-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Journal of Mechanical Engineering and Automation

p-ISSN: 2163-2405 e-ISSN: 2163-2413

2017; 7(4): 109-111

doi:10.5923/j.jmea.20170704.04

Design and Fabrication of Crop Cutter for Multipurpose Application

Rudolf Charles D’Souza, Karthik Shenoy B., Keith Royston D’Silva, Rolin Antony D’Souza

Department of Mechanical Engineering, St. Joseph Engineering College, Mangaluru, India

Correspondence to: Rudolf Charles D’Souza, Department of Mechanical Engineering, St. Joseph Engineering College, Mangaluru, India.

| Email: |  |

Copyright © 2017 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Presently the agricultural industry has come up with vast range of equipments for efficient farming. At the same time the main drawback is that it is not affordable by farmers with poor economical background. This machine can be used for cutting variety of crops and helps the small scale farmers with the cost effective technology. The newly designed crop cutting unit works without using any type of fuel or electrical energy and can be operated with mere muscle force. This equipment uses combined blades for efficient crop cutting. The present designed and fabricated crop cutter can be used to cut the straws of different food grain crops like Paddy, wheat and also grass. It is simple in construction and the working is easy. The crop cutter is actually an application of pure mechanical knowledge to improve the quality of work with minimum labour and time, scope of research in agricultural equipments still remains a fertile field for innovative ideas.

Keywords: Crop cutter, Slider crank mechanism, Manual method, Combined blades

Cite this paper: Rudolf Charles D’Souza, Karthik Shenoy B., Keith Royston D’Silva, Rolin Antony D’Souza, Design and Fabrication of Crop Cutter for Multipurpose Application, Journal of Mechanical Engineering and Automation, Vol. 7 No. 4, 2017, pp. 109-111. doi: 10.5923/j.jmea.20170704.04.

Article Outline

1. Introduction

- The history of agriculture in India dates back to Indus valley civilization era and even before that in some parts of southern India. Today India ranks second worldwide in farm output, so there is always a need for more and more developments and innovations in the field of agricultural technology.Agriculture is the main source of income of India. Many people have agricultural lands and they use equipments which uses fossil fuel for their operation and this causes harm to ozone layer and also results in the depletion of fossil fuel for the future generation.It is important to concentrate in some aspects like how to increase productivity and profit, how to reduce waste and how to solve and ease the problems of workers. To overcome this a new manually operated crop cutter is in need of the hour. It possesses four major criterion that is ease in manufacturing, ease in handling, low cost and light weight. There are some procedures involved in fabrication of this device such as designing using Solid Edge, material and component selection and the like. The agricultural practices which are currently employed are neither economically nor environmentally sustainable and India’s yields for many agricultural material are comparatively low.In the recent years we have seen a shortage of skilled labour available for agriculture, hence due to this shortage the farmers have transitioned to using harvesters. These harvesters are available for purchase but they are not affordable because of their high costs. However agricultural groups make these available for rent on a hourly basis. Considering the Indian market, it has been noted that small holding farm owners having land less than two acres generally do not require the full-featured combine harvesters. Due to financial or transportation reasons these combine harvesters are not available in all parts of rural areas. Thus there is a need for a smaller and efficient combine harvester which would be considerably cheaper and more accessible. The mission is to create a portable, low cost mini harvester and user friendly.

2. Literature Survey

- A simple and cost effective “Mini Paddy Harvester” was fabricated. A detailed design of paddy harvester which included cutting system, transmission from the engine to the cutting system and main frame had been carried out. The assembled paddy harvester was tested for its working and found to be working satisfactorily. But the developed mini paddy harvester was large in size and there is a scope for making it more compact and light in weight [1].Pamujula Hythika Madhav and Bhaskar H D, Tumkur designed and fabricated “Manually operated rotary lawn mower”. The manually operated lawn mower works without fuel. The gear train mechanism and bevel gear system used to rotate the cutting blade. By this lawn mower variety of grass lawns can be cut. Energy expenditure on operating model requires fewer calories. It can be operated easily and is economically cheaper [2].Dr. U.V. Kongre along with his team fabricated a “Multi Crop Cutter”. The machine was manually operated. The uses of it was that it makes the harvesting process faster. Hence reduce most of the cutting time and labour required to operate the machine is also less [3].

2.1. Field Survey

- To understand the variety of crops grown and the crop spacing we conducted a field survey by visiting a few villages near our region.During our survey we observed the following,i. The distance between each successive crop was 10.5 inch.ii. The average height of crop was found to be 30-36 inch. iii. The thickness of the stalk was found to be 0.3 inch. iv. We observed the irregularities in the field in order to select the dimension of the wheel. v. We observed the appropriate height at which the blade must cut the cup (ground clearance of the Blade) The following conclusions were made from the surveyi. The maintenance of currently used fuel based machinery was not economical.ii. Semi skilled labour is required for operating the machinery.

3. Design

- The crop cutter was designed keeping small scale farmers in mind. This crop cutter which was designed is having good harvesting capacity for small farms. Since it does not utilise any engine for its operation, the cutting action is done by cranking of lever by hand. The cutting action is transmitted to the blades by chain and sprockets, and bevel gear arrangement with the use of slider crank mechanism.

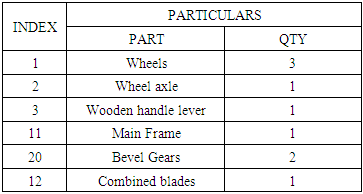

| Figure 1. Final Fabricated model |

|

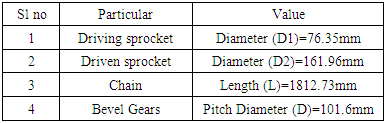

4. Calculation

- The necessary dimension’s of the crop cutter were first calculated by using standard formulas. The dimensions that have been implemented in this manual crop cutter is as follows.

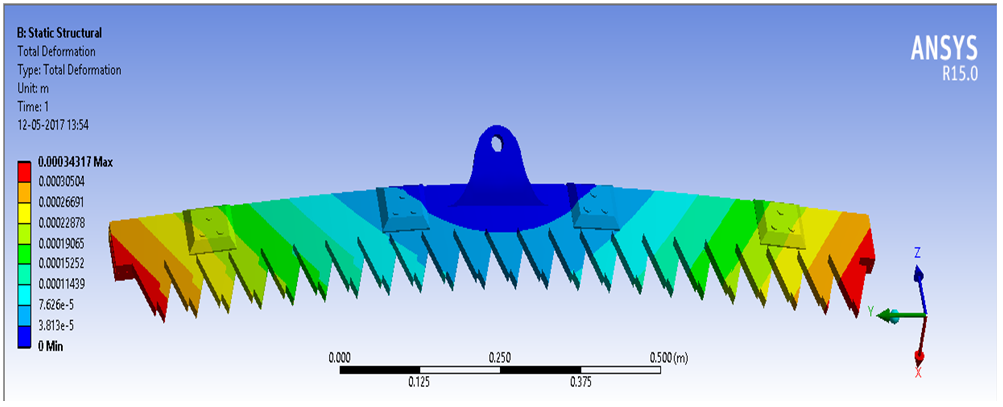

5. Analysis of Blade

- Steps involved in analysis,i. Designing of 3D model of elements.ii. Meshing of the designed elements.iii. Analysis using ANSYS software.

5.1. Total Deformation

| Figure 2. Deformation acting on blade |

6. Conclusions

- The multi-crop cutter has been designed, fabricated and analysed for its performance. This project was an attempt to achieve three main objectives. First is to make it an economical and efficient crop cutter. Second objective is to reduce the cost involved in maintenance and the third objective is to overcome the lack of availability of skilled labourers. The multi-crop cutter is designed, fabricated and tested. The machine does not employ any use of power equipments such as D.C. motors, engines, and it is fully human operated. The use of this machine makes harvesting process faster, hence reduces most of the cutting time and labour required to operate the machine is also less. This machine is very helpful for farmers having small farm land.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML