-

Paper Information

- Next Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Journal of Mechanical Engineering and Automation

p-ISSN: 2163-2405 e-ISSN: 2163-2413

2015; 5(1): 1-13

doi:10.5923/j.jmea.20150501.01

Experimental Investigation of Cutting Parameters on Surface Roughness Prediction during End Milling of Aluminium 6061 under MQL (Minimum Quantity Lubrication)

Ojolo Sunday Joshua1, Money Ochuko David1, Ismail Oluwarotimi Sikiru2

1Mechanical Engineering Department, University of Lagos, Lagos, Nigeria

2Mechanical and Design Engineering Department, University of Portsmouth, UK

Correspondence to: Ojolo Sunday Joshua, Mechanical Engineering Department, University of Lagos, Lagos, Nigeria.

| Email: |  |

Copyright © 2015 Scientific & Academic Publishing. All Rights Reserved.

This work investigates the effect of cutting parameters such as cutting feed, depth of cut and spindle speed on end milling of 6061aluminium so as to predict the surface roughness. One hundred and twenty experiments were carried out on aluminum 6061 rectangular rods. The experiments were conducted in dry and MQL environments using Mac-power V-645 CNC machine with HSS cutting tool inserts where five spindle speeds (700, 1500, 2000, 3000 and 4000rpm), four cutting feeds (120, 200, 500 and 1000mm/min) and three depths of cut (0.4, 0.8 and 1.0mm) were selected. The surface roughness obtained from each experiment was measured using Mitutoyo surface tester. Response surface methodology (RSM) was employed in the experimental design using Design Expert 8.0.1. Two mathematical models were developed; one for dry and the other for MQL machining using multiple regression analysis which can be applied to surface roughness prediction of end milling of aluminium under dry and MQL environments; analysis of variance (ANOVA) was used to determine the significance of cutting parameters on surface roughness. The results obtained show that cutting feeds have the most significant effect on surface roughness, followed by spindle speed; depth of cut has the least effect on surface roughness. The results also show that machining under MQL environment apart from being environmentally friendly reduced the surface roughness value to about 20% leading to a better surface finish. It was also observed that combination of cutting feed and spindle speed have the best interaction, followed by spindle speed and depth of cut. Cutting feed and depth of cut combination have the least interaction, leading to a poor surface finish.

Keywords: Cutting feed, Spindle speed, Depth of cut, Aluminium, Surface roughness

Cite this paper: Ojolo Sunday Joshua, Money Ochuko David, Ismail Oluwarotimi Sikiru, Experimental Investigation of Cutting Parameters on Surface Roughness Prediction during End Milling of Aluminium 6061 under MQL (Minimum Quantity Lubrication), Journal of Mechanical Engineering and Automation, Vol. 5 No. 1, 2015, pp. 1-13. doi: 10.5923/j.jmea.20150501.01.

Article Outline

1. Introduction

- Machining operations have been the core of the manufacturing industry since the industrial revolution [1]. Industries employing metal removing operations are now receiving great attention on cutting fluids in metal working to minimise the volume of lubricants due to occupational, economical and ecological reasons [2-6].Milling is one of the most common metal cutting or removing processes. It is a process of generating machined surfaces by progressively removing a predetermined amount of material or stock from the work-piece at a relatively slow rate of movement or feed by a milling cutter rotating at a comparatively high speed. End milling is one of the most common metal removal operations encountered in industrial processes. It is widely used in the manufacturing industries which include the automotive and aerospace sectors, where quality is an important factor in the production of slots, pockets, precision molds, and dies. In end milling, the cutter generally rotates on an axis vertical to the work-piece. It can be tilted to machine tapered surfaces. Cutting teeth are located on both the end face of the cutter and the periphery of the cutter body [7, 8].One of the problems which may arise in using the end milling process is that the finished part does not satisfy the product design specifications. During the machining process, fiction exists between the tool and the work material, giving rise to heat and more energy is required for the machining operation [9]. The friction, heat and high energy have effect on the tool life, surface quality and tool wear etc.The quality of the surface plays a very important role in the performance of milling as a good-quality milled surface significantly improves fatigue strength, corrosion resistance, or creep life. Surface finish also affects several functional attributes of parts, such as contact causing surface friction, wearing, light reflection, heat transmission, ability of distributing and holding a lubricant, coating, or resisting fatigue [8, 10, 11]. Therefore the need to optimize cutting parameters to produce good surface finish is important. Lou et al [11] developed a model for surface roughness technique for prediction of CNC end milling. The experiment was carried out on a vertical milling centre with the predictor variables being cutting speed, feed rate, and depth of cut. The material used was 6061 aluminium and multiple regression analysis was used to build the model. They were able to predict the surface roughness with about 90% accuracy and also noted that feed rate was the most significant machining parameter used to predict the surface roughness in the multiple regression model. It was recommended that further research should be considered using different cutting tools and materials of the work-piece. In addition, artificial intelligent systems such as the fuzzy logic system or neural networks technique might be included to enhance the ability of the prediction system.Arokiadass et al [12] also studied the influence of four machining parameters including spindle speed (N), feed rate (f), depth of cut (d), and various percentage weight of silicon carbide (S) on surface roughness (Ra). The response surface methodology was employed to establish the mathematical relationship between the response and the various process parameters. The result obtained showed that the quadratic model is statistically significant for analysis of surface roughness. The value of regression coefficient (R) was 99.85 %, which indicated that the developed regression model is adequately significant at a 95% confidence level. The model also indicated that the feed rate was the most dominant parameter on surface roughness followed by spindle speed and %weight of SiC. Depth of cut has less influence on surface roughness. It was also concluded that the regression model is well fitted with the observed values and high correlation exists between fitted values and observed values.The use of lubricant or cutting fluids in metal machining operations is to serve as a coolant i.e. to cool, as well as a lubricant i.e. to reduce friction and wash away chips. It is generally agreed that the application of cutting fluids can improve the tool life and results in good surface finish by reducing thermal distortion and flushing away of machined chips [13]. Better surface finish and dimensional accuracy are also obtained from cutting fluids [14]. The flooding method is the conventional method used in which a high volume of lubricant flow is applied and floods the entire machining area, effectively removing the heat generated from the machining process [15]. Flooding method required a large quantity of the cutting fluid and the cutting fluid is not able to reach the cutting zone due to obstruction from chips. This method has health implications on the operator(s) of the machining centre, environmental hazards and excessive waste of the cutting fluids and definitely high cost of production results. Ojolo et al. [16] made investigation into the effects of solid lubricant on the surface characteristics of some metals during orthogonal machining where it was shown that significant improvement in the surface finish of the machined steel surface and reduction in the surface roughness were obtained when compared to wet machining. The solid lubricant was also recoverable and more environmental friendly to the operator and surroundings when compared to wet machining.The necessity to machine using less harmful cutting fluids has prompted many researchers to investigate the use of minimum quantity lubrication (MQL) [17]. MQL, also known as “Near-Dry Machining” [18] and as “Micro-lubrication” [19], is the latest technique of delivering metal cutting fluid to the tool/work interface. Dry machining, also known as green manufacturing is progressively becoming more popular as it protects the environment and reduces manufacturing cost [20-22]. MQL machining provides an economically and ecologically reasonable alternative to the traditional wet machining process [23].Abhang et al. [24] investigated the use of minimum quantity lubricants in alloy steel turning where 10% boric acid is mixed with base oil SAE 40 proved to be a feasible alternative to the conventional cutting fluid. The result obtained indicated that there is a considerable improvement in machining performance with MQL machining compared to dry machining. It was concluded that MQL can reduce the chip tool interface temperature by 20 to 30% depending upon the level of process parameters and work material. The reduction in cutting temperature using MQL was high at lower level of machining parameters and low at high level of machining parameters. Also that the cutting forces is reduced by about 5% to 12% favorable change in the chip-tool interaction and retention of cutting edge sharpness due to reduction of cutting zone temperature seemed to be the main reason behind reduction of cutting forces by the minimum quantity of lubrication. Surface finish also significantly improved mainly due to significant reduction of wear and damage at the tool tip by the application of minimum quantity lubricantion.Ali et al. [25] also investigated the role of MQL by cutting oil on chip thickness ratio, cutting temperature, cutting forces, tool wear and surface roughness in turning medium carbon steel at industrial speed-feed combinations by uncoated carbide insert. The result indicated reduction in tool wear rate, dimensional inaccuracy and surface roughness by MQL over a dry machining mainly through reduction in the cutting zone temperature and favorable change in the work-tool interaction. Also it showed that MQL improves productivity, product quality and overall machine economy even after covering the additional cost of designing and implementing MQL system.The objective of this work is to investigate in MQL environment, the effect of cutting parameters such as cutting speed, depth of cut and feed on surface roughness of aluminium during end milling. It is also to compare these effects and to what extent surface roughness will be affected when machining in dry and MQL environment. To achieve the objective of ecological machining in manufacturing processes using MQL, it is essential to study and model the effects of MQL on the machining performance measures, in this case, surface finish. The key to successful incorporation of MQL in industrial machining processes is to be able to develop a capability to predict the effects and optimize the use of MQL.

2. Materials and Methods

2.1. Experimental Considerations

- An extensive experimental work in end milling of 6061 aluminum rectangular block was carried out to establish inter-relationships between machining performance measures and cutting parameters such as speed, feed and depth of cut. The machining performance measure under consideration is surface roughness. These inter-relationships were estimated for end milling under two different lubrication conditions which were dry cutting, and MQL (coolant + water). Table1 shows the levels of cutting parameter and Table 2 shows the cutting condition for the dry and MQL environments.

|

2.2. Work and Tool Materials

- This investigation is limited to Aluminium material only in which 50% of the experiment is on dry machining and the other 50% required lubrication (MQL) at the machining zone. The lubricant used for the MQL system is CUMISTAR 600 which is a combination of water and coolant. The aluminium rectangular block used for the experiment was obtained from Owode-Onirin market; the cutting tool used is 25.4 mm diameter end mill holding four indexable cutting HSS inserts

2.3. Experimental Set up

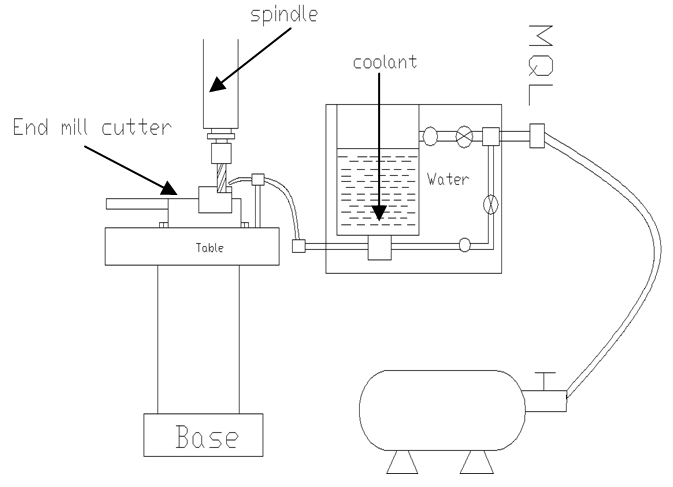

- The experiment was performed on a Macpower speed CNC machine vertical milling centre, model V-645 at Stanfrey Engineering Ltd., Lagos. The vertical milling center has three (3) planes namely x,y and z planes. The experimental set up is shown in Fig.1.

| Figure 1. Schematic diagram of the experimental set up |

3. Results and Discussions

3.1. Results

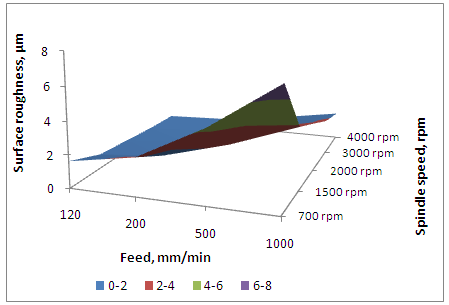

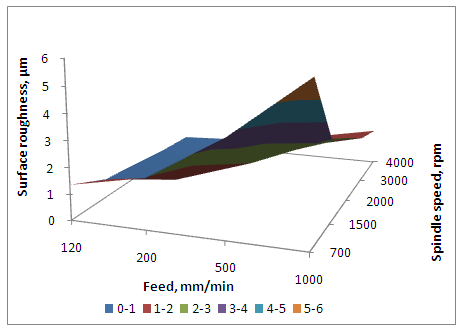

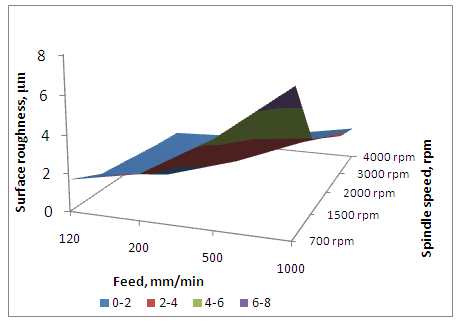

- The basic objective of the experiments was to establish the polynomial constants for the surface roughness model and to know the effect of each parameter on the surface roughness or quality of aluminium. The constants for the correlation between input parameters (cutting speed, feed and depth of cut) and measured output parameter (surface roughness) were established for different lubrication conditions by applying non-linear regression analysis to the quantitative data obtained from the experiments. The results of the experiment in both dry and MQL condition are presented in Tables 3-4 and Figures 2-17.

|

|

| (1) |

| (2) |

| (3) |

| (4) |

| (5) |

| (6) |

3.2. Discussions

3.2.1. Effect of Spindle Speed on Surface Roughness at Varying Cutting Feed

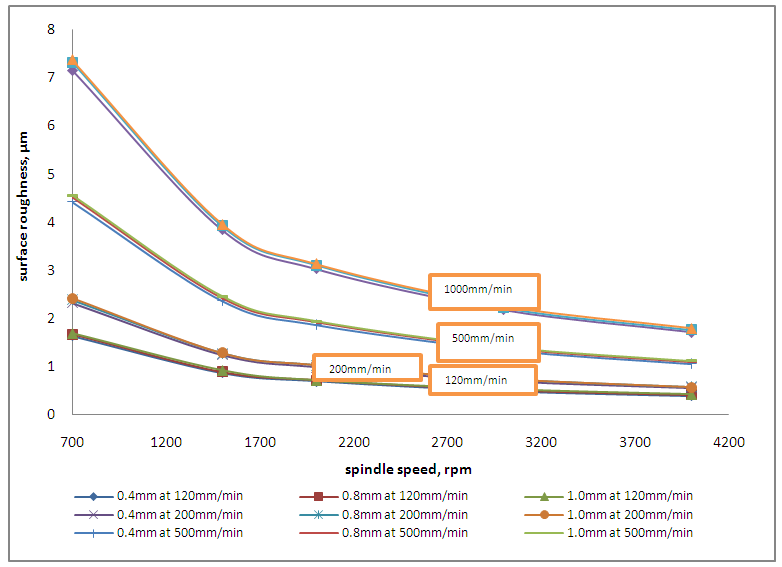

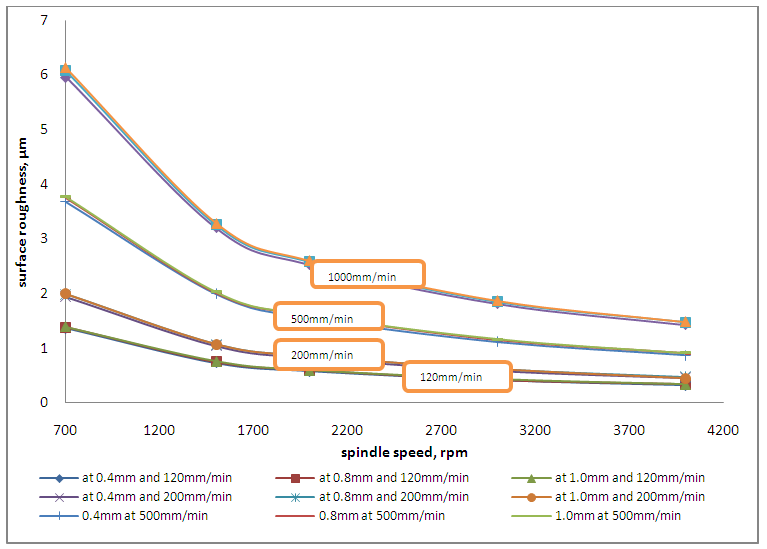

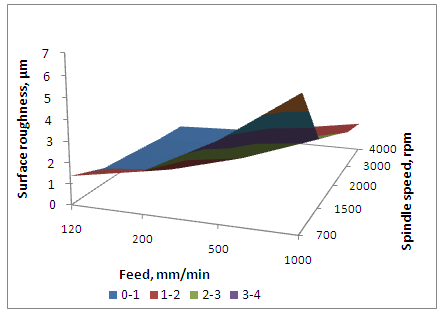

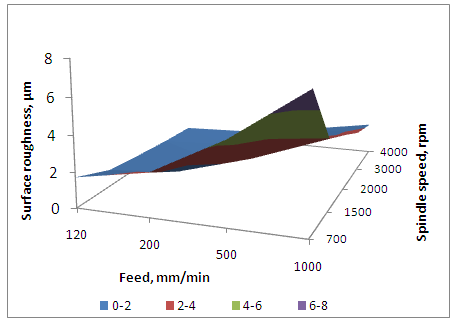

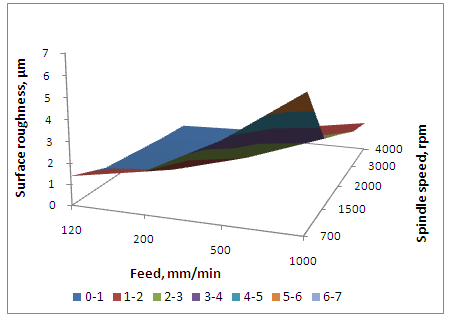

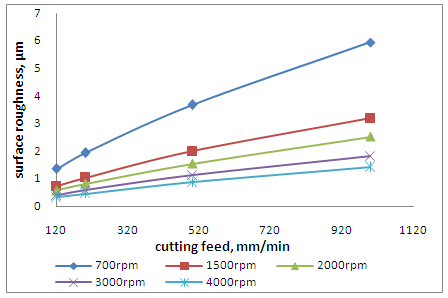

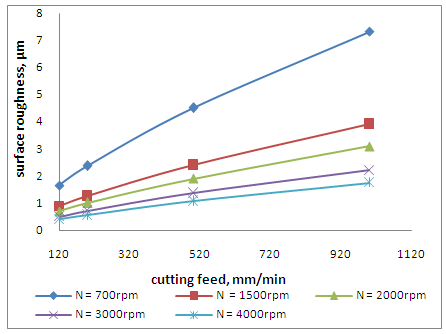

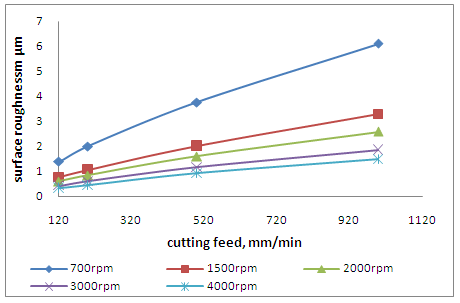

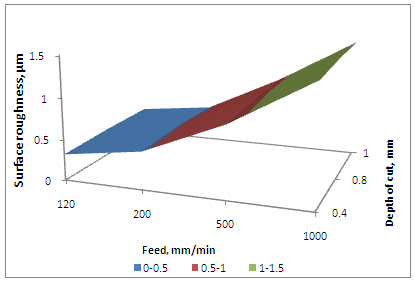

- The effects of spindle speed on surface roughness at varying cutting feed are presented in Figures 2 and 3.

| Figure 2. Effect of spindle speed on surface roughness at varying cutting feed (dry) |

| Figure 3. Effect of spindle speed on surface roughness at varying cutting feed (MQL) |

| Figure 4a. Effect of spindle speed on surface roughness at constant DOC of 0.4mm (dry) |

| Figure 4b. Effect of spindle speed on surface roughness at constant DOC of 0.4mm (MQL) |

| Figure 5a. Effect of spindle speed on surface roughness at constant DOC of 0.8mm (dry) |

| Figure 5b. Effect of spindle speed on surface roughness at constant DOC of 0.8mm (MQL) |

| Figure 6a. Effect of spindle speed on surface roughness at constant DOC of 1.0mm (dry) |

| Figure 6b. Effect of spindle speed on surface roughness at constant DOC of 1.0mm (MQL) |

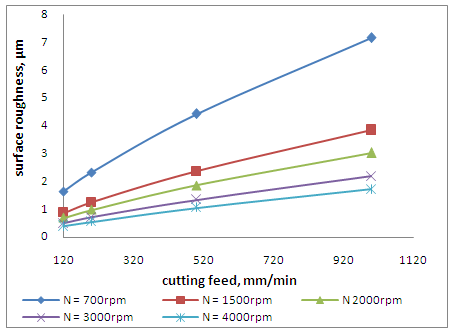

3.2.2. Effect of Cutting Feed on Surface Roughness at Diffrent Spindle Speed

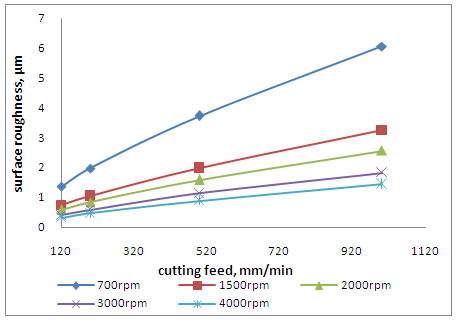

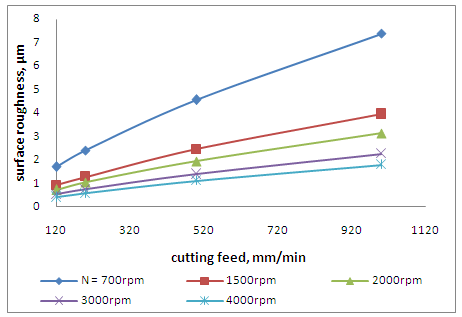

- Figures 7-9 show the relationship between cutting feed and surface roughness at varying spindle speed of 700, 1500, 2000, 3000 and 400rpm respectively. The depth of cut was kept constant at 0.4, 0.8 and 1.0 mm.

| Figure 7a. Effect of cutting feed on surface roughness at constant DOC of 0.4mm (dry) |

| Figure 7b. Effect of cutting feed on surface roughness at constant DOC of 0.4mm (MQL) |

| Figure 8a. Effect of cutting feed on surface roughness at constant DOC of 0.4mm (dry) |

| Figure 8b. Effect of cutting feed on surface roughness at constant DOC of 0.4mm (MQL) |

| Figure 9a. Effect of cutting feed on surface roughness at constant DOC of 1.0mm (dry) |

| Figure 9b. Effect of cutting feed on surface roughness at constant DOC of 1.0mm (MQL) |

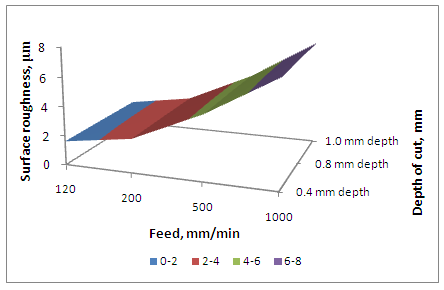

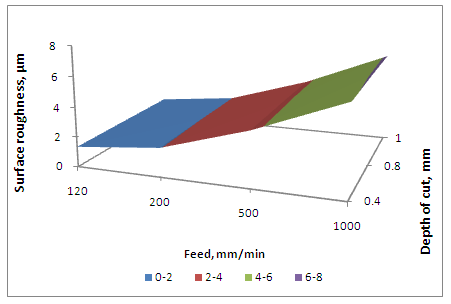

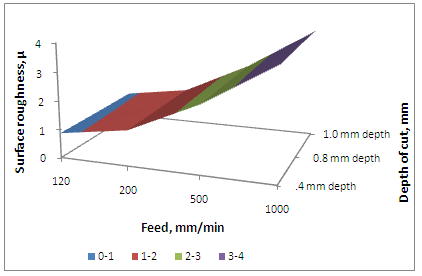

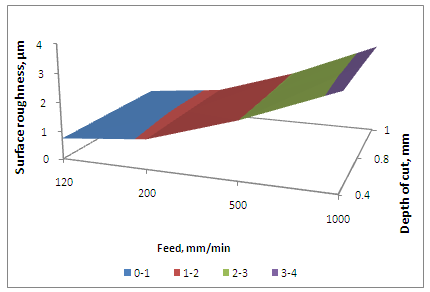

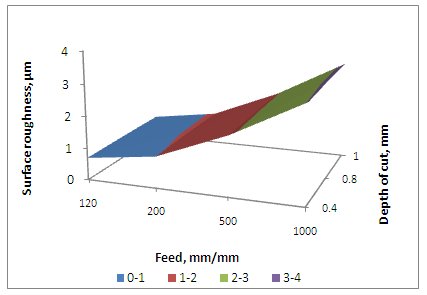

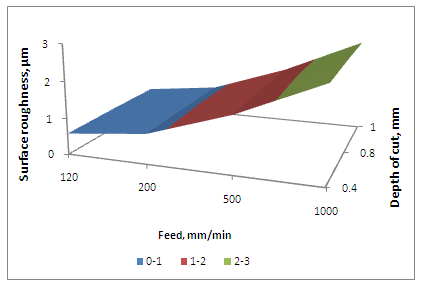

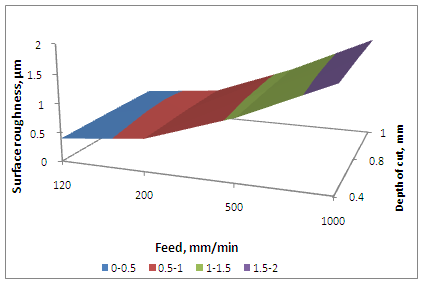

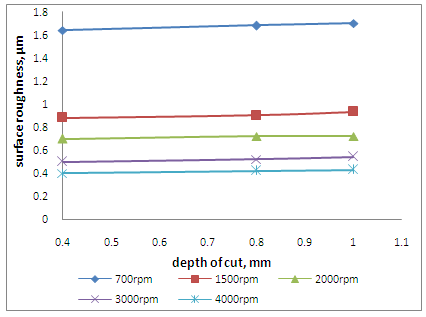

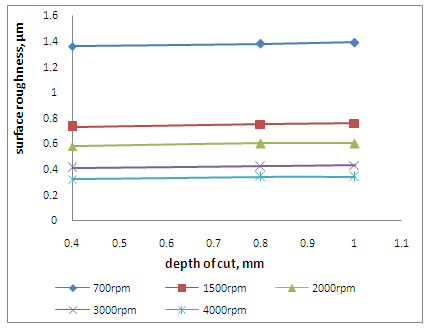

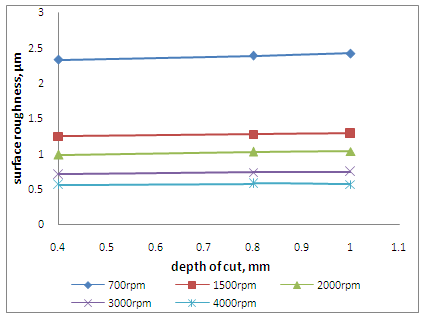

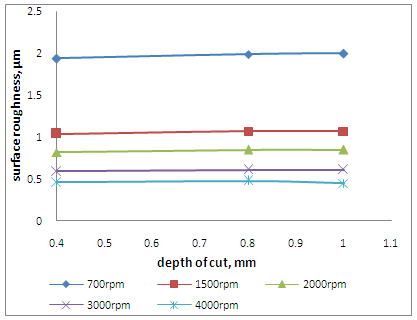

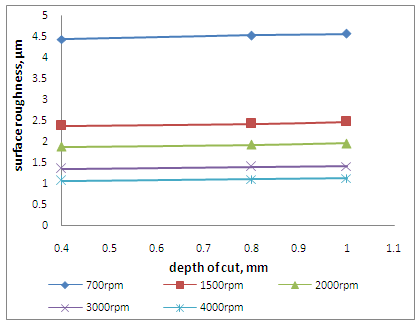

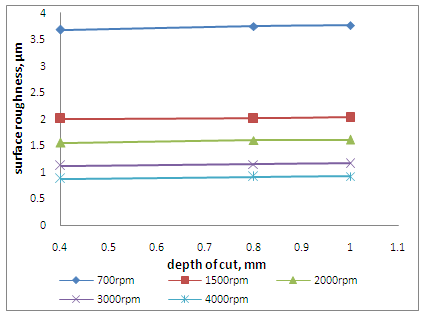

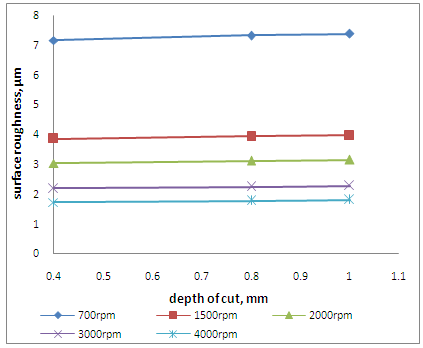

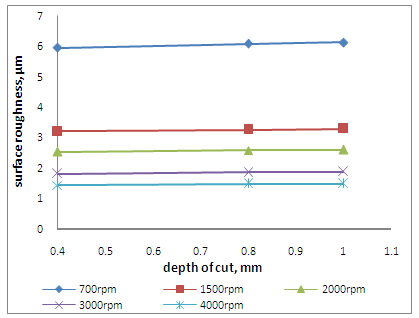

3.2.3. Effect of Depth of Cut on Surface Roughness at Varying Cutting Feed

- Figures 10-13 show the relationship between surface roughness and depth of cut at constant spindle speed of 700, 1500, 2000, 3000 and 4000rpm respectively with varying cutting feed. These graphs give an insight on how the surface responds with change in depth of cut for both dry and MQL environment.From the result, it is observed that an increase in the depth of cut has little effect on the surface roughness of the milled aluminium rods. An increase in the depth of cut causes a little increase in the surface roughness. From Figure 10a, surface roughness value increased (1.64-1.7µm) as the depth of cut is increased at constant spindle speed of 700rpm and varying feed. As the cutting feed is increased to a maximum of 1000mm/min, there is a significant increase in the surface roughness value (7.16µm – 7.38µm) then a little increased is maintained with increased depth of cut. This variation in surface roughness value is the same for MQL environment with reduced surface roughness values (at constant speed of 700rpm, roughness value is 1.36µm – 1.39µm) because the frictional effect is reduced due to the lubrication at the workpiece and tool interface. The increase in surface roughness is expected because the width of contact between the material and cutting tool is more, giving rise to fiction between the workpiece and tool, leading to interruption in cutting operation. More force and energy will be required for the cutting operation and eventually affecting the surface roughness (poor surface quality). This result agrees with that obtained by Arokiadass et al [12] that the depth of cut has minimal effect on surface roughness.

| Figure 10a. Effect of DOC on surface roughness roughness at constant spindle speed of 700rpm (dry) |

| Figure 10b. Effect of DOC on surface at constant spindle speed of 700rpm (MQL) |

| Figure 11a. Effect of DOC on surface roughness at constant spindle speed of 1500rpm (dry) |

| Figure 11b. Effect of DOC on surface roughness at constant spindle speed of 1500rpm (MQL) |

| Figure 12a. Effect of DOC on surface roughness at constant spindle speed of 2000rpm (dry) |

| Figure 12b. Effect of DOC on surface roughness at constant spindle speed of 2000rpm (MQL) |

| Figure 13a. Effect of DOC on surface roughness at constant spindle speed of 4000rpm (dry) |

| Figure 13b. Effect of DOC on surface roughness at constant spindle speed of 4000rpm (MQL) |

| Figure 14a. Effect of DOC on surface roughness at constant cutting feed of 120mm/min (dry) |

| Figure 14b. Effect of DOC on surface roughness at constant cutting feed of 120mm/min (MQL) |

| Figure 15a. Effect of DOC on surface roughness at constant cutting feed of 200mm/min (dry) |

| Figure 15b. Effect of DOC on surface roughness at constant cutting feed of 200mm/min (MQL) |

| Figure 16a. Effect of DOC on surface roughness at constant cutting feed of 500mm/min (dry) |

| Figure 16b. Effect of DOC on surface roughness at constant cutting feed of 500mm/min (MQL) |

| Figure 17a. Effect of DOC on surface roughness at constant cutting feed of1000mm/min (dry) |

| Figure 17b. Effect of DOC on surface roughness at constant cutting feed of 1000mm/min (MQL) |

4. Conclusions

- From the results and analysis of the experiments, it can thus be concluded that the surface roughness (Ra) of a machined surface whether obtained in a dry or MQL environment could be predicted effectively by combining two of these parameters- spindle speed, feed rate, depth of cut- while keeping one of them constant at a time and their interactions in the multiple regression model. It can also be concluded that machining with MQL (a good alternative to flooding lubrication/cooling), apart from being environmentally friendly, reduces the surface roughness value better when compared to dry machining. Surface roughness values were affected mostly by cutting feed, followed by spindle speed and depth of cut has the least impact on surface roughness values. The result also shows that spindle speed and cutting feed combination has the best interaction while combination of cutting feed and depth of cut has the worst interaction leading to a poor surface finish. The model developed can be used to select the best combination of cutting variables for achieving optimum conditions that will result in minimum surface roughness during cutting operation.

ACKNOWLEDGEMENTS

- The authors are very grateful to the Management of Sanfrey Engineering Ltd., Lagos for the use of their facilities in carrying out the experiments.

References

| [1] | R.V. Rao, R.V., 2006. Machinability evaluation of work materials using a combined multiple attribute decision-making method. Int. J. Adv. Manuf. Technol., vol. 28, pp. 221-227, 2006. |

| [2] | P.S. Sreejith, B.K.A. Ngoi, “Dry machining: Machining of the future”, J. Mater. Proc. Technol., vol. 101, nos. 1-3, pp. 287 – 291, 2000. |

| [3] | K. Weinert, I. Inasaki, J.W. Sutherland, T. Wakabayashi, “Dry, machining and minimum quantity lubrication”, Annals CIRP, vol. 53, no. 2, pp. 511–537, 2004. |

| [4] | E. Kalhofer, “Dry machining principles and applications”, In: Proceedings of the 2nd Seminario Inter. deAlta Tecnologia UNIMEP, Santa Barbara D’Oeste, SP, Julho, Brazil, pp. 519–526, 1997. |

| [5] | C. Clauding, G. Poulachon, and M. Lamberting, “Correlation Between Drill Geometry and Mechanical Forces in MQL Conditions”, Machining Science and Technology, vol. 12, pp.133-144, 2008. |

| [6] | M.M.A. Khan, M.H.A. Mithu, N. R. Dhar. “Effects of minimum quantity lubrication on turning AISI 9310 alloy steel using vegetable oil based cutting fluid”, Journal of Materials Processing Technology, vol. 209, pp. 5573–5583, 2009. |

| [7] | B.S. Reddy, J.S. Kumar, K.V.K. Reddy, “Optimization of surface roughness in CNC end milling using response surface methodology and genetic algorithm”, International Journal of Engineering, Science and Technology, vol. 3, no. 8, 2011, pp. 102-109, 2011. |

| [8] | Safari, H., S. Sharif, S. Izman, H. Jafari, “High Speed Dry End Milling of Ti-6Al-4V Alloy towards Nano-scale Surface Roughness”, Journal of Applied Sciences Research, vol. 8, no. 11, pp. 5280-5284, 2012. |

| [9] | A.R.C. Sharman, D.K. Aspinwall, R.C. Dewes, P. Bowen, “Workpiece surface integrity considerations when finish turning titanium aluminide”, Wear, vol. 249, pp. 473-481, 2001. |

| [10] | F. Ghanem, C. Braham, M.E. Fitzpatrick, H. Sidhom, “Effect of near-surface residual stress and microstructure modification from machining on the fatigue endurance of a tool steel”, Journal of Materials Engineering and Performance, vol. 11, no. 6, pp. 631-639, 2002. |

| [11] | M.S. Lou, J.C. Chen, C.M. Li, “Surface Roughness Prediction Technique For CNC End-milling” Journal of Industrial Technology, vol.15, no.1, 1998. |

| [12] | R. Arokiadass, K. Palaniradja, N. Alagumoorthi, “Predictive modeling of surface roughness in end milling of Al/SiC metal matrix composite”, Archive of Applied Science Research, vol. 3, no. 2, pp. 228-236, 2011. |

| [13] | E. Kuram, B. Ozceik, E. Demirbas, E. S, “Effects of the Cutting Fluid Types and Cutting Parameters on Surface Roughness and Thrust Force”, World Congress on Engineering (WCE), vol. II, 2010. |

| [14] | M. Soković, K. Mijanović, “Ecological aspects of cutting fluids and its influence on quantifiable parameters of the cutting processes,” Journal of Materials Processing Technology, vol. 109, pp. 181-189, 2001. |

| [15] | P.N. Rao, “Manufacturing technology: metal cutting and machine tools”, New Delhi :Tata McGraw Hill Publication, 2000. |

| [16] | J.S. Ojolo, O. Damisa, O. Iyekolo, “Investigation into the effects of solid lubricant on surface characteristics of some metals during orthogonal machining”, Journal of Engineering Design and Technology, vol. 9, no. 2, 2011. |

| [17] | N. Boubekri, V. Shaikh, “Machining Using Minimum Quantity Lubrication: A Technology for Sustainability”, International Journal of Applied Science and Technology, vol. 2, no. 1, 2012. |

| [18] | F. Klocke, G. Eisenblatter, “Dry Cutting”, Annals of the CIRP, vol.46, no.2, pp. 519-526. |

| [19] | E. Sabahudin, V.C. Joan, B. Edin, O.A. Nadja, “Experimental modeling of surface roughness parameters during cutting steel NiMo”, 15th International research/Expert Conference, TMT, 2011. |

| [20] | E. Abele, B. Schramm, H. Scheerer, “Dry Machining Using Novel Chromium Based Coatings”, Journal of Advances in Production Engineering & Management, vol. 3, no. 3, pp. 141-148, 2008. |

| [21] | A. Li, Z. Jun, L. Hanbing, P. Zhiqiang, W. Zeming, “Progressive tool failure in high-speed dry milling of Ti-6Al-4V alloy with coated carbide tools”, Int. J. Adv. Manuf. Technol. vol. 58, pp. 465-478, 2012. |

| [22] | A. Li, Z. Jun, L. Hanbing, Z. Wei, “Machined Surface Analysis in High-Speed Dry Milling of Ti-6Al-4V Alloy with Coated Carbide Inserts”, Advanced Materials Research, vol. 325, pp. 412-417, 2011. |

| [23] | T. Wakabayashi, I. Inasaki, S. Suda, H. Yokota, “Tribological Characteristics and Cutting Performance of Lubricant Esters for Semi- Dry Machining”, CIRP Annals, vol. 51, no.1, pp. 61–64, 2003. |

| [24] | L.B. Abhang, M. Hameedullah, “Experimental investigation of minimum quantity lubricants in alloy steel turning”, International Journal of Engineering Science and Technology, vol. , no.7, pp. 3045-3053, 2010. |

| [25] | S.M. Ali, N.R. Dhar, S.K. Dey, “Effect of minimum quantity lubrication (MQL) on cutting performance in turning medium carbon steel by uncoated carbide insert at different speed-feed combinations”, Journal of Advances in Production Engineering and Management, vol. 6, no. 3, pp. 185-198, 2011. |

| [26] | T.H. Mohammed, S.T. Montasser, B. Joachim, “A study of the effects of machining parameters on the surface roughness in end-milling process”, Jordan Journal of Machining and Industrial Engineering, vol. 1, no. 1, pp. 1-5, 2007. |

| [27] | C. Natarajan, S. Muthu, P. Karuppuswamy, “Investigation of cutting parameters of surface roughness for a non-ferrous material using artificial neural network in CNC turning”, Journal of Mechanical Engineering Research, vol. 3, no. 1, pp. 1-14, 2011. |

| [28] | H. SuhailAdeel, N. Ismail, S.V. Wong, N.A. Jalil, “Optimization of Cutting Parameters Based on Surface Roughness and Assistance of Workpiece Surface Temperature in Turning Process”, American Journal of Engineering and Applied Sciences, vol. 3, no. 1, pp. 102-108, 2010. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML