-

Paper Information

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Journal of Mechanical Engineering and Automation

p-ISSN: 2163-2405 e-ISSN: 2163-2413

2016; 6(5): 139-140

doi:10.5923/j.jmea.20160605.06

Research on Precision Process in MCF Polishing

Yaoyang Zheng

Department of Mechanical Engineering Fukushima National College of Technology, Fukushima, Japan

Correspondence to: Yaoyang Zheng, Department of Mechanical Engineering Fukushima National College of Technology, Fukushima, Japan.

| Email: |  |

Copyright © 2016 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Our research group has demonstrated experimentally that the polishing effect using our developed intelligent fluid, magnetic compound fluid (MCF), is greater than that using previously developed intelligent fluids, i.e., magnetic fluid (MF) and magneto-rheological fluid (MRF). Prof. Shimada succeeded in float polishing with a large clearance utilizing a newly developed magnetic responsive fluid, MCF, which was improved by the addition of a-cellulose, thereby achieving a clearance as great as 8mm. He also clarified the mechanism of the new polishing technique. A comparison of the MCF polishing effect with those of techniques using the ordinary magnetic responsive fluids, MF and MRF, showed the polishing effect of MCF to be greater than those of MF and MRF. The MCF polishing technique is applicable to many types of polishing, widening the variety of the uses of magnetic float polishing (MFP). In this study, we proposed a new process method for the MCF polishing.

Keywords: MCF (Magnetic Compound Fluid), Polishing, Abrasion liquid, Surface roughness

Cite this paper: Yaoyang Zheng, Research on Precision Process in MCF Polishing, Journal of Mechanical Engineering and Automation, Vol. 6 No. 5, 2016, pp. 139-140. doi: 10.5923/j.jmea.20160605.06.

Article Outline

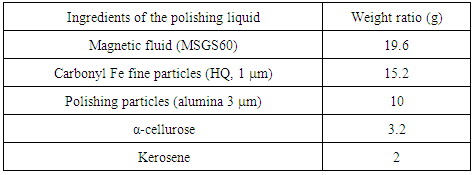

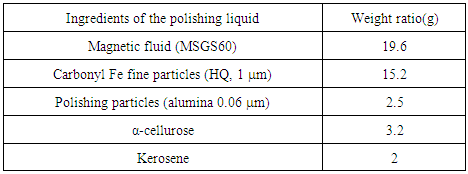

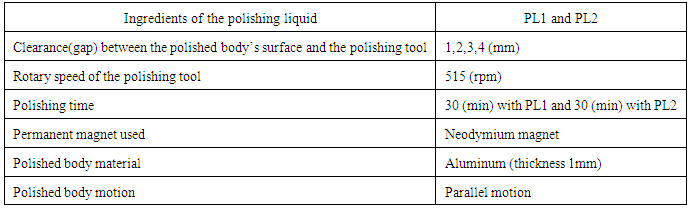

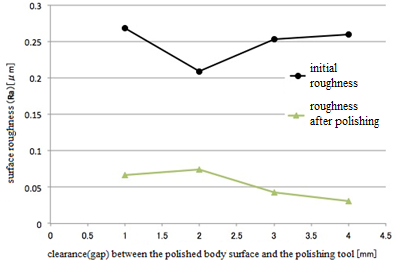

- In order to further develop nano- or micro-technology, nano- or micro-polishing techniques are needed to polish or grind the material surfaces of nano- or micro-devices on a nm-order. In response to this need, in our laboratory, we have researched MCF (Magnetic Compound Fluid) polishing for years. MCF polishing is a kind of smart fluid polish. An alumina abrasive particle of 3.0[µm] was included in the MCF abrasion liquid (Table 1) used for conventional experiments. However, undulation sometimes occurred on the surface of the polished samples (aluminium, acrylic resin etc.). This was because the abrasive particle was relatively large, which made it glide on the polished sample surface. As a result, the polishing process did not work well. Therefore, I proposed a new method of MCF polishing. The new method uses a smaller abrasive particle (alumina particle of 0.06[µm]) to accomplish MCF polishing (Table 2, Table 3). Using this method, we expected to be able to polish away the smaller irregularities. In addition, we assumed that undulation on the sample surface would disappear after MCF polishing.Accordingly, some proof experiments were performed in our lab. Under the conventional experimental conditions, it was difficult to achieve a surface roughness Ra smaller than 0.05[µm]. Conversely, after completing the MCF polishing process (Fig.1), the surface roughness Ra of samples was smaller (Ra was around 0.03[µm] and minimum Ra was 0.013[µm]). Therefore, it may be said that the newly proposed experimental method provided sufficient abrasive effect. Through these experiments, I am convinced that using MCF abrasion liquid with smaller alumina abrasive particles (0.06[µm]) for MCF polishing is a superior method. It creates polished sample surfaces that are sleek, like a mirror.Furthermore, when you see the appearance of the polished samples, there is neither undulation nor irregularities on the sample surface, so that it appears mirror-like. Thus, I can report that the complete MCF polishing technology has arrived at the practical level and will be applied widely in the industrial world.

|

|

|

| Figure 1. Results of new experiment condition (polished material was an aluminum plate) |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML