-

Paper Information

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

American Journal of Materials Science

p-ISSN: 2162-9382 e-ISSN: 2162-8424

2011; 1(2): 103-107

doi:10.5923/j.materials.20110102.17

Sliding Behavior of C/C and C/C-SiC Composites in Acidic Environment-Against High Chromium Steel Disc

V. K. Srivastava

Department of Mechanical Engineering, Institute of Technology, BHU, Varanasi, 221005, India

Correspondence to: V. K. Srivastava, Department of Mechanical Engineering, Institute of Technology, BHU, Varanasi, 221005, India.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

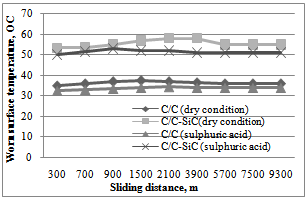

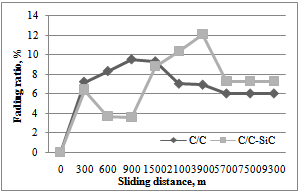

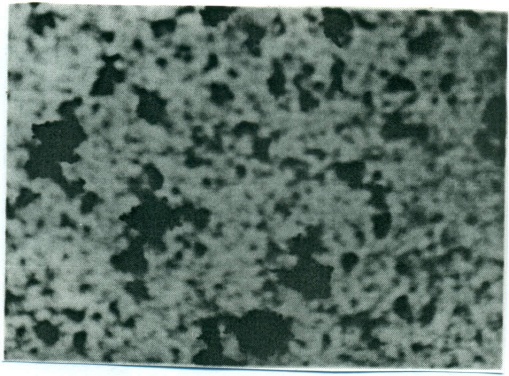

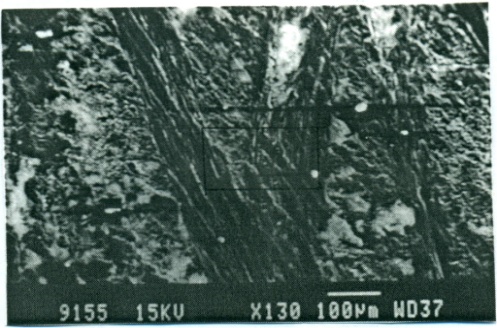

The wear behaviour of carbon-carbon (C/C) and carbon-carbon-silicon-carbide (C/C-SiC) composites were studied using a pin-on-disc test rig under dry condition before and after immersion in 25% concentrated H2SO4. The influence of the weight loss and worn temperature against sliding distance and time were investigated. It was found that the weight loss increases with increasing of sliding distance and time, where worn surface temperature increases slowly up to 1.5 Km sliding distance and then tended to become constant. Also, weight loss and worn surface temperature reduces with the exposure of 25% concentrated sulphuric acid.However, the C/C-SiC composites exhibiting a lower weight loss but higher worn surface temperature compare to C/C composites at constant load. The wear and worn temperature of C/C composite gradually increases compare to C/C-SiC composite, with an average fading ratio of 7.7% (C/C composite) and 7.4% (C/C-SiC composite). Scanning electron microscope and projection microscope micrographs show that the graphite film was transferred on the test pin side, which stabilized the increase in test pin temperature after the formation of a thick film of graphite debris.

Keywords: Sliding Wear, Carbon-Carbon Composite, Carbon-Carbon-Silicon-Carbide Composite, Mild Steel, Scanning Electron Microscopy

Cite this paper: V. K. Srivastava, Sliding Behavior of C/C and C/C-SiC Composites in Acidic Environment-Against High Chromium Steel Disc, American Journal of Materials Science, Vol. 1 No. 2, 2011, pp. 103-107. doi: 10.5923/j.materials.20110102.17.

Article Outline

1. Introduction

- Carbon/carbon (C/C) composites have received considerable attention in the aircraft and automobile brake industry as strong candidate materials because of their low density and unique thermal and mechanical properties [1-3]. In order to utilize these materials as friction materials, the evaluation of their wear behavior is important. However, very little effort has been made to characterize the wear behavior of C/C composites. Recently some researchers have studied the wear of C/C composites under representative aircraft braking conditions [4-7]. They have found that oxidation in the subsurface was the predominant wear mechanism due to the high interfacial temperature of the friction material and, as a result, most previous works have concentrated on the oxidative mass loss of C/C composites. Under braking conditions the material loss of the friction surface also occurs with the oxidative mass loss in the subsurface. Therefore, the investigation of frictional wear is also important to characterize the wear behavior of C/C composites. However, the frictional wear mechanism of C/C composites is not understood well at this stage. C/C-SiC composites, made by liquid silicon infiltration (LSI-process), offer superior tribological properties in terms of high coefficient of friction and wear resistance. The carbon fibres lead to an improved damage tolerance in comparison to monolithic SiC, whereas the silicon carbide matrix improves the wear resistance compared to carbon/carbon (C/C) composites. C/C-SiC composites are therefore new, outstanding materials for brakes and clutches of high speed cars, trains and emergency brakes in the field of mechanical engineering and conveying.First attempts to investigate C/C-SiC composites for their use as frictional materials for brake pads and disks started in the early nineties [8]. C/C-SiC material shows, in comparison to carbon-carbon, a considerably lower open porosity (less than 5%), a moderately higher density (about 2g/cm3) and a ceramic share of at least 20% in mass. Several activities in institutes as well as in industries now exist to investigate CMC materials for their use as frictional materials for brake pads and disks [9-12]. The resulting materials differ in their constituent (fibres, fillers), microstructure (ceramic content, density, strength, and thermal conductivity) and also in their processing conditions (fibre coating, temperature, etc.). Nevertheless, they are all based on carbon fibres and silicon carbide matrices as the main constituents of the composite materials. The carbon fibres generally decrease the brittleness of SiC considerably so that the damage tolerance of C/C-SiC components lies in the same order of magnitude as for grey cast iron.In this study the wear behavior of C/C and C/C-SiC composites were investigated against sliding on high chromium steel disc before and after exposure of 25% concentrated sulphuric acid. Weight loss and worn surface temperature were measured with the variation of sliding distance and time at constant load of 6 Kg. Finally, micrographic analysis was used to obtain detailed information about the worn surfaces of the composites.

2. Experimental Procedure

2.1. Materials and Specimen

- The materials used in this investigation were two kinds of cross-woven C/C and C/C-SiC composites. The C/C-SiC composite was manufactured by liquid siliconising infiltration (LSI) method. Usually, the LSI-process gives C/C-SiC composites containing significant amount of unreacted free carbon together with unreacted free silicon. C/C-SiC ceramics were oxidized in ambient air/oxygen. However, the temperature to which the samples were subjected and the holding times play an important role. C/C-SiC was fabricated in the form of rectangular plates of 3 mm nominal thickness. C/C-SiC is a tough ceramics. The investigations refer to cross-woven (0o/90o) C/C-SiC composites with high tenacity (HTA) carbon fibre (ф=7μm) as reinforcement, and the matrix was silicon carbide. The volume fractions are 60% carbon fibre, 38% silicon carbide and 2% silicon. The carbon/carbon (C/C) composite was produced by processing route of yarn method with 3 mm thickness, fibre orientation of 0o/90o and 50 % volume fraction. Polyacrylonitrile (PAN) based high modulus (HTA) carbon fibre (Torayca M40) was used because of good properties at high temperature. The plates were cut into the desired shape (cuboids 25 mm x 3 mm) for the wear test. All the wear test specimens were polished to a surface roughness of about 0.3 µm. Before wear testing, the composite test pins and steel disc counterpart were cleaned with carbon tetrachloride and dried. Some specimens were immersed in the 25% concentrated sulphuric acid for the fixed period of time 312 hrs.

2.2. Wear and Temperature Tests

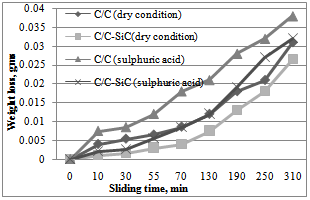

- The apparatus used in this investigation was a pin-on-disc type apparatus. A test pin (3 mm x 3 mm cross-section and 25 mm length) was inserted into the hole of the specimen holder. The outer diameter was 8 mm, the length 36 mm, with a rectangular 4 mm x 4 mm x 20 mm blind hole, designed for holding the test pin. A clamping device (screw) was provided on the holder for holding the test pin. To avoid vibration on the test pin, a mild steel strip (0.5 mm thick x 3 mm wide and 20 mm long) was inserted with the test pin. A high-carbon chromium steel disc of 120 mm diameter, heat-treated to a hardness of 63 HRC, was rigidly mounted on a brass disc to avoid vibration of the motor. The disc was also polished with a fine grade of emery paper, followed by cleaning with carbon tetrachloride solvent, and dried in air. The weight platform was directly attached to the one end of the test pin, and the second end of the test pin was just touching the chromium steel disc for the measurement of wear. The test specimen was directly loaded with constant weight 6 Kg (58.8 N). The wear losses were recorded by an electric balance to an accuracy of ± 0.1 mg. The difference in weight of the test pins before and after the experiment was the weight loss of the sample. The position of the test pin over the disc was changed to produce wear tracks of various diameters. A new pin and fresh wear track were adjusted by regulating the speed of the variable direct-current motor. The sliding speed and time at different tracks were also changed for the measurement of wear loss. The wear loss of C/C and C/C-SiC composites specimens were measured before and after exposure of 25% concentrated sulphuric acid.A digital thermocouple was used to measure the temperature of the worn surface. The rise in temperature was noted at intervals of 30 min. The same procedure was adopted at various sliding speed and times. The fading ratio D of the worn surfaces in moist condition, which represents the sensitivity of the worn surface temperature to an acidic condition, can be determined according to the following relation;

| (1) |

3. Results and Discussion

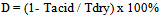

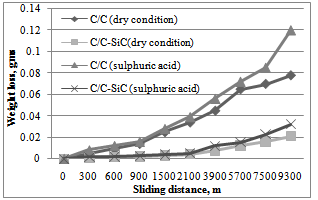

- Figure 1 and 2 shows the variation in the weight loss as a function of sliding speed and sliding time for C/C and C/C-SiC composites under dry and acidic condition. The weight losses increased with increase of sliding distance and time, tended to become steady after 3.0 Km.

| Figure 1. Variation of weight loss with sliding distance at constant load of 6 Kg of C/C and C/C-SiC composites under dry and sulphuric acid condition |

| Figure 2. Variation of weight loss with sliding time at constant load of 6 Kg of C/C and C/C-SiC composites under dry and sulphuric acid condition |

| Figure 3. Variation of worn surface temperature with sliding distance at constant load of 6 Kg of C/C and C/C-SiC composites under dry and sulphuric acid condition |

| Figure 4. Variation of fading ratio with sliding distance at constant load of 6 Kg of C/C and C/C-SiC composites |

| Figure 5. Projection micrograph (100X) showing thick steady state debris of C/C composite under dry condition at load of 6 Kg and sliding speed 0.5 m/s |

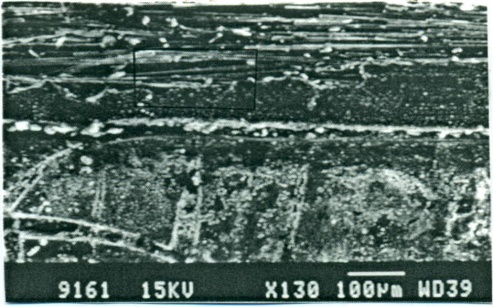

| Figure 6. SEM micrograph shows the effect of wear on counterpart of C/C composite (exposed with sulphuric acid) at the load of 6 Kg and sliding speed 0.5 m/s |

| Figure 7. Projection micrograph (100X) showing steady state debris of C/C-SiC composite under dry condition at load of 6 Kg and sliding speed 0.5 m/s |

| Figure 8. SEM micrograph shows the effect of wear on counterpart of C/C-SiC composite (exposed with sulphuric acid) at the load of 6 Kg and sliding speed 0.5 m/s |

4. Conclusions

- Experiments were carried out to study the effect of 25% sulphuric acid on the wear behavior of C/C and C/C-SiC composites with the variation of sliding speed and time. Based on these studies, following conclusions are drawn:*For a particular load, the wear of C/C and C/C-SiC composites increased with increase of sliding distance / time and tended to steady state, which indicates that the sliding temperature increased and attained a steady state after the transfer of thick graphite film to the counter face, which acts as a self-lubricating film. *The wear behavior of C/C and C/C-SiC composites marginally affected by the exposure of 25% sulphuric acid for the period of 312 hrs.*The fading ratio of C/C composite increased very rapidly with increase of sliding distance and appeared to steady state after 1.5 Km sliding distance, whereas, fading ration of C/C-SiC composite turned random behavior with increase of sliding distance.The C/C composites resulted higher wear losses compare to C/C-SiC composites during the sliding against chromium steel disc. Micrographic studied show that the thick film of debris on the counter sides transferred in the case of C/C composite compare to C/C-SiC composite.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML