-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Journal of Logistics Management

2013; 2(2): 35-40

doi:10.5923/j.logistics.20130202.01

Analysing Supply Chain Risk Factors: A Probability-Impact Matrix Applied to Pharmaceutical Industry

Lhoussaine Ouabouch1, Mostapha Amri2

1PhD Student, National School of Trade and Management, Ibnou Zohr University, Agadir, Morocco

2Professor, National School of Trade and Management, Ibnou Zohr University, Agadir, Morocco

Correspondence to: Lhoussaine Ouabouch, PhD Student, National School of Trade and Management, Ibnou Zohr University, Agadir, Morocco.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

In this article, we aim to elaborate a better comprehensive overview of main logistics and supply chain risk factors (SCRF), in an assessment perspective. The study, based on data collected from a sample of Moroccan Pharmaceutical Industry, contributes to the existing literature by prioritizing several dimensions of supply chain risk. It can be useful for managers and researchers engaged in investigating the design of supply chain risk analysis models, and by pointing out critical risk factors which should retain main attention in a special industrial context.

Keywords: Supply Chain, Risk Assessment, Probability, Impact, Risk Matrix, Morocco, Pharmaceutical Industry

Cite this paper: Lhoussaine Ouabouch, Mostapha Amri, Analysing Supply Chain Risk Factors: A Probability-Impact Matrix Applied to Pharmaceutical Industry, Journal of Logistics Management, Vol. 2 No. 2, 2013, pp. 35-40. doi: 10.5923/j.logistics.20130202.01.

Article Outline

1. Introduction

- As stated in[1],[2], companies are more than ever exposed to a diverse set of risks in operating their supply chains. Industries have witnessed a remarkable change in their business environment in particular due to increased competitive pressure and the globalization of markets[3].Several researchers emphasize that as a consequence of this development which is characterized by a relatively unstable state of the world and an increased susceptibility of supply chains to disruptions, companies are compelled to tackle supply chain risks just as seriously as they tackle other business risks[4].Earlier articles in supply chain management (ex. By Kraljic[5]) stressed the importance to consider the risks arising from interconnected flows of material, information and funds in inter-organizational networks[3].From this same point of view, Wagner et Bode[6] affirmed that companies are faced with managing these risks which adversely affect their capacity to efficiently serve the final customers. In this context, in spite of its negative impact, Khan and Burnes[7] argue that risk is less understood in the area of supply chain management (SCM) than in other disciplines and less developed. Furthermore, although supply chain risk management has gained attention in the past years in academia[8], there is a need for empirical work in the field of supply chain risk management analyzing the main supply chain risks[9].Our objective is precisely to contribute to the enrichment of the corpus on supply chain risk management, on which Sodhi and al.[10] emphasize great promptness during this decade. What is a risk factor in the SCM sphere?In the supply chain management area (SCM), some definitions of the concept of risk are proposed(ex.[11],[12],[13]). In this article, the concept of "supply chain risk" refers to those little predictable incidents or events, affecting or originating from one or several partners in a supply chain and/or its processes, and may influence negatively the achievement of organizations’ goals[14].Jüttner[15] extends the construct of supply risk and argues that risk in the supply chain centres around the disruption of flows between organizations. These flows relate to information, materials, products, and money. A key feature of supply chain risk is that, by definition, it extends beyond the boundaries of the single firm, and moreover, the boundary spanning flows can become a source of supply risks. In the process of the supply chain risk analysis, the stage of the identification is often regarded as paramount. Through the recent literature about supply chain risk management, we can identify a whole of risk factors related to the operations in the supply chains, and being able to harm the level of logistical performance.Although it is virtually impossible to list every conceivable risk[16], the Supply Chain Risk Factors (SCRFs) faced by an organization can be classified in different ways depending on the criteria.SCRFs classification and characteristicsSCRFs can, for example, be listed according to their origin, endogenous, exogenous[17], internal orexternal[9], [18], their scope, operational, catastrophic, bureaucratic and legal, economic, etc.[3],[6],[19],[20], or according to the process to which they refer: supply side, demand side, etc.[21].Regarding existing typologies of the SCRFs, we adopted a classification into three families inspired from[21],[22] and[23]. It successively analyzes the risks associated with management of the upstream supply chain (relations with suppliers), operational risks (internal to the company), and the risks associated with management of the downstream supply chain (customer relationships).One finds a relatively close vision in Pfohl and al.[24] speaking about risks within a focal firm and risks outside of the company and within the supply chain. The authors add the risks outside of the supply chain that affect the focal firm, such as natural disasters or wars, which we will not discuss in this article. A recent synthesis is proposed by Behnezhad and al.[20].Moreover, every risk factor has three main characteristics: a probability of occurrence, an impact and a criticality. The third characteristic is the combination of the impact (effect or severity) and the likelihood of a risk factor. In other words, criticality is related to the intensity of the incident when it occurs[25][26, p. 54] .In the following, the empirical part of the study will be presented. It begins with a description of the research methods and the case supply chain. The findings from the questionnaire survey are reported and the SCRFs related to three classes are assessed. Finally, the findings are discussed and the conclusions are presented.

2. Methods

- The empirical findings come from a questionnaire survey. Descriptions of the specific measures and items used in this study are reported in the following section.

2.1. Survey Instrument and Measures

- The questionnaire is based on the items composing the three classes of supply chain risk factors (SCRFs) identified in the previous section. The measurement of the variables employed Likert-type scales where possible employing items from existing scales drawn from other studies. However, this was not possible for all measures, and consequently two new items were added.In order to measure the upstream risk factors, five items were used, in relation to the supplier failures, economic conditions in the supply markets, customs restrictions and failures of services providers. These are the five items: Supplier failure (UpR1), Supplier quality problems (UpR1), Increasing in raw materials (RM) prices (UpR3), Unpredictable trade barrier (UpR4) and Upstream transportation failure (UpR5).The internal risk factors were evaluated using three items related to the potential failures of infrastructure, whether for technical or human reasons. It concerns in particular: Machine breakdown (IR1), Outage of IT System (IR2) and work accidents (IR3).Finally, downstream risk factors are related to the management of the downstream supply chain. They are measured by four items related to the variability of the market downstream and the risks associated with the business relationship. The four items are: Unexpected demand fluctuations (DwR1), Inventory shortage (DwR2), Delivery chain disrupts (DwR3) and Decline in market prices (DwR4).For each SCRF, the respondents were asked to estimate the probability and the consequences concerning their company. The scale ranged from “never” to “always” for probability measurement; and from “no gravity” to “very serious consequences” for the impact.

2.2. Survey Context

- As we already announced, this research relates to the pharmaceutical supply chain. The interest in this branch of activity comes from both its importance in the national economy, and its fertility as a field of research in the SCM area.The pharmaceutical industry has constituted for more than fifty years, one of the pillars of Moroccan economy. According to[27] and[28], the sector has experienced in recent years sustained growth, with a level of performance and expertise recognized by the World Health Organization. Otherwise, the conformity of the production of the sector to the international standards of quality, including the GMPs (Good Manufacturing Practices), enabled companies to export more than 10% of their production towards European, Arabic and African countries[27],[28].Furthermore, Moroccan pharmaceutical sector is strongly regulated in all its aspects including, the creation, the functioning and the control of the industrial pharmaceutical establishments, the launches on the market and the prices of the medicines[27].However, in spite of its mentioned importance, this branch of industry is one of the least explored in research on SCM and supply chain risk management in Morocco.To our knowledge, this research constitutes a first reflection on the supply chain risk analysis and assessment within the national pharmaceutical industry, on the scale of the business sector.

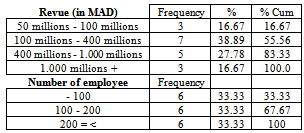

2.3. Data Collection and Sample Structure

- In Morocco, there are 40 pharmaceutical laboratories[27]. Based on our questionnaire, data were collected through an electronic survey administered in October-December 2012 to a convenience sample of 27 top-level executives in logistics and supply chain management. The mailing and one follow-up generated 21 feedbacks and 18 usable responses, yielding a high response rate of about 67%. Therefore, our useful sample represents 45% of the total population. General descriptions of the sample in terms of annual revenue and company size are shown in Table 1 bellow.

|

| (1) |

3. Results

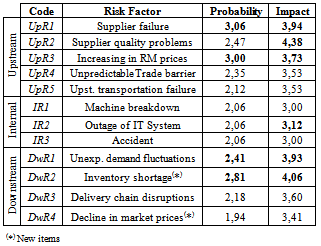

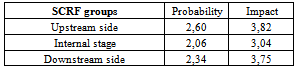

- First of all, we have calculated the likelihood of occurrence and the impact of all the risk factors. Table 2 shows the indicators relating to each stage, and the impact and probability values (based on average means) for different SCRFs. Table 3 indicates the averages in terms of probability and impact among the three stages of the supply chain.

3.1. Likelihood/Probability Analysis

- In order to assess the SCRFs probabilities and impacts, the risk factors individual features from Table 2 are compared to the groups averages shown in Table 3.First, in the upstream side, two SCRFs have notable probability values: Supplier failure and increasing in RM prices. The two risk factors and supplier quality problems gain great impact values.

|

|

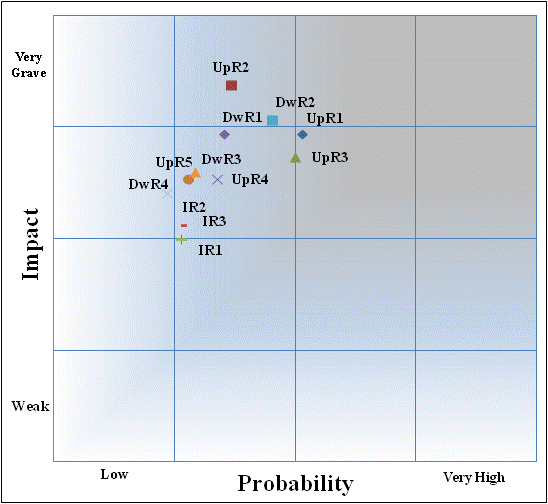

3.2. Supply Chain Risk Matrix

- The risk matrix shows the overall picture of SCRFs in the survey, with the probability increasing from left to right, and move towards the upper right corner (grey zone), the greater is the SCRF criticality (Figure1). As the figure illustrates, there are observable differences in terms of SCRFs. Supplier quality problems (UpR2) must be regarded as most grave risk factor and Supplier failure (UpR1) and increasing in RM prices (UpR3) as most probable risk factors. Unexpected demand fluctuations (DwR1), delivery chain disruptions (DwR1), decreasing market prices, unpredictable trade barrier (UpR4) and upstream transportation failure (UpR5) are seen as severe risk factors but are less likely to occur. The highest probability values are observed in terms of supplier failure and increasing raw material prices. However, internal risk factors have the least probability-impact positions.

| Figure 1. Supply Chain risk Matrix for Moroccan Pharmaceutical Industry |

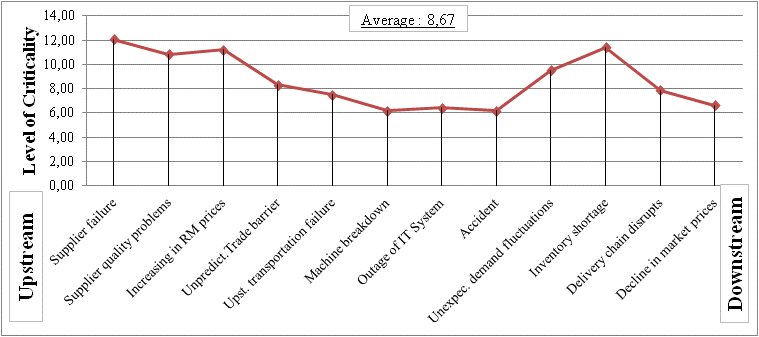

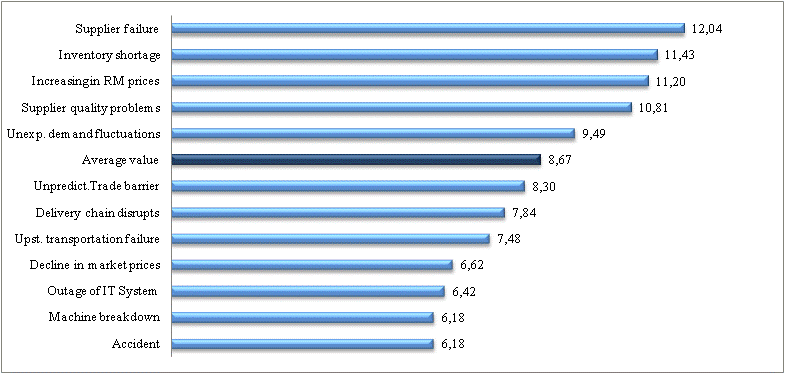

3.3. SCRFs Criticality Levels

- In order to confirm previous findings, we calculated the levels of criticality for each risk factor using the equation (1). Figure 2 below, shows criticality diagram along the logistical chain. Figure 3 indicates criticality levels for different SCRFs studied. Five SCRFs may especially be considered as critical (surpass average value which is 8.67). As it can be seen from Figure 3, supplier failure, inventory shortage, increasing in RM prices, supplier quality problems and unexpected demand fluctuations have the highest criticality levels. In addition, internal risk factors i.e. outage of IT system (value of 6.42), machine breakdown and work accidents with a same value (6.18), have the lowest criticality levels.At a medium criticality level, we find trade barriers, delivery chain disruptions, and upstream transportation non-performance. Obviously, these results are convergent with our previous analyses about SCRFs probability-impact matrix. All these remarks will be discussed in the following section.

| Figure 2. SCRFs criticality from Upstream to Downstream |

| Figure 3. SCRFs by level of criticality |

4. Discussion

- To discuss the main results of this research, we first need to remind some essential features of the Moroccan pharmaceutical activity. On the one hand, Morocco has adopted a very rigorous pharmaceutical regulation. Consequently, the issues like drugs availability, their quality and their prices in the domestic market are rigorously monitored by Moroccan Ministry of Health. On the other hand, Moroccan pharmaceutical industry is mainly focused on the production, but the share of imported drugs is in steady growth. The distance of suppliers as well can thus be a source of risk.These elements may explain the fact that the majority of SCRFs have low to medium probabilities of occurrence, but are estimated as serious to very serious. For example, a problem in supplier delivered products/raw materials is considered as the most grave. This severity may also originate in company’s dependence on global suppliers, which many authors consider as a supply chain vulnerability driver[29],[30].Also, a supplier failure, for example because of a weak logistical performance, or even a bankruptcy, is also regarded as the most critical risk factor. Otherwise, increasing in RM prices (supply side) is estimated to be critical because the selling prices of drugs on the market are regulated and the sales margins are likely to be rigid. Indeed, only the Ministry of Health is able to set the prices of medicines and eventually to increase or to reduce them.Likewise, inventory shortage is not allowed for the medicine as a vital product. In spite of its relatively mastered probability of occurrence, this incident is considered as very serious. Nevertheless, decline in market prices (demand side) does not matter to pharmaceutical companies, because of the same cited regulatory control on prices.From another point of view, the national pharmaceutical market is animated as much by domestic and international companies. The latter contribute for more than half of the total sales of the sector[26][27]. Moroccan pharmaceutical industrial and technological know-how is recognized on a world level and according to[27], Morocco is classified in Europe zone in terms of the quality of drugs.Accordingly, “obtained” values by internal risk factors in terms of probability, impact and criticality, can be explained by companies infrastructure performance and the implementation of the GMPs. Thus, internal risk factors are perceived as less grave, less probable and less critical; yet it is that Machine breakdown and work accidents are the lowest critical SCRFs in the investigation results.

5. Conclusions

- The aim of this empirical investigation into pharmaceutical SCRFs is to contribute to the current literature on supply-chain risk management by prioritizing several dimensions of pharmaceutical supply chain risk.Our attention was focused on the main risk factors at three stages of the supply chain: upstream, internal and downstream. Our contribution represents a solution to estimate and assess the extent of a range of potential incidents throughout the three strands.The methods used in this paper can be useful for managers and researchers engaged in investigate the design of supply chain risk analysis models, as well by pointing out critical risk factors which should retain main attention in the pharmaceutical industry context. The results advocate managers to primarily turn their attention on supply side and demand side risk sources and on excelling in the supply chain management activities such as supplier relationship management, demand forecasting as well as cooperative information sharing with customers and suppliers. Finally, a remark has to be made on the objectivity of responses given by the respondents. Therefore, a larger sample could be interesting to lessen the subjective perceptions’ effects of values assigned to risk dimensions on the analysis output of the research.

ACKNOWLEDGEMENTS

- The authors wish to acknowledge all the respondent companies for their collaboration to carry out empirical data of this research.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML