-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Journal of Logistics Management

2020; 9(1): 17-22

doi:10.5923/j.logistics.20200901.03

Factors of Sesame Supply Chain Management Practice in Ethiopia

Meaza Getnet1, Minda Yirga2, Tagay Firde2

1Department of Marketing Management, Wolkite University, Ethiopia

2Department of Management, Wolkite University, Ethiopia

Correspondence to: Tagay Firde, Department of Management, Wolkite University, Ethiopia.

| Email: |  |

Copyright © 2020 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

This is a study with an objective of assessing the Factors of Sesame Supply chain Management practice in Ethiopia. As sesame is an oil seed that is generating the lion share of foreign currency for Ethiopia, the study will have bigger significance in evaluating and identifying the significant factors of the sesame flow from origin/farm to exporting firms in the country. The study has targeted the whole chain participants which are large scale registered farmers, traders who collect sesame from the farmers, Ethiopian Commodity Exchange an authority controlling the overall flow of export items in the country and finally the exporters. Using primary data mainly questionnaires collected from 336 respondents, the research objectives have been achieved and found that the logistics system, chain members integration and operational capacity of each chain element participants are significant factors facilitating the flow of sesame from the farm to its export point.

Keywords: Logistics system, Chain members’ integration, Operational capacity

Cite this paper: Meaza Getnet, Minda Yirga, Tagay Firde, Factors of Sesame Supply Chain Management Practice in Ethiopia, Journal of Logistics Management, Vol. 9 No. 1, 2020, pp. 17-22. doi: 10.5923/j.logistics.20200901.03.

Article Outline

1. Introduction

1.1. Background of the Study

- Sesame is believed to be the native oil seed to the African savanna, however, its domestic production was recorded in the Middle East and India since 4000 years ago (Ayana, 2015). Globally, the top largest producers of sesame are Myanmar, India, China, Sudan, Uganda and Ethiopia (Girmay, 2018). Evidences also indicated that Ethiopia ranked third in Africa in terms of sesame production (Hagose, 2017; Wijnands, Biersteker, & van Loo, 2009).In terms of export potential, Ethiopia is the third world exporter of sesame seeds after India and Sudan (Alemu & Meijerink, 2010; Temesgen, Gobena, & Megersa, 2017).Sesame is the second largest export item in Ethiopia next to coffee from which the country gains large share of foreign currency. (Ministry of Trade, 2018/19) Being cultivated in the western and North western part of Ethiopia, Sesame flows through different chains to be exported out the country. These chains elements are the large scale farmers, the traders, ECX and the exporters on which this study has highly relied on. Sesame supply chain management has been studied in depth even though the factors associated to its performance have been ignored by many researchers. Supply chain management of such products has been evaluated from the point of many factors from which the dominant ones are the production capacity of the origin/farmers in our case/, the logistics system which comes from the transportation, warehousing and information sharing aspect, the chain environment through which the items flow related to the climatic conditions, social and political situations and finally the integration among the chain members of the item under consideration which is sesame in our case. Ethiopian sesame supply chain is regulated by the government body, ECX, with a role of promoting sesame trade and regulating the overall supply chain that sesame passes through. ECX is authorized body playing the role of assuring quality of the sesame traded, facilitating quality warehouse, smooth process flow/system and protecting the participants having forecasted market and environmental conditions in the country. (ECX, 2019)

1.2. Statement of the Problem

- Unlike that of Coffee which is largest export commodity in Ethiopia, Sesame supply chain has been found to be too slow and unfitted with the expectations of the government in the country. In terms of export potential, Ethiopia is the third world exporter of sesame seeds after India and Sudan (Temesgen, 2017). Sesame is the second major export cash crop in Ethiopia, next to coffee (Abebe, 2016). According to Food and Agriculture Organizations (FAO) (2015), Sesame is an important cash crop and plays a vital role in the livelihood of many people in Ethiopia. However, a number of challenges hamper the development of the sesame sector along with the supply chain (Berhe, 2019) Therefore, this study is meant to evaluate the Factors of Sesame Supply chain Management practice in Ethiopia.

1.3. Hypothesis

- In order to address the problem specified, the following null hypothesis has been developed.√ Production/operational capacity participants has significant effect on the Sesame Supply Chain Management practice in Ethiopia √ Logistics system has significant effect on the of Sesame Supply Chain Management practice in Ethiopia√ Chain member integration has significant effect on Sesame Supply Chain Management practice in Ethiopia√ Chain Environment has significant effect on Sesame Supply Chain Management practice in Ethiopia

1.4. Objectives of the Study

- The main objective of this study is to evaluate the Factors of Sesame Supply chain Management practice in Ethiopia specifically being target to evaluate the roles of logistics system, operational capacity, chain members’ integration and chain environment on the sesame supply chain management practice in Ethiopia.

1.5. Scope of the Study

- This study is mainly targeted at sesame supply chain management factors in Ethiopia specifically on the north and western part of the country from where the main sesame production starts. Additionally, the study has incorporated the traders and exporters in Addis Ababa who are the chain elements dwelling in the capital while working with the farmers and ECX in the north and western Ethiopia.

2. Review of Literature

2.1. Definition and Concepts of Supply Chain Management Performance

- Supply chain management has been defined by scholars of who have common means with Martin Christopher, 2011 who has stated supply chain management as the management of upstream and downstream relationships with suppliers and customers in order to deliver superior customer value at less cost to the supply chain as a whole. Supply chain management is applied by companies across the globe due to its demonstrated results such as delivery time reduction, improved financial performance, greater customer satisfaction, building trust among suppliers, and others. Supply chain management performance is defined as the operational excellence to deliver leading customer experience (Simchi-Levi et al., 2003). This shows the supply chain is assumed to be performing better whenever the customers are being delivered with the product under consideration without major interruption and flexibly with changes in the demand level of the product that the customers demand.

2.2. Factors Affecting Supply Chain Management Performance

- Even though the factors affecting supply chain management performance vary from product to product, the most commonly referred ones are manufacturing capacity, logistics system, and integration among the chain participants, environmental factors in which the participants reside in.

2.2.1. Mannufacturing Capacity

- Manufacturers create value by producing and marketing product/service bundles to either end customers or intermediate members of the supply chain (Bowersox et al. 2007). According to Benetto and et al, 2009, manufacturing which is the first supply chain point, next to the raw material sourcing, is expected to be one providing quality and being flexible in providing what and how much the customers are in need of.

2.2.2. Logistics System

- Businesses in all types of industries are placing far greater emphasis on the design and management of logistics processes and the integration of those processes upstream and downstream with those of suppliers and customers, Donalde waters, 2010. Logistics system is then defined well by most writers from whom the common definition by Bowersox et al. 2007 states that logistics is a flow of material between two points including the storage and geographical movement to be underlined in any logistical systems.

2.2.3. Integration among Chain Participants

- Supply chain integration as defined by DrDawei Lu, 2011, is a cross organizational interaction and exchange between participating members of a supply chain. This integration is stated to be the key for performing the overall delivery of a product from the point of its origin to the point of the end consumption, consumers.

2.2.4. Chain Environment

- Companies need to implement new strategies that allow them to deal with environmental uncertainties in the supply chain (Wu, 2006) in order to perform in a proficient manner. The environment includes the natural environment the participants reside in and the government support and regulations.

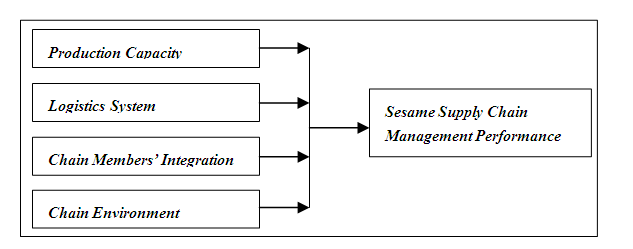

2.3. Conceptual Frame Work of the Study

- For the purpose of addressing the objectives of this study, after reviewing certain literature on the supply chain management performance, here the researcher has developed proper conceptual framework on the factors in the sesame supply chain management practice in Ethiopia.

| Source: developed for this study |

3. Material and Methods

3.1. Population and Sampling

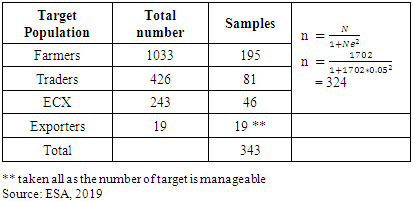

- The target of this study are the sesame supply chain participants in Ethiopia who are the farmers, traders, ECX and the exporters whose number has been given as the following along with the proportional samples derived from the total population using Yamane Taro’s formula displayed where n stands for the sample desired, N for the total population at hand and e stands for the error margin.

|

3.2. Data Types, Collection Procedures Analysis Methods

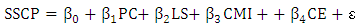

- Primary data mainly questionnaire has been distribute to the total of 343 target. The questionnaires were distributed randomly to the respondents to avoid bias and 336 questionnaires were full returned having desired responses.The collected data have been coded and fed on SPSS 20 version form which descriptive and inferential analysis has been obtained. The descriptive analysis was made in terms of standard deviation, min and max response rate to evaluate the respondents’ evaluation of the chain as a whole from the point of pre-stated factors and chain performance. Inferential analysis mainly multiple linear regression has been used to measure the effect of the independent variable/factors of sesame supply chain/ on the dependent/sesame supply chain performance in Ethiopia.The mathematical model for the multiple linear regression of this study has been presented here, where SSCP represents sesame supply chain performance in Ethiopia, LS stands for logistics system, CMI stands for chain members’ integration, CE for chain environment and PC is to mean production capacity of the farmers/operational capacity of the other chain elements.

stand for the coefficient of the variables in having contribution to the sesame supply chain performance in Ethiopia while

stand for the coefficient of the variables in having contribution to the sesame supply chain performance in Ethiopia while  stands for the expected tolerable error margin of the model under consideration.

stands for the expected tolerable error margin of the model under consideration.

4. Results and Discussion

- From the sample of 346 respondents 336 ones have returned well written responses which are used to evaluate the major and specific objectives of the sesame supply chain performance factors in Ethiopia. All the respondents were from the highly concerned staff about the flow of sesame throughout the chain and they are the ones chosen based on their experience which is a minimum of a year stay in their current unit.

4.1. Descriptive Analysis

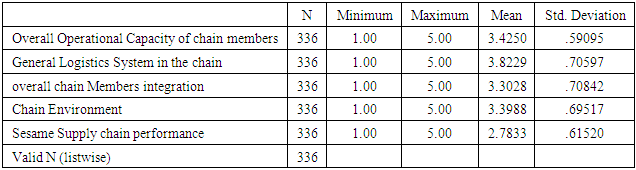

- Sesame supply chain management practicehas been investigated from the influencing factors indicated as Operational capacity of the chain members, Flow Facilitating Logistics system, the chain members’ integration and their environment in which the chain operates. Each of these factors and the sesame supply chain performance has been evaluated through detailed sub variables and the overall average view has been shown with the SPSS output below.

|

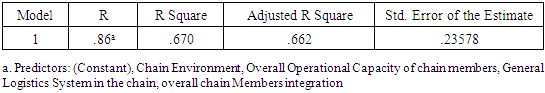

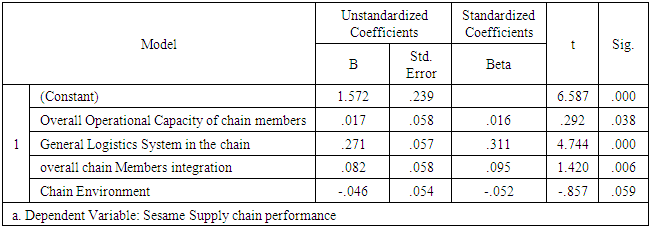

4.2. Regression Analysis

- As the sesame supply chain in Ethiopia has been rated to perform lesser this study has tried to answers what the role of the factors is in affecting the chain performance. Therefore multiple linear regression has been run through SPSS and the following out comes have been drawn.

|

|

5. Conclusions

- Being based on the data analysis made in relation with the objectives of the study the following major conclusions have been reached.Logistics system has been proving to have the highest effect on the performance of sesame supply chain in Ethiopia. Logistics system which is the sum total factor of material flow, information sharing, transportation and warehouse management is bigger factor determining whether the performance of sesame is better or not in general. Therefore the stronger the information sharing, material flow, transportation and warehouse management is made to be, the better the performance of sesame supply chain can be concluded in this sense. The second significant factor proved is, chain Members integration which is expressed in terms of chain members joint planning culture, communication, feedback taking, evaluation and information reliability among has been found to have significant contribution to the performance of sesame supply chain in the country. The third significant contributor to the performance of sesame supply chain management is operational capacity of sesame supply chain participants in Ethiopia seen form the perspectives of meeting quantity and quality requirement so the other chain elements, flexibility to raise or lower their supply and consistency of deliver to their respective customers in the chain.Finally, chain environment was found to be insignificant factor contributing lesser to the performance of sesame supply chain performance in the country.In conclusion, as these contributors have significant role in the sesame supply chain performance of Ethiopia, must be given emphasis by the sector leaders in improving their practice to help the oilseeds export in the country as it is the base for foreign exchange generation.

6. Recommendations

- Logistics System an organized way used to plan, organize, coordinate, and implement the bridging of the dimensions of time and space within a supply chain system. Logistics is thus one of the most important functions of the economy. These ranges from the procurement of raw materials to their processing and to the delivery of the goods to the end-user or throughout the chain of a product flow (Harald Gleissner and J. Christian Femerling, 2013). This shows how much we must emphasize on the logistics system as key for the better performance of the whole chain in which the logistics system exists. Therefore the government as a primary beneficiary of the sesame export must control and facilitate the transportation availability and safety, warehousing infrastructures at specific nodes area and develop information exchange infrastructures thought the areas of sesame supply flow. Chain members’ integration is the other important contributor to the performance of sesame supply chain performance. Integration is the best tool of facilitating stronger supply chain flow in supporting joint planning, action as well us commonly agreed evaluation of operations among the chain elements (Tagay F. and Lamesgin D, 2019). A such the sesame supply chain elements shall be advised to jointly plan their respective demands, supply abilities, feedback giving and taking procedures and the like to let succeed in this operation.The other contributor of better supply chain performance is production/operation capacity of chain elements in meeting the demands of the respective elements they serve. According to Kenta Tomura, 2015 many supply chain elements failed to plan and raise their production capacity in a way it meets the requirements/demand of the other demanding chain element and the final output of the supply chain fails lately as a result of the poor production capacity of such firms. Therefore our sesame supply chain members must be motivated to plan and make their production/operation capacity competitive to each other in a way it supports the final goal of the sesame supply chain.

7. Future Research Directions

- This study has final concluded that the major significant factors influencing the sesame supply chain management practice are logistics system, operational capacity and chain members’ integration whose effect accounts to 66.2% on the practice indicating that the remaining 33.8% are factors whose effect has not been predicted yet and we recommend other researchers to address untouched factors here in this study.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML