-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Journal of Logistics Management

2020; 9(2): 31-38

doi:10.5923/j.logistics.20200902.02

Received: Jul. 28, 2020; Accepted: Aug. 22, 2020; Published: Sep. 28, 2020

How Important is Supply Chain Management for Minimizing the Impact of Covid-19 on Moroccan Firms’ Profitability

Najat Toufah

PhD Supply Chain Management and Operations Management at the Faculty of Law, Economic and Social Sciences, Ain Chock- Hassan II University, Casablanca, MAROC

Correspondence to: Najat Toufah, PhD Supply Chain Management and Operations Management at the Faculty of Law, Economic and Social Sciences, Ain Chock- Hassan II University, Casablanca, MAROC.

| Email: |  |

Copyright © 2020 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

The global crisis caused by the Covid-19 pandemic is one of the most exceptional crises that has engulfed the wide world. In fact, this health crisis has quickly evolved into a social and economic crisis, which has been affecting different sectors across countries. Its impact actually differs from economic sector to another. The aim of this paper is to explore the relationship between the integration of supply chain management (SCM) and the level of impact of this current pandemic crisis on Moroccan industrial firms. The benefits of SCM for maintaining the Moroccan firms’ profitability should be pointed out. More especially, it could be possible that firms’ awareness of the advantages of supply chain management in minimizing the incertitude around business environment, promotes collaboration and the development of new business partnership, and eventually enables the firm to meet its main objective of reducing, as much as possible, the risks posed by this pandemic crisis. These effects are studied through an empirical study; a survey questionnaire was conducted within Moroccan firms to check the impact of supply chain management integration on Moroccan firms’ resistance in this specific context of the global crisis. The present paper aims to be a preliminary study to initiate an investigation regarding the evaluation of the impact of supply chain integration on the industrial firms’ performance especially in the current context of the pandemic crisis. A pilot study was conducted. The survey questionnaire used as a primary data collection method was completed by industrial Moroccan firms. Our aim is to analyze the correlation between several supply chain integration specificities as the origin of raw material, partners’ up stream and down stream, and their effect of the firms’ resistance and robustness to resist change through the analysis of the impact level of the Covid-19 crisis on firms. The result shows the interest in the establishment of special collaboration between firms and their partners’ upstream and downstream chain and its resistance to the current crisis. Moreover, this study revealed how aware are the industrial Moroccan firms to the necessity to implement exceptional process to adapt the firms’ flows to the new context of exchange. This study outlines the finding of the survey questionnaire analysis, which meant to analyze some specific relationships related to the firms’ global environment organization and to the supply chain adaptation to this changing crisis context. Another limit of is study is the fact that the analysis is restricted to industrial firms only instead of including all Moroccan firms which are also affected by this pandemic crisis. Yet, it is to highlight the need to fix a consistent sector for focused research analysis. The present study provides a strong basis for analysis of the relevance of the supply chain integration for enhancing firms’ resistance and competitiveness within and after the crisis.

Keywords: Covid-19 pandemic crisis, Supply chain management, Supply chain integration, Supply chains, Profitability

Cite this paper: Najat Toufah, How Important is Supply Chain Management for Minimizing the Impact of Covid-19 on Moroccan Firms’ Profitability, Journal of Logistics Management, Vol. 9 No. 2, 2020, pp. 31-38. doi: 10.5923/j.logistics.20200902.02.

Article Outline

1. Introduction

- Morocco is one of the few countries whose anti-Covid19 strategy has prioritized the safety and the well-being of the citizens. To contain the spread of the virus, a forced containment was adopted and many considered it as courageous decision due to the huge impact it would have will have on Moroccan economy (HCP, 2020)1. Moreover, a solidarity fund was created by the King of Morocco and his people donation to help the people worst affected by the imposed lockdown, but implicitly it is a way to support sustainable consumption and thus minimize the negative impact of this crisis on some of the key Moroccan economic sectors. This can be considered as one of the short-term economic policies that aimed to support some of the vulnerable people and economic sectors. The goal of all of the early decisions making was to first to manage the ongoing crisis and implicitly to take necessary time to understand and analyze the economic sectors resistance and then hopefully prepare as well as possible for the development of an integrated post-crisis recovery strategy. Overall, the crisis follows five main stage, understanding, reacting, adaptation, control and finally adjustment and return to normalcy, of course, the duration of each stage varies in space and depends on the speed of reaction and the relevance of the primarily measures for each country.Nowadays, the world is facing a general crisis, which has threatened all countries’ economic stability. In Morocco, the consequences of this Covid-19 crisis are already felt in many economic sectors (HCP)2, it is reflected mainly in the tourism sector, which showed a sharp drop in its results because of closing borders with all countries, and so for the moving people between Moroccan cities; that is a forced containment, which is one of the deployed measures to keep such situation under control. The same holds true for the import and export activities, creating a decrease in the volume of production caused by the decrease of the volume of raw material importations which in turn affected negatively the export sales volume. These various aspects have generated together a widespread crisis. Our purpose is to ensure a sustainable client value creation and firms’ profitability in this specific context. The Supply chain management is highly advocated to be horizontally and/or vertically integrated, several possible ways for supply chain integration and the selected choice depends on firms’ capacity to share information and their results, to synchronize their process and developing jointly improvement solutions (D. Power, 2005). Of course supply chain management is another way to collaborate with firms’ upstream and downstream chain links it is an organization initiative to standardize communication and business process which leads to synchronizing flow with and between all chains’ links. This make possible to target the weak chain links to be the improvement area. In the next part we will first define the supply chain to next analyzing how beneficial is the supply chain integration for targeting and improving business weak area and hence creating and delivering value to the customer, for the last section is it dedicated to analyze the Moroccan industrial firms’ measures to evaluate how it leads to minimizing the covid-19 impact and quick recovery for these industrial firms.

2. Supply Chain Management

- Nowadays, Moroccan firms in this context of the economic crisis, which is characterized by a sharp economic slowdown, cannot work in isolation to its suppliers or other of its links from the upstream or downstream chain. Supply chain organization become absolutely necessary for the survival of the industrial firms specifically. To reduce the uncertainly surrounding the economic environment is it worth looking for strategic collaboration with the main chain partners from the suppliers of the suppliers to the final consumer. It can be beneficial in this crisis context to unify and harmonize the firms’ strategic objectives as well as those of its suppliers and key clients. This strategic supply chain integration goes beyond sharing information, resources and rewards between it links chain but also risk sharing, all of this can be possible by formalizing agreement, contract or other type of arrangement between chain partners. (Burgelman et Doz, 2001; Fuchs et al, 2010; Johnson, 1999)The supply chain is a set of the activities associated with moving goods from the raw-material stage through to the end user. This includes the organization of all activities linked to managing supply and demand, sourcing raw material, spare parts and other components, manufacturing and assembly, warehousing and inventory tracking, distribution across all the channels for the purpose of delivering on time the right product to the final client. (Rhonda R Lummus, R. J. Vokurka, 99)Mostly, firms’ success depends on its ability to meet customer needs and good profitability. Hence, Cost, speed and innovation are the main keys leading to firms’ success.

3. Supply Chain Management is a Way to Integrate Key Business Process

- For the supply chain strategies is it important for the firm to find a way to manage, integrate and coordinate both internal and external processes with focus to serve the final customers. It is worth highlighting in this section that the supply chain organization and integration vary greatly according to the level of internal structure organization and then to the enterprises’ ability to coordinate and synchronize their flow with each link in the value chain. The supply chain can encompass three or more entities directly involved in the upstream or the downstream chain until the final customer (Felea, Ablastrpiu, 2013), its complexity degree can be summarized as below: Direct supply chain: it is a channel that encompasses the company and it suppliers from the downstream and the customer from the upstream flow. This is easy to manage and very appropriated for less experienced firms.Extended supply chain: this later integrates in addition to the extended supply chain, the supplier’s supplier and the customers of the immediate customer.Ultimate supply chain: for this degree of supply chain complexity, the ultimate supply chain includes all organization involved in the upstream and the downstream flow of products or services, which means the integration of the ultimate supplier to the ultimate customer. This structure is beneficial for firms’ flexibility and mostly in case of detecting products no-conformity it makes easier to target the origin of dysfunction and more makes the product recall highly fluent and efficient. Moreover, it is highly helpful to specify the need of adequate infrastructure to facilitate such organization. The relevance of the communication and information system is just as important for the supply chain integration, and so to integrates process from sourcing, manufacturing, distributing across the supply chain and then to the final customer (Cooper and all 97). There is no best choice; each company selects according to its means, the product features, skills and the appropriate level of supply chain integration. Of course for the less experienced ones, it is worth selecting the least complex structure and formalize by modeling business processes as simple and straightforward as possible to ensure processes understanding and their use. In this context of the global crisis, to minimize the uncertainly surrounding flow synchronization, and more about sharing information among supply chain partners, we shed light in this part on the value of cooperation and collaboration for firms’ to increase their responsiveness and to master their global environment. Of course with the objective of enhancing control of supply and distribution channel, partnership and strategic alliances, co-operative and developing close relationship with chain links, across boundaries as the upstream suppliers and downstream customer are highly required.

4. The Main Pillars for Successful Supply Chain Integration

- Today, each company needs to be reassured against running out of the raw material and spares part stock, and the supplier need to be reassured in case of there is no contract guaranteeing that the manufacturer will order continually in this time of crisis which allows him to maintain its activity even in a limited manner throughout the period during which the market has undergone dramatic change and characterized by weak domestic and export demand. Collaboration in these days is a way for mutual support and risk reduction (J T. Mentzer et al., 2001). Furthermore, the improvement in information availability allows firms to manage and control the flow in the operating systems mostly the inventory control and the scheduling system, which are needed to reach the firms’ objectives (T.P. Stank et al. 2001).To survive in this constantly changing and uncertain, Moroccan industrial firms need to commit to business process management implementation. We don’t focus on this paper on competitiveness or enhancing firms’ performance but our objective is to ensure company stability and maintaining its profitability thanks to business reorganization. It goes without saying that supply chain management has a positive effect on firms’ performance. This relationship was widely hypothesized in many scientific papers. (Armistead and Mapes 1993, Tan 2002, Kenneth W. and Dwayne 2008) research confirms a highly positive correlation between supply chain integration and manufacturing performance. Our purpose is to evaluate the effect of adopting or adapting supply chain management to the new pace of doing business which did slow down somewhat, however, in the last recent months. It would be rational for industry to adapt their production volume to the market capacity, and hence ensuring business sustainability in this exceptional context of the global crisis.It is appropriate to find the adequate way to organize the supply chain allowing firms to sustain their competitiveness, efficiency and effectiveness. First of all, the BPM is an imperative for any firm seeking to sustain its growth whatever line of business they are belonging to.

4.1. Business Process Management

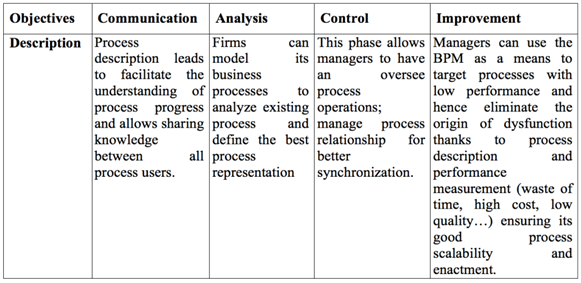

- The business process management is a holistic approach management, which supports the process in its complete lifecycle; from modeling, analyzing, monitoring and optimization. Business process modeling is the main pillar for business process management, the table 1 encompasses the main firms’ objectives by modeling its business process (W. Luo, A. A. Ting, 99).

|

4.2. Collaboration and Cooperation

- Nowadays, establishment of cooperative linkage with supply chain partners involved with developing partnership and are committed to be part of a not stop improvement mission is recommended3. Of course the process of improvement never stop by reaching high level of performance, but each arrival point constitutes the departure point for the next stage. It is necessary highlighting the main stage of partners’ integration; only trust and partners’ commitment define the level of this integration. Here after we summarize the main difference between cooperation and collaboration.“Cooperation emphasizes the need to integrate functional silos a views these units as interdependent parts charged with meeting the end-user customers’ needs.” (R. E. Spekman et al., 1998)Of course, cooperation is the starting point for the supply chain management; at this stage partners exchange bits of essential information. With cooperating firms’ partners are engaged for customer satisfaction but it is not sufficient for real supply chain management. Supply chain management relies on partner commitment and willingness to ensure sustainable growth not in isolation but with chain partners. The working together is not possible only if trust exists among all partners. This is the crucial factor to forming collaboration and hence working closely. The collaboration approach: the main partners openly share information that facilitates their ability to jointly meet users’ requirement. And with collaboration, companies are more flexible to handle sudden change and even to take bold/emergency measures that are beneficial for all chain partners (R. E. Spekman et al., 1998). The firms have a clear view of it partners’ goal, it allows adapting it strategic objectives to its key chains’ partner. This collaboration leads to developing interactive relationship with chain links where partners working together to achieve common objective or to solve problems which can affect all other chains’ links. It should be noted that each company can be part of many other supply chains and hence the complexity level of managing flow crossing this latter can be higher. In fact, companies are facing an economic crisis following the spread of the covid-19. This crisis has increased the negative effect of firms’ specialization and more the weak of managing the external interactions of the company with suppliers and customers. Firms underestimate the benefit of collaboration and were unaware of the importance of suppliers and customers’ integration for obtaining organization resistance and to mitigate risks during disasters. Despite the huge impact of the Covid-19 on economic and social sectors, companies are called upon to make hard decisions, timely acting is crucial to minimize damages and avoid bankruptcy.

5. Analysis of Moroccan Firms’ Special Measures Undertaken in the Disaster Context (Covid-19)

- (List of measures over the survey questionnaire and official communication of the Moroccan Minister of Trade and Industry Mly Hfid El Alami)Moroccan industrial firm quick supply chain adaptation: Moroccan firms are aware of the necessity to the operating system adaptation; many of them come up with measures that would have helped maintain their business running such as: The e-commerce instead of the traditional way of selling goods. E-commerce is an effective solution at this point in time, because of the forced containment of the population. We have noticed a growth in activities like “home delivery business” that was advantageous both, because it is more beneficial for compensated the lowest number of market visitors, as it encourages buyers to order online instead of moving to where are the point of sales and also to avoid any potential cluttering on the point sales and hence protect people against possible contamination. Thus, the e-commerce has contributed not only to ensure company stability by keeping contact with their client, but it has contributed even to reduce effectively the spread of the Covid-19.Innovated and customized offer: In Morocco, many textiles and aeronautic companies have adapted their operating channel to produce customized product and hence respond quickly to customer requirements at that moment of crisis; we noticed the need of news products not only by consumers as a face mask and gloves also liquid disinfectant for hand, clothes and surface, but also new domestic demand from the health sector, the aeronautic companies have produced locally for the first time some of the medical material requested by the health sector as the resuscitation equipment and other respiratory assistance equipment. It is not only quick adaptation of their production chain but also innovative offer. These are some of the innovative product introduced during this time of crisis and the list is not exhaustive.Co-operation and collaboration are frequent to stay resilience when crisis occurs. One of the negative effects of this crisis is the lack of communication and the incertitude surrounding the business environment. For that, many firms developed interactive relationship with its partners who are able to share information and work collaboratively to solve common problems, it means in this context, firms are able to pull themselves together in order to successfully cope with change. The most telling example is the integration of the downstream partner to organize the logistics chain. We highlight in this point the relevance of E-commerce that actually encouraged partnership for the goods delivery activity where many «prêt à porter», hypermarkets and catering business cooperate with intermediary to deliver their client (GLOVO, JUMIA,…).“Tele-working” many companies have early adopted this new way of work for positions that do not require a physical presence. In fact, the informational BPM perspective allows firms to know at any time, who does what, when, where and what are the resources needed to accomplish its tasks. Thus, by analyzing the functioning of several firms’ departments many of them may maintain their functioning thanks to employee’s remote work. This teleworking is highly beneficial for the commercial department to keep contact with the market, enabling them to manage client enquiries at a faster rate. Of course many other companies’ department adopt this new method of working as the finance and accounting, human capital, remote support and many more, these are just a few example of the more successful among others. Modeling exceptional processes: in this context, firms are facing both slow down demand and organizational issue. It is worth noting that it is no longer possible to keep the same flow organization and business management as it was done before. Many process adjustments are advocated to adapt the supply chain internal structure to the external environment. Business process management is one of the crucial pillars for business organization and within this context on pandemic crisis it is evident to adapt firms’ key business process to the new pace and way of work and include some of the specific arrangement and special authorization procedure established since the onset of the crisis and hence keep business going through the firms’ flow synchronizing to its partners and managing wasting time and low productivity as much as the demanding client with it specific requirements.

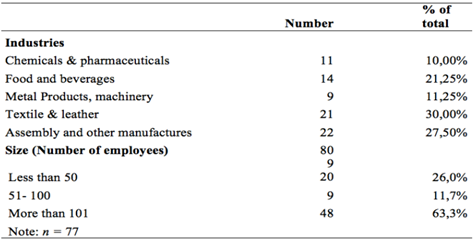

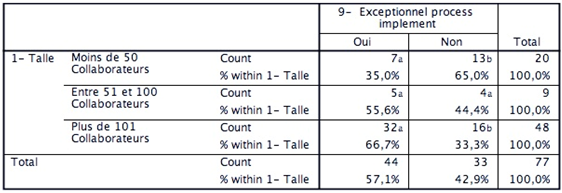

6. The Survey Description: An Investigation Analysis

- For the survey questionnaire of this present study, four main parts are considered: The first is linked to global information of the surveyed firms; location, size and activity sector. Which followed the topical main part with open question.The second part is linked to the supply chain organization; supplier location, market location and exceptional process modeling implementation. The data collection was ensured with dichotomous question. For the third part it aims to identify the quick measures adopted by the firms in this current crisis context, as far as the last forth part, the need is to check the firms level of the Covid-19 impact on the profitability of the industrial firm and then the level of the estimated resistance of the firm. For this part Likert Scale questions was mobilized to check the level of resistance of industrial firms and the level of impact of Covid-19 on the profitability of the surveyed industrial firms.The sector studied The area studied includes only industrial firms. Our choice is based upon several specificities of our questionnaire survey, as the supplier of raw material and good delivery partners’ (physical flow) integration. A total of 200 questionnaires were distributed, from the stratified random sample of manufactures, 77 have completed the survey, for response rate 40%. Our population covers all areas of industry, and the demography of respondent organization is shown in the table 2 below.

|

7. Result and Discussion

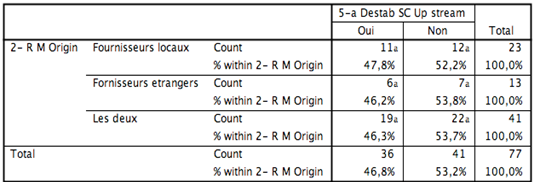

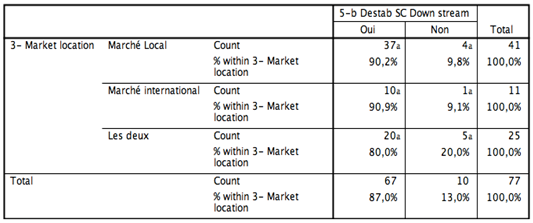

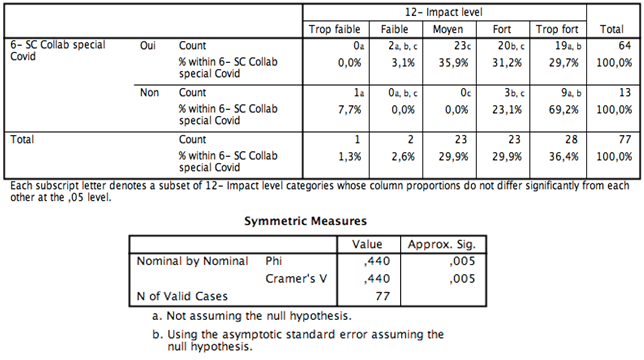

- By conducting this survey, our aim is to conduct a preliminary investigation of industrial Moroccan firms conditions and to check how they react to this acute crisis. Also to check if there is any primary impact of this pandemic crisis on the SC organization to finally verify the impact level of the Covid-19 on industrial firms linked to the firms’ size. In order to check how confident are the industrial firms and their ability to resist to this general crisis to ensure the business ongoing sustainability. The following illustrates the distribution of the surveyed industrial firms with regard to the origin of the raw material and market location to check if it affects the stability of their supply chain and disruption of workflow.

|

|

|

|

8. Conclusions

- To conclude, Moroccan firms have demonstrated their ability to quickly adapt their supply chain to the covid-19 outbreak-changing context. They are aware of the necessity to work in collaborative manner with supply chain partners to mitigate the uncertainty of the crisis consequences. This paper presented a combination of practices of supply chain integration and some of the immediate solutions adopted by the Moroccan firms to sustain the continuity of the workflow. This early study examination is to complete in future papers to examine deeply the relations between selected variables of impact level, suppliers’ location, market location, Special collaboration within the Covid-19 crisis, level of resistance of firms and immediate solution implementation (as E-commerce, Productivity reduction and Product innovation, new distribution channel).

Notes

- 1. Rapport: Pandémie Covid-19 dans le contexte national: Situation et scénarios Juillet, 2020 (www.hcp.ma)2. Rapport: Principaux résultats de l’enquête de conjoncture sur les effets du Covid-19 sur l’activité des entreprises, www.hcp.ma3. Kristian Rotaru Carla Wilkin Andrzej Ceglowski, (2014), "Analysis of SCOR’s approach to supply chain riskmanagement", International Journal of Operations & Production Management, Vol. 34 Iss 10 pp. 1246 -1268

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML