-

Paper Information

- Next Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Journal of Logistics Management

2013; 2(1): 9-14

doi:10.5923/j.logistics.20130201.02

Green Supply Chain Management Evaluation in Publishing Industry Based on Fuzzy AHP Approach

Ali Asghar Anvary Rostamy1, Meysam Shaverdi2, Iman Ramezani3

1Professor of department of finance and accounting, Faculty of Economic and Management, Tarbiat Modares University, Tehran, Iran

2R&D department, Sooreh Mehr Publication Company, Tehran, Iran

3Department of productivity management, Faculty of industrial engineering, Sharif University of Technology, Tehran, Iran

Correspondence to: Ali Asghar Anvary Rostamy, Professor of department of finance and accounting, Faculty of Economic and Management, Tarbiat Modares University, Tehran, Iran.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

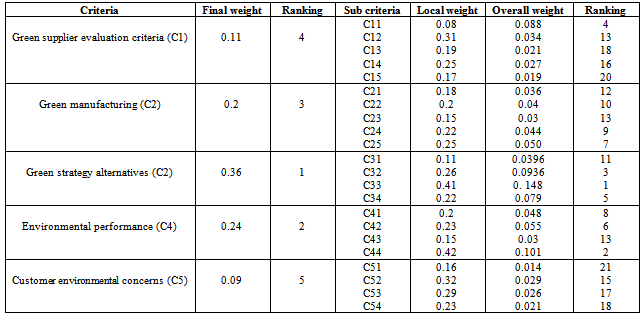

Green Supply Chain Management (GSCM) is an increasingly widely-diffused practice among companies that are seeking to improve their environmental performance. This study designates green supply chain management (GSCM) evaluation model in publishing industry by using fuzzy AHP approach. Our proposed model is applied in Sooreh Mehr Publication as one of the best companies in this sector. Research model has 5 main criteria and 21 sub criteria. We find that GSCM in publishing industry focus more on green strategy alternatives and environmental performance as main criteria. Also, result shows that innovation based strategy (C33), E-publishing (C44) and efficiency based strategy (C32) are most important sub criteria.

Keywords: Green SCM, Evaluation model, MCDM, Fuzzy AHP, Sooreh Mehr Publication Company

Cite this paper: Ali Asghar Anvary Rostamy, Meysam Shaverdi, Iman Ramezani, Green Supply Chain Management Evaluation in Publishing Industry Based on Fuzzy AHP Approach, Journal of Logistics Management, Vol. 2 No. 1, 2013, pp. 9-14. doi: 10.5923/j.logistics.20130201.02.

Article Outline

1. Introduction

- Increasing pressures and challenges to improve economic and environmental performance have caused developing countries in general and automobile manufacturing firms in particular to consider and start implementing green supply chain management. It is emerging as an important approach which not only reduces environmental issues but also brings economic benefit to manufacturers[1]. In response to concerns over the integration of economics, environment and society, green supply chain management (GSCM) is seen by many as a promising organizing concept, which takes environmental elements into consideration when managing the supply chain. GSCM aims to maximize overall environmental profit by adopting a life cycle approach through product design, material selection, manufacturing, and sales and recovery, and therefore helps the firm to realize its sustainable development and improvement. Over the last decade or so, the GSCM literature has grown considerably[2].The concept of Green SC Management (GSCM) emerged in the late 1990s, and encompasses the reactive monitoring of general environmental management programs, moving to more proactive practices such as the recycling, reclamation, remanufacturing and reverse logistics (RL), as well as incorporating innovations[3]. For the last 20 years, GSCM has been adopted by the companies to lower environmental risks and raise ecological efficiency, therefore to achieve profit and increase market share[4]. Realizing the significance of the GSCM implemented by organizations, Sarkis[5] developed a strategic decision framework that aids managerial decision making in selecting GSCM alternatives. The foundations of this decision framework are: product life cycle, operational life cycle (including procurement, production, distribution and RL), organizational performance measurements and environmentally conscious business practices. Considering the literature that addressed various elements of GSCM[6, 7, 8]. Zhu and Sarkis[3] developed four categories of GSCM practices, i.e. internal environmental management, external GSCM, investment recovery, and ecodesign or design for environment practices. The relationship between the practices and environmental and economic performance were examined through empirical studies in the Chinese manufacturers[9].Many authors have been identified different dimensions and factors for green SCM in various studies. In this paper we proposed evaluation model for green SCM by using multi-criteria decision making (MCDM) approach. The reason of our selected model related to simple and understandable logic of MCDM and AHP method. Also fuzzy approach is combined with AHP for attainment of more accurate results.

2. Green Supply Chain Management

- GSCM is defined to be the addition of green issues into supply chain management[10, 11]. In addition, Zhu and Sarkis[3] state that GSCM supply chain involves from suppliers to manufacturers, customers and reverse logistics throughout the so called closed-loop supply chain. Hervani et al.[10] indicate there are various activities involving GSCM such as reuse, remanufacturing, and recycling which are embedded in green design, green procurement practices, total quality environmental management, environmentally friendly packaging, transportation, and various product end-of-life practices. In the global economy, the automobile industry transforms rapidly with the dramatic expansion of leading automobile manufacturers (e.g. Honda, Toyota, General Motor, Ford, Daimler Chrysler, Suzuki, Hyundai, and Fiat) into the Asia region. Lee[12] identified the main drivers for companies to participate in GSCM practices as buyer influence, government involvement and green supply chain (GSC) readiness. Wee and Quazi[13] identified seven critical factors in their research into environmental management: top management commitment; total involvement of employees; training; green products/process design; supplier management; measurement; and information management. Greening the automobile industry has been disputed in international energy and environmental policy studies. Green supply chain in automobile industry has become the main interest in many industrial fields. The evaluation and measurement of its performance is essential when environmental issues have been addressed all over the world[14]. However, there have been few studies exploring the issue of GSCM performance evaluation. Hence, applying green concepts into automobile manufacturing is essential to reduce environmental impacts, enhance market competition, and ensure regulation compliance. Reference 11 (developed four types of environmental strategies: reactive, focused, opportunistic, and proactive. Reactive strategies are applied for low levels of environmental responsiveness, focused strategies are applied for high levels of environmental management, opportunistic strategies are applied for a medium level and proactive strategies are applied to the latest environmental practices.Zhu et al.[16] claim that the automobile manufacturing industry in developing countries is a potential and promising industry because it creates a huge market, especially after entering into WTO. However, automobile supply chains are lagging. For instance, Zhu et al.[16] indicate that Chinese automobile industry is quite nascent and the recycling of used cars is not paid enough attention to. Facing environmental burdens, the Chinese government has enacted tighten environment regulations[16]. Hence, Chinese automobile enterprises have started to study GSCM experiences from international partners[17]. Other example is that Malaysia government has not been addressed environmental issues, especially end-of-life vehicles recovery[18]. Since Malaysian automobile industry develops rapidly, GSCM forces local automobile manufacturers and government to become concern about their environmental burdens[19]. For these reasons, GSCM is emerging as an important approach to reduce environmental risks and brings economic benefit to manufacturers[20]. Hu and Hsu[21] explore factors that are critical for implementing green supply chain management (GSCM) practices in the Taiwanese electrical and electronics industries relative to European Union directives, and extract 20 critical factors along four dimensions (supplier management, product recycling, organization involvement and life cycle management).

3. Fuzzy Analytic Hierarchy Process

- Analysis Hierarchical Process (AHP) is a multi-criteria decision making tool first proposed by Saaty[22]. Since it was introduced, AHP have been one of the most useful multi-criteria decision making tools available to decision makers and researchers. Although AHP is sophisticated in recording knowledge, the conventional AHP is unable to veritably reflect the way human thinks. Although it uses a precise yardstick to compare the opinions of decision makers, the conventional AHP becomes confusing. AHP is criticized for using lopsided judgmental scales and its inability to properly consider the inherent uncertainty and carelessness of pair comparisons[23].To overcome these deficiencies, FAHP is developed to resolve the expanded hierarchical issues. Decision makers found out that distanced judgment is more persuasive than rigid judgments. That’s because the individual often cannot explicitly express his preferences regarding the fuzzy nature of comparison process. Since the relative importance specified by the AHP decision makers is oral, it is vague and imprecise. Decision makers often prefer to employ oral presentation rather than numerical value. Because due to the nature of pair comparisons, they can not explicitly express their opinions about priorities. In such conditions the best solution is to make decisions on the basis of multiple conditions and goals to achieve a relatively desirable level of achievement. These issues have caused the nature of decision making to be full of complexities and ambiguities in the most minor to most major cases. Consequently, most decisions are made in a fuzzy environment. Therefore, considering that the fuzzy logic method is proposed for decision making in uncertain and ambiguous situations, using this method can reduce ambiguities and increase the effectiveness of decisions made[24].

4. FAHP Methodology

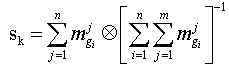

- In this study, we utilize Extent Analysis (EA) method, as originally proposed by Chang[24]. In this method, for each pair rows of pair-wise comparisons matrix, the amount of Sk which is a triangular number, is calculated as follows[21]:

| (1) |

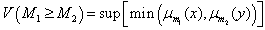

| (2) |

| (3) |

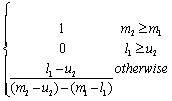

Suppose that d (Ai) = min V (Si ≥Sk), k=1, 2, 3,…, n, k≠ i. Then the following weight vector is obtained.

Suppose that d (Ai) = min V (Si ≥Sk), k=1, 2, 3,…, n, k≠ i. Then the following weight vector is obtained. | (4) |

are n elements. For normalization, the normalized weight vectors as follows which W is a non-fuzzy number:

are n elements. For normalization, the normalized weight vectors as follows which W is a non-fuzzy number: | (5) |

5. Proposed Model

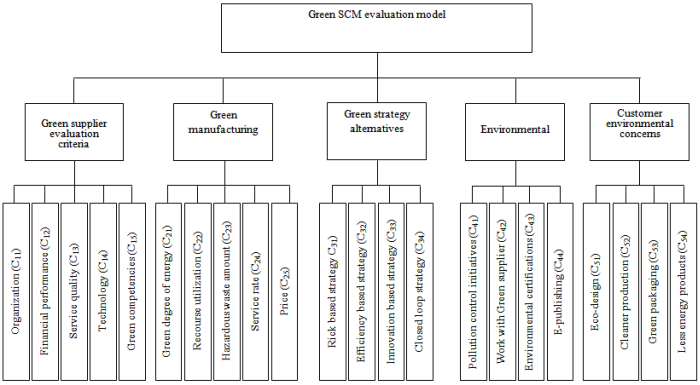

- In this study we want to apply a fuzzy AHP model for evaluation of green SCM in publishing industry and Sooreh Mehr Publication as one of the best publishing companies in Iran. Firstly, we consider some of paper and their model that applied green SCM concept with other methodologies for designing a novel model. For doing this, all applied models in the papers are scrutinized and finally our original model is constructed. Our proposed model is based on Chen et al.[25], Boyozkan and Cifsi[26] and Lin et al.[27] models. These models are the newest models in green SCM evaluation area. Then for designing our model, all index and factors in three models are extracted and considered by Sooreh Mehr and academic experts. Finally the proposed model for evaluation of green SCM in Sooreh Mehr Publication is presented (Fig. 1). After developing model, pair-wise comparisons questionnaire is prepared and distributed among experts. Comparison logic of these questionnaires is based on Saaty five point scale. As you see in Fig. 1, proposed model have five main criteria and each criteria has some sub criteria. Main criteria are included: Green supplier evaluation criteria (C1), Green manufacturing (C2), Green strategy alternatives (C2), Environmental performance (C4) and Customer environmental concerns (C5). Details of sub criteria are shown in fig.1. After designing model, questionnaires are distributed among 18 experts including 9 academic experts and 9 experts from Sooreh Mehr Publication. The final result is presented in

|

| Figure 1. Proposed model for green SCM evaluation |

6. Discussion and Suggestion

- The publishing in Iran or even in many countries around the world have met with some problems in their supply chain management. One of the most important matters in mentioned field can be considering the environmental effects that create by publishers and their upstream or low stream suppliers. In fact, the row materials of publishing industry are directly extracted from ecosystem and it is very important to analyse the other probable and alternative resources for minimizing the damage of environment. Additionally, the paper price has been recently increased in Iran and many publishers have obliged to move up their price over last year dramatically. Generally, these tow topics lead to designing a green SCM model for coming over and decreasing the potential threats. The proposed model not only identifies the significant factors in green SCM, but also specifies their importance degree and priority. The proposed model is trying to present a relatively comprehensive model for evaluating green SCM in publishing industry based on MCDM approach and fuzzy logic to offer an optimum framework. Actually, the research model can be used in other industries and sections but a modification must be applied for increasing the creditability of structure. In one hand, applying the model in other business section can contribute and improve it but on the other hand, because of being unique and novel the proposed model, other researchers would be very free in their innovation and modifying it. The financial factors can be added to model for enhancing the model comprehensiveness due to the mentioned discussion about paper price moving up. Also, consideration of newest models in green SCM and redesign and redefine of research model can be other valuable suggestions.

7. Conclusions

- The growth in green supply chain literature extends back to the early 1990s with the advent of corporate environmental management, environmentally conscious manufacturing strategy, and supply chain management literature. In recent years, green supply chain management (GSCM) initiatives have gained considerable prominence. However, how much value it brings to organizations is still being investigated.Publishing industry is always considered as an important industry in each country. Publishers as active members of this industry want to have an effective and efficient supply chains for reducing their cost and just in time production. The nature of this industry have always involved with environmental issues because their row materials for producing paper are directly extracted from natural recourses. Regarding with these problems, greening supply chains is converted to one of the most crucial challenges in publishing industry. At this study, a evaluation framework for green SCM based on MCDM approach is proposed. This novel model is tested in Sooreh Mehr Publication as one of the best publishers in Iran. Our proposed model is combination of some new models for green supply chain. Results show that green strategy alternatives are the vital factors. Also, innovation based strategy and eco-design are the best and worst sub criteria respectively.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML