-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Journal of Mechanical Engineering and Automation

p-ISSN: 2163-2405 e-ISSN: 2163-2413

2017; 7(3): 63-71

doi:10.5923/j.jmea.20170703.01

Development of Conceptual Framework for Ship Maintenance Performance Measurements

Yousef Alhouli1, Taha Elhag2, Mohsen Alardhi1, Jasem Alazemi1

1Automotive and Marine Engineering Technology Dept. / College of Technological Studies, Public Authority of Applied Education and Training (PAAET), Kuwait

2School of Energy, Geoscience, Infrastructure and Society, Heriot-Watt University, United Kingdom

Correspondence to: Yousef Alhouli, Automotive and Marine Engineering Technology Dept. / College of Technological Studies, Public Authority of Applied Education and Training (PAAET), Kuwait.

| Email: |  |

Copyright © 2017 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

In the marine shipping industry, maintenance planning is very significant due to its complexity and the obligations on shipping organizations to comply with certain international regulations and requirements. Decision makers some time need a tool to guide them in taking effective and informed decisions on maintenance planning. In this Paper new methodology was developed to measure the maintenance performance for marine shipping organization, which is the ship maintenance performance measurement (SMPM) framework. The framework is developed based on ten thematic criteria that can influence the decision making of ship maintenance schemes such as: maintenance strategy, customers’ satisfaction, employees’ satisfaction, budget and profit margins, health, safety and environment. The research methodology is based on: (a) review of relevant literature to develop the conceptual framework; and (b) interviews survey of three leading marine shipping organizations. The SMPM framework is developed based upon multiple criteria under four organizational hierarchical levels: (1) top management; (2) middle management; (3) ship senior staff; and (4) ship crew. The developed framework is validated by conducting another set of interviews with marine experts. The interviewees reveal that the framework is practically viable; and could be adopted and implemented in industry.

Keywords: Maintenance, Performance Measurements, Key Performance Indicators, Conceptual framework

Cite this paper: Yousef Alhouli, Taha Elhag, Mohsen Alardhi, Jasem Alazemi, Development of Conceptual Framework for Ship Maintenance Performance Measurements, Journal of Mechanical Engineering and Automation, Vol. 7 No. 3, 2017, pp. 63-71. doi: 10.5923/j.jmea.20170703.01.

Article Outline

1. Introduction

- In modern industrial organizations, maintenance departments have important roles because of their ability to have an economic balancing effect (Dekker 1996). However, the importance of effective maintenance is related to availability and performance, and it may also be concerned with issues related to the safety-critical nature of mercantile industries (Artana, et al. 2005). In practice, serious accidents and interruptions in many industries are related to poor maintenance or more specifically to poor maintenance planning (Reason and Hobbs 2003).The marine industry faces unique challenges in the execution of planned and unplanned maintenance; the mere fact that ships spend significant periods at sea impacts upon supply-chain management (e.g., labour and availability of resources), (Rustenburg, et al. 2001). A ship at sea is isolated from onshore repair and maintenance facilities and if a failure occurs during the passage, the required replacement parts may not be available on board. Added to this is the cost of downtime, when the ship is out of service (off hire). Other challenges are the ship’s safety and environmental requirements, as poor maintenance may result in significant operational and environmental damages, (Rothblum 2000).Therefore, maintenance is a crucial factor in a ship’s performance and, in turn, can affect the shipping company’s revenue. Nevertheless, there should be a balance between maintenance cost and over-maintenance. Thus, a good framework with which to measure maintenance performance and to plan maintenance policy for shipping marine organization is of vital importance.Based upon these issues, the questions which need to be addressed are: What factors influence the performance of a shipping marine organization? What are the issues related to developing a ship maintenance performance framework (SMPM)? How can such a framework be validated and implemented?Ship maintenance performance measurement is very important to keep the ship working in a good and efficient manner. Therefore it is essential to Identify performance measurement criteria for ship maintenance such as the framework proposed in this paper. Different maintenance performance indicators (MPIs) can be identified for each criterion, which are a set of measurements of the impact of maintenance on process performance (Wireman 1998).Therefore, to develop an effective maintenance performance framework, the following issues should be addressed: (a) identify the purpose of this measurements, (b) what should be measured and what factors effect this measurements, (c) how should it be measured and what method can be used to measure it, (d) when should it be measured and identify the time frame for this measure, (e) also who should measure it the persons who are involved in the measurements, and finally (f) how the results can be used and how the assessment can be made on such results.The purpose of developing this new methodology of Ship Maintenance Performance Measurement (SMPM) framework is to assess how well the organization is progressing toward its maintenance objectives; it will also help the decision maker to react to that assessment in order to improve the overall performance of the organization maintenance management. The framework can also support: increased safety, increased market share of the organization, increased profits, and enhanced recognition within the industry. The maintenance performance measurement will be based on multiple criteria that can evaluate and achieve the purpose of the new methodology which is the SMPM framework.

2. Literature Review

- On measuring organizations performance, Kaplan and Norton (1992) developed a balanced scorecard that works on four perspectives: (1) financial, (2) customers, (3) internal processes, and (4) innovation and learning. It covers both financial and non-financial aspects of the business process. Integration of the four perspectives into a graphical presentation has made the balanced scorecard a very useful method for measuring organization performance. The balanced scorecard was utilized by Tsang (1998) to bring a strategic approach to maintenance performance management (MPM) within the balanced scorecards four perspectives. Tsang approach consists of a mix of outcome measures and performance drivers, which indicate the outcome of past decisions and predict future outcomes, respectively. Sinclair and Zairi (1995) involved employees in the development of a performance measurement system. Another framework was developed by Riis, et al. (1997), which shows cross levels and functional integration of maintenance management and attempts to relate maintenance to manufacturing strategy. On the other hand, two approaches were provided by Dwight (1999): (1) the system audit approach; and (2) the event analysis approach. The system audit approach concentrates on the degree of alignment between the maintenance systems and the goals of the organization they are serving. The event analysis approach focuses on understanding the impacts of the specific actions undertaken during the period on the value of the organization.The strategic maintenance management (SMM) approach was presented by Murthy et al. (2002) and has two elements, maintenance management and effective maintenance management. Maintenance management is a critical, core business activity that is crucial for the business‘s survival and success and, as such, must be managed strategically. The effective maintenance management must be based on quantitative business models that integrate maintenance with other decisions, such as production levels. Mojdeh (2005) developed a four-step process, the business performance management (BPM) framework, which can also be applied in MPM. The steps are: (1) strategies; (2) plan; (3) monitor; and (4) act and adjust.Kumar (2006) discussed the issues and challenges associated with the development and implementation of maintenance performance systems and maintenance performance indicators for the effective management of infrastructure and industrial assets. The study was based on some of the research and development (R&D) projects being pursued at the Division of Operation and Maintenance Engineering at Lulea University of Technology in Sweden.Parida and Chattopadhyay (2007) presented an MPM framework that is balanced, holistic, and integrated and focuses on both internal and external effectiveness, considering the maintenance PIs from the multi-criteria hierarchical level of the organization. Muchiri et al. (2009) conducted an industrial survey of Belgian industries to explore the use of performance measurement in maintenance management. The analysis they used was based on the popularly-used KPIs and how these KPIs are sourced or chosen, as well as the influence of the manufacturing environment and maintenance objectives on the choice of KPIs and the effective use of these KPIs in decision support and performance improvement. The results show no direct correlations between the maintenance objectives pursued and the KPIs used.Yuniarto and Osada (2009) developed a framework that enables maintenance operatives to plan maintenance actions through the identification of the root cause of failures and the quest of optimal solutions by viewing problems as a system in its entirety. It integrates between the six sigma and the system‘s dynamics. An extended Overall equipment effectiveness (OEE) framework that incorporates six sigma thinking and asset management strategy PIs was proposed by Gibbons (2010). The OEE framework is based around incorporating an understanding of asset management effectiveness measured against Mean time to failure (MTTF), Mean time to repair (MTTR), and Mean time between failures (MTBF) into the availability element of the OEE calculation and an understanding of the process capability measured against six sigma levels into the quality element of the OEE framework.Muchiri et al. (2011) developed maintenance function performance measurement framework and indicators. They verified that performance indicators are not defined in isolation, but should be the result of a careful analysis of the interaction of the maintenance function with other organizational functions. A guideline for choosing maintenance function performance indicators is proposed, also a link between the maintenance objectives, maintenance process/efforts and maintenance results is provided. Zeszyty (2011) studied the universal maintenance performance indicator for technical objects operated on floating units. Zeszyty defines a universal maintenance performance indicator (UMPI) using methods of numerical taxonomy. The results of the study allowed to rank objects from the best to the worst maintained according to multi criterial evaluation.Lin and Chang (2013) constructed a network model and proposed a key performance indicator (KPI) for a cloud computing system from Quality of Service viewpoint. They developed a method to derive the interval estimation for the KPI. Van Horenbeek and Pintelon (2014) developed a maintenance performance measurement framework using the analytic network process (ANP) for maintenance performance indicator selection. The objective of their work was to develop an MPM framework that aligns the maintenance objectives on all management levels with the relevant MPI used. An analytic network process (ANP) model and methodology were presented which based on the designed MPM framework. Rødseth et al. (2015) develop the novel maintenance KPI profit loss indicator (PLI). This indicator was based on measuring both the “hidden factory” and waste in production, presenting it as a financial measure.

3. Interviews Survey

- As discussed earlier to develop ship maintenance performance measurement framework it is important to identify the elements of such framework and those elements can be interpreted based on the opinions of experts from marine shipping companies.This study interviewed key personnel from Kuwait Oil Tanker Company (KOTC), Kuwait Livestock Transport and Trading Company (KLTT), and Gulf Rocks Company (GRC) concerning the subject of maintenance strategy and planning.KOTC, KLTT, and GRC are leading marine shipping companies in Kuwait. Therefore, the three companies were selected on that basis as well as on the basis of their considerable data sets; and their kind agreement to make that data available and accessible for this research.The interviews were planned to obtain their understanding of how maintenance is planned in their organizations and their perspective concerning the most important factors that influence maintenance planning. The personnel interviewed were the Manager of the KOTC Fleet Engineering Group; the Team Leader of Marine Affairs and Risk Assessment at KOTC; the Deputy General Manager of GRC; the Chief Executive Officer of Gulf Maritime Ship Management Company (GMSM), which provides technical management for GRC; the Deputy Manager of the Fleet Department at KLTT; and the Technical Operation Superintendent of the Fleet Department at KLTT.

4. Analysis and Results of the Interviews

- An interpretive approach was used in this research in order to analyze and identify the present status of the maintenance organization and plans of these three marine shipping companies. The results shows that maintenance is very important to all the shipping companies as a good maintenance plan can increase the ship’s availability as well as a safe ship operation. Using more than one maintenance strategy, and a combination of maintenance strategies can optimize maintenance planning.The maintenance objectives for all the shipping companies are similar; they all aim to maximize the ships availability with a safe environment. The objectives of coordination between the departments for maintenance planning within the shipping organization are to achieve the best maintenance window which has less effect on ship demand. Breakdown records can help in future prevention from similar failures, which reflect on the companies’ performance.Personal experience is very important which improve the maintenance forecasting for the shipping companies. Which means good crew on-board vessels can reduce the maintenance costs as they can carry out some maintenance work, whereas substandard crew can increase maintenance costs and expenditure. So budget is very important to as maintenance is considered as one part of the budget.Maintenance planning is very important to any industry, especially to the marine industry, as good maintenance planning can maximize the ship’s availability which will maximize the companies’ profits. This can be achieved by measuring maintenance performance and selecting the factors which influence planning and evaluating them very carefully.

5. Framework Development

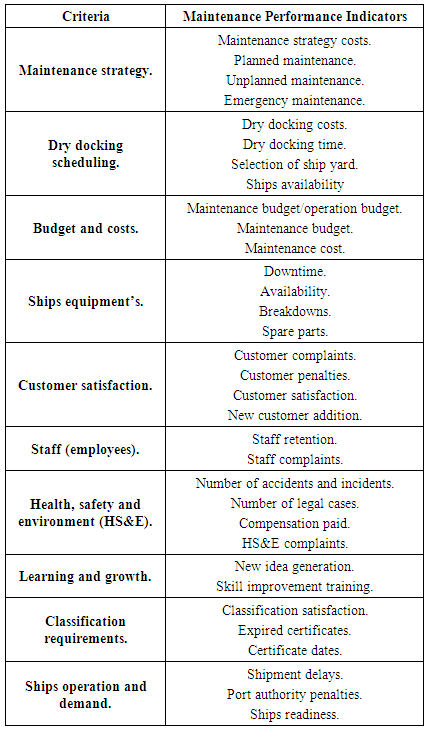

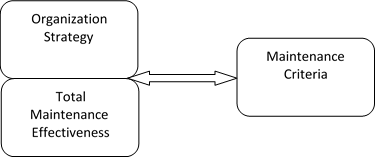

- In this section the proposed framework is developed, this framework is based on the information gathered from the interviews. Understanding the Hierarchical Levels of the marine organization is a key in developing Ship Maintenance Performance Measurement Framework. Every organization has multi-hierarchical levels and, at each level, certain decisions are made concerning the performance indicators (PIs) that can be used to guide the decision-making process. In general, the strategic planning level is the top hierarchical level followed by the tactical or managerial level and finally the functional or operational level (Parida, et al. 2005).According to the conducted interviews with the marine shipping organizations normally there can be four hierarchical levels. (a) the first (top) level is the strategic level, which is the top management level; (b) the second level is the strategic/tactical level, which is the middle management team or the superintendent‘s team; (c) the third level is the tactical/operational level, which is the ship‘s captain and chief engineer; and (d) the fourth level is the operational or functional level, which is the ship‘s crew. Figure 1 depicts these four hierarchical levels.

| Figure 1. Hierarchical levels of the marine shipping industry |

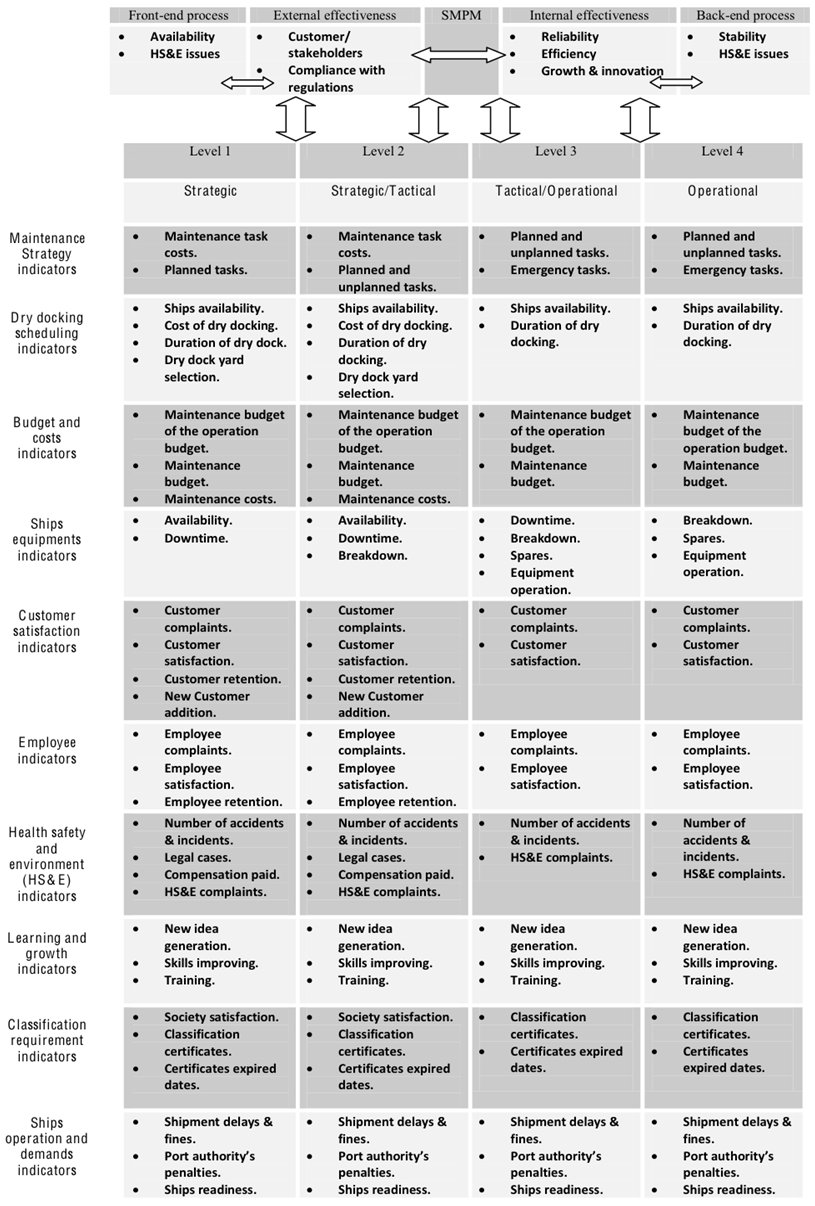

6. Framework Criteria

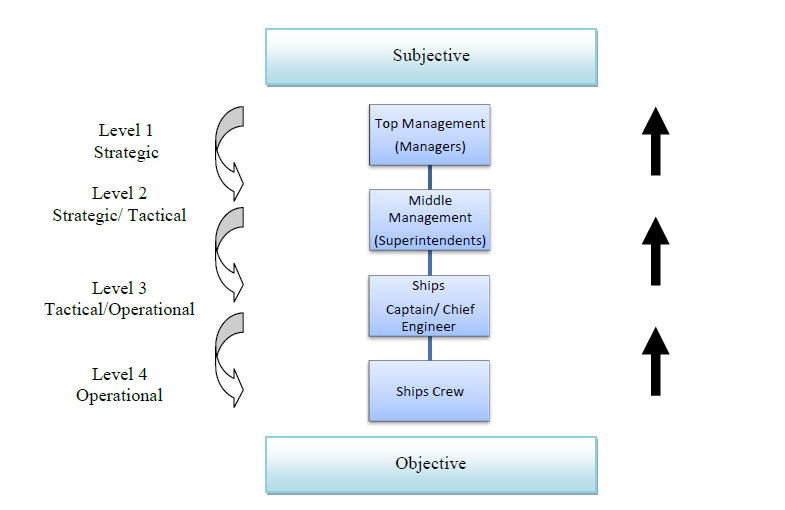

- Ship maintenance performance measurement criteria are captured based on the abduction research approach which combines a literature review finding and the interview results. Ten different criteria were developed and used in the SMPM framework to measure the maintenance performance of the marine shipping organization, as shown in Figure 2.

| Figure 2. Ship Maintenance Performance Measurement (SMPM) Criteria |

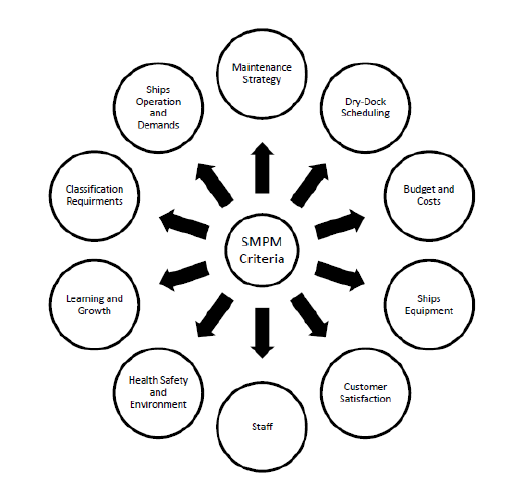

7. Framework Maintenance Performance Indicators

- The SMPM framework is developed using ten criteria. These criteria are expressed in terms of different performance indicators measurements, as presented in Table 1. These indicators are measured under different organization hierarchical levels, as indicated in Figure 1.

|

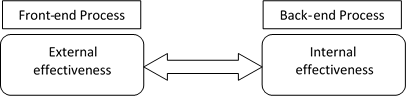

8. The Development of SMPM Framework and Its Effectiveness

- The effectiveness of the ship maintenance performance measurement method is intended to satisfy the requirements of the maintenance process in a marine organization. That can be achieved by scrutinizing the ship maintenance performance measurement from different perspectives such as financial, customers, employees, and safety. The ship maintenance performance measurement methodology can be achieved by developing a framework that can represent the status of maintenance in the marine shipping organization.The developed SMPM framework has the following three characteristics: (1) all the criteria included in the framework are applied in parallel to measure the maintenance performance without predefined preference between them; (2) these criteria were chosen to complement each other to cover major aspects affecting the maintenance performance of the entire organization without overlap or duplication; and (3) the framework considers the entire organization system as a whole in order to understand how its different aspects are interrelated. In addition, the framework links the organization strategy with the total maintenance effectiveness and maintenance criteria as shown in Figure 3.

| Figure 3. Linking Organization strategy, total maintenance effectiveness, and maintenance criteria |

| Figure 4. Front-end to back-end processes |

| Figure 5. The Proposed Ship Maintenance Performance Measurement (SMPM) framework |

9. SMPM Framework Validation

- This section presents the results of the validation of the developed framework by conducting interviews with five experts from KOTC to obtain their opinions and views of the framework. Interviews were conducted with: (a) the manager of the Fleet Engineering Group; (b) the team leader of the Fleet Engineering Group; (c) the team leader of the dry docking division; (d) the team leader of the electrical division; (e) acting manager of Fleet Personnel Group; and (f) the team leader of the Fleet Personnel Group. The interviews were analyzed and discussed by implementing an interpretive methodological approach. The findings from the interviews are discussed next.During the interview sessions, one of the issues raised is whether the company has any maintenance performance measurements. They responded that the KOTC has established an overall organization performance measure in order to comply with international standards for ship safety and pollution prevention. The Tanker Management and Safety Assessment (TMSA) is an international regulation system for tanker companies. One element of TMSA touches upon maintenance performance but without the details of a full maintenance performance measurement system. The KOTC has a TMSA system in place; but they don’t have maintenance performance measurement system. Therefore the proposed MPM framework in this paper will fulfil that need for KOTC. Identifying the maintenance performance measurement indicators was very interesting for the interviewees. They identified some indicators based on their work experience, and they identified various indicators, including those associated with customer satisfaction, employees, budget, breakdowns, safety, classification requirements, and dry docking scheduling. The manager of Fleet Engineering identified some maintenance performance indicators as follows, “In my opinion, the most important indicators are those that reflect on customers’ needs; other indicators are related to employee satisfaction and budget”.After identifying the maintenance performance indicators, the interviews proceeded into discussions of the hierarchy levels of the organization and how maintenance is arranged in these levels. The results of these discussions are presented next.The interviewees divided the hierarchy levels into three and four levels, starting with the top management level, followed by the management/operational level and the operational level.The interviewees identified the stakeholders in a marine shipping organization to be those who can have benefit from the company‘s operations. Such stakeholders are the customers, employees, and the owners. As the team leader of the Fleet Personnel Group said, “The main stakeholder of our company is Kuwait Petroleum Company (KPC), which charters KOTC vessels to transport its petroleum products”.In general terms, the interviewees were very interested in the developed framework, and their comments were positive, reflecting their appreciation of each criterion and measure it with the key performance indicators described. The team leader of the Fleet Engineering Group‘s electrical division said, “The implementation of this framework is ideal; it can provide us, the decision makers, a guide for measuring the maintenance performance of our company”.Since the interviewees found the framework easy to understand and implement, it can be a good guide for measuring the maintenance performance in a marine shipping organization. The manager of the Fleet Engineering Group said, “I would call the criteria (elements) and each element can be measured by different key performance indicators”.The implementation of this framework requires the availability of data and the approval of the management team. As the team leader of the Fleet Engineering Group said, “The implementation of this framework is possible, but it will require some time before we make decisions concerning how and when we can implement this framework”.This framework could be enhanced by the expertise and processes of KOTC. Also with the aid of this framework, good maintenance performance measurement can be achieved. As the team leader of the Fleet Engineering Group‘s dry docking division said, “Using our experience with this framework can help us in providing a good maintenance performance measurement in our organization”. Therefore, the interviews indicated that the framework is practically viable; and could be adopted and implemented according to the interviewees opinions. Finally, based on the validation of the framework, the study will embark on an industrial implementation plan of the framework as future work.

10. Conclusions

- In this paper new method of developing a conceptual ship maintenance performance measurement (SMPM) framework was analyzed and discussed. The multi-criteria approach was used to measure the maintenance performance of a marine organization.The presented framework evaluates the total maintenance effectiveness by individually applying each criterion and collectively utilizing the results to produce a comprehensive measure of the maintenance performance in a marine shipping organization. The framework was developed by using ten criteria, maintenance strategy, dry docking scheduling, budget and costs, ships equipment’s, customer satisfaction, staff (employees), health safety and environment, learning and growth, classification requirements, and ship operation and demand. The SMPM framework has been developed based upon those multiple criteria under four hierarchical level of the organization.The validation of this framework was undertaken with five experts from KOTC Company and the possibility of implementing such framework within the company processes. The experts evaluated and approved the maintenance performance indicators then they proceeded into discussing the hierarchy levels of the organization. The experts identified the stakeholders of their organization as those who can have benefit from the organization such as customers, employees, and owners. The validation of the framework showed that it is a successful tool for measuring maintenance performance in a marine shipping organization. It can aid the decision making process in measuring the maintenance performance of the organization, which represents a key component of the overall measure of the organizational performance.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML