-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Journal of Logistics Management

2021; 10(1): 1-10

doi:10.5923/j.logistics.20211001.01

Received: Jan. 23, 2021; Accepted: Feb. 22, 2021; Published: Mar. 28, 2021

Impact of Supply Chain Management on Competitive Advantage in Agro-Businesses in Ghana: Case Study of Selected Agro Business Companies in Kumasi

Asare Benjamin1, Bruce Emmanuel2, Azamela John Coffie2

1Business School, Kwame Nkrumah University of Science and Technology, Kumasi, Ghana

2School of Management and Economics and University of Electronic Science and Technology, Chengdu, China

Correspondence to: Asare Benjamin, Business School, Kwame Nkrumah University of Science and Technology, Kumasi, Ghana.

| Email: |  |

Copyright © 2021 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

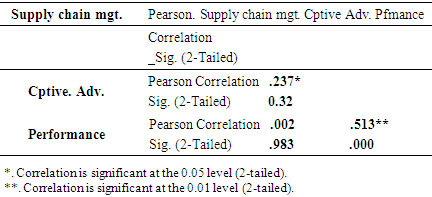

The study was to assess the impact of supply chain management on competitive advantage in Agro-business business in Ghana. Both primary and secondary data were used. Structured questionnaires were used in collecting data for the study. One hundred and fifty (150) questionnaires were distributed however, 148 were received in good form giving a response rate of 98.6%. The field data were analyzed with the aid of SPSS. The study discovered that there is a weak positive and insignificant (r= 0.002, p-value > 0.05) association between sustainable supply chain management and performance of the agro-businesses. The study however found a positive and significant (r= 0.237, p-value < 0.05) association between sustainable supply chain management and competitive advantage of the agro-businesses. Moreover, the study found that there is a strong positive and significant (r= 0.513, p-value < 0.05) association between competitive advantage and performance of the agro-businesses. In conclusion, the study had established that supply chain management practices such as strategic supplier partnerships (SSP), Customer Relationship (CR), Information sharing (IS) and internal lean practices are significant determinants of agro-businesses performance and competitive advantages. It is recommended that agro-businesses should embrace full the supply chain management concepts and enjoy concomitant effects associated this. Resources constraints limited the study scope to only agro-businesses in the Kumasi Metropolis. It is recommended that future researchers should consider other sectors.

Keywords: Supply Chain, Competitive Advantage, Agro-businesses, Strategies, Performance

Cite this paper: Asare Benjamin, Bruce Emmanuel, Azamela John Coffie, Impact of Supply Chain Management on Competitive Advantage in Agro-Businesses in Ghana: Case Study of Selected Agro Business Companies in Kumasi, Journal of Logistics Management, Vol. 10 No. 1, 2021, pp. 1-10. doi: 10.5923/j.logistics.20211001.01.

Article Outline

1. Introduction

- Supply chain management (SCM) has become a potentially valuable way of securing competitive advantage and improving organizational performance since competition is no longer between organizations, but among supply chains. The main motive of this SCM is to collectively manage the supply chain as though they were one company with the aim of fixing sub-optimal deployment of inventory and capacity (Hunka et al, 2011). SCM is contextualized by the Council of Supply Chain Management Professionals (CSCMP) to include planning and management activities involved in sourcing, purchasing, transforming and related logistics management activities. Definitions of SCM reveal a chain of integrative supply chains. For instance, Slack et al. (2010) stated that managing the interconnections between supply chain organizations that relate to one another through up and down stream links through the processes that produce value to the end-user. It’s an integrative function used to link businesses within and across organizations under a comprehensive and coherent high performing model of businesses including managing logistics (Vitasek, 2010). SCMs are simply the process through which buyers relate with suppliers to produce goods and services to suit customer specification (Schwartz et al., 2008). Around the 1980s, SCM was focused on improving quality which latter transformed to include environmentally friendly policies while operating business and solving customer specific needs. The supply chain encompasses all activities associated with the flow and exchange of goods and services from raw material stage to the final product usable by the client and supply chain management emphasis on integration of supply chain activities and information flows associated with them to achieve competitive advantage of continued and reliable through improved supply chain relationships. Understanding and implementation of supply chain management is a necessary condition to remain competitive in the global competition enhance sales and improving profitability [1]. Supply chain’s management strategies are important to business organizations today and are critical factors to its success. Market studies and effective market coverage, availability of products at locations which hold the key to revenue recognition depends upon the effectiveness of supply chain strategy rolled out. Very simply stated, when a product is introduced in the market and advertised, the entire market in the country and all the sales counters need to have the product where the customer is able to buy and take delivery. (Asare & Prempeh, 2016). Supply chain management approaches management that goes beyond the boundaries of company (Sctwartz et al., 2008). Hence manufacturing organization in the supply chain should be able to consider inventory demand and according to the number products in stock identified a fraction number the product and do production planning. By determine production schedules, do raw material supply and the schedule of production, distribution of products as well is planned. Competitive advantage is one factor that an organization is able to create a state of defense against competitors and includes a feature that allows an organization to distinguish itself from its competitors (Li et al., 2006). The concept of competitive advantage is directly related to desired value of the customer [2]. Competitive advantage includes set of capabilities and factors that always demonstrated better performance of company than competitors. [3]. Strategic partnerships with suppliers are organized efforts to create and maintain of a network of qualified suppliers. Strategic partnership emphasizes direct relationship and long-term and encourages mutual planning and efforts to resolve problem. Effective partnerships with suppliers can be critical factor to guide supply chain management. Information sharing in interactive system of supply chain includes information between direct partners and all network of supply chain. Effective use of relevant and timely information by all the functional elements in the supply chain is considered as a competitive factor and distinctive. [4]. Nowadays, the development of customization and customer expectations lead to a period that customer relationship management is vital to the survival of the company. Good relationships with members of the supply chain, including customers are required to run successful SCM applications. Close relationships with customer organizations enables to distinguish their products to competitors, retain customer loyalty and this value is protected largely to consumers (Li et al. 2006). Generally, SCM has being an effective valuable means of getting in touch competitive rule of graphic, and production companies as well, through the upbringing of organizational standard. The damage of supply chain integration to standard level and company performance is part. There is a positive but loose partnership between supply chain and supply chain management style in getting advantage in competitiveness and the company performance. However, since the methods of supply chain management are different, thus this study tried to investigate impact of supply chain management practices on competitive advantage. In the view of the above, the leading question in this study is: Has the practices of supply chain management (SCM) impact on competitive advantage in selected Agro-business Company in Kumasi metropolis of Ghana?Research Objectives The study had the following primary objectives: - Explaining the supply chain management practices of the selected Agro-business companies in Kumasi.- To examine the effect of supply chain management practices on competitive advantage of the selected Agro-business companies in Kumasi. - Analyse and assess the association between competitive advantage and performance of the selected Agro-business company in Kumasi.

2. Literature Review

- Due to globalization and information technology, supply chain management has become a tool for companies to compete effectively either at a local level or at a global scale. SCM has become a necessity especially for manufacturing industry when it comes to deliver products at a competitive cost and at a higher quality than their competitors. Hunka et al., 2011 defined supply chain as the materials are actually the raw materials that are purchased and transformed into finished and semi-finished product and services that are distributed to end users. Within this supply chain, there are informational flow barriers that affect feedback. In other to overcome this, most companies decentralize their operations through their supply chain partners (Waters, 2003). Again, Mentzeret al. (2001) defined supply chain as a system that contains three complex dimensions; direct supply chain, ultimate supply chain and extended supply chain. Direct supply chain includes the company, the supplier and the customer who contributes to streamlining the ups and down flows of products, services, financial and informational exigencies from an origin to a destination. Ultimate supply chain involves all companies that are directly or indirectly involved in the flow of goods, services, finances and information from the initial suppliers to the customer. Ayers (2000) equated supply chain to a cycle that is in constant motion from one point to the other; that is from physical support, information, financial and knowledge are in constant flotation which moves products and services to end-users. Moreover, supply chain as a pipeline was used by Slack et al, (2010). They explained the analogy of “pipeline” as supply chain locomotes as liquid flows through pipelines where physical products and services move through a supply chain. He further explained that as longer pipe lines contain more liquid, so is a wide supply chain hence its complexities are that it will take a longer period for information to successfully flow from one point to the other. Stocks may be regarded as analogous to storage tanks. Through the pipelines, products go through different changes and are transformed until they get to the final consumer. The traditional form of supply chain limits the real supply chain. Supply chain goes beyond just mere physical distribution into knowledge sharing. The fundamental purpose of every organization is to satisfy the specific needs to customers while ensuring that the company maximizes profit. There is always coordination and sharing of information through a supply chain using market mechanisms, contracts and partnership arrangements which brings efficiency to the chain of partners (Xia and Tang, 2011). This means there should be a strategic management plans to help maximize gains, increase value and ensure efficiency. The Council of Supply Chain Management Professionals (CSCMP) is a bit more descriptive with its definition. To them it encompasses the planning and management of all activities involved in sourcing and procurement, conversion, and all logistics management activities. That includes coordinating and collaborating with channel partners, including suppliers, intermediaries, third parties, and customers (Blanchard, 2010). Managing the SCM leads to efficiency, cost effectiveness across board (totals costs e.g. from transportation to distribution to purchasing of raw materials, work in progress to finished goods). When consumers turn to evaluate supply chain, they enjoy the advantage of knowing products that are available, less stock output, have knowledge on fresh products on the market and the associated cost (Wilson, 2005). This brings about market intelligence, obtaining quality information for planning, makes accurate investment, maximizes revenue generation, less obsolesces, assured volume, enhance reputation and gain competitive edge (Ayers, 2000; Votano et al., 2004 & Wilson, 2005).

2.1. Competitive Advantage

- Competition is now seen as a “war of movement” that is built around anticipation and quickly responding to the taste and preference of consumers (Stalk, Evans and Schulman, 1992). Competitive advantage comes as a result of developing superior competencies that create value but with reduced costs to meet market needs (Barney, 1991; Day and Wensley, 1988). Sustaining competitive advantage demands that the company make conscious effort to prevent competitors from imitating her brand (Day and Wensley, 1998). According to Porter, competitive advantage means producing at low price but in a unique way to meet customers’ admiration (Porter, 1991). Porter in 1980 stated that competitive strategy deals with searching convenient position within the industry that businesses operate. In order to sustain the competitive advantage a company has gained; they need to set-up barriers and must constantly work to strengthen the barriers to make it impossible for other companies to copy. D’Souza (2002) mentioned that achieving cost efficiency and quality will continue to be competitive edge dimensions of a firm. Wheelwright (1978) stressed that variables like quality, cost, dependability as well as speed contribute to gaining a competitive edge and has been accepted that timing of market is relevant. Similarly, quality, cost, delivery dependability and timing of market is integral to competitive advantage. An effective means of competing within the global market is adopting SCM and their implementations have strong effect on competitive edge. In modern day’s global competition is running fast, organizations want greater responsiveness, so that customer needs may be met. However, there are responsiveness on the dimensions, which are supply side, within the organization and fundamental knowledge is needed to be effective in their industry. Supply chain responsiveness has been ineffectively stated and an increasing rate of variability (ranging from flexibility to agility) in people’s mind on its meaning. The result shows the users the vital parts of responsiveness, and how they can be achieved. Organizations have a wide range of valid and reliable estimates for evaluating, benchmarking, and similarities in supply chain responsiveness at individual roots within the supply chain (i.e. raw material supplier, component supplier, assembler, sub-assembler, manufacturer, distributor, wholesaler, and retailer).

2.2. Quality Management and Supply Chain Management

- The integration between quality management and SCM has been termed as supply chain quality management (SCQM) [5]. Through quality management, supply chain provides quality products across companies to meet customers’ expectation. According to Robinson and Malhotra (2005) affirmed that SCQM is the traditional coordination and integration of business activities including all partners in the supply chain where they analyze and constantly improve products, goods, services and processes to offer value and satisfy customers. [6]. Supply chain management uses a procedural pattern and integrative approach to handling business operations and relationships with supply chain partners and in the long run, assemble all the value chain partners under one unit [7]. Enhancing and ensuring efficiency through the supply chain system contributes to cost reduction, improved process efficiency and improved resource usage (Wang et al., 2004). Studies have tried to look at how quality management enhances the performance of supply chain and neutralizes all problems within a supply chain [8]. Some researchers’ belief that integrating quality management into every aspect of the supply chain brings a synergetic collaboration which leads to improved performance and organizational performance can be enhanced when suppliers are regarded as an integral part of the value chain (Lin et al., 2005). Kannan and Tan (2005) explored the link between just in time (JIT), Supply Chain Management (SCM) and Quality Management and its effect on organizational performance. They found that at the strategic and operational levels, there are strings that link the units within the system and should be integrated as part of the strategies that are designed for the organization. Commitment and understanding of supply chain have positive impact on performance. [9]. The fusion of SCM and QM is regarded as a benign procedure because the traditional focus of supply chain was on purchasing, manufacturing and shipping to facilitate organizational activities. Owing to the competition within the business environment, there is the need to improve cost efficiency and high service levels, high quality products and services [10]. The high level of supply chain management initiatives promotes competitive edge and the performance of an organization. Also, the integration of SRM, MFM and PDAC practices has a positive effect on the performance of an organization. There should be an active policy integrated into all aspect of organizations in the supply chain. Competition around the global market has become very competitive and companies that do not deploy SCM find it difficult to sustain their business [11]. There are five facets of identifying the relationship among SCM practices, performance of the organization and competitive edge. Comprehensive, reliable and valid SCM activities have been developed by companies and with the variables tested in terms of its validity, reliability and validation of construct [12]. SSCM has positive impact on organizations but this has a long-lasting effect on organization. Chain members build synergy to source for opportunities in order to improve overall performance [13]. Farmers are noted to be much concerned about economic conditions than social and environmental impact of the cocoa market where they channel their strengths to solidify their internal structures. The supply chain within the cocoa industry is exposed to massive risks and these risks involve farm level risks (stock-out, environmental, shrinkage, loss of cocoa land, spoilage, pest infections, theft), Purchasing Clerks (which include cocoa beans losing weight, unpaid credit, environmental, pest infestation), Licensing Buying Companies (LBCs) suffer risks such as poor quality supply, contractual, commercial, employee turnover, environmental, shrinkage, reputation, technical, performance, pest infection, robbery/theft, outsourcing, smuggling, short landed, and CMC risks such as shortage, spoilage, over supply, add-mixture, smuggling, theft/robbery and health. The study contributed to SSCM was positively related to competitive advantage and SCM has a link to SSCM [14].

2.3. Information sharing in Supply Chain Management

- Information sharing is linked with supply chain strategy which has more connection with responsiveness of supply chain. Linking up with changes in the environment to meet the demands of consumers is very important and sharing of information leads to an increased level of information exchange. The link between supply chain strategies (responsiveness and efficiency) and performance has been accepted. This shows that higher responsiveness and performance of supply chain would be higher performance for supply chain. Looking at importance of information flow and its role in the supply chain it can be said that supply chain compared to individual firms has three main features which are; more coverage, more channels and access to high quality information. Information technologies improve distribution and exchange information and improve supply chain efficiency effectively. The results of information technology in supply chain management are; improving cooperation relationships in two internal and external areas, increasing responsibility, creating new relationships with customers to identify their needs, developing sales channels, improving performance and improving the competitive position of the chain [15]. As a result, in the kind of hospitality sector, hotels struggle with a lot of situations which are required to upgrade effectiveness in their SC. For example, if SCM practices are effective which leads to a better SCM which results has a significant effect on competitive advantage on the hotels. It came out that the challenges which managers face most is to avoid them from having strong SC is technology. There are factors that show that SCM has a positive importance on competitive advantage and operational performance. As a result, hotels should take a strong responsibility in managing all areas of their SC. In modern days the rate of competition in global markets that is hotels that do not practice sound SCM techniques may notice that they are not able to challenge their business competitors. Therefore, there is the need for hotels to look through their SCM so as to benefit from adopting it [16]. It was found in a textile company that to be aware of information technology and taking it into consideration is important for supply chain performance (firm logistics, vendor relationship management), information technology is used to bring down the problems in the supply chain performance. To be aware of information technologies is an important tool for manufacturing companies and to gain the advantages of information technologies, the manufacturers also uses information technologies for saving labour’s time using the working hours in a better way to support supply chain performance [17]. The consequences for production and graphic companies as well, are moving from internal efficiency to give out chain efficiency to get in touch competitive results. Developing and making two-dimensional, operational rules of the construct of the standard SCM practice given to SCM managers’ advantage equipment’s for value the effectiveness of their new SCM practices. Done with the results of the relationship of SCM practice and effective advantage, it displays the SCM practice may proper useful in competitive. By sharing different ideas of SCM practice across the supply chain, you can easily locate the strength and weakness of the supply chain and available SCM practice as well. Strategic advantage as mediation in cooperation with the link of supply chain integration, supply. Competitive source as mediation addition to the link of supply chain integration, given out chain loose and supply chain management skills in the organizational goal. Integrating supply chain and becoming committed and responsive leads to competitive advantage. SCM maintains some level of focus and keeps organizations aligned to a course that have a structured plan. The alignment streamlines the pattern of communication within the organization, brings orderliness in the company, qualifies for supply chain metric and be available to partnership. The ability to manage these complex systems requires effectiveness and being cost efficiency which requires supply chain goals. Integrating this complex system is very challenging and has lots of barriers [18]. Suppliers’ management has positive effect on SCM effectiveness. In Sudan, a study carried was on assessing Sudanese manufacturing companies and their application of supply chain management. [19]. Managing suppliers influences the cost of supply chain thereby contributing positively to effective organizational performance. Integration also influence SC effectiveness but the researcher found no correlation between information sharing, customer management, integration, responsiveness and being effective through the sharing of information which may influence uncertainties, doubts, unfairly distribution of cause and effect and improves behavioural patterns of employees by shaping their divergent interest [20]. Integrating organizations reduces the ability and desire to rapidly change and due to the effect of integrating supply chain, customer relationship management affects SCM and makes it complex [21]. However, in SCM the Industry players and academicians needs to consider market-oriented sustainability from a broader perspective which should encompass the concept of the triple bottom line [22].

2.4. Theoretical Framework

2.4.1. Porter’s Generic Competitive Strategies

- The relative position of firms discloses their wealth and determines whether they are profitable above or below the industry average. For a company to be considered as profitable above the industry average, then they have incorporated sustainability into their operations which will yield positive results in the long run. Companies might have diverse strengths, weaknesses and competitors but there are two basic underpinnings that provide competitive advantage; being different and offering low prices. These competitive advantages when combined leads to the development of three main strategies; focus, differentiation and cost leadership. Organizations can achieve competitive edge through the application of either of the three and selection must be a perfect fit for the strategies of the organization (Porter, 1998). Developing mean to be cost effective and different contributes to a competitive advantage on a broader industry perspective while focus only drives a company to being cost effective or being different from other organizations [23].

2.4.2. Cost Leadership

- Cost leadership is when a company, an organization or a business intends to operate in a cost-effective way in order to offer their customers low cost. The nature and structure of the banking sector has compelled banks to deliver varied cost-effective products and packages. Reis and Trout (1982) asserted that products that are low cost sells on no-frills, standard product and lays emphasizes on becoming an absolute cost advantaged company. Achieving cost advantage in the banking industry requires immense low-price overheads, less expensive labor and developing efficient way for training staffs. To become cost advantaged bank, one has to exploit several avenues to enjoy economies of scale, adopting new technologies as well as finding preferred raw materials. Achieving a cost advantage in an industry depend on the type of leadership within the organization which demands that a bank will be different when compared to their competitors so as to make them perform above industry average [24]. Differentiation is very critical and cannot be overlooked because a marred image of a products needs rebranding to regain its competitive price position in the market or reduce the cost of products to sell more (Peattie and Peattie, 1994). Proximity is also important to provide cost or price discount boost the chances of banks to attaining above average returns. Porter (1998) mentioned that companies have to make a decision to be cost leaders in their industry and not just jostling for the position. This requires a pre-empted decision unless technological advancement causes drastic changes in the industry. (Porter, 1998).

2.4.3. Differentiation

- According to Porter (1998), differentiation should not be clustered around competition but the firm itself must be unique in its own way and its brand must be distinct from other competitors. Through comparison of cost leadership and differentiation, it can be concluded that there are many ways of providing value to the customer.

2.4.4. Focus

- Undoubtedly, the above-mentioned strategies (low cost and differentiation) are instituted to achieve company objectives; focus is more concentrated on achieving specific functions. The base of focus narrows the scope of competition. Focus makes management pick key items and aspects of their products and develop them but these are mostly done by assessing the resources of the organization. Focus has two main part; cost focus and differentiation focus. Cost focus converges the strength of the firm on only cost-effective tools and activities while focus differentiation centers its operations solely on being market leaders through innovation. The difference between the two is the focus of management and the firm. Having already existing market is ideal to facilitate growth [25].

3. Methodology

3.1. Research Design

- A descriptive survey design was used since the study was aimed to explain, describe and validate. A survey is used to collect original data for describing a population too large to observe directly (Mouton, 1996). A survey involves a process of eliciting information from a sample of people by means of self-report, that is, the people respond to a series of questions posed by the investigator (Polit and Hungler, 1993).

3.2. Population of the Study

- Population is defined as all elements (individuals, objects and events) that meet the sample criteria for inclusion in a study. (Burns and Grove, 1993), The study population of this consisted of all Staff and Management in the working in the Agro-Business industry in the Kumasi metropolis. These companies were considered because they agreed to participate in this study when consent letters were distributed to them. The target population of the study consisted of staffs who are involved in supply chain management decisions e.g. sourcing, purchasing, procurement, logistics, warehousing, distribution, Finance and Administration Units.

3.3. Sampling Techniques and Sample Size

- The sampling techniques used for this study were purposive and convenience sampling techniques. Purposive sampling technique was used to select staff and departmental personnel who acquire and manage stock at the Agro-business companies. Convenience sampling was used to select a representative number of the different units of the companies. The sample size for the study was 150 employees were administered in order to ascertain the perceptions of both staff and management with respect to supply chain management practices and competitive advantage of some selected Agro - business. The sample size selection was again based on chance selection and the readiness and availability of the respondents.

3.4. Data Analysis and Collection Methods

- A questionnaire was chosen as the main data collection instrument. A questionnaire is a printed self-report form designed to elicit information that can be obtained through the written responses of the respondents. The information obtained through a questionnaire is similar to that obtained by an interview, but the questions tend to have less depth (Burns and Grove, 1993). Data was collected with the aid of questionnaires to assess the impact of supply chain management on competitive advantage in Agro-business business in Ghana. The questionnaire was designed to meet the objectives of the study. Questionnaires were personally distributed by the researcher to top management officials and their staff to complete. The data gathered from the questionnaire was edited to ensure completeness, consistency and accuracy. Data collected were analyzed through the use of Statistical Package for Social Sciences (SPSS) version 20 software and Microsoft Excel. In analysing the data, frequency, correlations, regressions and descriptive tables were used as analytical tools. Quantitative explanations were made of quantitative data to give meaning to them as well as explain their implications.

3.5. Reliability of the Data Collection Instrument

- The validity of an instrument is the degree to which an instrument measures what it is intended to measure (Polit and Hungler, 1993). Content validity refers to the extent to which an instrument represents the factors under study. To achieve content validity, questionnaires included a variety of questions on the knowledge of the top management officials and their staff on the impact of supply chain management on competitive advantage in Agro-business business in Ghana. Questions were based on information gathered during the literature review to ensure that they were representative of what respondents should know. Content validity was further ensured by consistency in administering the questionnaires. All questionnaires were distributed to respondents by the researcher personally.

3.6. Ethical Considerations

- The research questions were framed such that inconvenience and embarrassment were not caused to the participants in the research. The participating companies’ staffs and management were assured of their utmost confidentiality with regards to information provided. Those who participated in the study were not coerced but did so voluntarily. The consents of the respondents were obtained before they participated in the research. As a much as possible, the researcher exercised a great deal of circumspection and objectivity throughout the research period.

4. Analysis and Discussions

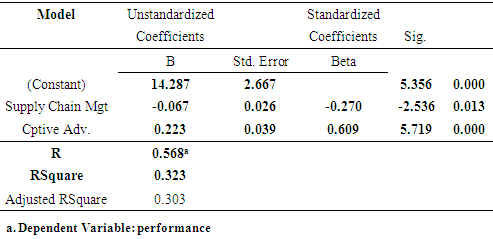

- The analysis was based on the supply chain management practices of the selected Agro-business companies in Kumasi. The results show that businesses consider equality as their number one criterion for selecting suppliers and this recorded a mean=4.01 and SD=0.86. Also, the agro-companies involve suppliers in solving problem with a mean=3.94 and SD=1.03. Moreover, agro-companies assist businesses to improve their product quality and this recorded a mean=3.99 and SD=1.08 and respondents affirmed that they continuously improve their programs which includes their key suppliers with a mean=3.83 and SD=1.04. Respondents also agreed that they include their suppliers in planning and goal setting activities with a mean=3.68 and SD=1.09 and also include suppliers in new product development which recorded a mean=3.75 and SD=1.12. Relatedly, respondents agreed that they relate with customers in order to be reliable and responsive which recorded a mean=3.75 and SD=0.99. Similarly, agro-businesses stated that they frequently measure and evaluate customer satisfaction with a mean=3.88 and SD=0.92, agro-businesses further determine future customer expectation with a mean=3.82 and SD=0.84 and they also facilitate customers’ ability to seek assistance from agro-companies with a mean=3.76 and SD=0.98 and they periodically evaluate the importance of their relationship with our customers with a mean=3.65 and SD=1.10. In time of changing needs, agro-businesses inform their suppliers with a mean=3.63 and SD=0.98 and this allow trading partners to share proprietary information with agro-companies with a mean=3.73 and SD=1.01 and agro-businesses belief that trading partners keep them fully informed about issues that affect their businesses with mean=3.69 and SD=0.88. Again, trading partners share business knowledge of core business processes with us with a mean=3.63 and SD=0.99, agro-companies and their trading partners exchange information that helps establishment of business planning with a mean=3.72 and SD=0.86 and both parties keep each other informed about events or changes that may affect the other partners with a mean=3.82 and SD=1.01. Both parties’ belief information exchange between them is timely with mean=3.74 and SD=1.07, accurate with mean=3.88 and SD=0.89, complete mean=3.69 and SD=0.88, adequate with mean=3.63 and SD=0.95, reliable with mean=3.80 and SD=0.88. Respondents agreed that their products are designed for modular assembly with a mean=3.29 and SD=0.97, delaying final product assembly activities until customer orders have actually been received recorded a mean=3.17 and SD=1.17 and lastly, agro-companies delay final product assembly activities until the last possible position (or nearest to customers) in the supply chain with a mean=3.09 and SD=1.03. These findings are related to past studies for instance supply chain management approaches management that goes beyond the boundaries of company (Sctwartzet al., 2008). Moreover, the study examined the competitive advantages of supply chain practices among agro- companies. The results show offering competitive prices for agro-business partners recorded a mean=4.00 and SD=0.87, companies also offer as low or lower than their competitors with a mean=3.92 and SD=0.85, they also compete based on quality with a mean=4.02 and SD=0.84, offering products that are highly reliable with a mean=4.13 and SD=0.86 and they also offer products that are very durable with a mean=4.07 and SD=0.98. The study found that respondents offer high-quality products to our customer with a mean=4.07 and SD=0.88, deliver the kind of product needed with a mean=3.78 and SD=0.92, delivers orders in time recorded a mean=3.84 and SD=0.97, provided dependable delivery recorded a mean=3.80 and SD=0.84, provide customized products which recorded a mean=3.47 and SD=1.17. results indicated that products offerings are altered to meet client needs with a mean=3.44 and SD=1.18, respond well to customer demand for "new" features with a mean=3.73 and SD=1.22, delivering product to market quickly recorded a mean=3.67 and SD=1.06 and respondents stated that they are first in the market in introducing new products with a mean=3.25 and SD=1.06, have time-to-market lower than industry average with a mean=3.39 and SD=1.07 and lastly, they have a fast product development with a mean=3.18 and SD=1.34. these results support past studies on comparative advantages. From the other analysis based on the effects of supply chain management practices on competitive advantage and performance. Correlation results show the degree of associations among the variables. From the study the following were reviewed. The study found that there is a weak positive and insignificant (r= 0.002, p-value > 0.05) association between sustainable supply chain management and performance of the agro-businesses. The study however found a positive and significant (r= 0.237, p-value < 0.05) association between sustainable supply chain management and competitive advantage of the agro-businesses. Moreover, the study found that there is a strong positive and significant (r= 0.513, p-value < 0.05) association between competitive advantage and performance of the agro-businesses. The beta coefficients show the effects that the independent variables (competitive advantage and supply chain management practices) exert on the dependent variable (performance). From the regression table below, holding competitive advantage constant at zero, units change in supply chain management practices would result bring -0.067 changes in the performance of the agro-businesses which is also significant (p-value < 0.05). Also, holding supply chain management practices constant a unit change in competitive advantage would result in 0.223 changes in performance. desire to rapidly change and due to the effect of integrating supply chain, customer relationship management affects SCM and makes it complex.

|

|

4.1. Performance of Agro-business Companies

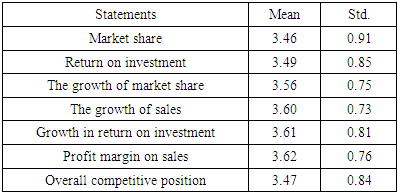

- From the Table 4.3 analyzed that they have enough market share with a mean=3.46 and SD=0.91, return on investment recorded a mean=3.49 and SD=0.85, experience a growth in a market share with mean=3.56 and SD=0.75, growth of sales recorded a mean=3.60 and SD=0.73, growth in return on investment with a mean=3.61 and SD=0.81, increase profit margin on sales recorded a mean=3.62 and SD=0.76 and overall competitive position with a mean=3.47 and SD=0.84. The performance findings are closely related to many previous studies including the following; competitive edge is conditions that enable companies to be efficient and operate at a higher quality level and increases the benefit of the company.

|

5. Conclusions and Recommendations

- The purpose of the study was to assess the impact of supply chain management on competitive advantage in Agro-business business in Ghana. The study found that businesses consider equality as their number one criterion for selecting suppliers and this recorded a mean=4.01 and SD=0.86. Also, the agro-companies involve suppliers in solving problem with a mean=3.94 and SD=1.03. Moreover, agro-companies assist businesses to improve their product quality and this recorded a mean=3.99 and SD=1.08 and it was affirmed that companies continuously improve their programs which includes their key suppliers, include their suppliers in planning and goal setting activities, include suppliers in new product development, relate with customers in order to be reliable and responsive which recorded a mean=3.75 and SD=0.99. Similarly, agro-businesses stated that they frequently measure and evaluate customer satisfaction with a mean=3.88 and SD=0.92, agro-businesses further determine future customer expectation with a mean=3.82 and SD=0.84 and they also facilitate customers’ ability to seek assistance from agro-companies with a mean=3.76 and SD=0.98 and they periodically evaluate the importance of their relationship with our customers with a mean=3.65 and SD=1.10. Furthermore, the study also revealed that in time of changing needs, agro-businesses inform their suppliers, allow trading partners to share proprietary information with agro-companies, keep them fully informed about issues that affect their businesses, share business knowledge of core business processes, exchange information that helps establishment of business planning and both parties keep each other informed about events or changes that may affect the other partners with a mean=3.82 and SD=1.01. Both parties’ belief information exchange between them is timely, accurate, complete, adequate and reliable. Respondents agreed that their products are designed for modular assembly with a mean=3.29 and SD=0.97, delaying final product assembly activities until customer orders have actually been received recorded a mean=3.17 and SD=1.17 and lastly, agro-companies delay final product assembly activities until the last possible position (or nearest to customers) in the supply chain with a mean=3.09 and SD=1.03. The study also discovered found that businesses offer competitive prices for agro-business partners, companies also offer as low or lower than their competitors, they also compete base on quality, offer products that are highly reliable and products that are very durable with a mean=4.07 and SD=0.98. The study found that companies offer high quality products to their customer, deliver the kind of product needed, delivers orders in time, provided dependable delivery recorded a mean=3.80 and SD=0.84, provide customized products which recorded a mean=3.47 and SD=1.17. results indicated that products offerings are altered to meet client needs with a mean=3.44 and SD=1.18, respond well to customer demand for "new" features with a mean=3.73 and SD=1.22, delivering product to market quickly recorded a mean=3.67 and SD=1.06 and respondents stated that they are first in the market in introducing new products with a mean=3.25 and SD=1.06, have time-to-market lower than industry average with a mean=3.39 and SD=1.07 and lastly, they have a fast product development with a mean=3.18 and SD=1.34. In conclusion, supply chain management practices and competitive advantages are both significant determinants of agro-businesses performance. Also, regression results further indicated that supply chain management practices exert -0.067 changes in the performance of the agro-businesses to a significant extent. Also, competitive advantage exerts 0.223 changes in performance significantly. The researcher concludes that agro-business companies in Ghana are becoming dynamic due to the fast-changing needs to customers and also to particularly deal effectively with external pressures from other countries trying to satisfy the niche market within the agricultural industry. On the bases of this, the study revealed that in time of changing needs, agro-businesses inform their suppliers, allow trading partners to share proprietary information with agro-companies, keep them fully informed about issues that affect their businesses, share business knowledge of core business processes, exchange information that helps establishment of business planning and both parties keep each other informed about events or changes that may affect the other partners. Both parties’ belief information exchange between them is timely, accurate, complete, adequate and reliable. The study concludes that the competition within the agro-business companies in Ghana has led to a healthy market where prices and relationships are defined by the competition that exists. Also, companies have become efficient in deploying and management of resources but human and raw materials to curb or reduce the cost of production in order to attract customers. Competition has led to businesses offering competitive prices for agro-business partners, offering of low or lower costs, compete base on quality, offer products that are highly reliable and products that are very durable, deliver the kind of product needed, delivers orders in time, provided dependable delivery, customized products, product offerings that meet client needs and among others. On the other hand, the study recommends that research should be considered as a tool to identifying their chain of supply partners in order to align themselves with businesses and other companies that credible and reliable. The study should endeavor to thoroughly research into the past of sub- companies so as to have a strategic partnership that will deepen the image of the agro-business companies other than to tarnish their image. This image can be built through involving suppliers in solving problem, assist businesses to improve their product quality, engaging in continuously improvement programs which includes their key suppliers and also involve partners in planning and goal setting activities, include suppliers in new product development, relate with customers in order to be reliable and responsiveness. The study further recommends that agro-business companies should be customer centered or should be sensitive to the needs to the existing markets to be able to deliver service specific to the customers. This can be done to allow trading partners to share proprietary information with agro-companies, keep them fully informed about issues that affect their businesses, share business knowledge of core business processes, exchange information that helps establishment of business planning and both parties keep each other informed about events or changes that may affect the other partners. The study recommends that the government through the Ministry of Agriculture should establish standards of operation to ensure that strict rules are complied with by companies. This is because agro-business are becoming commonly used by farmers in producing food stuffs and any attempt to reduce the standards in order to reduce cost will have a devastating effect on the health of Ghanaian citizens hence the need to spell out standards that will regulate the industry.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML