-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Journal of Logistics Management

2016; 5(1): 6-15

doi:10.5923/j.logistics.20160501.02

The Impact of Supply Chain Relationship Quality and Cooperative Strategy on Strategic Purchasing

S. Mostafa Razavi, Mehdi Abdi, Shobeir Amirnequiee, Rohollah Ghasemi

Faculty of Management, University of Tehran, Iran

Correspondence to: Rohollah Ghasemi, Faculty of Management, University of Tehran, Iran.

| Email: |  |

Copyright © 2016 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Developing a close relationship between suppliers and customers is well encouraged in the literature of supply chain management. Considering the dimensions of Supply Chain Relationship Quality (SCRQ) and Cooperative Strategy (CS), we aim to present a conceptual model for the effects of their indicators on Strategic Purchasing (SP). For this purpose, 187 questionnaires were distributed among recycling experts in order to identify the effective factors. Factor Analysis and Structural Equation Modelling (SEM) are used to discover the relationship among them. Moreover, this study utilizes descriptive-correlation methods with an applied approach. Through confirmatory factor analysis in SEM, factoring is accepted. Exploratory factor analysis is performed by SPSS 18. LISREL is then used for structural equation modelling. Research results demonstrate a significant and positive relationship among Supply Chain Relationship Quality, Cooperative Strategy, and Strategic Purchasing in recycling industries in Iran.

Keywords: Supply Chain Relationship Quality, Cooperative Strategy, Strategic Purchasing, Recycling Industries

Cite this paper: S. Mostafa Razavi, Mehdi Abdi, Shobeir Amirnequiee, Rohollah Ghasemi, The Impact of Supply Chain Relationship Quality and Cooperative Strategy on Strategic Purchasing, Journal of Logistics Management, Vol. 5 No. 1, 2016, pp. 6-15. doi: 10.5923/j.logistics.20160501.02.

Article Outline

1. Introduction

- Supply Chain Management (SCM) is the whole set of measures taken to integrate suppliers, manufacturers, warehouses, and markets; which consequently leads to manufacturing products at the best possible cost, in the right time and right place. This alliance reduces the total costs in supply chain while satisfying the market demand (Simchi-Levi, 2005). Thus, the significance of supply chain is winning approval of firms to correlate their competitive edge to SCM (Zuckerman, 2002). Su et al. (2008) mentioned that supply chain relationship exists as long as both parties in the supply chain are involved in a short-term or long-term interaction. Supply chain relationship favours a long range relation to maintain and develop cooperation. So, companies strive more and more to establish and develop close and long-term relationships with suppliers (Fynes et al., 2005b). With a glimpse into literature, we encounter numerous studies that have investigated interactions among different dimensions of supply chain relationships (SCR) (Fynes et al., 2008, Fynes et al., 2004, Fynes et al., 2005a, Fynes et al., 2005b, Huntley, 2006, Mohaghar et al., 2011, Rauyruen and Miller, 2007, Su et al., 2008, Woo and Ennew, 2004). However, quite a few ones considered the effects of SCR on cooperation strategy (Su et al., 2008, Chang et al., 2012). The growing importance of supply chain management highlights the strategic role of purchasing, derived from “buying” to “procurement” and “supply management” (Paulraj et al., 2006). Strategic role of purchasing in the firm’s long-term planning is defined as strategic purchasing. A group of suppliers are selected to promote a possible long-term partnership (Chiang et al., 2012). According to Chen et al. (2004), strategic purchasing develops close relations, increases open communications and develops strategic relationship.Maintaining a strong supplier partnership and an effective supply chain requires a small manageable supply base (Sarkar and Mohapatra, 2006). This is a cost-efficient approach which may lower the transaction costs and increase supplier responsiveness. But, blind reduction in supply base may also increase supply risk and reduce supplier innovation and consequently jeopardize the overall competitiveness (Choi and Krause, 2006).In this paper, we try to investigate the relations between the indicators of supply chain relationship quality (SCRQ) and cooperative strategy (CS) which affect strategic purchasing (SP). To determine the relative significance of identified factors (in our case, in the recycling industries) we first studied the literature on SCRQ, CS, and SP, in addition to a thorough review of studies on the effects of SCRQ on firms. Having identified the indicators, a questionnaire was distributed among experts of recycling industry in Iran. 187 questionnaires were completed and returned. Through confirmatory factor analysis (performed by SPSS 18.0), factoring is either accepted or rejected. Finally, we used structural equation modelling (SEM) in LISREL 8.8 to analyse our data.

2. Theoretical Background

2.1. Supply Chain Relationship Quality (SCRQ)

- As we explained, SCRQ is concerned about the degree to which parties are engaged in an active, long-term working relationship. Fynes et al. (2004) have conceptualized such definition, using different indicators and dimensions. The research utilizes the SCRQ model presented by Mohaghar and Ghasemi (2011). They define SCRQ as a higher order latent variable for: Trust, communication, commitment, co-operation, interdependence, atmosphere, and adaptation.

2.1.1. Communication (CM)

- Communication difficulties are identified as a major problem among parties (Lages et al., 2005). Communication is ‘‘the formal as well as informal sharing of meaningful and timely information between firms’’ (Anderson and Narus, 1990). Frequent and timely communication is important since it assists companies in resolving disputes and aligning perceptions and expectations (Morgan and Hunt, 1994).

2.1.2. Trust (T)

- Trust is among the most prevalent cited indicator of SCR in the literature, since a crucial reason for unsuccessful relationships in a supply chain is the lack of trust between the partners. The establishment of trust between companies is considered as the basic reason for the prosperous long-term relationships by both researchers and practitioners (Walter et al., 2002). It has been defined as the established belief in a firm that another company will perform actions that would result in positive actions for the firm, while avoiding unexpected actions that entail negative outcomes (Anderson and Narus, 1990).

2.1.3. Adaptation (A)

- By investing in transaction specific assets such as product/process technology and human resources, suppliers adapt to the needs of specific important customers and customers adapt to the capabilities of specific suppliers (Håkansson and Group, 1982). Such adaptations frequently occur between suppliers and customers because of some critical reasons. First of all, these adaptations, as stated, can represent considerable investments by one or both parties. Second, they may have a critical importance to conduct a business. And third, the aforementioned investments frequently cannot be transferred to other SC relationships. (Fynes et al., 2005b).

2.1.4. Commitment (C)

- Commitment refers to the willingness of trading partners to exert effort on behalf of the relationship and suggests a future orientation in which firms attempt to construct a relationship that can support unanticipated problems (Gundlach et al., 1995). Organizations build and maintain long-term relationships if they perceive mutually beneficial outcomes accruing from such a commitment (Morgan and Hunt, 1994). So, commitment is actually an important variable for long-term success because supply chain partners are willing to invest resources, sacrifice short-term benefits for long-term success (Mentzer et al., 2000a, Mentzer et al., 2000b).

2.1.5. Interdependence (I)

- In exchange relationships, both parties may be, to some degree, dependent on each other (Gundlach and Cadotte, 1994). In fact, interdependence exists whenever a firm does not entirely control all of the conditions which is necessary for the achievement of an action or for obtaining the desired outcome from the action’’ (Pfeffer and Salancik, 2003).

2.1.6. Co-operation (CO)

- Co-operation makes reference to situations in which firms work conjointly to achieve mutual goals (Anderson and Narus, 1990).

2.1.7. Atmosphere (AT)

- Woo and Ennew (2004) explained atmosphere as the result of relationship that indicate the closeness of two partners. They stated that atmosphere, like the environment, is technically external to the firm, and unlike the environment, is an immediate consequence of the relationship. They believe that atmosphere exists when both parties interact.

2.2. Cooperative Strategy (CS)

- Cooperative strategy is the strategy both parties took in the further state of business relationships, i.e., decide to terminate, maintain or extend relations; and this strategy determines the future of relationships (Su et al., 2008). The significant advantages of inter-organizational cooperation in supply chain are as follows:Ÿ Pertaining to valuable contacts along the supply chain,Ÿ Profoundly understanding the usual activities of the organization and identifying the opportunities for doing projects with other members of the chain,Ÿ Discussing and solving common problems by having regular meetings between the members,Ÿ And facilitating the future strategies of the supply chain (Bayat, 2008).Su et al. (2008) presented a conceptual model for SCRQ and cooperative strategy with data collected from 311 manufacturing firms in West China. They stated that SCRQ can be defined as a construct of communication, cooperation, trust, adaptation, and atmosphere, and SCRQ has a significant positive impact on relationship persistence, relationship frequency, and relationship diversity.Su et al. (2008) defined “relationship persistence” as the perception of the firms that both parties expect the relationship to continue into the future, involves anticipated duration into the future rather than the historical duration to date. Young (2000) defined “relationship diversity” as the perception of the extent and scope of future interaction which describes the complexity, extent and scope of the collaborative activities. Su et al. (2008) defined “relationship frequency” as the times that both parties in a relationship cooperate/interact in a fixed period of time.

2.3. Strategic Purchasing (SP)

- Resource-based theory implies that the attributes of purchasing and supply chain management may be regarded as the sources of competitive advantage (Barney, 2012). According to Glock and Hochrein (2011), the trend line of research on organizational aspects of purchasing shows a continuous growth in the number of studies over the years. The purchasing function is becoming a strategic part of firms rather than the conventional operational task of ordering (Castaldi et al., 2011).

2.4. Structural Equation Modelling (SEM)

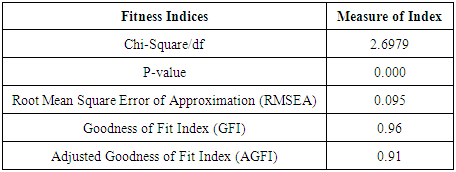

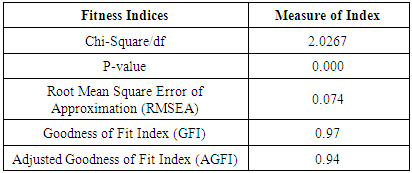

- SEM is a comprehensive statistical approach for testing hypotheses about relations among observed and latent variables. A major advantage of SEM is the ability to estimate a complete model incorporating both measurement and structural considerations. We tested the measurement and research models using structural equation modelling (SEM) in LISREL 8.8 with 187 samples. A variety of indices were used to evaluate model fitness. Seven fitness indices were utilized. Indicating acceptable model fitness values are:1. The ratio of the χ2 statistic to its degrees of freedom, with values of less than 3 indicating acceptable fit; 2. Root mean squared error of approximation (RMSEA), with values below 0.08 representing acceptable fit; 3. Goodness of fit index (GFI), with values exceeding 0.9 indicating good fitness; 4. Adjusted GFI (AGFI), with values exceeding 0.8 indicating acceptable fitness (Ngai et al., 2007).

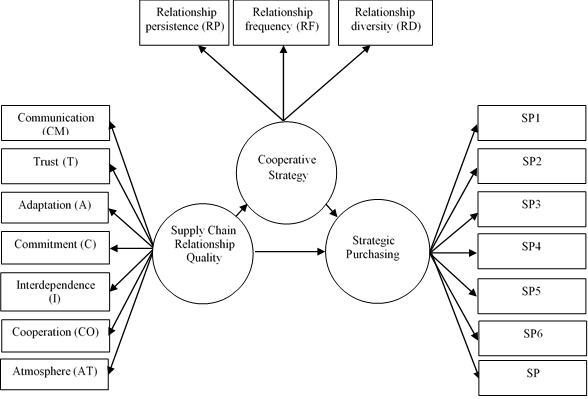

3. Hypotheses and Proposed Model

- The proposed model is composed of three kinds of variables: SCRQ, CS and SP. The conceptual model incorporating the research hypotheses is shown in the following figure.

| Figure 1. Proposed research model |

4. Methodology

4.1. Survey Instrument

- After reviewing the literature and interviews with experts (16 experts of recycling industry and supply chain management), a questionnaire based on existing measurement scales for the research constructs (see Appendix A) was initially drafted. This draft questionnaire was then pretested with academics and practitioners to check its content validity and terminology and modified accordingly. The modified questionnaire was then pilot tested to check its suitability and appropriateness for the target population before distributing.

4.2. Statistical Population and Sample Size

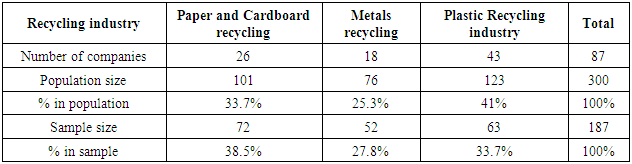

- Statistical population of this research included 300 industrial experts (CEO, Logistic experts, purchasing experts, strategic managers, and operational managers) from 87 companies in recycling industries of paper and cardboard, metals, and plastic. According to population, sample size was determined to be 169 persons. Random classified sampling was used for this research. Table 1 shows the ratio of this groups and sample sizes. After the distribution of 250 questionnaires, 187 filled questionnaires from experts were returned.

|

4.3. Information Gathering Tools

- Implemented questionnaires are composed of three parts: the first part consists of 26 questions about SCRQ's dimensions; each one of communication, trust, adaptation, interdependence, and cooperation had 3 questions; and finally commitment and atmosphere had 3 questions. Second part was about CS which contained 8 questions about relationship persistence (with 2 questions), relationship frequency (with 3 questions) and relationship diversity (with 3 questions). Third part was about SP with 7 questions (see appendix A).

4.4. Reliability and Validity

4.4.1. Reliability

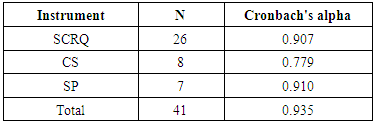

- For reliability evaluation we utilized Cronbach's alpha (as shown in Table 2). The Cronbach's alpha reliability of all the ten latent variables are more than 0.6 (α>0.6), which indicates that all scales demonstrate good reliability.

|

4.4.2. Validity

- For evaluating validity of questionnaires, content validity and construct validity were used. Content validity deals with how representative and comprehensive the items were in creating the scale. It is assessed by examining the process by which scale items are generated (Moon and Kim, 2001). Content validity assured us that all aspects and parameters that impact the main content were evaluated. For testing content validity after devising a framework for questionnaire, we asked 16 people (including 4 scholar and 12 recycling industries experts) to evaluate all implemented criteria and modify the questionnaire if needed. Construct validity determines the extent to which a scale measures a variable of interest (Moon and Kim, 2001). In this research, “exploratory factor analysis” was used to consider the structure of research. Exploring factor analysis and criteria factor was used to investigate the construction of questionnaire and confirm that all of the criteria are measured in these questionnaires.

5. Analysis of Findings

- The relationships among variables are identified in the following sections. These variables are then properly factored and put into structural equation modelling (SEM). Through confirmatory factor analysis in SEM, factoring is either accepted or rejected.

5.1. Exploring Factor Analysis

- We considered 26 questions by factor analysis and based on 187 gathered questionnaires, KMO was 0.812, showing that the sample size was enough. Also note that the sig. in Bartlett test was lower than 0.05. The total variance explained for the seven factors in the questionnaire was 67.92%, which explains the variance of the concept of SCRQ, indicating a high level of reliability for the questionnaire. Also, we considered 8 questions by factor analysis, and based on 187 gathered questionnaires, KMO was 0.689 showing that the sample size was enough. Also note that sig. in Bartlett test was lower than 0.05. The total variance explained for the 3 factors in the questionnaire was 72.70%, which explains the variance of the concept of CS, indicating a high level of reliability for the questionnaire. Finally, we considered 7 questions by factor analysis, and based on 187 gathered questionnaires, KMO was 0.606 showing that the sample size was enough. Also note that sig. in Bartlett test was lower than 0.05. The total variance explained for the 1 factor in the questionnaire was found to be 65.21%, which explains the variance of the concept of SP, indicating a high level of reliability for the questionnaire. The first step of the abovementioned analyses is performed by SPSS 18.0 and the second step by LISREL 8.53. The following sections present the results of exploratory factor analysis and structural equation modelling. The secondary hypotheses (H2, H3, H4 and H5) are examined, and finally the main hypothesis is explained after the confirmatory factor analysis of both sides of the model. In fact, the proposed model is put to test in the following steps:1.SCRQ: its latents and indicators; 2.CS: its latents and indicators; 3.The effect of SCRQ on CS;4.The effect of CS on SP;5.The effect of SCRQ on SP.

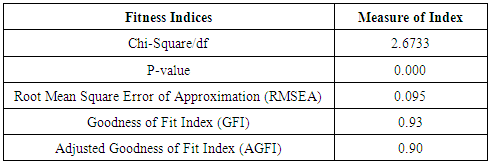

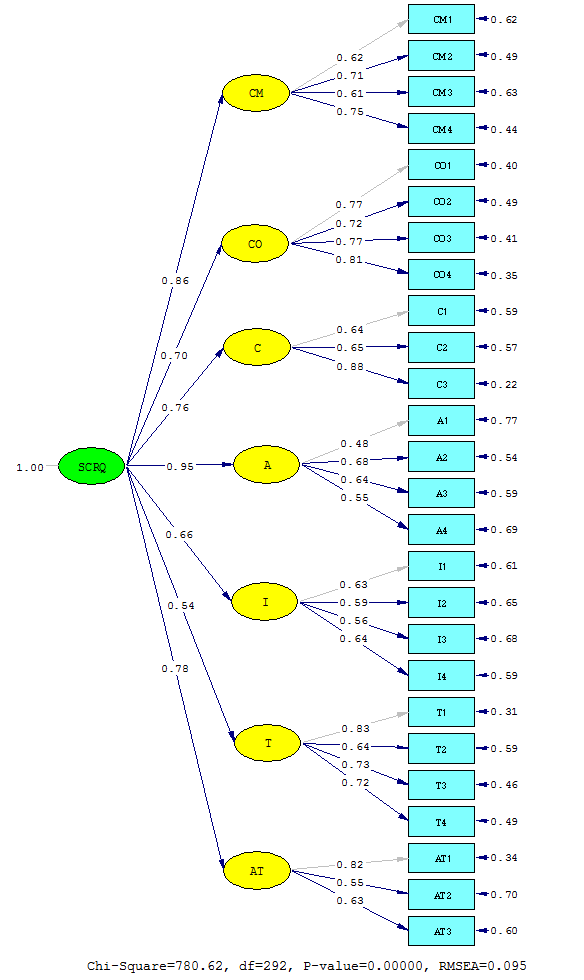

5.2. X Model; Measurement Model of SCRQ

- In the initial step, confirmatory factor analysis is conducted in LISREL 8.8. The path diagram of X model eventually evolves as shown in Figure 2. Then, the relationship between SCRQ latent and its indicators are studied. Goodness indices in Table 3 show that our X model fits well, and the selected indicators are a proper representative for each dimension of SCRQ. Thus, our second hypothesis (H2) is supported.

|

| Figure 2. Standardized solutions model for SCRQ |

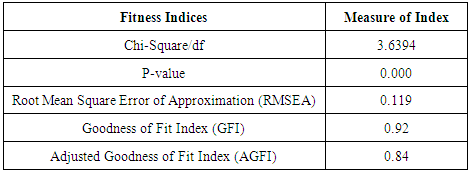

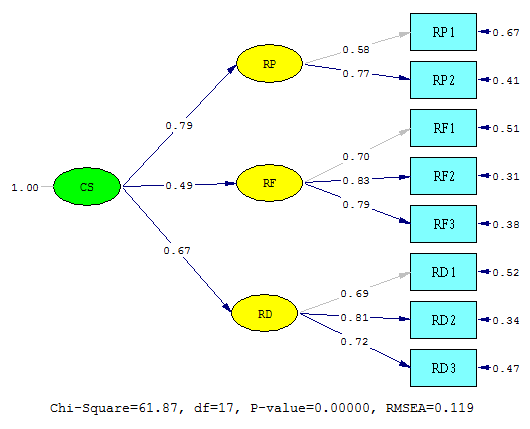

5.3. Y Model; Measurement Model of CS

- In the next step, the same procedure is repeated for CS: confirmatory factor analysis is conducted for CS and its indicators in LISREL. The path diagram of Y model is shown in Figure 3. The relationship between CS latent and its indicators are then put to test. Goodness indices in Table 4 show that our Y model is fitted well, proving that the selected indicators are a good representative for each dimension of CS. So, our third hypothesis (H3) is also supported.

| Figure 3. Standardized solutions model for CS |

|

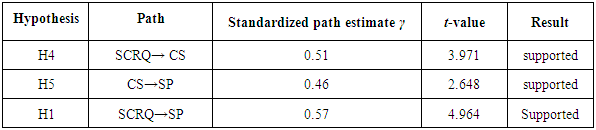

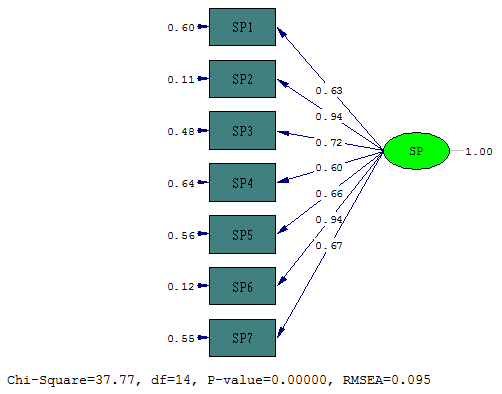

5.4. Y Model; Measurement Model of SP

- Confirmatory analysis is also repeated for SP and its indicators in LISREL. The path diagram of Y model is shown in Figure 5. Table 5 proves that the selected indicator are good representative for each dimension of SP and our forth hypothesis (H4) is supported.

| Figure 4. Standardized solutions model for SP |

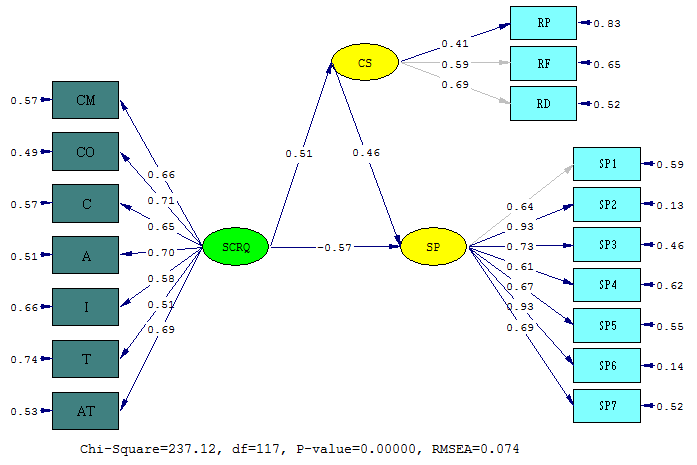

| Figure 5. Structural path analysis |

|

5.5. Structural Model; Path Analysis

- In order to apply the data gathered from questionnaires into SEM, we defined a new variable for every latent variable of SCRQ and CS and then used the mean of scored answers for investigating our primary hypothesis. The structural model consists of seven dimensions of SCRQ and three component of CS and seven questions for SP.

|

The indirect effect is

The indirect effect is  So, the total effect, which is the sum of these two effects, is 0.8046.

So, the total effect, which is the sum of these two effects, is 0.8046.

|

6. Conclusions

- The main purpose of this study was presenting a conceptual model to discover the effects of the indicators of supply chain relationship quality and cooperative strategy on strategic purchasing. Having identified the factors of SCRQ, CS, and SP in the recycling industries after a thorough literature review and some interviews with experts, a questionnaire was distributed among experts. Exploratory factor analysis is used for the identification of relationships among variables. These variables are then properly factored and put into structural equation modelling (SEM). Through confirmatory factor analysis in SEM, factoring is either accepted or rejected. Exploratory factor analysis is performed by SPSS 18.LISREL is then used for structural equation modelling.Based on our result, enhancing SCRQ could lead to an improved level of Cooperative Strategy and strategic purchasing in recycling industry. Adaptation, among other factors, has the highest effect on SCRQ; and the significant factor in Adaptation is tailoring the production system to meet the requirements of the supplier.The same procedure was repeated for CS and Relationship persistence was found the most important factor in CS; and the unceasing cooperation with supplier is the most important issue in Relationship persistence.In SP, a sound knowledge of the firm’s strategic goals and focus on longer term issues that involve risk and uncertainty are both considered as the most important factors in strategic purchasing.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML