-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Journal of Mechanical Engineering and Automation

p-ISSN: 2163-2405 e-ISSN: 2163-2413

2014; 4(1): 43-48

doi:10.5923/j.jmea.20140401.03

Crackable Connecting Rod Material Selection by Using TOPSIS Method

1Balıkesir University, Mechanical Engineering Department, Balıkesir, 10100, Turkey

2Marmara University, Social Sciences Institute, İstanbul, 34100, Turkey

Correspondence to: Zafer Özdemir, Balıkesir University, Mechanical Engineering Department, Balıkesir, 10100, Turkey.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

Fracture splitting method is an innovative processing technique in the field of automobile engine connecting rod (con/rod) manufacturing. Compared with traditional methods, this technique has remarkable advantages. Manufacturing procedures, equipment and tools investment can be decreased and energy consumption reduced remarkably in this method. Furthermore, product quality and bearing capability could be improved. It provides a high quality, high accuracy and low cost route for producing connecting rods (con/rods). This method has attracted manufacturers attention and has been utilized in many types of con/rod manufacturing due to the many advantages mentioned above. In this study, the outranking of crackable connecting rod material has been obtained by using TOPSIS (Technique For Order Preference By Similarity To Ideal Solution), Multiple Criteria Decision Making method. We outrank C70S6 (pearlite, bainite, martensite and tempered martensite), 70MnSV4 and FRACTIM crackable connecting materials with 6 criteria.

Keywords: Crackable Connecting Rod, Material Selection, TOPSIS Method, Ranking

Cite this paper: Zafer Özdemir, Tolga Genç, Crackable Connecting Rod Material Selection by Using TOPSIS Method, Journal of Mechanical Engineering and Automation, Vol. 4 No. 1, 2014, pp. 43-48. doi: 10.5923/j.jmea.20140401.03.

Article Outline

1. Introduction

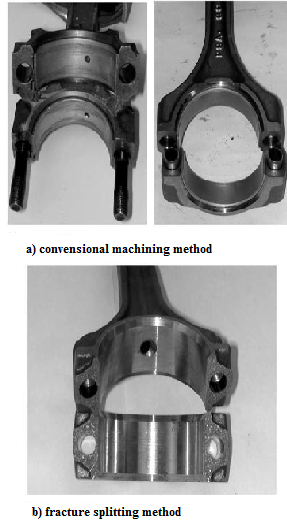

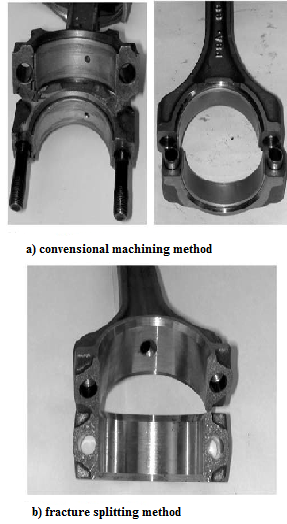

- Connecting rods are widely used in variety of automobile engines. The function of the connecting rod is to transmit the thrust of the piston to the crankshaft and translate the transverse motion to rotational motion. It should be strong enough to remain rigid under loading, and also be light enough to reduce the inertia forces, which are produced when the rod and piston stop, change directions and start again at the end of each stroke [1].The fracture splitting method is an innovative processing technique in the field of the automobile engine connecting rod (con-rod) manufacturing. Compared with traditional method, the technique has remarkable advantages. It can decrease manufacturing procedures, reduce equipment and tools investment and save energy. Hence the total production cost is greatly reduced. Furthermore, the technique can also improve product quality and bearing capability. It provides a high quality, high accuracy and low cost route for producing connecting rods (con/rods). The method has attracted extensive attention and has been used in some types of con/rods manufacturing. In recent years, with the rapid development of the automobile industry, the competition in the international automobile markets has become more severe. New market conditions demand manufacturers employ higher quality, greater efficiency and lower cost manufacturing technology to fabricate automobile parts so as to improve their competitive capability and meet the market requirements [2].Microalloyed high carbon steels (such as C70S6, SMA40 and FRACTIM) have been considered to be economical alternatives to powder metal and conventional steel, having been used as main crackable con-rod materials (Figure 1 and 2) in recent years used in the fracture splitting method. Compared with powder metal and conventional steel, these microalloyed high carbon steels have remarkable advantages. One of the main advantages is that cost reduction can be achieved by changing the micro-structure of the con-rod. Sawing and machining processes of the rod and cap, in order to mate two faces can be eliminated, and is believed to reduce the production cost by 25%. Another advantage of this production method is that fracture-splitting connecting rods exhibit 30% higher fatigue strength and 13% less weight than conventional connecting rods, and can be splitted into two pieces (big body and cap) by fracturing with an instant impact load. Compared with powder metal and cast con-rods, it also has lower cost for the whole manufacturing process. Hence, it provides more advantageous production opportunities, and is preferred in manufacturing technology mostly [3].

| Figure 1. Crackable Connecting Rod Manufacturing Processes, Convensional Machining Method [4] |

| Figure 2. Crackable Connecting Rod Manufacturing Processes, Fracture Splitting Method [4] |

2. Literature Review

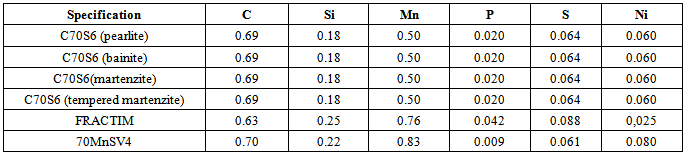

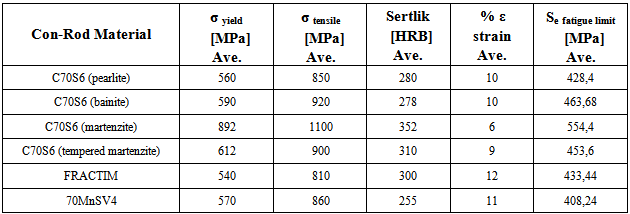

- Considerable studies have been made on the fracture splitting parameters of connecting rods. Some of them have been discussed below. Especially C70S6 steel has been investigated mostly. Fractim and C70S6 have been used in industry mostly and carried on academic research. C70S6 is excellent in fracture-splitability thanks to its small deformation during splitting, It has a coarser structure than the ferrite/pearlite structure of the medium-carbon micro-alloyed steels currently used as con-rod steels. It is therefore low in yield ratio (yield strength/tensile strength) and cannot be applied to high-strength con-rods requiring high yield strength. Moreover, the inferior machinability of C70S6 owing to its pearlite structure has kept the steel from finding extensive utilization [7]. Chemical compositions of materials used for comparing is shown in Table 1 and mechanical properties in Table 2.

|

|

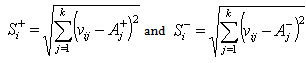

3. TOPSIS Method

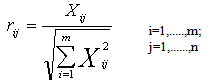

- MCDM is used to select a project from several alternatives according to various criteria. TOPSIS method was first developed by Hwang and Yoon [19] based on the concept that the chosen alternative should have the shortest distance from the positive ideal solution (PIS) and the farthest from the negative ideal solution (NIS) for solving a MCDM problem. Thus, the best alternative should not only have the shortest distance from the positive ideal solution, but also should have the largest distance from the negative ideal solution. In short, the ideal solution is composed of all best values attainable of criteria, where as the negative ideal solution is made up of all worst values attainable of criteria [20].The TOPSIS method consists of the following process [21, 22].Calculate the normalized decision matrix. The normalized value rij is calculated as it follows:

| (1) |

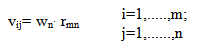

Calculate the weighted normalized decision matrix. The weighted normalized value vij is calculated as it follows;

Calculate the weighted normalized decision matrix. The weighted normalized value vij is calculated as it follows;  | (2) |

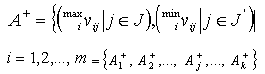

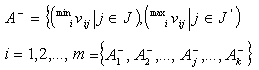

The ideal A+ and the negative-ideal A- solutions are defined as follows:

The ideal A+ and the negative-ideal A- solutions are defined as follows: | (3) |

| (4) |

(distances to the ideal solution) and

(distances to the ideal solution) and  (distances to the negative-ideal solution) are calculated with given formulas.

(distances to the negative-ideal solution) are calculated with given formulas. | (5) |

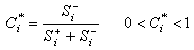

≤ 1, an alternative i is closer to A+ as

≤ 1, an alternative i is closer to A+ as  approaches to 1.

approaches to 1. | (6) |

or outrank the alternatives according to

or outrank the alternatives according to  in descending order.The best (optimal) alternative can now be decided according to the preference rank order of

in descending order.The best (optimal) alternative can now be decided according to the preference rank order of  . Therefore, the best alternative is the one that has the shortest distance to the ideal solution. The previous definition can also be used to demonstrate that any alternative which has the shortest distance from the ideal solution is also guaranteed to have the longest distance from the negative-ideal solution.

. Therefore, the best alternative is the one that has the shortest distance to the ideal solution. The previous definition can also be used to demonstrate that any alternative which has the shortest distance from the ideal solution is also guaranteed to have the longest distance from the negative-ideal solution. 4. Materials and Methods

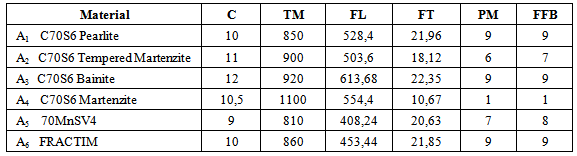

- In this study TOPSIS has been used to choose the best alternative material for crackable connecting rod. The alternative materials list is shown in Table 3. Choice criteria are shown in Table 4. These criteria are cost, tensile strength, fatigue limit, fracture toughness, productivity-machining and first fracture brittleness.

|

|

|

|

|

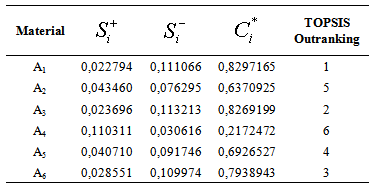

5. Results and Discussion

- In Table 8, it is not so much surprising that C70S6-pearlite (A1) is the dominant material for crackable connecting rod material. C70S6-bainite (A3) outranking TOPSIS value is at close quarters to C70S6-pearlite. The chemical composition of A1 is same as A3, but when austempering is applied, the microstructure is transformed into bainite; so some mechanical properties change.Then it could be seen FRACTIM (A6) and 70MnSV4 (A5) are the next alternatives for crackable connecting rod materials. It was concluded that tempered martensite (A2) could be used as another alternative but martensite (A4) is not a choice for crackable connecting rods.Due to its' mechanical properties; martensite is too hard and is not a suitable material composition for use in machines, but it can gain some toughness by tempering so called tempered marten site. It has been shown experimentally by Z.Özdemir and his friends [7,8] that tempered martenzite and bainite [23] could also be an important material alternative for crackable connecting rods.Pearlite, FRACTIM and 70MnSV4 is still used technologically for crackable connecting rods.

6. Conclusions

- In this study the material choice has been studied and investigated for crackable connecting rods. TOPSIS method is used in this analysis. As a result it was concluded that the best choices for crackable connecting rod materials are pearlitic and bainitic C70S6.This result is very much adequate to the material selection and mechanics references for material design. Pearlitic structure is preferred in most of the materials used in machines. Bainite is also used but it is much more high-cost production because of heat-treatment method (austempering) as compared with pearlite. FRACTIM is another alternative and it is also used in technology widespread with 70MnSV4. Tempered martenzite is not cost effective but it could be used mechanically. Martenzite is neither cost effective nor mechanically proper for use.This study could be applied to other materials and analysed with other MCDM methods such as PROMETHEE, VIKOR, etc.

References

| [1] | J.W. Qiu, Y. Liu , Y.B. Liu , B. Liu , B. Wang , Earle Ryba , H.P. Tang (2011) "Microstructures and Mechanical Properties of Titanium Alloy Connecting Rod Made by Powder Forging Process", Materials and Design Elsevier, 213-219. |

| [2] | Afzal, A. (2004) "Fatigue Behavior And Life Predictions Of Forged Steel And Powder Metal Connecting Rods", MSc Thesis, University of Toledo, Toledo. |

| [3] | Z.Özdemir, Z.Aksoy, T.Özdemir (2012) "A Metallographic Examination Of Fracture Splitting C70S6 Steel Used In Connecting Rods", Fen Bilimleri Dergisi, Marmara Üniversitesi, 24(2), 45-58. |

| [4] | Z.Özdemir, Z.Aksoy, T.Özdemir (2012) "Kırılarak İki Parçaya Ayrılabilen Biyel Kollarının Ayrılma Parametreleri Üzerine Bir İnceleme", Fen Bilimleri Dergisi, Sakarya Üniversitesi, 16(2) 113-122. |

| [5] | GRANDZOL, J.R (2005) “Improving the Faculty Selection Process in Higher Education: A Case for the Analytic Hierarchy Process”, IR Applications, Vol.6, p. 1-13. |

| [6] | JAHANSHAHLOO, G.R., F.H. LOTFI and M. IZADIKHAH (2006) “Extension of the TOPSIS Method for Decision-Making Problems with Fuzzy Data”, Applied Mathematics and Computation, Vol.181, p. 1544-1551. |

| [7] | Z.Özdemir, Z.Aksoy, T.Özdemir (2013) "An Examination Of Different Heat Treatment Effects To The Fracture Parameters Of Connecting Rod Made From C70S6 Steel", Fen Bilimleri Dergisi, Marmara Üniversitesi, 25(2), 75-90. |

| [8] | Z.Özdemir, O.S. Türkbaş, T.Özdemir (2013) "C70S6 Çeliğinden İmal Edilen Biyel Kolunun Çentikli Kırma Yöntemi İle İmalatı Esnasında Isıl İşlem Parametrelerinin Kırılmaya Etkisi", Makine Teknolojileri Elektronik Dergisi, Afyon Kocatepe Üniversitesi, 10 (2), 49-58. |

| [9] | Z, Gu,. Yang, S., Ku, S., Zhao, Y,. ve Dai, X., (2005) "Fracture Splitting Technology Of Automobile Engine Connecting Rod". Journal of Advanced Manufacturing Technology, 25, 883-887. |

| [10] | Manabu Kubota, Tokyo (JP); Shinya Teramoto, Tokyo (JP) (2010) "Hot-Forging Micro-Alloyed Steel And Hot-Rolled Steel Excellent In Fracture-Splitability And Machinability, And Component Made Of Hot-Forged Microalloyed Steel", United States Patent Application, US 2010/0143180. |

| [11] | X Zhang, Z., Q Cai, G. Zhou et al., (2011) "Microstructure and Mechanical Properties of V-Ti-N Microalloyed Steel Used For Fracture Sptlitting Connecting Rod”, Journal of Material Science, 46:1789-1795, |

| [12] | Liming, Z., Shuqing, K., Shenhua,Y., Lili, Li. ve Fei. Li., (2009) "A Study Of Process Parameters During Pulsed Nd:YAG Laser Notching Of C70S6 Fracture Splitting Connecting Rods", Optics and Laser Technology, 42: 985-993. |

| [13] | Deen, Z., Harris, S.J., McCartney, D.G., Pashby, I.R., Towell, J., Shipway P.H., et al., (2008)"The Effect Of Laser Transformation Notching On The Controlled Fracture Of A High Carbon (C70S6) Steel", Material Science and Engineering, 489, 273-284, |

| [14] | Schijve J., (2004) "Fatigue Of Structures and Materials", Kluwer Academic Publishers, Newyork. |

| [15] | Jahan, A., M.Y. ısmaıl, S.M. Sapuan and F. Mustapha, (2010) “Material Screening and Choosing Methods-A Review”, Materials & Design, Vol.31, Issue.2, p. 696-705. |

| [16] | Shanıan, A. and O. Savadogo (2006) “TOPSIS Multiple-Criteria Decision Support Analysis for Material Selection of Metallic Bipolar Plates for Polymer Electrolyte Fuel Cell”, Journal of Power Sources, Vol.159, p. 1095-1104. |

| [17] | Jahan, A., F. Mustapha, M.Y. Ismail, S.M. Sapuan and M. Bahramınasab (2011) “A Comprehensive VIKOR Method for Material Selection”, Materials & Design, Vol.32, Issue.3, p. 1215-1221. |

| [18] | Chatterjee, P., V.M. Athawale and S. Chakraborty (2009) “Selection of Materials Using Compromise Ranking and Outranking Methods”, Materials & Design, Vol.30, Issue.10, p. 4043-4053. |

| [19] | Hwang, C.L. and K. Yoon (1981) Multiple Attribute Decision Making:Methods and Applications, Springer-Verlag, New York. |

| [20] | Chen, M.F. and G.H. Tzeng (2004) “Combining Grey Relation and TOPSIS Concepts for Selecting an Expatriate Host Country”, Mathematical and Computer Modelling, p. 1473-1490 |

| [21] | Oprıcovıc, S. and G.H. Tzeng (2004) “Compromise Solution by MCDM Methods: A Comparative Analysis of VIKOR and TOPSIS”, European Journal of Operational Research, Vol.156, p. 445-455. |

| [22] | Triantaphyllou, E., B. Shu, S. Nieto Sanchez and T.Ray (1998) “Multi-Criteria Decision Making: An Operations Research Approach”, Encyclopedia of Electrical and Electronics Engineering, Vol.15, p. 175-186. |

| [23] | Z.Aksoy, Z.Özdemir, T.Özdemir (2014) "An Examination Of Bainitic Structure To The Fracture Parameters Of Crackable C70S6 Connecting Rod ", Fen Bilimleri Dergisi, Marmara Üniversitesi, Inpress. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML