-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Journal of Wireless Networking and Communications

p-ISSN: 2167-7328 e-ISSN: 2167-7336

2017; 7(3): 53-58

doi:10.5923/j.jwnc.20170703.01

Real-Time, Web-based Temperature Monitoring System for Cold Chain Management in Malawi

Alinafe Kaliwo1, Jonathan Pinifolo2, Chomora Mikeka3

1Department of Electrical Engineering, University of Malawi, The Polytechnic, Malawi

2Department of Electrical and Electronic Engineering Science, University of Johannesburg, South Africa

3Department Physics, University of Malawi, Chancellor College, Zomba, Malawi

Correspondence to: Alinafe Kaliwo, Department of Electrical Engineering, University of Malawi, The Polytechnic, Malawi.

| Email: |  |

Copyright © 2017 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Temperature is regarded as one of the fundamental factors of increase in the microbial activity. Most food stuffs, drug and water are initially found in the products to be affected by this increase in microbial activity. As the temperature rises, the number of microbes increases hence causing increase in the rate of damage and spoilage of the products. Every day, millions of tons of temperature sensitive goods are produced, transported, stored or distributed worldwide. For all these products the monitoring and control of temperature is essential. In this paper, a low cost, real-time, web-based temperature monitoring system is being designed and implemented to monitor both fixed and mobile cold chain. The results show tremendous improvement in the process of monitoring one’s cold chain.

Keywords: Microbial, Microchips, GSM, Arduino, Real time, Malawi

Cite this paper: Alinafe Kaliwo, Jonathan Pinifolo, Chomora Mikeka, Real-Time, Web-based Temperature Monitoring System for Cold Chain Management in Malawi, Journal of Wireless Networking and Communications, Vol. 7 No. 3, 2017, pp. 53-58. doi: 10.5923/j.jwnc.20170703.01.

Article Outline

1. Introduction

- The term “cold chain” describes the series of interdependent equipment and processes employed to ensure the temperature preservation of perishables and other temperature controlled products from the production to the consumption end in a safe, wholesome, and good quality state [1]. In other words, it is a supply chain of temperature sensitive products. So temperature-control is the key point in cold chain operation and the most important factor when prolonging the practical shelf life of produce. Thus, the major challenge is to ensure a continuous ‘cold chain’ from producer to consumer in order to guarantee prime condition of goods [2]. These products can be perishable items like fruits, vegetables, flowers, fish, meat and dairy products or medical products like drugs, blood, vaccines, organs, plasma and tissues. All of them can have their properties affected by temperature changes. Also some chemicals and electronic components like microchips are temperature sensitive.

1.1. The Importance of Temperature Monitoring of One’s Cold Chain

- In food stuffs and drugs, the issue of inappropriate temperatures during processing, transportation and storage cause the development of toxic substances that are lethal to the human beings once consumed. Decreasing refrigeration temperatures decrease bacterial growth, and affect the composition of the bacterial flora [3] hence the requirement for some food stuffs and drugs to be produced, transported and kept in temperature-controlled rooms.Determining the integrity of one’s cold chain system, which is from the point of production and processing, to storage at the consuming household or restaurant or retailer [4], is the primary goal for sustainable food and drug supplies management. This helps the producers and manufacturers to deter food spoilage by involving preventive measures in time.

1.2. Monitoring Temperature of One’s Cold Chain in Malawi

- In Malawi, there is a lot to be done to achieve proper cold chain management during food and drug storage, distribution and selling. Currently, cold chain suppliers monitor the temperature of their merchandize using mercury thermometers and temperature displays. This means they are unable to monitor their cold chain remotely without actually having someone to physically check on the aforementioned devices. It has been an utmost interest of the authors of this paper to come up with a system which can be used to monitor temperature changes remotely. The development of this Real-time, Web-based Temperature Monitoring System (RWTMS) has opened new opportunities for companies in Malawi, especially those in cold chain, to reduce their losses and expenses that arise due to poor monitoring of their both fixed and mobile cold chain assets.In respect of paper structure, the rest of the paper is organized as follows: Section 2 presents methodology. Design aspects of the RWTMS are outlined in section 3 while section 4 presents observations and results. Conclusions have been finally drawn in section 5.

2. Methodology

2.1. The Increase in Microbial activity due to the Rise in Temperature and Associated Food Spoilage

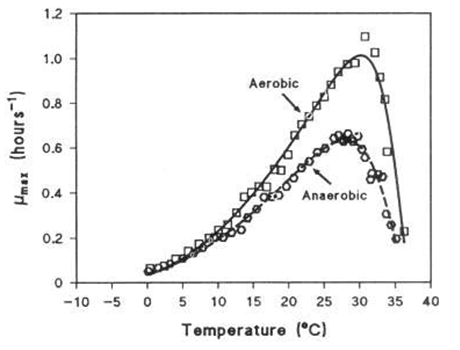

- Recent study has shown that refrigerated shipments rise above the optimum temperature in 30% of trips from the supplier to the distribution centre, and in 15% of trips from the distribution centre to the stores [5]. This increase in temperature causes the increase in microbial activities which and as result cause the reduction in shelf life and spoilage of food products. It is well known from recent findings that both enzymatic and microbiological activities are greatly influenced by temperature. However, in the temperature range from 0 to 25°C, microbiological activity is relatively more important, and temperature changes have greater impact on microbiological growth than on enzymatic activity [6]. Many bacteria are unable to grow at temperatures below 10°C and even psychrotrophic organisms grow very slowly, and sometimes with extended lag phases, when temperatures approach 0°C. Figure 1 below shows the effect of temperature on the growth rate of the fish spoilage bacterium Shewanella Putrefaciens. At 0°C the growth rate is less than one-tenth of the rate at the optimum growth temperature [6].

| Figure 1. Effect of temperature on the maximum specific growth rate (µmax) of Shewanella putrefaciens grown in a complex medium containing TMAO (Dalgaard, 1993) |

2.2. The Importance of Open-source Technologies in the Design

- Open source technology is defined as the production and development philosophy of allowing end users and developers to not only see the source code of software, but modify it as well. The Linux operating system is a one of the best-known examples of open source software technology [7]. Apart from just looking at the software, hardware with design specifications of a physical object licensed in such a way that the said object can be studied, modified, created, and distributed by anyone is also termed as open source.Most of technologies (software and hardware) that were used in the design of the RWTMS are open source. These helped us to realise the objectives of this innovation because it was easy to manipulate the source hardware and software. The interoperability of open source technologies also made it easier for us to come up with system units that would work together on different software platforms like on the Server, windows PC, Linux, Mac OS etc. On the hardware side we used the arduino technology. Arduino has an easy-to-use software and hardware embedded on an ATMEGA 328/P chip. Open source software units were also used and the design process was completed within the set time frame.

2.3. The Idea of Internet of Things in Designing the RWTMS

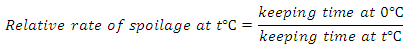

- The RWTMS has been developed using the idea of Internet of Things (IoT). With just simple applications on the top of the architecture, exporting all the system’s functionalities to the final user becomes easier. Through the use of standard web service protocols and service composition technologies, applications can realize a perfect integration between distributed systems (cold chain) and applications [8].Depending on complexity of the IoT systems, there are different layers stacks for achieving a workable IoT-based monitoring system. One of the models was used by Guinard, D. et al (2011) [9] as used in a prototype for a smart meter infrastructure that illustrates the application of the Web of Things (WoT) architecture and the concept of Smart Gateways for monitoring and controlling the energy consumption of households.

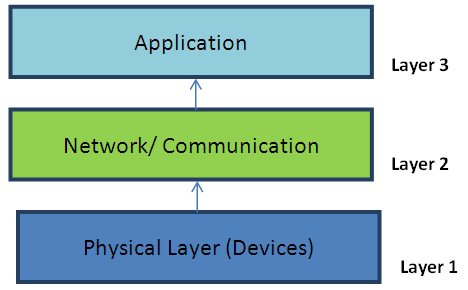

| Figure 2. Prototype for a smart meter infrastructure that illustrates the application of the Web of Things (WoT) architecture |

3. RWTMS Design

- Our design borrows the concept presented in Guinard D. et al by combining other layers to make three main layers. The three-layer-protocol architecture comprises of the devices (Device Level + Sensing Layer), network (Gateway Layer) and the application (Mashup Layer + User Interface Layer). The table below shows the layers of the protocol that was used.

| Figure 3. The three-layer-protocol architecture used in designing the RWTMS |

3.1. Layer 1: Physical Layer (Devices)

- This layer comprises the assets and the devices that have been designed to monitor those assets. Various fixed and mobile cold chain assets were analysed for the design of the system namely: refrigerated truck vans, refrigerated minivans, temperature controlled blood chests, cold rooms, ice cream hardeners, retail-shop fridges and temperature controlled conference rooms.The technology takes advantage of the presence of Open source technologies. Open-source software and hardware provide the opportunity to build low-cost information systems (Yi et al, 2008) [10] that have brought to life new services and applications, made possible, directly or indirectly, by smart things [7].

| Figure 4. A mobile truck van and van refrigerator that was fully analysed for the design of the RWTMS |

| Figure 5. The DS18B20 temperature sensor used in the RWTMS |

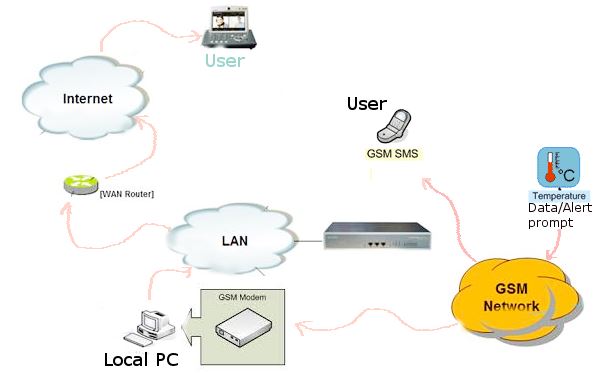

3.2. Layer 2: Network/ Communication Layer

- The transmission of data from one component of the system to another for the achievement of the intended objective was a crucial design constraint in development of IoT or WoT systems. It is on this layer where all signal data transfer is done. The data signal is initiated by a pre-programmed operation within the controller which, after translating the voltage information from the sensor, sends a digital reading of the measured temperature through the GSM module into the local GSM network infrastructure.The data is sent in a form of a Short Text Message (SMS) to a local number that sits on a modem. The modem receives the SMS data and sends it to a cloud database through an http request and the use of an SMS gateway program. The server that hosts the database is connected online and is powered by an application that fetches the right data at the right time for use by the user in monitoring the temperature of their assets.

| Figure 6. A Network diagram to show transmission of data using the RWTMS |

3.3. Layer 3: Application Layer

- This is where you find your end-user and end-application protocols, such as telnet, ftp, and mail (pop3 and smtp) [13]. The telecommunication protocols provide a conduit or passage of information transfer whereas the application layer deals with the keeping and presentation of information or data processing, storage and interface. In this project, various software solutions were used to achieve the objectives. On the cloud server, a mysql database was employed to keep data in tables. Then a Hypertext Preprocessor (PHP) script language is used to query the information that is being kept in the database. By employing these two server-side, open-source database languages, the system has proven performance, reliability, and ease-of-use, and will soon be the leading web-based application for temperature monitoring. For easy access to the information on the server, a web-based online application was designed by combining different web-programming languages namely: Java, html, CSS, and PHP. The system has a number of functionalities which include; graphical presentation of data, automatic refreshing for information updates on the dashboard, some administration controls and security attributes.

4. Results and Discussion

4.1. RWTMS System Observations on Workability and Functionality

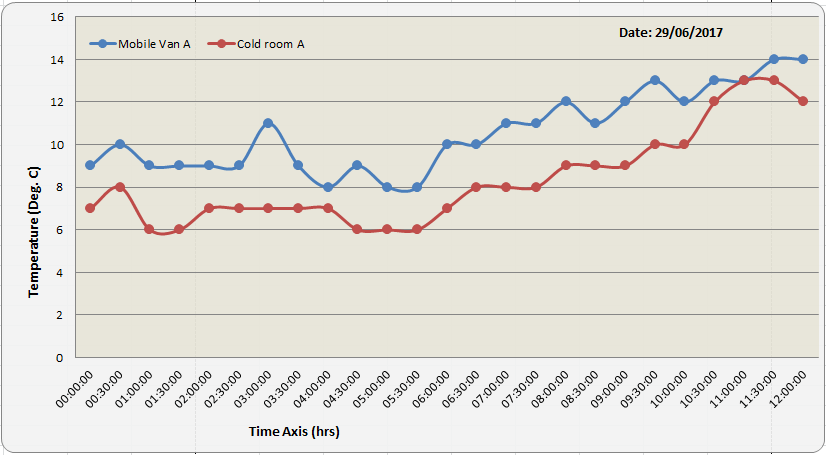

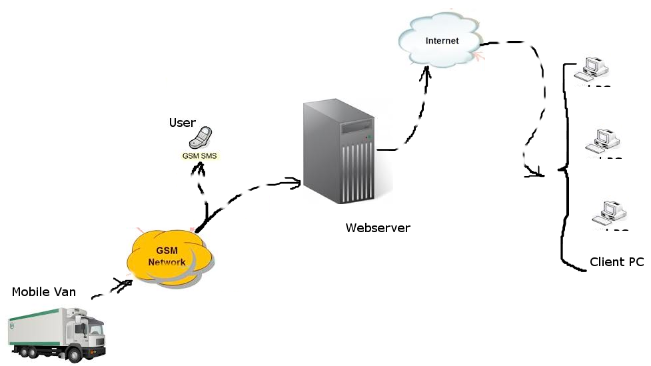

- The system was designed and manufactured well within the set time and budget. It was then tested on the assets of one of the local dairy industries in Malawi. The system was able to link up with the users. They could see the conditions of their refrigerated van while it was in transit. They were also able to monitor their on-site assets which are one hardener and one cold-room. They could also generate temperature reports of these assets in PDF and management could timely plan preventive maintenance. The graph below shows the presentation of temperature data that was collected on 29th June, 2017 for about Twelve hours.The system satisfied the users because it was simple to install, simple to use and flexible in functionalities. Figure 7 below shows the pictorial representation on how the system works.

| Figure 7. A graphical representation of data collected and presented using the RWTMS |

4.2. Cost Evaluation on the Final RWTMS Product

- Through observations made on online market, the average cost of a likewise system on an international market is in the range of US$300.00 per unit. The total cost of producing one RWTMS unit is about US$150 which gives about 50% cost advantage to the users of the system.

| Figure 8. A pictorial representation of system workability for the RWTMS |

5. Conclusions

- In this paper, a real-time web-based temperature monitoring system for cold-chain management has been presented. This RWTMS has demonstrated a huge potential in tackling issues that arise due to poor monitoring solutions. Our solution allows users to log in at anytime, anywhere to check the condition of their assets. The system is also able to prompt the user when an abnormal scenario has occurred in their cold-chain to prevent further damage of their merchandize. The system becomes very important to an agricultural based economy like Malawi since losses in food products will be reduced. RWTMS can help to improve stability of prices of dairy products as suppliers would not lose much in returns and hence stabilizing the prices.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML