-

Paper Information

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

American Journal of Materials Science

p-ISSN: 2162-9382 e-ISSN: 2162-8424

2013; 3(2): 36-40

doi:10.5923/j.materials.20130302.03

Substructure of Polysynthetic Crystals of Zinc Sulfide Mono-Domained by Oriented Deformation

U. K. Ernazarov1, Zh. Zhanabergenov2

1Karakalpak State University, Berdahstr 1, 742015 Nukus, Uzbekistan

2Karakalpak State Pedagogik Institute, Nukus, Karakalpakstan, Uzbekistan

Correspondence to: U. K. Ernazarov, Karakalpak State University, Berdahstr 1, 742015 Nukus, Uzbekistan.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

This work presents a study of polysynthetic crystals of zinc sulfide (ZnS) consisting of thin domains of sphalerite-type of single oriented substructure by X-ray diffraction (XRD) and electron microscopy. XRD studies have shown that upon plastic deformation in a certain direction thickness of domains of one direction increases in the main part of polysynthetic crystal ZnS. Based on the XRD and electron microscopy studies we found that the mono-domain substructure of the polysynthetic ZnS crystals consists of dangling oblique cross-domain boundary of the original crystals generated by inhibited dislocations in the crystal. We identify the sequential processes of formation of the substructure, which are accumulations of the inhibited dislocations in certain regions of the deformed crystals, of the slip partial dislocations stretched in the direction perpendicular to the slip plane of the dislocation complexes dividing the crystal into fan-shaped disoriented sub-blocs, which in macroscopic scale imitate “S”-shaped bending of the shear plane.

Keywords: PolysyntheticZns Crystals, Dislocations, Polysynthetic Zns Crystals

Cite this paper: U. K. Ernazarov, Zh. Zhanabergenov, Substructure of Polysynthetic Crystals of Zinc Sulfide Mono-Domained by Oriented Deformation, American Journal of Materials Science, Vol. 3 No. 2, 2013, pp. 36-40. doi: 10.5923/j.materials.20130302.03.

Article Outline

1. Introduction

- Crystals of zinc sulfide (ZnS) grown from the melt at a temperature below 1000C have polysynthetic structure consisting of thin domains with sphalerite structure of two orientations. As a result of the oriented plastic deformation they turn into monodomain crystal of sphalerite with a specific substructure[1], which is single-oriented. In Refs[2, 3] substructure of the mono-domain crystals has been presented as a "fan-like" set of crystalline sub grains creating “S”-shaped bend of the slip plane around the direction

. Nanometer size of the elements forming the substructure and low resolution of the methods used in these studies did not allow to establish structure of the original and deformed polysynthetic crystals. For these reasons the origin of formation of such substructure of the mono-oriented crystal has remained unclear. Later, it has been established experimentally[4] structure of the crystal not subjected to oriented plastic deformation. It consists of micro twin domains of sphalerite with average thickness of 30−40 Å passing through the whole crystal and forming a coherent plane-parallel boundaries.Also it contains a number of randomly distributed domains with limited size along the slip directions

. Nanometer size of the elements forming the substructure and low resolution of the methods used in these studies did not allow to establish structure of the original and deformed polysynthetic crystals. For these reasons the origin of formation of such substructure of the mono-oriented crystal has remained unclear. Later, it has been established experimentally[4] structure of the crystal not subjected to oriented plastic deformation. It consists of micro twin domains of sphalerite with average thickness of 30−40 Å passing through the whole crystal and forming a coherent plane-parallel boundaries.Also it contains a number of randomly distributed domains with limited size along the slip directions . It is well-known that the limited size of these domains is consequence of incomplete shifts of the crystallographic planes that are spread out from different centers during the martensitic type phase transitions[5, 6]. This type of cross-domain boundaries are called as inclined boundary that are broken inside the crystal. Partial dislocations are located along perimeter of such domains that are inhibited by various obstacles.Also, they create obstacles to the dislocationsgliding along the plane of stacking faults. Formation of substructures arising as a result of interaction of the partial dislocations with those inhibited at the inclined boundaries gliding under the action of applied mechanical stress has been studied theoretically in Refs.[7-9]. Properties of substructure of the initial polysynthetic crystals not subjected to plastic deformation has been studied experimentally[4] and theoretically[7-9]. These studies have led us to the idea of this work about investigation of deformed crystals of ZnS by XRD and electron microscope to establish the origin of formation of substructure of the mono-oriented crystal.

. It is well-known that the limited size of these domains is consequence of incomplete shifts of the crystallographic planes that are spread out from different centers during the martensitic type phase transitions[5, 6]. This type of cross-domain boundaries are called as inclined boundary that are broken inside the crystal. Partial dislocations are located along perimeter of such domains that are inhibited by various obstacles.Also, they create obstacles to the dislocationsgliding along the plane of stacking faults. Formation of substructures arising as a result of interaction of the partial dislocations with those inhibited at the inclined boundaries gliding under the action of applied mechanical stress has been studied theoretically in Refs.[7-9]. Properties of substructure of the initial polysynthetic crystals not subjected to plastic deformation has been studied experimentally[4] and theoretically[7-9]. These studies have led us to the idea of this work about investigation of deformed crystals of ZnS by XRD and electron microscope to establish the origin of formation of substructure of the mono-oriented crystal.2. Experimental Methods

- ZnS crystals have been grown from the melt by the Bridgman method in the argon atmosphere under the pressure of 150 atm. Samples of size 222 mm3 have been cut in such a way that the gliding planes, whichare active under deformation,are located under the angle 45 with respect to uniaxial pressure. Upon oriented pressing, gliding of the complete and partial dislocations in the crystal can take place only in one of the planes (111) selected by twinning. Method of deformation of crystals had been described in detail in Ref.[1]. Construction of cross sections of the points of the reciprocal lattice is done by scanning the reciprocal space of the crystal with a DRON-UM1. Primary beam has been formed by Si (111) monochromator and point collimator with output gap size of 0.05 mm.Distribution of intensity along 004 and

orientations of domains has been registered by scintillation detector with a gap of 0.1 mm width in the θ-2θ scanning mode with step Δ2θ = 0.02°. Before each of the angular intervals, crystal orientation with respect to the primary beam along the horizontal plane of the X-ray goniometer has been changed to Δθ = 0.1°. From these data obtained for the distribution of the scattering intensity two-dimensional sections reciprocal lattices have been built. In these sections scales along the coordinate axes have been selected as a fraction of the length of the reciprocal lattice vector g111. Images of thin sections of the crystal have been obtained by the electron microscope UEMV-100K. The advantage of this mode is that the resulting diffraction pattern clearly shows the area of the crystal, which directly contributes to the diffracted beam. Thin samples used in these studies were obtained by ultramicrotoming along the cleavage planes (110). In these studies diffraction peaks of sphalerite have been used, for which the requirement h + k + l = 3n ± 1 is fulfilled. Reciprocal lattice with such Miller indices are spatially separated, which allows obtaining the averaged sub structural characteristics of individual orientations of domains. Usage of the XRD method for constructingthe sections of the reciprocal lattice together with the diffraction pattern from the electron microscope provides an unambiguous determination of the real structure of crystals with nanoscale inhomogeneities.

orientations of domains has been registered by scintillation detector with a gap of 0.1 mm width in the θ-2θ scanning mode with step Δ2θ = 0.02°. Before each of the angular intervals, crystal orientation with respect to the primary beam along the horizontal plane of the X-ray goniometer has been changed to Δθ = 0.1°. From these data obtained for the distribution of the scattering intensity two-dimensional sections reciprocal lattices have been built. In these sections scales along the coordinate axes have been selected as a fraction of the length of the reciprocal lattice vector g111. Images of thin sections of the crystal have been obtained by the electron microscope UEMV-100K. The advantage of this mode is that the resulting diffraction pattern clearly shows the area of the crystal, which directly contributes to the diffracted beam. Thin samples used in these studies were obtained by ultramicrotoming along the cleavage planes (110). In these studies diffraction peaks of sphalerite have been used, for which the requirement h + k + l = 3n ± 1 is fulfilled. Reciprocal lattice with such Miller indices are spatially separated, which allows obtaining the averaged sub structural characteristics of individual orientations of domains. Usage of the XRD method for constructingthe sections of the reciprocal lattice together with the diffraction pattern from the electron microscope provides an unambiguous determination of the real structure of crystals with nanoscale inhomogeneities.3. Results

3.1. X-ray diffractometry

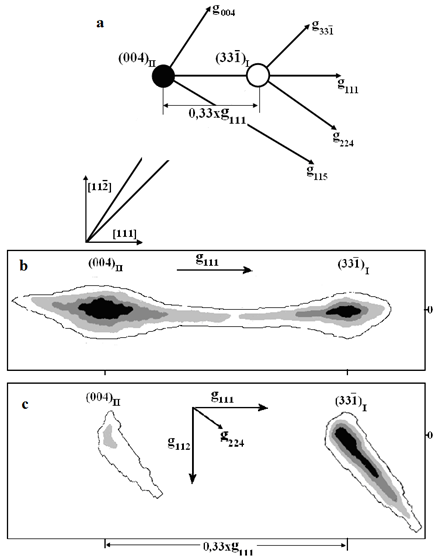

- Fig. 1a shows a fragment of the reciprocal space of the polysynthetic crystal and the directions of some reciprocal lattice vectors of domains of one orientation needed to describe the experimental conditions and diffraction characteristics of the experimentally established distribution of scattering intensity. One of the characteristic features of the diffractive cross section of the reciprocal lattice of the non-deformed and deformed up to ε ≈ 8 %samples[Figs. 1, b and c] is presence of the bands of large intensity.On the section of the reciprocal lattice of the original crystal the bands are extended along the direction of the g111 and are connected with each other thus confirming the conclusion of Ref.[4] about average thickness of the domains of sphalerite. The intensity ratio of nodes 004 and

defined by summing of symmetric parts of the cross sections taking into account the structural factors of the planes (F2331/F2400=1/3) was approximately equal to 1:3. This result indicates that thin domains of each orientation of the original polysynthetic ZnS occupy the volumes, which are approximately equal to each other. On sections of nodes 004 and

defined by summing of symmetric parts of the cross sections taking into account the structural factors of the planes (F2331/F2400=1/3) was approximately equal to 1:3. This result indicates that thin domains of each orientation of the original polysynthetic ZnS occupy the volumes, which are approximately equal to each other. On sections of nodes 004 and  deformed up to ε ≈ 8÷12%, directions of the "strands" are perpendicular to the corresponding diffraction vectors and are located between the directions

deformed up to ε ≈ 8÷12%, directions of the "strands" are perpendicular to the corresponding diffraction vectors and are located between the directions  and

and . Then the ratio of the intensity of nodes 004 and

. Then the ratio of the intensity of nodes 004 and  was found to be approximately 1:7, which confirms the increase in the net volume of domains of one orientation due to fibrewise reorientation of the layers of the domains of the other orientations. The symmetry of the lengths of the "strands" of nodes 004 and

was found to be approximately 1:7, which confirms the increase in the net volume of domains of one orientation due to fibrewise reorientation of the layers of the domains of the other orientations. The symmetry of the lengths of the "strands" of nodes 004 and  along the directions

along the directions  and

and  shows that in some parts of the crystal, crystallographically disoriented subunits and net change of directions of the respective reciprocal lattice vectors have been formed that reach 5-7 angular degrees. Then the main part of the intensity of the diffracted rays is localized in the head sections of the reciprocal lattice. The features described in the distribution of the scattering intensity of the reciprocal-lattice shows that the origin of the boundaries of blocks (sub-blocks) is related to dislocations and that the net volume occupied by them is not significant.Consequently, formation of new systems of dislocation structures begins at these levels of plastic deformation and goes along with the reorientation of domains.

shows that in some parts of the crystal, crystallographically disoriented subunits and net change of directions of the respective reciprocal lattice vectors have been formed that reach 5-7 angular degrees. Then the main part of the intensity of the diffracted rays is localized in the head sections of the reciprocal lattice. The features described in the distribution of the scattering intensity of the reciprocal-lattice shows that the origin of the boundaries of blocks (sub-blocks) is related to dislocations and that the net volume occupied by them is not significant.Consequently, formation of new systems of dislocation structures begins at these levels of plastic deformation and goes along with the reorientation of domains. 3.2. Electron Microscope

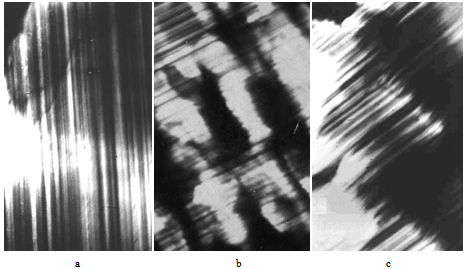

- Original polysynthetic crystals of ZnS show the diffraction pattern with parallel to each other maxima along the direction[111] in the elongated reciprocal lattice. On some electron diffraction patterns weak stretched maxima are observed with rods of a length of g111/3 and sharp boundaries along the nodal line[111] at the distance (ghhh±g111/2) from the main peaks of the structures. Estimations showed that these points correspond to the to the interplanar distance of 6.25 Å of the reciprocal lattice. They correspond to hexagonal packing of defects, and to thickness 9.37 Å of the finest domains, which is equal to three layers d111(d111=a/3, a = 5.4092 Å). Fig. 2a shows the diffraction pattern of the state of the crystal obtained with the use of the maximum

of the domains of one orientation. Despite blurring of the boundary of the image of the domain related to large increase of the diffraction image, it is possible to see the features discussed in Ref.[3]about extents of the domains and inter-domain boundaries. Analysis of the diffraction patterns of the samples deformed at ε ≈ 3÷5% show that the diffraction peaks of only those domains which are oriented in one direction preserve the elongated form, which is parallel to the direction[111]. Peaks at positions ghhh±g111/2 disappear and the sharp boundaries of the rods have been blurred. Thickness of the domains estimated from diffraction images of the state of the crystal reaches 80÷100 Å. Analysis of diffraction patters of some regions of the crystal shows that at plastic strains ε≈6÷12% direction of elongation of maxima of only one orientation of the domains will be changed in the direction

of the domains of one orientation. Despite blurring of the boundary of the image of the domain related to large increase of the diffraction image, it is possible to see the features discussed in Ref.[3]about extents of the domains and inter-domain boundaries. Analysis of the diffraction patterns of the samples deformed at ε ≈ 3÷5% show that the diffraction peaks of only those domains which are oriented in one direction preserve the elongated form, which is parallel to the direction[111]. Peaks at positions ghhh±g111/2 disappear and the sharp boundaries of the rods have been blurred. Thickness of the domains estimated from diffraction images of the state of the crystal reaches 80÷100 Å. Analysis of diffraction patters of some regions of the crystal shows that at plastic strains ε≈6÷12% direction of elongation of maxima of only one orientation of the domains will be changed in the direction . Figures 2b and c display diffraction patterns characteristic to this plasticdeformation. The regions extended in the direction perpendicular to the slip planes are seen in Fig. 2b withenhanced intensity and low contrast. More organized forms of the dislocation structure is seen in the diffraction pattern[Fig. 2c] formed at such level of plastic deformation. XRD spectra of the central part of crystal deformed at ε≈18-20% has a maximum corresponding to only one orientation of the domains stretched parallel to the axis of oscillation[112].

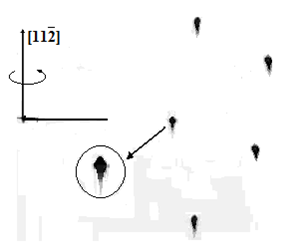

. Figures 2b and c display diffraction patterns characteristic to this plasticdeformation. The regions extended in the direction perpendicular to the slip planes are seen in Fig. 2b withenhanced intensity and low contrast. More organized forms of the dislocation structure is seen in the diffraction pattern[Fig. 2c] formed at such level of plastic deformation. XRD spectra of the central part of crystal deformed at ε≈18-20% has a maximum corresponding to only one orientation of the domains stretched parallel to the axis of oscillation[112].  | Figure 2. Diffraction patterns of the (a) initial and (b,c) deformed samples of ZnS up to 8÷12% |

4. Discussion of the Results

- According to Ref.[3], the lamellar reorientation of the domains of the sphaleriteZnS, which are unstable to uniaxial strain, takes place due to the movement of partial dislocations with the lattice parameters a||

, b=

, b= and the slip plane (111). Twinning dislocations are generated at the boundary between the twins.During the movement the plane of twinning shiftsinto one interplanar spacing d111 in the direction[111].The observed increase of the thickness of the domains of one orientation as a function of the plastic deformation indicates to correlated motion of partial dislocations. Assuming that they pass only once through every plane of stacking faults and that both orientations of the domains have approximately the same average thicknesses we find that consistent shift of about half of the (111) planes is required for formation ofa single domain. Consequently, magnitude of the plastic deformation required for obtaining the mono-oriented state of sphalerite equals to ε≈18 ÷ 22%, which is in good agreement with theoretical estimations of Refs.[1-3]. The above described mechanism of transformation of polysynthetic structure into single oriented one is achieved only if the domains form a flat-parallel-sphalerite coherent boundary. The results of this paper show that the declined cross-domain boundaries formed by a small group of hindered dislocations strongly influence on the processes of plastic deformation at small thicknesses of the domains. Consequently, upon constructing the real sequence of the processes of formation of the substructures, it is necessary to take into account the collective effect of the interaction of the group of inhibited dislocations with gliding partial dislocations occurring by de-twinning up to complete re-orientation through the volume of the deformed crystal.As is known, the reason of inhibition of gliding dislocations during the martensitic type phase transition might be different [5, 6]. In the initial polysynthetic crystals ZnS the inhibited dislocations are distributed at the locations where front planes of the growth of sphalerite phases face each other. This dislocation restricts the shear plane from one side and forms the stable and unstable slopes of the boundaries broken inside the crystal. The results of the diffraction studies show that the significant portion of the sloping boundaries lost stability at small plastic deformations (ε≈3÷5 %) and together with de-twinning partial dislocations take part in the processes of plastic deformation of micro twins. On the contrary, the declined borders, which are stable at such plastic deformations, resist to the motion of the de-twinned dislocations with elastic fields. At the locations of the inclined boundaries dislocation precipitations will be formed that divides the crystal into non-reoriented subunits. On the diffraction patterns this region of the crystal is shown with high intensity and low contrast [Fig. 2 b]. Analysis of Fig. 2b shows that the area where the dislocation precipitates are located is stretched perpendicular to the active gliding planes and size of the area is of the same magnitude as thickness of the domains. At larger plastic deformations ε≈6÷12% densification of dislocation precipitates will take place. As a result of that immobile dislocations will be located closer to each other to allow overlapping of their elastic fields. Relaxation of the elastic energy stored in the dislocation precipitates occurs by partial annihilation and rearrangement of dislocations in the configuration creating plastic bending of the gliding planes [7-9]. For larger plastic deformations the regions of plastic bending will be expanded in the direction perpendicular to that of the gliding plane due to absorbing the de-twinning partial dislocations. In macroscopic scale the regions of the plastic bending possess small thicknesses and divide the crystal to “fan-shaped” reoriented subunits. Angle of disorientation of the subunits (5 ÷ 7 angular degrees) obtained from analysis of XRD results is the net magnitude of plastic bending creating several areas of plastic bending. Completion of reorientation of the domains of unstable orientation through the volume of the crystal obtained by analysis of several XRD spectra for the samples deformed by ε ≈ 18 ÷ 22% [Fig. 3] shows to passage of the de-twinned partial dislocations through the border of sub units or their absorption at the borders.

and the slip plane (111). Twinning dislocations are generated at the boundary between the twins.During the movement the plane of twinning shiftsinto one interplanar spacing d111 in the direction[111].The observed increase of the thickness of the domains of one orientation as a function of the plastic deformation indicates to correlated motion of partial dislocations. Assuming that they pass only once through every plane of stacking faults and that both orientations of the domains have approximately the same average thicknesses we find that consistent shift of about half of the (111) planes is required for formation ofa single domain. Consequently, magnitude of the plastic deformation required for obtaining the mono-oriented state of sphalerite equals to ε≈18 ÷ 22%, which is in good agreement with theoretical estimations of Refs.[1-3]. The above described mechanism of transformation of polysynthetic structure into single oriented one is achieved only if the domains form a flat-parallel-sphalerite coherent boundary. The results of this paper show that the declined cross-domain boundaries formed by a small group of hindered dislocations strongly influence on the processes of plastic deformation at small thicknesses of the domains. Consequently, upon constructing the real sequence of the processes of formation of the substructures, it is necessary to take into account the collective effect of the interaction of the group of inhibited dislocations with gliding partial dislocations occurring by de-twinning up to complete re-orientation through the volume of the deformed crystal.As is known, the reason of inhibition of gliding dislocations during the martensitic type phase transition might be different [5, 6]. In the initial polysynthetic crystals ZnS the inhibited dislocations are distributed at the locations where front planes of the growth of sphalerite phases face each other. This dislocation restricts the shear plane from one side and forms the stable and unstable slopes of the boundaries broken inside the crystal. The results of the diffraction studies show that the significant portion of the sloping boundaries lost stability at small plastic deformations (ε≈3÷5 %) and together with de-twinning partial dislocations take part in the processes of plastic deformation of micro twins. On the contrary, the declined borders, which are stable at such plastic deformations, resist to the motion of the de-twinned dislocations with elastic fields. At the locations of the inclined boundaries dislocation precipitations will be formed that divides the crystal into non-reoriented subunits. On the diffraction patterns this region of the crystal is shown with high intensity and low contrast [Fig. 2 b]. Analysis of Fig. 2b shows that the area where the dislocation precipitates are located is stretched perpendicular to the active gliding planes and size of the area is of the same magnitude as thickness of the domains. At larger plastic deformations ε≈6÷12% densification of dislocation precipitates will take place. As a result of that immobile dislocations will be located closer to each other to allow overlapping of their elastic fields. Relaxation of the elastic energy stored in the dislocation precipitates occurs by partial annihilation and rearrangement of dislocations in the configuration creating plastic bending of the gliding planes [7-9]. For larger plastic deformations the regions of plastic bending will be expanded in the direction perpendicular to that of the gliding plane due to absorbing the de-twinning partial dislocations. In macroscopic scale the regions of the plastic bending possess small thicknesses and divide the crystal to “fan-shaped” reoriented subunits. Angle of disorientation of the subunits (5 ÷ 7 angular degrees) obtained from analysis of XRD results is the net magnitude of plastic bending creating several areas of plastic bending. Completion of reorientation of the domains of unstable orientation through the volume of the crystal obtained by analysis of several XRD spectra for the samples deformed by ε ≈ 18 ÷ 22% [Fig. 3] shows to passage of the de-twinned partial dislocations through the border of sub units or their absorption at the borders.  | Figure 3. XRD pattern for ZnS deformed under 18÷22%.Swivel axis is[112] with oscillation Interval 15º |

5. Conclusions

- Thus, we have performed X-ray diffraction and electron microscopy studies of substructure of polysynthetic ZnS crystals. XRD studies have shown that upon plastic deformation in a certain direction thickness of domains of one direction increases in the main part of polysynthetic crystal ZnS. This process is accompanied by formation of dislocation precipitates in certain areas of the crystal, which at larger plastic deformations are rearranged together with mobile partial dislocations into more stable configurations determining the substructure of the uni-oriented ZnS crystals.Plastic deformation at ε≈18÷22% completes the transition of the crystal into the uni-oriented state. The rearrangement of the broken and inclined boundaries in the original polysynthetic crystal, capture and absorption by them the mobile partial dislocations are the sequence of the processes of formation of "fan-shaped" disoriented sub-units.In in macroscopic scale they imitate “S”-shaped bending of the gliding plane around the direction

perpendicular to

perpendicular to  of the forces and smallest gliding.

of the forces and smallest gliding. Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML