-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Journal of Logistics Management

2013; 2(1): 1-8

doi:10.5923/j.logistics.20130201.01

Routing Optimization of Third Party Logistics Operations Using Greedy Search Approach

Vivekanandhan. P1, Anand. S1, Paramasivam. A2

1Department of Mechanical Engineering, SRM Easwari Engineering College, Chennai, 600 089, India

2Department of Mechanical Engineering, St.Joseph’s College of Engineering, Chennai, 600 025, India

Correspondence to: Vivekanandhan. P, Department of Mechanical Engineering, SRM Easwari Engineering College, Chennai, 600 089, India.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

One of the important aspects of supply chain management is the maintenance of an efficient and cost effective system for the distribution of goods or products to customers end. Nowadays, it is almost inevitable that an efficient distribution network can only be achieved with the support of optimization technique in Computer based simulation software. This work describes how an Evolutionary Algorithms (EA) can play an effective role in this aspect. Besides being an effective and efficient optimization tool capable of handling problems of significant computational complexity, it enjoys great flexibility in copying with the constraints of typical real-life supply chain problems. This work considers the problem of managing a 3PL distribution network of Lucas-TVS for reaching various suppliers located around Chennai (Tamil Nadu, India). The simulation model is designed to generate an optimum route for a single truck to cover all suppliers situated within certain distance limit and integrating the suppliers as like Travelling Salesman Problem (TSP). The truck dispatched according to a pre-specified plan to reach the suppliers located around the hub subjected to several dynamic constraints. Greedy Search (GS) based dynamic simulation model was developed to generating the approximate shortest route solutions with reasonable computational time.Keywords Greedy Search Method, Logistics, Travelling Salesman Problem , Optimization, Simulation Model

Keywords:

Cite this paper: Vivekanandhan. P, Anand. S, Paramasivam. A, Routing Optimization of Third Party Logistics Operations Using Greedy Search Approach, Journal of Logistics Management, Vol. 2 No. 1, 2013, pp. 1-8. doi: 10.5923/j.logistics.20130201.01.

Article Outline

1. Introduction

- A supply chain is a network of facilities and distribution options that performs the functions of procurement of materials, transformation of these materials into intermediate and finished products to customers. Supply chain is a set of approaches utilized to efficiently integrate suppliers, manufacturers, warehouses, and stores, so that the merchandise is produced and distributed at the right quantities, to the right locations, and at the right time, in order to minimize system wide costs while satisfying service level requirements.There is difference between the concept of supply chain management and the traditional concept of logistics. Logistics typically refers to activities that occur within the boundaries of a single organization and supply chain refer to networks of companies that work together and coordinate their actions to deliver a product to market. Also traditional logistics focuses its attention on activities such as procurement, distribution, maintenance, and inventory management. Supply chain management acknowledges all of traditional logistics and also includes activities such as marketing, new product development, finance, and customer service. In wider view of supply chain thinking, these additional activities are now seen as part of the work needed to fulfil customer requests. Supply chain management views the supply chain and the organizations in it as a single entity. It brings a systems approach to understanding and managing the different activities needed to coordinate the flow of products and services to the best serve the ultimate customer. This system approach provides the frame work in which to best respond business requirements that otherwise would seem to be in conflict with each other. Taken individually, different supply chain requirements often have conflicting needs. For, instance, the requirement of maintaining high levels of customer service calls for maintaining high levels of inventory, but then the requirement to operate efficiency calls for reducing inventory levels. It is only when these requirements are seen together as parts of a larger picture that ways can be found to efficiency balance their different demands. Effective supply chain management requires simultaneous improvements in both customer service levels and the internal operating efficiencies of the companies in the supply chain. Customer service most basic level means consistently high order fill rates, high on-time delivery rates, and a very low rate of products returned by customers for whatever reason. Internal efficiency for organizations in a supply chain means that these organizations get an attractive rate of return on investments in inventory and other assets and they find ways to lower their operating and sales expenses.

2. Previous Work

- The Vehicle Routing Problem (VRP) with pickup and delivery time windows was studied with the objective of determining resource requirements and daily routing by minimizing the sum of vehicle fixed costs and travelling costs. The multiple uses of vehicles can reduce costs. Such a cooperative strategy, which has received little attention in past literature but which occurs in practice, may generate further savings. The strategy was studied here, with the single or multiple uses of vehicles. Vehicles were allowed to travel to transfer items to another vehicle returning to the depot, provided no time window constraint is violated. This is modelled by an exact integer programming formulation which includes the solutions of the independent strategy [7].The proposed models are compared with a construction heuristic with new insertion-based construction heuristic for solving pickup and delivery problem with time windows which was applied to this problem. Experiments with instances generated from real-life data and simulated data show (i) significant savings over the construction heuristic as problem size grows; and (ii) multiple uses of vehicles with a cooperative strategy may achieve cost savings over the independent strategy. An iterated local search algorithm for the Vehicle Routing Problem with time window constraints. The time window constraint for each customer as a penalty function, and assume that it is convex and piecewise linear. Given an order of customers each vehicle to visit, dynamic programming (DP) is used to determine the optimal start time to serve the customers so that the total time penalty is minimized. This DP algorithm is then incorporated in the iterated local search algorithm to efficiently evaluate solutions in various neighbourhoods. The amortized time complexity of evaluating a solution in the neighbourhoods is a logarithmic order of the input size (i.e., the total number of linear pieces that define the penalty functions). Computational comparisons on benchmark instances with up to 1000 customers show that the proposed method is quite effective, especially for large instances[4]. The standard vehicle routing problem by allowing soft time window and soft travelling time constraints, where both constraints are treated as cost functions[5]. The distribution of finished products from depots to customers is a practical and challenging problem in logistics management. Better routing and scheduling decisions could results in higher level of customer satisfaction because more customers could be served in a shorter time. The distribution problem is generally formulated as the vehicle routing problem (VRP). Nevertheless, there is a rigid assumption that there is only one depot. In cases, for instance, where a logistics company has more than one depot, the VRP is not suitable. To resolve this limitation, this paper focuses on the VRP with multiple depots, or multi-depot VRP (MDVRP). The MDVRP is NP-hard, which means that an efficient algorithm for solving the problem to optimality is unavailable[1]. To deal with the problem efficiently, two hybrid genetic algorithms (HGAs) are developed in this paper. The major difference between the HGAs is that the initial solutions are generated randomly in HGA. The Clarke and Wright saving method and the nearest neighbour heuristic are incorporated into HGA2 for the initialization procedure. A computational study was carried out to compare the algorithms with different problem sizes. It is proved that the performance of HGA2 is superior to that of HGA1 in terms of the total delivery time. The best solution of the vehicle routing problem simultaneously considering heterogeneous vehicles, double trips, and multiple depots by using a hybrid genetic algorithm[1][4][11]. This study suggested mathematical programming model with a new numerical formula which presents the amount of delivery and sub-tour elimination. This model gives an optimal solution by using OPL-STUDIO (ILOG CPLEX). It also suggests a hybrid genetic algorithm (HGA) which considers the improvement of generation for an initial solution, three different heuristic processes, and a float mutation rate for escaping from the local solution in order to find the best solution. The suggested HGA also compared with the results of a general genetic algorithm and existing problems[1]. A transportation problem for moving empty or laden containers for a logistic company. Owing to the limited resource of its vehicles (trucks and trailers), the company often needs to sub-contract certain job orders to Outsource companies. A model for this truck and trailer vehicle routing problem (TTVRP) is first constructed and the solution to the TTVRP consists of finding a complete routing schedule for serving the jobs with minimum routing distance and number of trucks, subject to a number of constraints such as time windows and availability of trailers. To solve such a multi-objective and multi-modal combinatorial optimization problem, a hybrid multi-objective evolutionary algorithm (HMOEA) featured with specialized genetic operators, variable-length representation and local search heuristic was applied to find the Pareto optimal routing solutions for the TTVRP[6]. Detailed analysis is performed to extract useful decision-making information from the multi-objective optimization results as well as to examine the correlations among different variables, such as the number of trucks and trailers, the trailer exchange points, and the utilization of trucks in the routing solutions. It has been shown that the HMOEA is effective in solving multi-objective combinatorial optimization problems, such as finding useful trade-off solutions for the TTVRP routing problem capacitated vehicle routing problem (CVRP) by applying a novel hybrid genetic algorithm (HGA) capable of practical use for manufacturers[11]. The proposed HGA has three stages. First, the nearest addition method (NAM) was incorporated into sweep algorithm (SA) that simultaneously accounts for axial and radius relationships among distribution points with the depot to generate a well-structured initial chromosome population, rather than adopting either the NAM OR SA alone[7]. Second, response surface methodology (RSM) was employed to optimize crossover probability and mutation probability via systematic experiments. Finally, an improved sweep algorithm was incorporated into the GA, producing a stir over gene permutations in chromosomes that enhance the exploration diversity of the GA, thereby avoiding convergence in a limited region, and enhancing the search capability of the GA in approaching a close-to-optimal solution. Furthermore, an elitism conservation strategy holding superior chromosomes to replace inferior chromosomes was also performed. As the proposed HGA is primarily used to solve practical problem, benchmark problems with fewer than 100 distribution points from an Internet website were utilized to confirm the CVRP[12]. The Vehicle Routing Problem (VRP).VRP as a field of study and practice is defined quite broadly. It is considered to encompass all of the managerial, physical, geographical, and informational considerations as well as the theoretic disciplines impacting this ever emerging-field. Over its lifespan the VRP literature has become quite disjointed and disparate. Keeping track of its development has become difficult because its subject matter transcends several academic disciplines and professions that range from algorithm design to traffic management. Consequently, this paper defines VRP’s domain in its entirety, accomplishes an all-encompassing taxonomy for the VRP literature, and delineates all of VRP’s facets in a parsimonious and discriminating manner. Sample articles chosen for their disparity are classified to illustrate the descriptive power and parsimony of the taxonomy. Moreover, all previously published VRP taxonomies are shown to be relatively Myopic; that is, they were subsumed by what is herein presented. Because the VRP literature encompasses esoteric and highly theoretical articles at one extreme and descriptions of actual applications at the other, the article sampling includes the entire range of the VRP literature. With the proposed generalization, the problem becomes very general[6]. In our approach, the use local search to determine the routes of vehicles. After fixing the route of each vehicle, determine the optimal start times of services at visited customers. It shows that this sub problem is NP-hard when cost functions are general, but can be efficiently solved with dynamic programming when travelling time cost functions are convex even if time window cost functions are non-convex. We deal with the latter situation in the developed iterated local search algorithm. Finally we report computational results on benchmark instances, and confirm the benefits of the proposed generalization.

3. Logistics Model

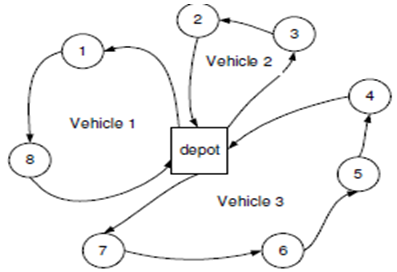

- The applications of vehicle routing problem (VRP) (proposed by Dantzig and Ramser, 1959) are very common in real life. It can be described by the scenario that follows. Let consider a depot having a fleet of vehicles with limited capacities and a set of customers, each with a certain demand for the merchandise or goods to be dispatched. The problem is to determine optimal routings for each vehicle to visit every customer exactly once in order to fulfil the demand. The most common goal for optimization is to minimize the overall distance travelled by the vehicles. It should be emphasized that in reality, for many real-life problems, it is common for practical constraints or limitations to be considered in the process of optimization. The vehicle routing problem has been one of the elementary problems in logistics ever since because of its wide use and high economic value the Vehicle Routing Problem (VRP) can be described as follows. Suppose there are M vehicles each of which has a capacity of Q and N customers who must be served from a certain depot. The goods each customer asks for and the distance between them are known in advance. The vehicles start from the depot, supply the customers and go back to the depot. It is required that the route of the vehicles should be arranged appropriately so that the least number of vehicles is used and the shortest distance is covered, and at the same time the following conditions must be satisfied.•The total demand of any vehicle route must not exceed the capacity of the vehicle.•Any given customer is served by one, and only one vehicle.•Customer delivery should be done efficiently and economically.An illustration is as shown in Fig.1 where there are 3 vehicles and 8 customers or stations in the delivery network. The goal of optimization is to route all 3 vehicles such that all the 8 stations are visited by one of the vehicles. The plan for routing the 3 vehicles is such that the total distance travelled by the vehicles is minimal. Fig.1 presents an illustration of one possible plan of routing the three vehicles starting and ending at the depot. It should be emphasized that in reality, for many real-life problems, it is common for practical constraints or limitations to be considered in the process of optimization.

| Figure 1. Routing Single Depot with 3 Vehicles and 8 Customers |

3.1. Problem Representation

- This study deals with the application of VRP in a supply distribution network. Specifically, the problem deals with reaching the suppliers from the manufacturing hub considered as depot here and again returning to the depot. The prime objective of the study is•To optimize the total distance travelled by 3PL.•To minimize the administrative costs associated with transportation of Logistics Industry.•To maximize the efficiency in satisfying the customers in an economical manner.The system generates a plan for routing truck being managed and the dispatch schedule is subject to a series of constraints described below.•The truck originates from the terminal station (Depot) and it will send out to service a number of suppliers according to the planned sequence assigned to it. •The truck returns to the terminal station (Depot) at the end of sequence. Upon arrival at each station, the truck collects a fixed amount of material allocated to the station, or any lesser amount that the station may be able to take in at the moment. The main goal of planning is to minimize the total distance travelled by the truck. From the description, it is clear that the problem to be solved belongs to the class of capacitated VRP (CVRP) integrated by means of traveling salesman problem (TSP) concept. In real life dispatch planning, there may be many constraints that the system has to deal with. Some of the likely constraints are described below. A station may require more than one type of material. However, truck is allowed to carry only one particular type of material in one dispatch. The planning should be flexible enough to handle certain priority cases. Priority may be accorded for situations, including extreme shortage of material, projected depletion of material, operator imposed priority and so on. Typically, material delivery is to be completed within a certain time limit. Certain timing elements such as truck speed, loading time, rest stop may also be considered. The system should be upward scalable in terms of the number of stations. The complexity of the TDS without handling constraints itself is challenging. It is therefore envisaged that real-life practical constraints imposed during planning may make the problem even more complex.

3.2. Assumption Considered

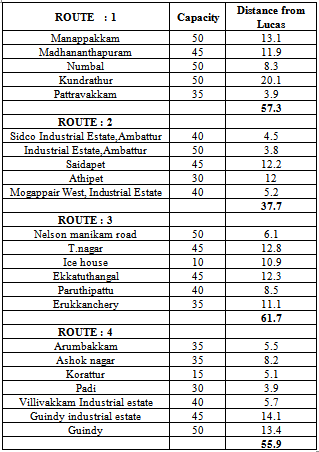

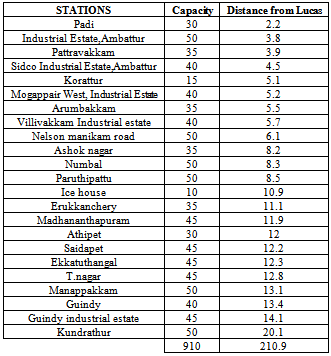

- Initially 4 routes have been employed to reach the suppliers from the depot and after servicing each supplier (i.e) collecting the materials, then they again travel back to the depot. Here suppliers are clustered according to their supply limits and their locations. Each route is assigned to that particular cluster. Here each route consists of individual vehicles to reach the suppliers. Here assumptions chosen are that the supplier whose location is within 25Kms from the depot was considered. All the suppliers within 25 Kms are integrated like a traveling salesman problem nodes and an individual truck is assigned to reach all the nodes (i.e. suppliers) from the depot and returning to the depot covering all the chosen suppliers and completing it by means of single tour.

4. Proposed Methodologies

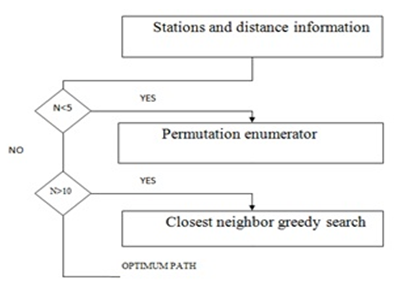

- The methodologies used to determine the best vehicle routing for truck dispatch system (TDS) are•Permutation Enumerator•Greedy search algorithmInitially the distance of the stations are considered as known factors along with the capacity of the vehicles used. Each vehicle is assigned to a set of stations based upon the demand and capacity of the vehicles. First by means of permutations and combinations possible set of routes for each vehicles are formed. Among the route combinations best routes are formed based upon the distance i.e., based on shortest distances. Above mentioned method is suitable for least no of stations (n< 5), for more number of stations to be found out this method will be hard and complex in the aspect of both calculations and final solutions. Here the greedy search algorithm is used to find out a feasible route plan with finding initially the total distance that each truck has to travel to reach the customers. Then, by knowing the distances to be travelled by the vehicles using greedy search algorithm an optimized routing plan is formed for each set of vehicles. This will help to reach the customers in both effective and efficient manner.

4.1. Greedy Search Algorithm

- A “greedy algorithm” firstly, based on the list of nodes that a truck is assigned to service; it starts the sequence by choosing from the list a station that is nearest to the terminal station. Then the next station in the sequence is determined by choosing the station that is nearest to the preceding station from the list of remaining stations. This process is repeated, until all the stations have been exhausted to form the complete sequence starting and ending at the terminal station and it works in phases. At each phase, the best outcome is considered without regard for future consequences. It is observed that by choosing a local optimum at each step, it finally end up at a global optimum. The computing time tends to increase exponentially and computational complexity, when other exhaustive methods are used. As an alternative for larger problems, the greedy search methodology can be adopted.

4.1.1. Reason for Choosing Greedy Search

- The computing time tends to increase exponentially, leading to computational complexity, when other exhaustive methods are used. As an alternative for larger problems, we adopt a greedy search methodology. Firstly, based on the list of nodes that a truck is assigned to service, it starts the sequence by choosing from the list a station that is nearest to the terminal station. Then the next station in the sequence is determined by choosing the station that is nearest to the preceding station from the list of remaining stations. This process is repeated, until all the stations have been exhausted to form the complete sequence starting and ending at the terminal station.

| Figure 2. Flow Chart |

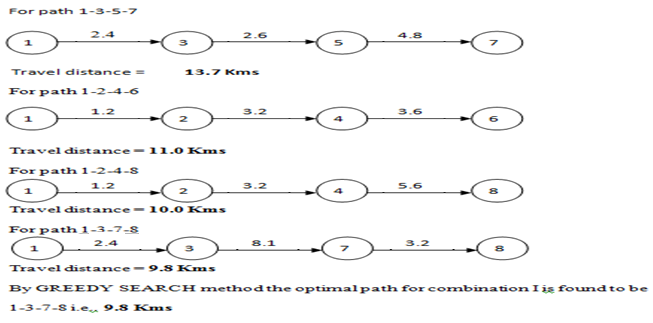

4.1.2. Distance Matrix and Shortest Route Calculations for the Stations

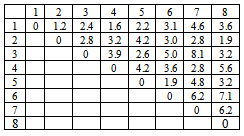

- The distance between 8 stations are shown in 8×8 distance matrix table. Since a symmetric matrix is taken only one half is filled in the Table.1The distances between the stations are quoted in kilometers (Kms).1 ̶ denotes the depot i.e. starting pt of the vehicles2-8 ̶ denotes the stations to be visited the vehicles.

|

Thus by repeating the procedures mentioned above for all 35 combinations, a set of optimum paths are obtained. Hence, in future if demand arises from any of these stations then, finding optimal path will be easier one. Then along with this transportation costs and administrative costs associated can be found. Application of genetic algorithm will make the process more reasonable with the effect of factors influencing the parameters chosen for VRP problems

Thus by repeating the procedures mentioned above for all 35 combinations, a set of optimum paths are obtained. Hence, in future if demand arises from any of these stations then, finding optimal path will be easier one. Then along with this transportation costs and administrative costs associated can be found. Application of genetic algorithm will make the process more reasonable with the effect of factors influencing the parameters chosen for VRP problems5. Results and Discussion

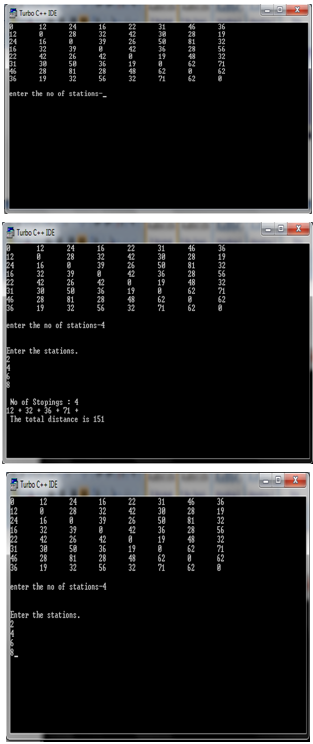

| Figure 3. Soft model of distance Matrix |

|

|

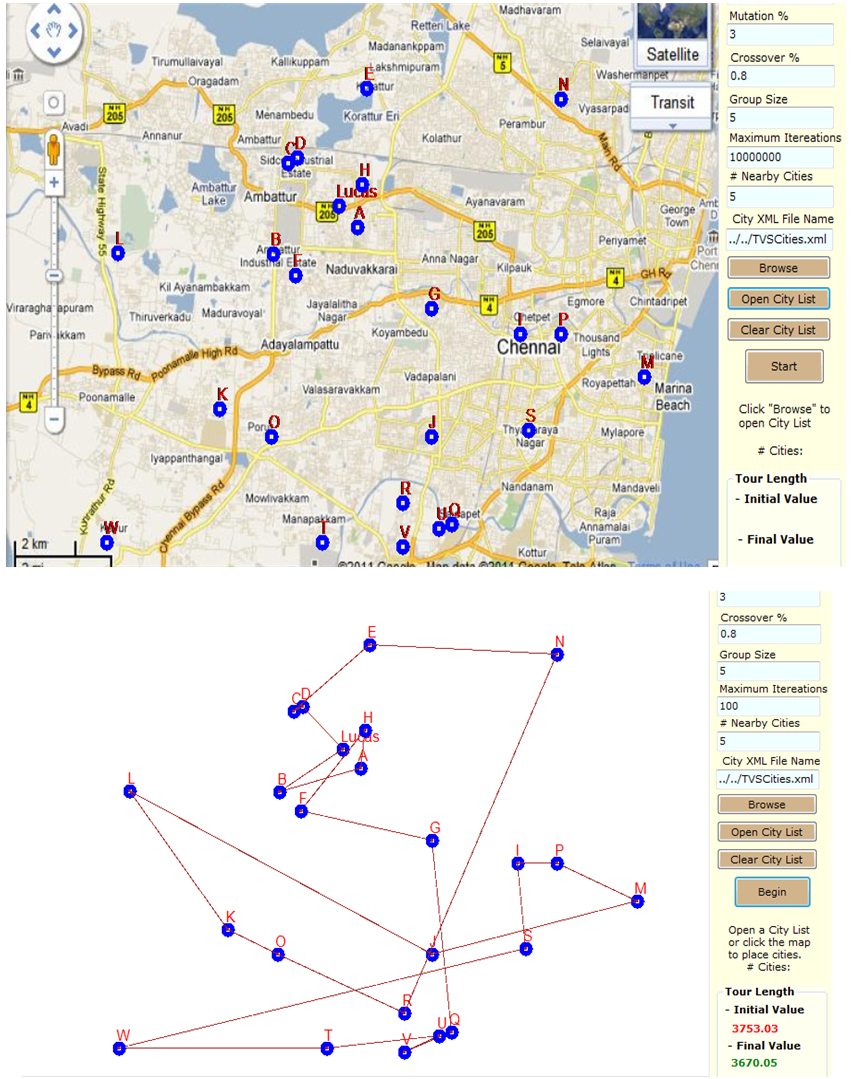

| Figure 4. Optimized simulation route |

6. Conclusions and Future Work

- Here vehicle routing for truck dispatch system was done based on known demand and customer locations. Further vehicle routing is first initiated with number of stations to be served and total no of vehicles employed to serve the stations based upon permutations and combinations. Based on permutation and combinations routings were formed. In case of large number of vehicles greedy search method is used to find the distances between the stations and the vehicle routes distances. This simulation helps the 3PL provider to execute the real time operations and also plan their daily despatching activities in an effective way in both route and cost associate with it. Here vehicle routing has been done based upon known demand and capacity of the suppliers. As the extension of this work, Vehicle routing can also be done for the suppliers with uncertain demand and without integrating the nodes. Further time window for vehicle routing can also be considered to form routing considering loading time, delay penalties, real time constraints etc. Evaluating the efficiency of the system by means of comparison tools like histogram to find the efficiency and performance of the system.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML