-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Journal of Mechanical Engineering and Automation

p-ISSN: 2163-2405 e-ISSN: 2163-2413

2017; 7(4): 99-102

doi:10.5923/j.jmea.20170704.02

Modelling, Fabrication and Automation of Areca Nut Sorting Machine

Ajith B. S., Pramod B. C., Impha Y. D., Rakshith H. S., Sudeep K., Pranav Padavu

Department of Mechanical Engineering, SCEM, Mangalore, India

Correspondence to: Ajith B. S., Department of Mechanical Engineering, SCEM, Mangalore, India.

| Email: |  |

Copyright © 2017 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Areca farming is a type of business which farmers do alongside with their crop cultivation. Indian farmers face immense pressure when it comes to the segregation of processed areca nuts. When it comes to paying wages to the labourers for their manual effort of segregating areca nuts based on their quality, the farmers suffer a loss of money and time which are trying to prevent by designing a machine. This machine is designed in such a way so as to be efficient compared to the normal scenario of utilizing manual labour for sorting the Areca nuts. This machine not only saves money but it also saves time for the farmers to focus on other aspects of cultivation. Since both money and time of every farmer is saved, the farmers not only will be encouraged to cultivate other crops but their lifestyle will be improved too. The machine is designed with two phases of separation, mainly based on size and color. The first type of larger Arecanut is separated by passing it through the sieves, where the rest of the types of Areca nuts will be separated based on their color by using a microcontroller. The input to the microcontroller is given by the camera and output using a servomotor. Further, the machine is designed to be robust and highly durable.

Keywords: Areca nut, Segregation, Arduino, Microcontroller

Cite this paper: Ajith B. S., Pramod B. C., Impha Y. D., Rakshith H. S., Sudeep K., Pranav Padavu, Modelling, Fabrication and Automation of Areca Nut Sorting Machine, Journal of Mechanical Engineering and Automation, Vol. 7 No. 4, 2017, pp. 99-102. doi: 10.5923/j.jmea.20170704.02.

1. Introduction

- Areca catechu is the most generally developed species in the genus Areca and has been appropriated by people all through the tropics. The seed of this palm ("areca nut") is utilized as a part of the planning of betel quid, by consolidating it with slaked lime and the leaf of Piper betle (betel leaf). Areca palm seed is presently among the most critical stimulant items on the planet, utilized by around 200 to 600 million individuals all inclusive [1, 2].The product of Areca catechu swings yellow to red shading as it ages and after that comprises of a thick sinewy pericarp, the alleged husk that encases the seed. Like other Areca palms, this species is an understory palm and flourishes in damp tropical woodlands at low to medium rises. Not at all like some different individuals from its class, Areca catechu promptly self-seeds and is tolerant of open conditions and this species is frequently experienced in town gardens, it is likewise developed on vast scale estates in a few territories, prominently in India. Since this palm is planted fundamentally for betel quid generation, foods grown from the ground have been the principle focus for determination by cultivators, despite the fact that development for decorative purposes has expanded as of late. In development, variety is found in the general development propensity and the size, shape, shading, and even taste of the foods grown from the ground.Consumption of Areca nut is very common in India. Elders from the rural area often chew betel nuts when they are discussing each other’s wellbeing. Areca nut bestows a special global cultural and social relevance. It is a prominent cultural behavior in many Asian and Pacific countries. In many areas, Areca nuts are also known as “Paan” and “Gutka” [5, 6].It is very common for any farmer to have lots of Areca palms growing in the environment around their house. Areca farming is a type of business which farmers do alongside with their crop cultivation. From the literature it has been seen that a lot of Engineers come up with special robots capable of climbing areca palms and aiding the farmers to harvest areca fruit from the palms. But even though with the help of the robots, the harvesting difficulty can be reduced to such an extent, the process which comes after the harvesting is even more problematic as the areca nuts which are yielded after the cleaning process will be of different quality and they will be mixed together. Segregating these areca nuts and sorting them according to their quality requires immense manpower and a labor of Rs.300 to Rs.500 is charged per bag of processed areca nuts. If the farmer has huge areca palm cultivation he would have to waste thousands of rupees just on the separation of processed areca nuts. So the present work focuses to develop a prototype which is designed to be highly efficient and economical. This machine is capable of separating 4 different qualities (types) of areca nuts. Figure 1 shows the different varieties of areca nuts.

| Figure 1. Varieties of Areca Nuts |

2. Objectives

- 1. Versatility in sorting: It is designed only for different types of Areca nuts and will be implemented with software to separate Areca nuts of any shape and color.2. Able to separate Before/After harvesting: Not only is the Machine designed to separate processed Areca Nuts but also it is capable of separating Areca nuts before processing.3. Reduce processing time: Usually, the Farmer will spend a lot of time in the last phase which is segregation; this machine will nullify the time spent in that case.4. Improve Farmer’s Lifestyle: Reduced Time spent and invested money can provide a better life for the farmers who are from a poor background.5. Prevent Adulteration: Very rarely Areca nuts will come with one or two nuts of different quality because of improper segregation. That will be avoided.

3. Design and Fabrication

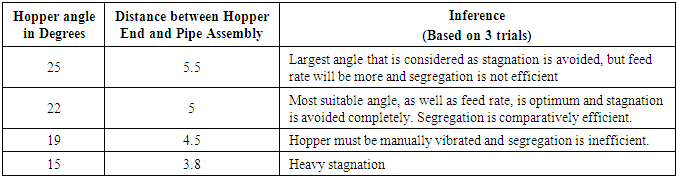

- Based on the pipe-model made so as to get the idea of basic sorting done by this method, it was found out that the segregation depended on certain parameters [3, 4]. The Parameters are as follows:a. The angle of entry (which here is the hopper inclination or hopper angle).b. The distance between hopper end and pipe assembly.c. The angle of inclination of the pipe assembly,d. The tapered clearance between the pipes in the pipe assembly.• Hopper Angle / Angle of EntryAfter many trials the angles of varying from 15° - 25°, it was found that an angle of 22° is provided an optimum segregation without any stagnation, because the Hopper angle directly influences to feed rate and machine then indirectly it also depends on the feed rate. Due to higher feed rate the segregation will be in-efficient and with lower feed rate there will be stagnation.• The distance between hopper and pipeThis parameter varies along with the Hopper angle and is an important consideration when it comes to stagnation also. If there is no sufficient gap between the Hopper end and the pipes there will be severe stagnation and Areca nuts will not be segregated. So based on the optimum Hopper angle, the distance between Hopper and Pipe assembly is setup.• The angle of inclination of the pipe assemblyThis is the most important and the basic parameter to be chosen when preparing the pipe model. Since the model is currently works on gravity only, the inclinations of the surface on which the areca nuts roll and segregate play a great role. To avail an optimum feed rate, consider angle of 63°, so as to obtain a smooth feed rate.• Tapered clearance between the pipes in the pipe assembly“Gorabulu” (Areca nuts with husk) were the largest amongst the four types of Areca nuts and planned on segregating them by making a roll over tapered pipes and the rest of areca nuts would fall at their respective places. The trial details are shown in the Table 1. It was found out the optimum clearance for the pipe spacing at the larger end of the taper was 4.5cm (Centre to Centre of the pipes) and there is no clearance provided at the smaller end of the taper.

|

4. Methodology

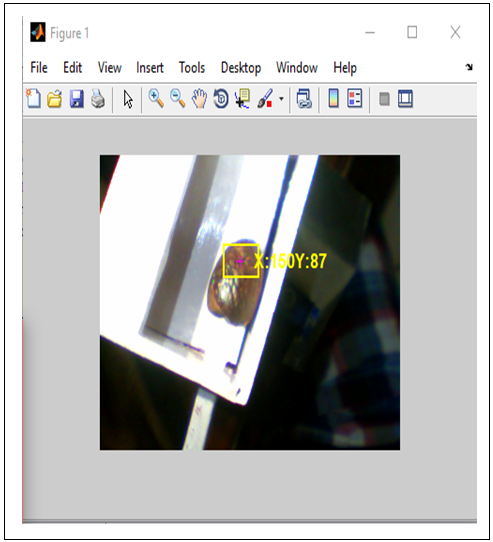

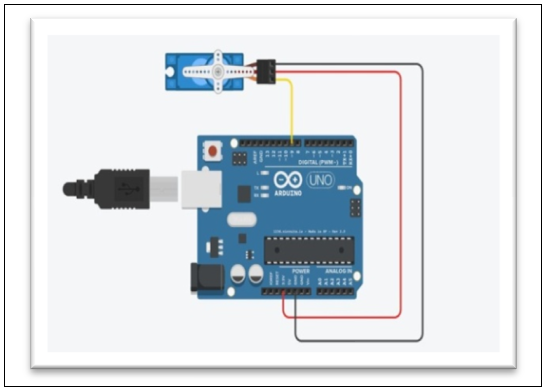

- Step 1: The processed mixture of areca nuts is poured into the hopper which is placed at the top of the machine (figure 5) it is made to pass through tapered clearance between a series of steel pipes (PIPE ASSEMBLY) where the areca nuts are separated based on the size of the nuts. After this is performed two varieties of areca nuts namely “GORABULU” and “SARAKU” are sorted. Whereas it obtain a small amount of mixture among the areca nuts namely, “RASHI” and “BETTE”. This mixture is further sorted using the microcontroller along with a camera and a servo motor which forms the electronic apparatus of the project.Step 2: The separated nuts based on their size will have a mixture of different quality nuts that has to be segregated. The difference in the quality of the areca nuts can be distinguished based on the outer surface color of the nuts. The segregation of the nuts based on their quality is done by using a microcontroller (figure 2). It has been used two software’s to achieve the task, they are MATLAB 2012a and Arduino Software [9-11].

| Figure 2. Arduino Uno Microcontroller |

| Figure 3. Camera Color Detection |

| Figure 4. Arduino Circuit Diagram |

| Figure 5. Pipe Screen Machine |

5. Conclusions

- The recent concern towards the wellbeing of farmers, especially from localities, it has been come up with a machine to aid the farmers in the segregation of processed Areca Nuts. The machine is designed in a user-friendly manner and almost all the raw materials utilized for building this prototype were available in the local area. The idea for the segregation of ‘Gorabulu’ (Biggest round in shape) was re-processed and a new method was found out namely tapered angle pipe arrangement. The segregation of the remaining types of the Areca nuts had to be done either with the use of a color sensor or load cell (weight sensor). After brainstorming, it was opted for sorting of areca nuts based on color because of the image processing efficiency. Hence the micro-controller region of this machine is a bit complex, but is accessible. This is the primary phase of prototype and it has been tried to make the machine accessible to any civilian or farmer and made it in the easiest way.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML