G. Sujaykumar, Shashidhar B. Asantapur, Vishwas C., Prashanth Kumar, Dhanush D.

Department of Mechanical Engineering, Yenepoya Institute of Technology, Moodbidri, India

Correspondence to: G. Sujaykumar, Department of Mechanical Engineering, Yenepoya Institute of Technology, Moodbidri, India.

| Email: |  |

Copyright © 2017 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Abstract

Coconut is a main crop of konkan region and dehusking of coconut is very necessary step in making the coconut ready for further utilization. Coconut dehusking involves removing of the husk from the coconut. Traditional dehusking is time consuming and difficult process. To overcome these limitations, to improve the automation and to provide safety for the operator, a new design of dehusking machine is introduced and fabricated. This dehusker comprises usage of two horizontal rollers with series of sharp tools which would shear the husk from coconut when rolling against each other. Shear force is required for dehusking of mature green coconut and dry brown coconut. Shear force required is more for mature green coconut than dry coconut. Torque and speed reduction required for dehusking is calculated by using the force required for shearing coconut. Optimum number of spikes is arranged on the rollers to dehusk the coconut with minimum force.

Keywords:

Shear force, Optimization of force, Design of rollers, Force analysis

Cite this paper: G. Sujaykumar, Shashidhar B. Asantapur, Vishwas C., Prashanth Kumar, Dhanush D., Design and Fabrication of Coconut Dehusker, Journal of Mechanical Engineering and Automation, Vol. 7 No. 3, 2017, pp. 77-81. doi: 10.5923/j.jmea.20170703.03.

1. Introduction

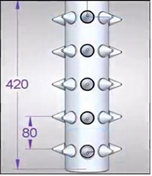

Kerala, which has one of the largest coconut growing area. is famous for its coconut-based products – coconut water, copra, coconut oil, coconut cake (also called coconut meal, copra cake, or copra meal), coconut toddy, coconut shell-based products, coconut wood-based products, coconut leaves, and coir pith. [1, 2]. Need for the improvement in present method is the lack of sufficient manpower. This necessitates the use of appropriate machinery to aid in various tasks in coconut plantation [3]. Traditional devices currently in use, such as the blade and spear are dangerous and minimally productive. Based on this realization, a machine is fabricated that simplifies an important process as well as increases the productivity of the coconut industry. This new mechanism will indirectly boost any economy that relies on coconut plantations [4]. The machine includes a base or a frame positioned on a support surface. Two rollers have spiked tool separated by a small distance, substantially parallel relation with each other. A drive is directly engaged to rollers. Interconnection forces it to rotate in opposite directions. Roller rotates in a direction towards centre, shearing the husk from coconut [5].This machine is useful to the coconut estates and co-operatives, coconut growers and coconut processing factory. The machine can provide faster work rate and less human interaction. This machine is expected to increase the coconut dehusking rate. hence an additional income to coconut growers. It does not require direct human force as in normal methods because in this the spiked rollers which are rotating are made to enhance the force at the head of the coconut to put pressure for dehusking. Also, coconut of any size and shape can be dehusked easily. It is easy to operate, does not need skilled labour, rapid, safe operation and simple maintenance. It can be easily assembled and disassembled and is portable. The cost of this machine is lesser as compared to the present available machines. Also, these available machines require external electrical power supply. Advantages are to remove the husk effectively and easily, to increase productivity, to reduce manual power, to reduce risks and accidents, to reduce labour cost and time consumption [6].This coconut dehusking machine peels off the coconut husk to obtain a dehusked coconut via mechanically controlled dehusking devices called as spiked rollers. To transmit the power from motor to cylindrical rollers gear and chain and sprocket transmission system shall be incorporated. The dehusking unit is consisting of cylindrical rollers attached with tynes (cutting pins) over the surface. The coconut is placed in the intermediate distance between rolling cylinders. The rollers will rotate in such a way that there will be tearing of coconut fiber from the shell. With proper meshing of fiber with tynes effective dehusking is achieved while consuming lesser time. The shape and size of coconut is considered while designing the machine. The rollers are interconnected each other by means of a spur gear arrangement. The rollers are kept apart with a centre distance depending on the average diameter of coconut shell, so that the coconut shell should not pass in between the rollers. The motor used is of 1hp geared motor of 1440rpm which rotates shaft at 70 rpm. The whole set up is mounted on a rigid frame made of mild steel.

2. Methodology

The coconut dehusker base assembly is fabricated using milling, grinding, and welding operations.

2.1. Collecting Data

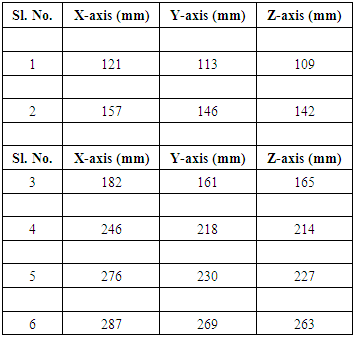

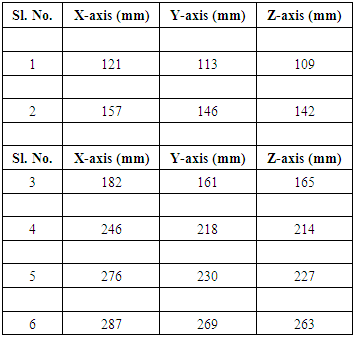

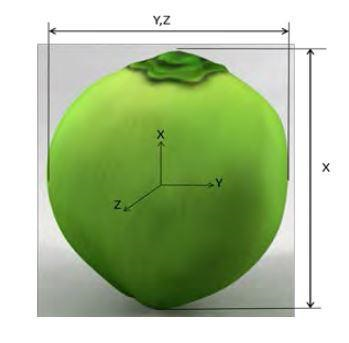

The dimensions of the mature coconut are very much significant as far as the machine design is concerned. Various farms and sites were visited to comprehend the band of dimensions involved in the mature coconut. Some coconuts from Andaman and Nicobar Islands are larger in size when compared to the areas thrived with coconuts in India like Tamil Nadu and Kerala. The machine has been designed to overcome a large range of coconut sizes, with equal importance to productivity. Various places in and around Tamil Nadu and Kerala have been considered predominately to arrive at a conclusion on the size of coconuts. The dimensions have been measured using an external caliper. Majority of coconuts appear to have the dimensions such that the Y and Z direction dimensions are almost identical. However, the critical and concerning dimension for this machine design is the dimension X.Table 1. Dimensions of the coconut with husk

|

| |

|

| Figure 1. Coconut dimensions |

Dry coconut with ovoid shape with length of 210-270 mm, Diameter of 160-206 mm, Weight of 0.62-125 kg, Shell diameter 80-120 mm, Hush thickness is 62 at pedicel end, Husk thickness is 34mm at apex end, Husk thickness is 32 mm from 1/4th distance from pedicel end, Husk thickness is 24 mm from half distance from pedicel end and Husk thickness is 28 mm from 3/4th distance from pedicel end.

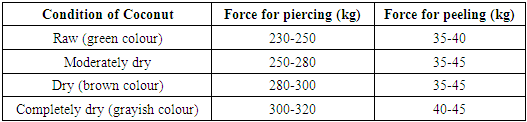

2.2. Testing

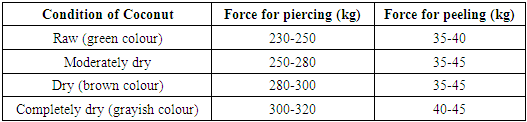

The husk is removed from the Machine through the shear force exerted by the fixed toothed rollers in the machine. SoShear force required to dehusk the different coconuts like raw, moderately dry, dry and completely dry coconut has been determined. Both dry and mature coconuts of various sizes are tested experimentally in the Standard Universal Testing Machine (UTM). The mechanical properties of the coconut fiber are studied from the works.Table 2. Force required for different coconuts

|

| |

|

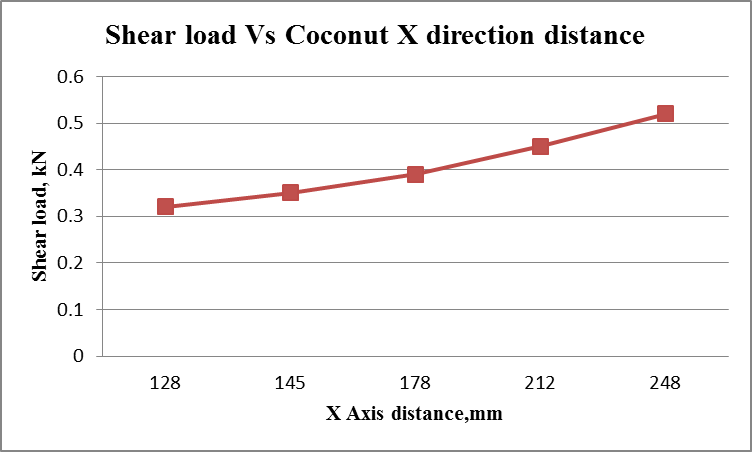

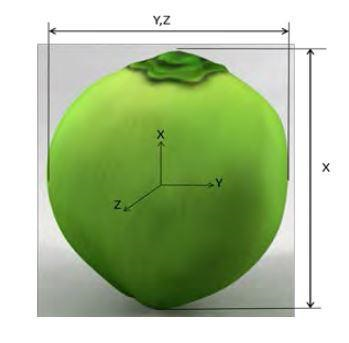

| Figure 2. Graph between X-direction dimensions of the mature coconut and shear load to de-husk the coconut |

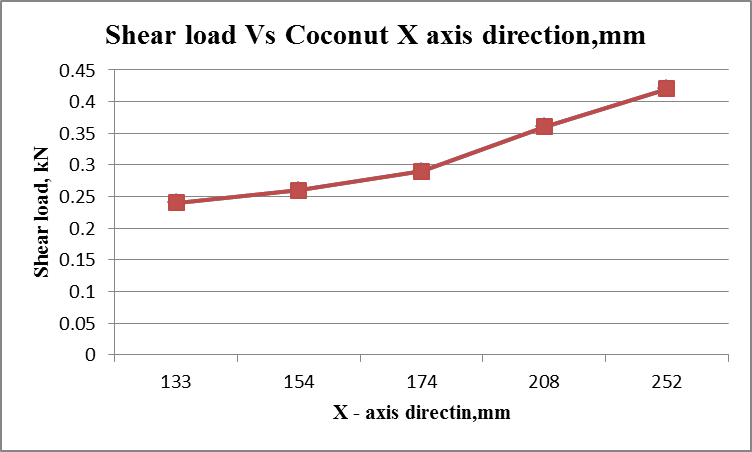

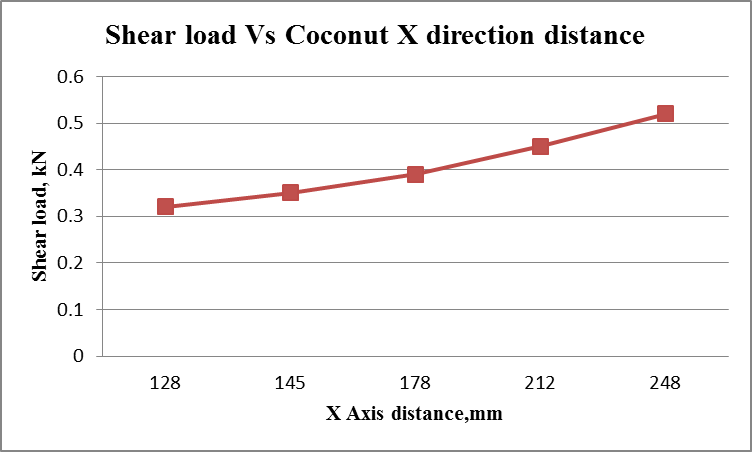

| Figure 3. Graph between X-direction dimensions of the dry coconut and shear load to de-husk the coconut |

It is evident from the above graph that the load required for de-husking the dry coconut is higher than the load required for de-husking the mature coconut. Also, graphs are plotted for both dry and mature coconuts in such a way that X-Dimension of the coconut is taken as an independent parameter in X-axis and the shear load is taken along the Y-axis. This is due to the fact that the shear load varies based on the size of the coconut.

2.3. Design of Dehusker

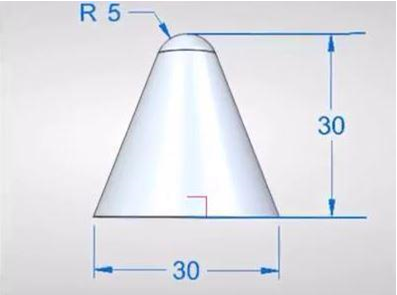

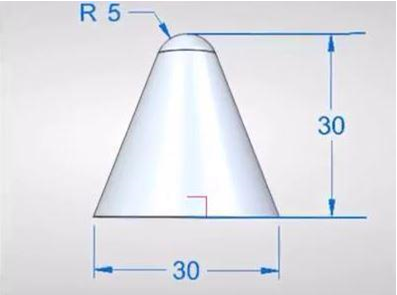

The dimensions of cylinders are designed in a manner to obtain effective mesh with coconut husk. Assumptions used are coconut contacts with cylinder at an average angle of 30 degree contact sector and 1/6th of width of coconut should be inserted into the intermediate space between cylinders. | Figure 3. Dimensions of spike on Roller |

The adhesion between fibers in the husk is greater than that between the shell and the husk; hence separation occurs at the husk-shell interface. The thickness of fiber is in the range of 20 to 40mm. The dimension of tynes should be so selected that to get effective penetration with coconut. The tynes can be attached to cylindrical rollers either by welding or by using fasteners. | Figure 4. Spike Dimension |

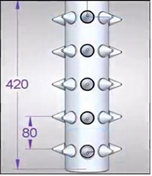

Both horizontal and circular pitch has to be designed. Horizontal pitch is the distance between tynes along the axis or length of cylinder. Circular pitch is the distance between tynes about the periphery of cylindrical roller. For selecting the horizontal pitch the average length of coconut is to be considered. It is found to be 300mm. The tynes are mounted on cylinder in such a way that optimum number of tynes should be in contact with the coconut. This will help in reducing the load on each tynes and increase efficiency of dehusking operation. For selecting circular pitch average width of coconut is found to be 200mm. Suitable number of tynes should be selected to have good mesh and effective dehusking.The power from electric motor is transmitted to the rotating cylinders through pulleys and gears. Power should have less speed and high torque at the rotating cylinders and this is obtained by using a speed reduction gearbox. The gears and pulleys will be arranged in such a way that desired output is obtained by making use of readily available sizes of gears and pulleys, so as to keep the manufacturing cost low.

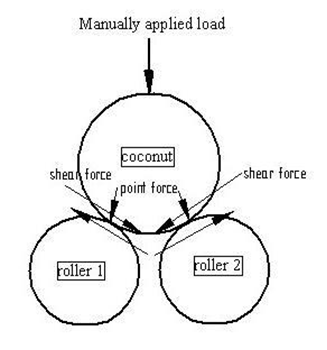

2.4. Force Analysis

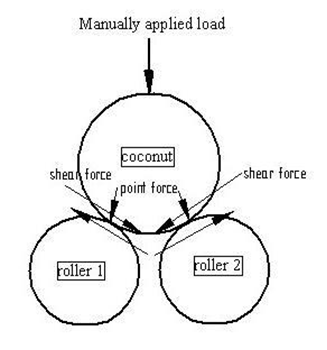

| Figure 5. Forces acting while Dehusking |

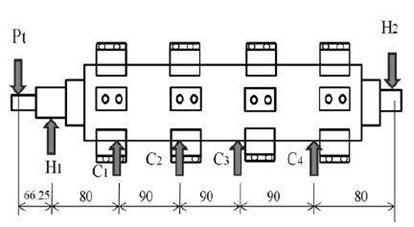

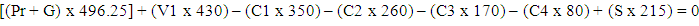

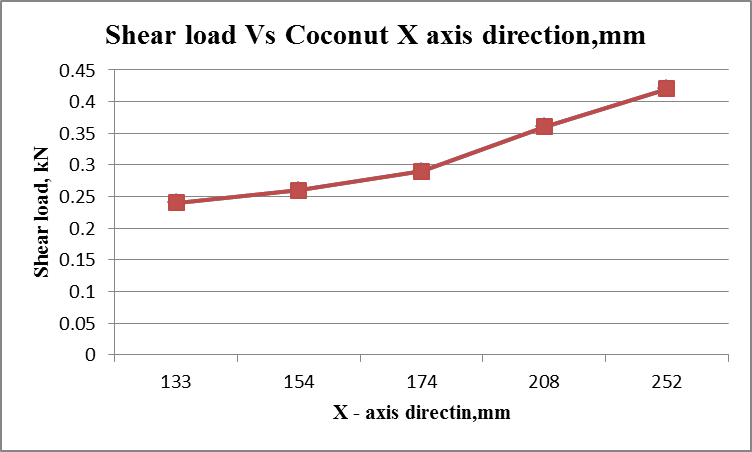

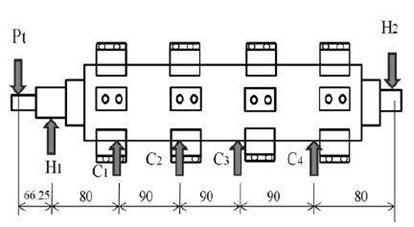

Manually applied load and self-weight of the coconut will be acting at the point of contact on the two rollers. Shearing force will act between the husk and the coconut. The resultant of these two forces will act on the rotating roller while dehusking. The method of Shear force evaluation is considered for the bearing force calculation. The following Nomenclatures are used in all the bearing calculations presented.C1, C2, C3 are the loads acting on the roller due to coconut. H1 and H2 are the loads acting on the bearing in the Horizontal plane. V1 and V2 are the loads acting on the bearing in the vertical plane. Pr is the radial load due to gear, Pt is the tangential load due to gear, G is the self-weight of the gear, S is Self-weight of the roller. | Figure 6. Forces acting on the roller in the Horizontal plane |

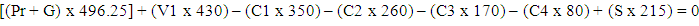

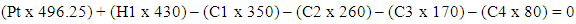

Taking Moment about vertical plane, | (1) |

Taking Moment about horizontal plane, | (2) |

Equation 1 and equation 2 are used to calculate the load acting in horizontal (H1) and vertical plane (V1). The coconut dehusking machine prepared is operated by mechanical system. This system exerts the force ten times more than the force applied in the manual method. With reference to some papers, it has been observed that the force applied to dehusk the coconut by manual methods is less than the machine. The frame is the main supporting structure upon which the other components are mounted on. The frame is a welded structure constructed from 50mmx50mmx5mm angle iron with dimensions 933mm in length, 515mm width and 845.1mm height. The unit comprises of 2 rollers, 2 roller shafts and 2 sprockets. Each roller shaft is a mild steel rod of 40mm diameter, with length 890mm supported at both ends by ball bearings. And the parts are painted to prevent from rusting.From SKF Bearing catalogue, Deep Groove Ball Bearing 6007 series with the following specifications has been selected. Shaft Diameter is 35mm, Tolerance of K6, Static load carrying capacity of 8800N, Dynamic load carrying capacity of 12500N, Maximum permissible of 13000rpm. Gears with 54 and 70 teeth are used. Selection of above specifications are done on average diameter of the coconut and forces acting in vertical and horizontal plane.

2.5. Fabrication

From the experimental values Torque required for de-husking has been determined. From that torque, the drive reduction between the motor and the rollers has been determined. Torque required to dehusk a coconut = Force required shearing the coconut x Perpendicular distance of spikeForce required = 450N Perpendicular distance b/w spike = 80mm= 450x80 = 36000Nmm = 36NmA factor of safety of 1.25 has been selected.So the Torque = 36x1.25 = 45Nm.Power of the motor (P) = 1 HP (0.74 KW)Speed of the motor (N) = 1440 rpmTorque developed by the motor = (60 x P) / (2 x3.14 x N) = (60 x 0.75) / (2 x 3.14 x 1440) = 4.90 Nm | Figure 7. Coconut dehusker |

Based on theoretical calculations, a 1hp geared motor with a speed of 1440rpm will produce torque of 4.09Nm. The machine has the capacity to dehusk the coconut of any shape and size. Also, the coconut shell with husk of different thickness and hardness can be easily removed by this, with a less force. The manually applied force is very less and the force produced to peel the coconut husk is very high. For a single operation, it is taking nearly 1 minute. The machine is capable of dehusking about 150 to 170 coconuts per hour.

3. Working

In manually operated dehuskers a sharp tool is pierced into the coconut by force and shearing action between the husk and the coconut results in removal of the husk. In this project, the same principle is used where the two rollers containing a series of sharp edges which will pierce into the husk of the coconut and shear the husk by a continuous rolling action. Tool used is a set of two rollers with sharp edged spike on the periphery. These two rollers will be connected to shaft rotated by an electrical motor with required power through speed reduction units. Roller 1 will act as dehusker and Roller 2 will act as guiding roller. Roller 1 rotates in clockwise direction while roller 2 rotates in counter clockwise direction. The spikes are machined according to the dimensions on the lathe and then welded on the roller surface. The Spiked roller gap of the machine was fixed either 2.5cm or 5.2cm apart by adjusting the positioning of the spiked roller and their centre distances are fixed. The rotational speeds were calibrated by adjusting the speed of geared motor which drives the rollers. The rotational speeds of rollers were measured using a digital tachometer and a digital stop watch is used to measure the time taken to dehusk a coconut. Speed reduction unit consists of gears which are selected based on the rpm of the roller tool required for the shearing action of husking. A suitable gear ratio is selected for the required operation. Also the direction of both rollers has to be opposite to each other which can be done with the help of idler gear.An electric motor of required power is to be selected based on the shearing force of husk, self-weight of coconut and manually applied load on coconut. The selected motor should possess high torque low rpm. The motor used is of single phase, 1hp, AC geared motor with 70rpm. The motor shaft is coupled to the roller by chain and sprocket mechanism which drives the system.For an efficient dehusking a manually operated arm is fixed which will force the coconut into the rollers in motion for a proper dehusking action. This helps to avoids direct contact of hands into the rotating rollers.

4. Conclusions

Research and development in the field of coconut dehusking can lead to a better usage of power dehusking machine for mass production which in turn can draw more farmers to cultivate this occupation. Power operated dehusking tool can help any unskilled operator to get his work done with ease. The dehusker is completely safe to operate. Low power consumption and low maintenance cost. Load required for de-husking the dry coconut is higher than the load required for de-husking the mature coconut. Dehusking may be incomplete if a very hard bound husked coconut is used for operation.

References

| [1] | Chandra Dinanath. “Coconut dehusking machine”. U.S. Patent 4708056 A, Nov. 24, 1987. |

| [2] | Luise Cancel, San Juan, Puerto Rico. “Coconut Breaking Machine”. U.S Patent 3,605,834, Sept. 20, 1971. |

| [3] | Albert L. Mix, Battle Creek, Mich. “Coconut Shelling Machine”. U.S Patent 2, 783, 801, Mar. 5, 1957. |

| [4] | Genaro Celaya. “Machine for Husking Coconuts”. U.S Patent 1,781,215, Nov. 11, 1930. |

| [5] | Ohler, J. G.. Coconut, Tree of Life. FAO Plant Production and Protection Paper 57. FAO, Rome, Italy, 1984. |

| [6] | APCC. Coconut Food Process – Coconut Processing Technology. Information Document. Arancon, Jr, R. N., ed. Asian and Pacific Coconut Community. Jakarta Indonesia, 1996. |

| [7] | Franco, P.J.H. and Gonzalez, A.V. Mechanical Properties of Continuous Natural Fibre-Reinforced Polymer Composites. Comp. Part A: App. Sci. Manuf., Vol. 35, pp.339-345, 2004. |

| [8] | Balzer, P.S., Vicente, L.L., Briesemeister, R., Becker, D., Sordi, V., Rodold, A. Jr and Feltran, M.B Study of Mechanical Properties of PVC/ Banana. Journal of Emerging Trends in Engineering and Applied Sciences (JETEAS) 2(2): 231-234, 2007. |

| [9] | Dr. H.D Ramachandra, Hydraulics & Pneumatics, Sudha Publications, Bangalore, Edition: 2005. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML