Vani R., Susilendra Mutalikdesai, Sowjanya B., Akshath Kumar

Department of Mechanical Engineering, Yenepoya Institute of Technology, Moodbidri, India

Correspondence to: Vani R., Department of Mechanical Engineering, Yenepoya Institute of Technology, Moodbidri, India.

| Email: |  |

Copyright © 2017 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Abstract

Over the past few decades, due to extensive use of fossil energy sources, world is facing global warming and increasing greenhouse effect. Higher need of energy and less accessibility to power supplies requires the use of renewable sources of energy like wind-energy, which is most prominent for suitable applications. In the present work, design and construction of a wind pump that can provide water to rural and remote areas facing electricity scarcity is attempted. Small wind turbines need to be cost effective, affordable, and incur minimum maintenance cost. Perfectly designed wind mill which can be used in optimal working climate could be a dependable energy source and produce socio-economically valuable energy not only in developing countries but also in local applications. The overall design goals of the present work focused on affordability and simplicity of design rather than efficiency.

Keywords:

Renewable energy, Wind pump

Cite this paper: Vani R., Susilendra Mutalikdesai, Sowjanya B., Akshath Kumar, Design and Fabrication of Vertical Axis Wind Turbine for Water Pump Application, Journal of Mechanical Engineering and Automation, Vol. 7 No. 4, 2017, pp. 95-98. doi: 10.5923/j.jmea.20170704.01.

1. Introduction

Water pumping in rural areas is very important aspect which requires energy [1]. Water sources like wells, dugouts, rivers are often used for agricultural fields. Power scarcity in rural areas is one of the major concerns in transportation of water from the sources to the agricultural fields. Wind energy is a significant source of renewable energy which can be used for pumping water in inaccessible localities. A wind pump is nothing but a windmill used for pumping water. It is one of the primary approaches of using the energy of the wind to pump water. Considering the available renewable energy resources, the generation of electrical energy & mechanical energy by wind turbines has appeared as a feasible and commercial option.In recent years people started using natural sources like wind, hydro, solar energy to produce electricity for providing power to the various power-plants. Energy is the main and most general measure of all kinds of work by human beings and nature. Everything what occurs in the world is the expression of flow of energy in one of its forms. This paper describes the design of a wind power operated small wind pump. This paper also explains the design and fabrication of such a wind turbine blade profile for domestic application. The main objectives of this work are,• To focus on energy generation where it is most needed, by designing a vertical axis wind mill.• To build up small wind turbine & to see practicality of it.• To design & develop water pump which will cope with ordinary pump.

2. Design and Fabrication of Wind Mill

2.1. Elements used for Turbine and Pump

• Aluminum sheet and Aluminum Strips• Mild steel Rod and Mild steel Strips• Flange bearings• Bevel gears• uPVC pipes• Non-return valves and bushes

2.1.1. Aluminum Sheet and Aluminum Strips

Blades are one of the most important components of the wind turbine which influence the power productivity of the system. The area of blades is directly proportional to the wind energy absorbed by the system. In the present work, aluminum sheet is selected to make the blades and aluminum strip was used to provide the support for blade members. | Figure 1. Blade and Strip |

2.1.2. Mild Steel Rods and Mild Steel Strips

The rotating shaft is the vertical shaft to which blade is mounted. Rotating shaft is supported with flange bearings. Mild steel strip is used to give support for blade at bottom side. | Figure 2. Mild steel Strip and rod |

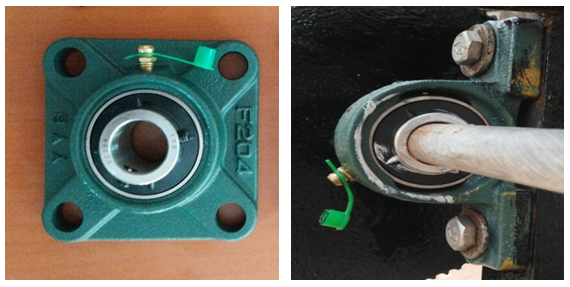

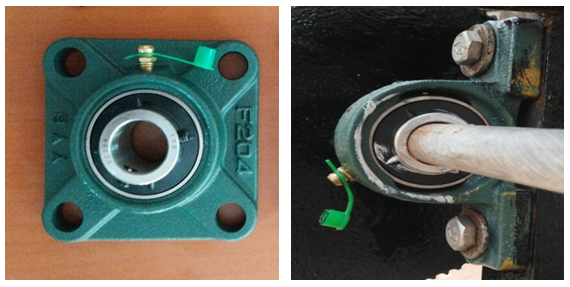

2.1.3. Flange Bearings

Bearings that are mounted within a flanged housing are used when the bearing mounting surface is perpendicular to a shaft axis. They are commonly available in two, three, or four-hole configurations. Four-bolt flanged ball bearing units have a square shape with 4 holes for mounting to accommodate higher loads than two-bolt flanges. | Figure 3. Flange bearing |

2.1.4. Bevel Gears

Gears are used for transmitting power from rotor to slider plate shaft. In this setup bevel gears are used to convert rotational motion of the shaft in vertical axis in to horizontal axis to rotate the slider plate in horizontal axis. The selected bevel gear is of module 2.62mm and number of teeth in pinion is 15 teeth and in gear is 30 teeth. | Figure 4. Bevel gears |

2.1.5. uPVC Pipes

In this work uPVC pipes were used to make the piston pump. Because uPVC pipes have more thickness than normal PVC pipes which has better strength. The whole setup of valves, plunger, caps and piston body are of same material. | Figure 5. uPVC pipes |

2.1.6. Non-return Valve

Non return valve or one way valve is a valve that normally allows fluid (liquid or gas) to flow through it in only one direction. These valves are two port valves, meaning they have two opening in the body, one for fluid to enter and other for fluid to leave. In this setup, the non-return valve of brass material were selected. | Figure 6. Non-return valve |

2.1.7. Miscellaneous Elements

The elements mainly used for assembly purpose are nuts, bolts, washer, rivets, base plate etc. These elements also used to fasten the parts and give support to the system.

2.2. Design

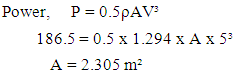

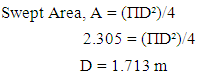

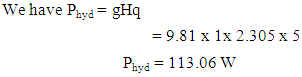

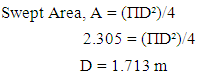

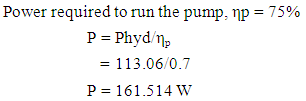

Design of Blade, Power output of turbine and pump: Considering 1/4 hp power, P=186.5WTo find area required for the design of blade, | (1) |

From power equation, power available is proportional to air density (1.225 kg/m3) & is proportional to the intercept area. Since the area is normally circular of diameter D in vertical axis aero turbines then,  | (2) |

| (3) |

| (4) |

| (5) |

| (6) |

Hence, 161.514 W (0.216 HP) power is required for pumping water under head of 1m.

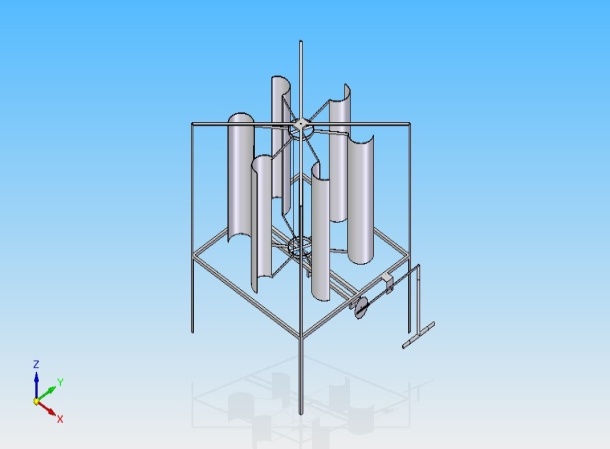

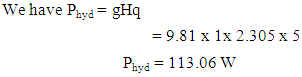

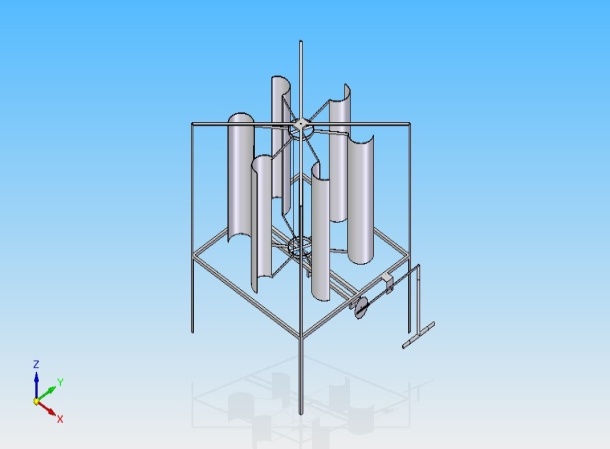

2.3. Fabrication of Wind Turbine

The fabrication of wind turbine shown in the figure 7 is explained as follows.Aluminium sheets cut in to required dimensions (130cm*35cm), then bent into required shape. The aluminium strips are cut and bent to match with the blade diameter, then it attached to the blades by gun riveting. Blade is mounted to the centre shaft plate by using bolt and nuts. Stand is fabricated by the welding process by using M S strips. Two 4-bolt flange bearing is used to mount the wind turbine and 2- bolt bearing is used to mount the slider plate and gear. UPVC pipes, non-return valves, bushes and caps have been used for the preparation of piston pump. The final setup of piston pump is attached to the link rod and to the slider plate. | Figure 7. Model of the wind operated water pump |

3. Working of Wind Pump

• This helical blade vertical axis wind turbine is designed to pump the water. When air blows and strikes the blade of turbine blade starts to rotate.• Rotation of blade mainly depends upon the velocity of air and surface area of blade. The bearings which are fixed to centre shaft will smoothen the rotation.• As blade shaft rotates, shaft of slider plate also rotates when two bevel gears are mesh with each other. • The circular rotation of slider plate causes the plunger rod to move up and down by the help of link rod connected to it. • As the plunger rod move up the suction of water takes place at one side of check valve and closes that valve after suction. • When plunger rod pushes the water releases at second check valve. The required head can be maintained by placing the outlet pipe in required position. | Figure 8. Working of wind operated water pump |

4. Conclusions

In the modern period of rapidly developing technology the design of this vertical axis wind mill generator can be able to full fill certain amount of energy requirements. All materials used are locally available and at a low cost making the model economically viable. In villages, these wind mill can be used for pumping of water when there is no power supply the ease of construction and design modification of the vertical Windmill pump meant that the system is well suited for technological transfer to rural-based community groups. Although it is capital intensive, these technologies will be one of the most cost effective renewable energy wind pumps in terms of the cost per water pumped in very low wind regimes.

References

| [1] | Prasad S.S, Virupaxi Auradi, “Optimized Design of Rotor Blade for a Wind Pump”, International Journal of Renewable Energy Research, volume 2, number 4, 2012. |

| [2] | C. Gopal, M. Mohanraj, P. Chandramohan, P. chandrasekar, “Renewable energy source water pumping systems”, Renewable and sustainable energy reviews 25(2013) 351-370. |

| [3] | Wind- powered water pumping systems for livestock watering, Agriculture and Agri- food Canada. |

| [4] | Ronak D Gandhi, Pramod kothmire, Debarshi Sharma, Bhushan kumbhare, Shubham Choukade, “Design and development of windmill operated water pump”, International journal on recent engineering research and development, Volume -3, issue -12, December 2015. |

| [5] | Hayder kahdim Khashan, “Design and Development of wind power water lifting mechanism”, International journal of science technology and engineering| volume 2| Issue 12| June 2016. |

| [6] | Abdulkadir Ali, Steve Golde, Firoz Alama, and Hazim Moria, “Experimental and Computational Study of a Micro Vertical Axis Wind Turbine”, Procedia Engineering 49 (2012) 254 – 262. |

| [7] | Dr. Abdullateef A. Jadallaha, Dr. Dhari Y. Mahmooda and Zaid A. Abdulqaderb, “Optimal Performance of Horizontal Axis Wind Turbine for Low Wind Speed Regime”, International Journal of Multidisciplinary and Current Research 2014. |

| [8] | Travis J. Carrigan, Brian H. Dennis, Zhen X. Han, and Bo P. Wang, “Aerodynamic Shape Optimization of a Vertical-Axis Wind Turbine Using Differential Evolution”, International Scholarly Research Network, ISRN Renewable Energy 2011. |

| [9] | W. T. Chong, s. C. Poh, a. Fazlizan, and k. C. Pan, “Vertical axis wind turbine with Omni-directional-guide-vane for urban high rise application”, Journal of Central South University of Technology. |

| [10] | Huimin Wanga, Jianliang Wanga, Ji Yao, Weibin Yuanb, Liang Cao, “Analysis on the influence of Turbulence model changes to aerodynamic performance of vertical axis wind turbine”, Procedia Engineering 31 (2012) 274 – 281. |

| [11] | In Seong Hwang, Seung Yong Min, In Oh Jeong, Yun Han Lee and Seung Jo Kim, “Efficiency Improvement of a New Vertical Axis Wind Turbine by Individual Active Control of Blade Motion”. |

| [12] | Farooq Ahmad Najar, G A Harmain, “Blade Design and Performance Analysis of Wind Turbine”, International Conference on Global Scenario in Environment and Energy 2013. |

| [13] | Kaminsky Chris, Filush Austin et al, “A CFD Study of Wind Turbine Aerodynamics”, Proceedings of the ASEE North Central Section Conference (2012). |

| [14] | M.A. Kamoji, S.B. Kedare, S.V. Prabhu, “Performance tests on helical Savonius rotors” Renewable energy 34(2009). |

| [15] | Peter J. Schubel, Richard J. Crossley, “Wind Turbine Blade Design”, Energies 2012, 5. |

| [16] | Piyush Gulve, Dr. S.B. Barve, “Design and construction of vertical axis wind turbine” International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 – 6340(Print), ISSN 0976 – 6359(Online), Volume 5, Issue 10, October (2014), pp. 148-155 © IAEME. |

| [17] | S. Balamurali P. Chinnamani, B. Hariharan, S.M. Hariprakas, B. Haswin, “Design and fabrication of windmill reciprocating water pumping system”, IJARIIE-ISSN (O)-2395-4396, Vol-2 Issue-3 2016. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML