-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Journal of Logistics Management

2019; 8(2): 45-50

doi:10.5923/j.logistics.20190802.03

Integration as Tool of Supply Chain Management and Its Effect on Performance of Private Road Construction Firms in Ethiopia

Tagay Firde Abebe1, Lamesgin Desalegn2

1Department of Management, Business and Economics College, Wolkite University

2Department of Civil Engineering, Engineering and Technology College, Wolkite University

Correspondence to: Tagay Firde Abebe, Department of Management, Business and Economics College, Wolkite University.

| Email: |  |

Copyright © 2019 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

This is a study on the role of supply chain integration on the overall performance of private road construction firms in Ethiopia with a main intention of assessing the effect of supply chain participants’ integration in facilitating the overall performance of these firms in Ethiopia. In order to achieve this objective Private road construction firms in Ethiopia, who are the supply chain destinations and other main supply chain elements including construction input producers, distributors, transporters and agencies having stronger link with these contractors totally who are 60 in number have been targeted in this study. In order to achieve this objective, the researchers have used primary data mainly questionnaires distributed to all the chain participants in consideration. Finally the major findings have shown that information sharing, transportation, and the supply chain participants’ relation are proved as the main factors resulting in the deviation of the private road contractors’ performance in the country.

Keywords: Supply chain integration, Performance

Cite this paper: Tagay Firde Abebe, Lamesgin Desalegn, Integration as Tool of Supply Chain Management and Its Effect on Performance of Private Road Construction Firms in Ethiopia, Journal of Logistics Management, Vol. 8 No. 2, 2019, pp. 45-50. doi: 10.5923/j.logistics.20190802.03.

Article Outline

1. Introduction

1.1. Background of the study

- Construction of road infrastructures in Ethiopia can be traced back to late 19th century when cars were imported and used by the royal family and road construction has grown quickly since then. Currently more than hundreds of thousands Kilometers of roads in urban and rural areas are constructed in Ethiopia. (Ethiopian Roads Authority, 2018)Supply chain, from general point of view has been defined as ‘the network of organizations that are involved, through upstream and downstream linkages, in the different processes and activities that produce value in the form of products and services in the hands of the ultimate customer which can be specifically seen in our case as the flow of information and materials from road construction input producers to the road construction firms/contractors. (Browersox, 2002)The Ethiopian road construction firm’s orientation towards SCM is traditional and poor that lacks substantial indicators of an integrated, efficient and effective supply chain management. And they also have great problem on time delivery of materials required from the suppliers (Dibaba, 2015). Even though a number of studies have been conducted on challenges of road construction supply chain management practice, there is no known study featuring supply chain participants integration in road construction projects in Ethiopia. This study therefore seeks to bridge this gap by examining the integration of supply chain management practice from the view of integration of the input suppliers of Ethiopian road construction firms.

1.2. Statement of the Problem

- A study conducted in Ethiopia on 24 projects by (Nega, 2008) Shows that 80% of the projects are experiencing delay in finishing road construction projects due to discontinuing supply of input resources required and this in turn has led them to cost or extending projects and continued legal accusation from the customers mainly Ethiopian roads authority. On the other side researchers like Nega F and Bethelhem K has identified no problem in the availability of input for the construction sector and even Ethiopian Ministry of trade has listed so many construction material producers and importers and that is why here the researchers has determined to ask a question as “if there is adequate road construction materials producers and importers, why the road construction sector private firms raise poor supply of construction materials as a reason for their delay in their projects?”. This could have been from the construction suppliers integration in having efficient flow of materials throughout their chain to deliver the final users/contractors get adequate supply of input for their timely accomplishment of their projects. Therefor the researchers have evaluated the potential effect of road construction material supply chain participants’ integration as a tool for road construction firms performance in Ethiopia in this study.

1.3. Objectives of the Study

- General ObjectiveThe main intention of this study is to analyses the supply chain participants’ integration as tool for the chain management performance in the private road construction of Ethiopia with special reference to contractors and their input material suppliers.Specific Objectives√ To evaluate the role of information sharing among the supply chain participants on the performance of private road constructors of Ethiopia. √ The role of material flow on the overall supply chain management performance in case of.√ To evaluate the role of chain participants relationship management practice on the chain performance of private road constructors of Ethiopia. √ The role of transportation management as a tool for integration on the performance of private road constructors of Ethiopia.

1.4. Scope of the Study

- This study has mainly targeted on the integration of road construction materials supply chain participants integration and its role in facilitating timely and less costly performance of road construction firms from the point of contractors in Ethiopia. The study has assessed the supply chain from the point of contraction raw materials producers, distributors, transporters and the users/road construction firms in Ethiopia.

2. Review of Related Literature

- The Notion of Supply chain management Business operations of this time are dependent on the resources that they are delivered to them from the suppliers. The main problem according to Donald J. Bowersox and etal, 2002, comes from the way the input materials are delivered to the final users who are further expected to deliver the finished goods to the end users. According to these authors, firms are claiming for the late delivery of inputs due to disintegrated flow of information and material among the supply chain participants of the business in target. Furthermore, these authors have underlined that while internal integrative management is important to success, the firm must also integrate across the supply chain. To be fully effective in today's competitive environment, firms must extend their enterprise integration to incorporate customers and suppliers. This extension reflects the position of logistics in the broader perspective of supply chain management.Martin Christopher on his fourth edition book in 2011 has clearly showed the supply chain management along with the need for it as “The management of upstream and downstream relationships with suppliers and customers in order to deliver superior customer value at less cost to the supply chain as a whole.” Here it has been assured that most organizations have viewed themselves as entities that exist independently from there and indeed need to compete with them in order to survive. However, such a philosophy can be self-defeating if it leads to an unwillingness to co-operate in order to compete. Behind this seemingly paradoxical concept is the idea of supply chain integration.Supply Chain IntegrationAccording to a hand book of USAID| Deliver Project By supply chain integration, we mean a performance-improving approach that develops seamless linkages between the various actors, levels, and functions within a given supply chain to maximize customer service. The objectives of supply chain integration are to improve efficiency and reduce redundancy, thus improving product availability and, often, reducing costs (USAID, 2011).Generally we can recognize that supply chain integration is closer supplier and customer operational relations for the better of the whole chain elements with a main intention of satisfying end users through timely delivery of the products/ projects with the required level. The main question here is that how could we develop stronger integration among the chain participants of a given business specifically in case of the road construction sector facing longer delay of completion in Ethiopia (Lu, 2011). Supply chain integration can be seen from many points of view information flow among the chain participants, material flow, and relationship management practice and transportation services efficiency in the road construction sector firms. Information SharingInformation sharing in the supply chain is regarded as the exchanging of information regarding the demand from the customers and the supply by the producers and suppliers. Information sharing can substantially reduce supply chain uncertainty and results in less inventory and shorter, more consistent performance cycles. The visibility can also assist in new product development by allowing suppliers, manufacturers, and even customers to design, refine, and source components prior to initiating production. According to Donaldê Waters, 2010 and others information sharing, if handled well through accuracy and reliability, can lead to stronger integration in the chain in turn resulting to the better performance of the final firms operation.Material Flow Material flow happen in the form of movement of raw/semi-finished input to business firms and finished goods going out to end users/customers (Lu, 2011) In the concept of materials flow, the first one is flow consistency in terms of delivering and being delivered with same amount of materials is helpful for the regular operations of business firms while the other one is having adequate supply of materials are some concepts. As such we can underline that material flow through having adequate supply of material consistently in a way that supports regular operation of a project/firm is big concept having support to the firms’ performance.Supply Chain Participants RelationshipSupply chain relationship refers to the legal/formal and informal relations that are created through long term interaction of the chain firms. All channel systems that involve two or more independent firms have a degree of relationship structure. When relationships are managed to achieve joint goals and participating firms feel obligated to each other, the relationship becomes a supply chain. Four forms of supply chain are common: administered systems, partnerships and alliances, contractual systems, and joint ventures. As one would expect, the acknowledgment of dependency increases the arrangement moves from administered system to joint venture where they are to start much more integrated act.Transportation Management Transportation refers to the movement of raw and finished goods in the whole supply chain lines of a business known to be big facilitator of the business operations. Transportation management from the point of supply chain management refers to process of planning, directing and controlling the speed, consistency and reliability of the materials movement between two or more supply chain elements in the specific business. Transportations can be evaluated from the point of the speed of delivery, consistency of the loading ability and speed, as well as the cost of transportation (Browersox, 2002).

3. Methodology

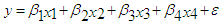

- This study is explanatory in design as it tries to show the role of integration as independents variable on the performance of road construction firms in Ethiopia. The study has targeted 24 road contractors/private road construction firms, 10 road construction material producers, 4 importers, 9 distributors, and 10 transport agencies which are known road construction material supply chain participants in Ethiopia. Questionnaires were distributed to those 60 respondents, and 51 were filled and returned correctly.Finally the questionnaires have been analyzed through inferential analysis to measure the potential influence of the integration among the construction materials supply chain participants on the final road contractors’ performance in Ethiopia. As such, assuming that the data nature is suitable for analysis in multiple linear regression the researchers have drawn the model as follows:

Where √ y stands for the overall performance of private road contractors in Ethiopia√ x1, x2, x3 and x4 stand for efficiency of information sharing, consistency of material flow, overall relation among the participants, and efficiency of transportation services in the chain.√

Where √ y stands for the overall performance of private road contractors in Ethiopia√ x1, x2, x3 and x4 stand for efficiency of information sharing, consistency of material flow, overall relation among the participants, and efficiency of transportation services in the chain.√  and

and  are coefficients showing the expected level of influence each variables√

are coefficients showing the expected level of influence each variables√  stands for error term expected in estimating the regression

stands for error term expected in estimating the regression4. Results and Discussion

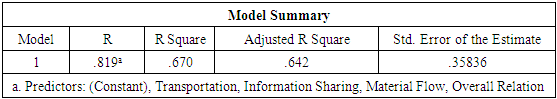

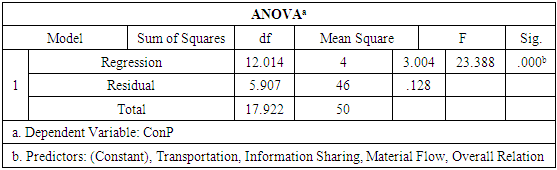

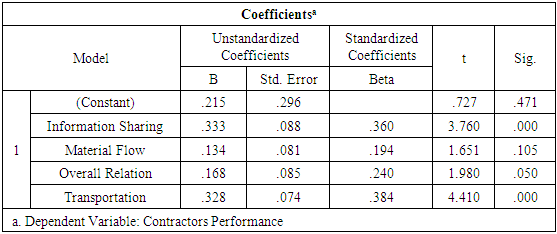

- In order to meet the desired objectives of this study the researchers have used multiple linear regressions and measured the role of supply chain integration in improving the overall performance of the road construction firms in Ethiopia.Here integration as an independent variable has been evaluated from the point of information sharing showing the integration of the chain participants in exchanging reliable and important information, material flow focusing on the adequacy, consistency, and flexibility of material flow among the chain participants, transportation is also the other dimension of integration among the supply chain integration of this sector from the perspective of speed, consistency and reliability and finally overall relationship is the other important dimension encompassing further dimensions overall support, trust and care one another with in the chain. Private road contractors’ performance has been evaluated from the point of early/timely finish, quality of constructions, cost effectiveness and meeting customers’ expectation. Therefore the linear regression output of Version SPSS 20 is given here below.Model SummaryThe degree of association that supply chain participants integration and the road contractors performance has been presented along with the estimated overall effect has been measured by the model summary below.

|

|

|

5. Conclusions and Recommendations

- Being based on the data analysis made, the researchers have concluded the following points;√ Information sharing results in the highest level of variation in the performance of the private road contractors in Ethiopia. This shows that further strengthening the information culture among the chain participants can facilitate the early finish, quality of constructions, cost effectiveness and meeting customers’ expectation resulting in general efficient performance of the contractors. √ Transportation has been found to be the other dominant factor affecting the better performance of the road construction firms in Ethiopia showing that better speed, consistency and reliability of the transportation services can lead to better accomplishments of the road construction firms in the country.√ The other moderate factor contributing to the variability of road construction firms is the relationship among the supply chain participants of this sector. It has been proved that building better relation among the participants can result in improved performance of the final contractors of the road construction industry.√ Material flow throughout the chain participants, starting from the construction material producers to the final road contractors have been indicated to have insignificant influence on the deviation of the final road contractors performance in Ethiopia. Generally, it can be stated that having improved information sharing among the chain participants, better transportation facility and stronger relation among the chain participants of the road construction sector could have much more importance to strengthen the better performance of the private road contractors in Ethiopia. Therefore the concerned body including the Ethiopian Roads Authority shall focus on these major factors of the sector in the country.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML