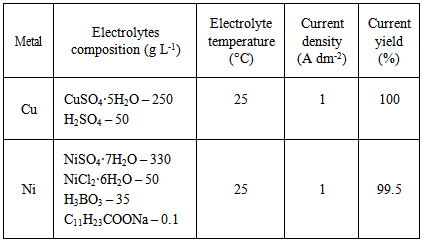

- The investigations of features of oriented structure formation in metals being electrodeposited in the field of centrifugal force were performed on copper and nickel samples using the unit described in the work [11]. The unit provided the influence of centrifugal force proportional to normal acceleration kg, where k is overload coefficient, on the process of electrocrystallization of metals. The values of centrifugal force were varied stepwise by the change of the centrifuge rotor speed from 0 to 3000 rotations per minute with the step of 500 rotations per minute, which provided normal acceleration 1g, 35g, 140g, 314g, 558g, 872g and 1256g. The cathode was mounted at the bottom of the cell perpendicular to its axis, therefore the cathode was perpendicular to the rotor radius during cell rotation. As during rotation centrifugal force is directed along the rotor radius from the circle center and the axis of deposit texture is oriented along the normal to its surface in the direction of growth from cathode toward external layers, that at such cathode arrangement the force influence on metal being electrodeposited was provided in the direction opposite to the texture axis. The composition of copper- and nickel-plating electrolytes as well as parameters and conditions of metals deposition in the field of centrifugal force are presented in the Table 1. As a result of metals current yield being 99.5-100 % and impossibility of electrolyte motion relative to the cathode in the cell during electrodeposition process [11] the influence of hydrogen evolvement and electrolyte motion on texture of samples being deposited was completely eliminated.

|

2.1.2. Results and Discussion

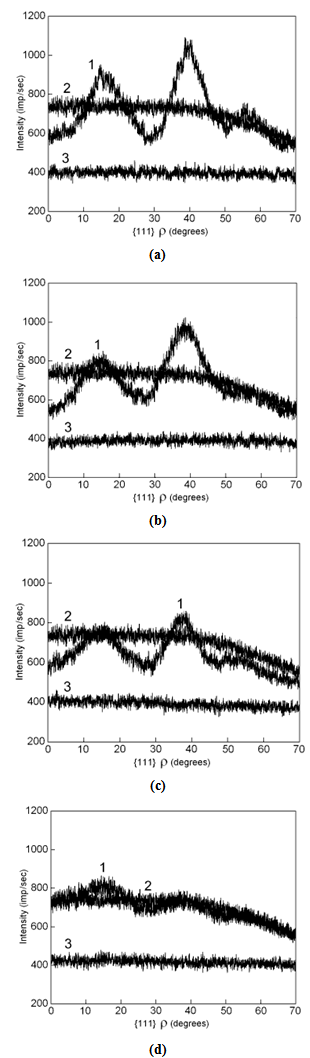

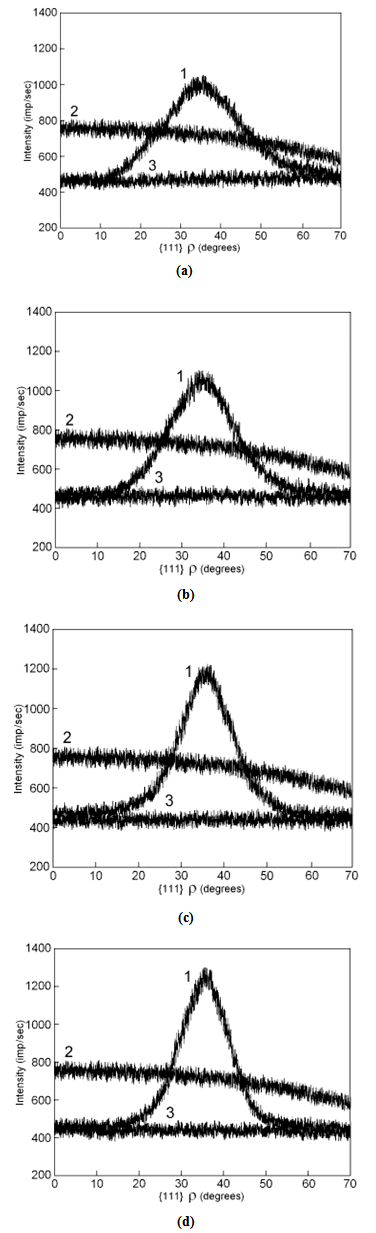

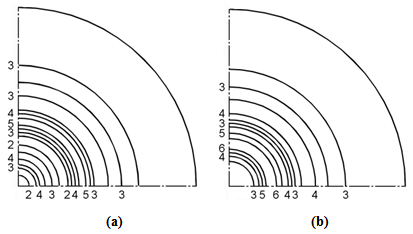

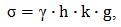

- As a result of completed investigations it was found that the texture of nickel electrodeposited at 1g can be described by the following components: the main axial component [210], the subsidiary axial component [221] and random component. At that the axes [210] and [221] of the axial texture components of nickel are oriented perpendicular to the surface of electrodeposits in the direction of growth from the cathode to the external layers. In fact, the presence of the textural maximum of the axial orientation with the axis [210] at 39.2° angle and the textural maximums of the axial orientation with the axis [221] at 15.8 and 54.7° angles on the (111) pole figure of electrodeposited nickel (Fig. 1a) allows making such conclusion. And the presence of the textural maximum of the axial orientation with the axis [210] at 26.6° angle and the textural maximum of the axial orientation with the axis [221] at 48.2 angle on the (100) pole figure (Fig. 1b) confirms this fact.

| Figure 1. Pole figures (111) (a) and (100) (b) of nickel, electrodeposited at 1g (initial condition). 2-6 – levels of equal intensity of diffraction X-rays |

| (1) |

2.2. Idea Two and Its Realization

- It is known, that texture formation during crystallization of metal occurs in the direction of the external force influencing the metal [9]. At that the degree of perfection of texture of metal being solidified increases with the growth of values of the external force. Therefore, if metal being electrodeposited really passes through a stage of liquid state, then at the influence of centrifugal force on metallic liquid being solidified perpendicular to the crystallization front and along the texture axis the processes of formation and development of texture will intensify. As a result of such action of centrifugal force phase formation of metal being electrodeposited will be accompanied by its intense texture formation. Formation of more perfect texture in metals being electrodeposited in the field of centrifugal force acting along the texture axis will be the fact proving the validity of the discussed phenomenon.

2.2.1. Materials and Methods

- Features of texture formation in metals being electrodeposited in the field of centrifugal force acting along the texture axis were investigated on copper and nickel samples. Electrodeposition of metals at the force action conditions was performed using the equipment described in the work [11]. The anode was built into the bottom of the cell and the cathode was mounted at the upper side of the cell perpendicular to its axis at the distance of 4·10ˉ2 m from the anode. Therefore, during rotation of the cell the electrodes were placed perpendicular to the rotor radius. As centrifugal force during rotation is directed along the rotor radius from the center of the circle and the texture axis of the deposit is oriented along the normal to its surface in the direction of growth from the cathode to the external layers, than at such position of the cathode the force action on metal being electrodeposited along the texture axis was provided.Obtaining metal deposits under the influence of centrifugal force opposite to the texture axis was performed at the force action values proportional to the normal acceleration of 1g, 35g, 140g, 314g, 558g, 872g and 1256g (see part 2.1). In order to the value of centrifugal force acting on the deposits being formed at the change of the electrodes position in the electrochemical cell to be constant, the centrifuge rotor speed was increased to 606, 1213, 1819, 2425, 3032 and 3638 rotations per minute respectively. The copper- and nickel-plating electrolytes compositions as well as method and parameters of X-ray texture analysis were as previous ones.

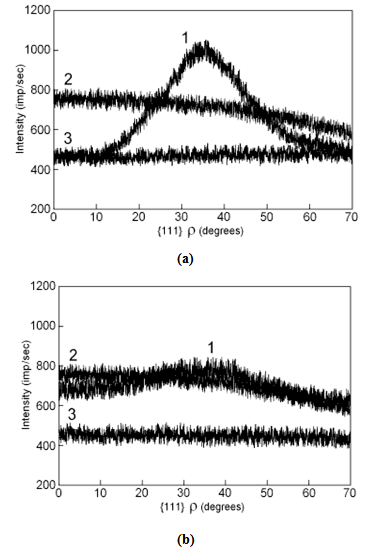

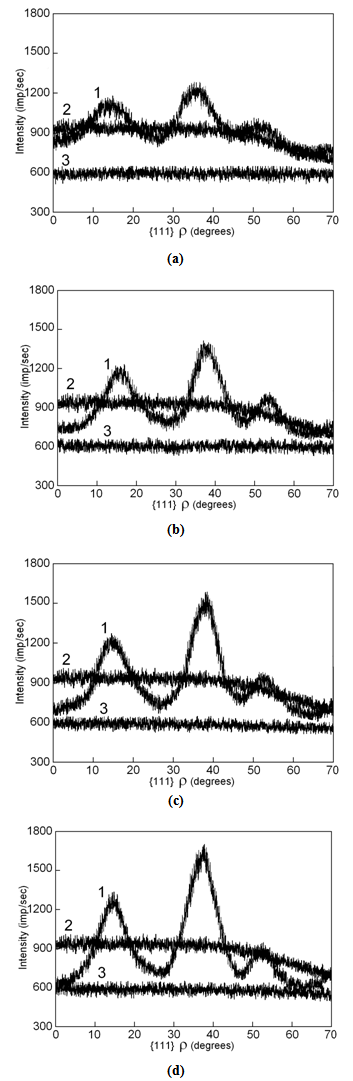

2.2.2. Results and Discussion

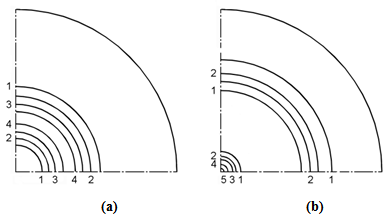

- As a result of the completed investigations it was found that texture of copper deposits electrodeposited at the normal conditions (i.e. at 1g) is characterized by the axial component [110]. At that the [110] axis of the axial texture component of copper deposits is oriented perpendicular to their surface in the direction of growth from the cathode to the external layers. In fact, the presence of the texture maximum of the axial orientation with the [110] axis at the 35.3º angle on the (111) pole figure of electrodeposited copper (Fig. 5a) allowed making this conclusion. And the presence of the texture maximums of the axial orientation with the [110] axis at the 0 and 60° angles on the (110) pole figure (Fig. 5b) confirmed it.

| Figure 5. Pole figures (111) (а) and (110) (b) of copper electrodeposited at 1g (initial condition). 1-5 – levels of equal intensities of diffraction X-rays |

3. Conclusions

- The investigations of the features of formation of crystallographic texture in metals being electrodeposited under the influence of external (centrifugal) force in the directions opposite and along the texture axis were completed. The effect of suppression of the process of texture formation in metals being electrodeposited up to complete disordering of crystal lattices of grains under the influence of external force in the direction opposite to the texture axis was discovered. The effect of intensification of the texture formation process in metals being electrodeposited at the influence of external force directed along the texture axis was also found. The comparative analysis of the degree of texture perfection of electrodeposited metals obtained at different directions of the force action during their phase formation was performed. It was found that regardless to the direction of the force influence the most significant change of the degree of texture perfection in metals being electrodeposited occurs at relatively low overloads. It was discovered that the action of external force in the direction opposite to the texture axis results in the more significant influence on the texture formation process in metals being electrodeposited in comparison with the force action along the texture axis. The obtained results prove the validity of the phenomenon of phase formation through a stage of liquid state in metals being electrodeposited.

ACKNOWLEDGEMENTS

- The author gratefully acknowledge the support of the Ministry for Education and Science of Ukraine (No. 0111U000110).

References

| [1] | Girin, O. B., and Vorob’ev, G. M., 1988, Change of diffraction of X-rays dissipated by metals during their electrolytic deposition., Journal of Physical Chemistry, 62(5), 1347–1349 (In Russian). |

| [2] | Girin, O. B., 1995, Substructure formation and texture in electrodeposits., Journal of Electronic Materials, 24(8), 947–953. |

| [3] | Girin, O. B., 2000, Phenomenon of precipitation of metal being electrodeposited, occurring via formation of an undercooled liquid metal phase and its subsequent solidification. Part 1. Experimental detection and theoretical grounding., Materials Development and Processing, 8, 183–188. |

| [4] | Girin, O. B., 2000, Phenomenon of precipitation of metal being electrodeposited, occurring via formation of an undercooled liquid metal phase and its subsequent solidification. Part 2. Experimental verification., Materials Development and Processing, 8, 189–194. |

| [5] | Girin, O. B., 2004, Phenomenon of structure formation of metals being electrodeposited via a super-cooled metal liquid, and its use for the development of advanced technologies of depositing new types of protective composite coats on canned food steel sheet, Proc. of the 5th Int. Sci. Forum AFES. Paris, France: Int. Acad. of Engn, 142-147. |

| [6] | Girin, O. B., 2007, Phase transformations in the metallic materials being electrodeposited and their application for the development of advanced technologies for anticorrosive protection of canned-food steel sheet., Materials Science Forum, 561-565, 2369–2372. |

| [7] | Girin, O. B., 2010, Phase and structure formation of metallic materials electrodeposited via a liquid state stage: new experimental proof., Defect and Diffusion Forum, 303-304, 99–105. |

| [8] | Girin, O. B., 2012, Phase formation through a stage of liquid state in metallic materials being electrodeposited: recent experimental proofs., International Journal of Material Science, 2(4), 108–118. |

| [9] | G. Wassermann und J. Grewen, Texturen Metallischer Werkstoffe, 2 auf. Berlin, Germany: Springer-Verlag, 1962. |

| [10] | S. M. Kochergin and A. V. Leontiev, Formation of the Textures During Electrocrystallization of Metals. Moscow, USSR: Metallurgiya, 1974 (In Russian). |

| [11] | Girin, O. B., and Zakharov, I. D., 2011, Increase of density of metals being electrodeposited under the influence of a centrifugal force., Eastern-European Journal of Enterprise Technologies, 5, 4–7 (In Russian). |

| [12] | O. B. Girin, and G. M. Vorob’ev, “A method for X-ray diffractometry analysis of textured materials,” The Patent of Russia 1 629 828, Feb. 23, 1991 (In Russian). |

| [13] | O. B. Girin, “Nonconventional X-ray Diffraction Techniques for Coating Characterization,” in Solidification’98, 1998, The Minerals, Metals & Materials Society, p. 161-169. |

| [14] | Girin, O. B., 1990, Texture and anisotropy of substructure in electrodeposited nickel., Izvestiya AN SSSR, Metally, 5, 113–119 (In Russian). |

| [15] | Ia. D. Vishniakov, A. A. Babareko, S. A. Vladimirov and I. V. Egiz, The Theory of Formation of Textures in Metals and Alloy Materials. Moscow, USSR: Nauka, 1979 (In Russian). |

| [16] | V. S. Zolotorevskii, Mechanical Properties of Metals, 2nd ed. Moscow, USSR: Metallurgiya, 1983 (In Russian). |

| [17] | M. Bauccio, Ed., ASM Metals Reference Book, 3rd ed. Materials Park, USA: ASM International, 1997. |

| [18] | A. Ohno, Solidification of the Metals. Moscow, USSR: Metallurgiya, 1980 (In Russian). |

| [19] | O. B. Girin, Yu. O. Proshenko, and E. P. Kalinushkin, 2000, Texture of electrodeposited copper coatings as related to their substructure, granular structure and surface morphology., Textures and Microstructures, 34(2-3), 171–179. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML