-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Journal of Mechanical Engineering and Automation

p-ISSN: 2163-2405 e-ISSN: 2163-2413

2012; 2(5): 91-99

doi: 10.5923/j.jmea.20120205.02

Experimental Study under Real-World Conditions to Develop Fault Detection for Automated Vehicles

Naohisa Hashimoto 1, Umit Ozguner 2, Masashi Yokozuka 1, Shin Kato 1, Osamu Matsumoto 1, Sadayuki Tsugawa 3

1Intelligent Systems Research Institute, National Institute of Advanced Industrial Science and Technology, Tsukuba, 305-8568, Japan

2Department of Electrical Computer Engineering, The Ohio State University, Columbus (OH), 43210, USA

3Department of Information Engineering, Meijo University, Nagoya, 468-8502, Japan

Correspondence to: Naohisa Hashimoto , Intelligent Systems Research Institute, National Institute of Advanced Industrial Science and Technology, Tsukuba, 305-8568, Japan.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

Automated vehicles can contribute to the improvement of transportation through their high capacity, increased safety, low emission and high efficiency. However, unstable conditions of automated mobile systems, which include automated vehicles and mobile robots) can cause serious problems, andthus, automated mobile system requiresto be highly reliable. The objective of this research is to develop on analgorithmfor detection faults (unstable condition) in an automated mobile system and to improve the overall reliability of this system. In this study, we initially stored and updated a few patterns of data constellations under normal and unstable conditions for fault identification through real-world experiments. Multiple experiments were performed in a public urban area (with course distance per set beingapproximately1.1[km]), where several pedestrians, bicycles, and other robots were also present. The method used for detecting faults utilizes Mahalanobis distance, correlation coefficient, and linearization in order to enhance the accuracy of detecting faults;further, because real-world experimental conditions vary frequently,it is essential for the proposed method to be robust undervarious conditions. The main feature of this study is that it involves the use of experimental results obtained under real-world conditions, to develop a fault detection algorithm and evaluate its validity. In addition, simulations were performed using the real-world experimental data, which includes newly logged experimental data after the algorithm was developed in order to evaluate the validity of the proposed algorithm. The simulation results show that the proposed algorithm detects faults accurately, thus, they prove its validity.

Keywords: Fault Detection, Fault Tolerant System, Mobile Robot, Intelligent Vehicle, Automated Vehicle

Article Outline

1. Introduction

- Transportation systems pose numerous problems such as traffic accidents, traffic congestion,high energy consumption, and air pollution.One of the ways to overcome these problems is to develop automated vehicles[1-9]. Automated vehicles can contribute to the improvement of transportation through their high capacity, increased safety, low emission and high efficiency. However, unstable conditions of or faults in automated vehicles can cause serious problems; thus, it is critical for an automated vehicle to be highly reliable.Further, an automated vehicle should be able to identify its own position with respect to surrounding obstacles. Therefore, automated vehicles are equipped with sensors for estimating their own position and detecting obstacles, and the automated mobile system controls the vehicle using the data obtained from the sensors. Some data sets are obtainedwhen the automated vehicle is under normal condition, and a few data sets are obtained when it is under unstable condition. In general it is easy to detect faults and unstable conditions using a simple algorithm. However, as the algorithm becomes complicated, it becomes difficult to detect faults in the vehicle because the number of data sets and the values to be calculated increase; further, because of the complexity of the algorithm, the obtained data tend to affect each other.Trough investigations, S.Shladoverestablished that a system for controlling automated vehicles requireto be highly reliable because the mean time between failures (MTBF) fora human driver was very high[10]. Further, he mentioned that one of the most significant challenges faced in the research on automated vehicles was fault detection and identification. The objective of this research is to develop an algorithm for detecting faults (unstable condition) in automated vehicles and to improve the overall reliability of the vehicles.A few researchers have concluded researches on fault detection (failure detection) algorithms and fault tolerant systems. T.H.Kerrconducteda study on fault alarm algorithm using a KalmanFilter[11]. He proposed a generalized technique for evaluating tightened upper bounds on false alarm and for correcting detection probabilities. This technique can be applied to detect any type of failure or signal. S.Schneider, et al. proposed a sensor fusion and a fault detection algorithm forlanekeeping and headway maintenanceapplications[12]. Theyused assumed fault patterns and evaluated the proposed algorithm via a simulation. In their study, fault signature was obtained virtually,and thus, the study did not involve the use of the experimentaldata. M.Hashimoto et al. proposed an algorithm for fault detection and identification of sensor-scale failure in a mobile robot, and they performed experiments by intentionally introducing faults in the robot, for evaluating the proposed algorithm[13]. Their study focused on the failure in velocity estimation, andthey evaluated the proposed algorithm usinga single-model-based Kalman Filter through experiments using a single mobile robot. With respect to fault detection at a system/device level, some algorithms for fault, failure, or unstable condition detection have already been proposed and evaluated[14-20]. In particular, statistical approaches used in these proposed algorithms have been referred to, in this study.In this study, we first solved and updated a few patterns of data constellations under normal and unstable conditions for fault identification through real-world experiments. We performed these experiments in a public urban area, where a few pedestrians, bicycles and other robots were present. The main feature of this study is that it involves the use of experimental data obtained under real-world conditions, to develop a fault detection algorithm and evaluate its validity of it. The algorithm continuously monitors all data obtained using sensors installed in the vehicle, and if the vehicle becomes unstable the algorithm detects the unstable condition by comparing the current data with the previously stocked data using statistical approach. We have already studied the framework of the proposed algorithm using a small amount of data, and evaluated its validity[21]. This study involves the evaluation of the validity of the proposed algorithm under different conditions using a large amount of experimental data.This paper describes an algorithm for constructing faults patterns and for detection faults, further, experiments are performed under real-world conditions, and simulation results are obtained.

2. Fault Detection Algorithm

2.1. Overview

- This study focuses on the estimation of velocity and yaw angle, which are necessary tocalculate a vehicle’s position.Moreover, it does not involve obstacle detection. In this section, we explain the types of data used in the proposed algorithm, fault data obtained through the real-world experiments, the method for detection and classifying faults and unstable conditions, and the flow of the study.

2.2. Three Types of Faults

- Three types of fault data sets that may lead to unstable conditions have been collected through real-world experiments; these data sets are described in section 3. It should be noted that we can obtain other types of fault data sets by performing further experiments; however, this study considers only three sets of faults data because the objective of this study is to evaluate the proposed algorithm, and these three faults can be detected manually and given that all results are known. The following are the three types of faults:1. Communication fault2. Encoder fault3. Gyro faultCommunication fault (#1) indicates communication failure between a laptop and an on-board PC.Encoder fault (#2) does not necessarily imply the failure of encoders. If a slope exists in the course taken by the vehicle, then a faulty estimate of the vehicle’s velocity is obtained because the encoders overestimate the distance covered by the vehicle while climbing a slope than while traveling on a flat road.Gyro fault (#3) implies that the standard deviation of data obtained from a gyro is considerably higher than its specified limit. Further, the gyro requires to be calibrated before use, for determining its performance. It should be noted that the temperature was very high on the day when the data with a considerable high standard deviation has obtained from the gyro; therefore, we could not determine the main reason for the high standard deviation, but we consider that high temperature had a negative effect on the gyro.

2.3. Data for Fault Detection

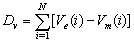

- The algorithm controls the automated vehicle by referring to its velocity and yaw angle, which are calculated using the different types of data obtained from the sensors. The vehicle’s position is calculated from its velocity and yaw angle.With regard to velocitydetermination, velocity(Ve) can be estimated by measuring the difference between the current and the former values of the wheel encoder count. Velocity (Vm) can be estimated usinga map-matching algorithm[22]. The integral of deviation between the above two values is considered as the threshold value for fault detection. The integral of velocity differences (Dv) is calculated as follows:

| (1) |

| (2) |

| (3) |

| (4) |

2.4. Signature of Each Fault Data Set

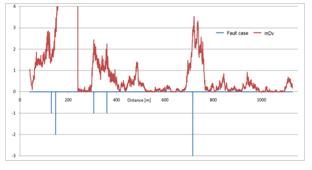

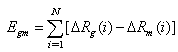

- Through experiments, three types of fault patterns were obtained. This section describes the method for constructing a signature data set using these fault patterns.First, we attempted to detect faults by using only the correlation coefficient in the same way as that proposed in the previous paper[12]. However, it was found that the use of only the correlation coefficient was not sufficient to correctly detect a fault because the experiments were performed under various real-world environmental conditions and multiplefaultswereexpected. Thus, along with the correlation coefficient, we also used the linearization methods to detect faults.In order to detect faults in velocity, linear approximations of every Dv of each fault pattern were constructedusing a least square algorithm; consequently, the linear approximate equation ofDv could be used to represent the relationship between Dv and the distance. Every Dv are shown in Fig.1.

| Figure 1. Parameter DV obtained through experiments when the mobile robot climbs a slope |

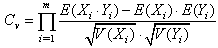

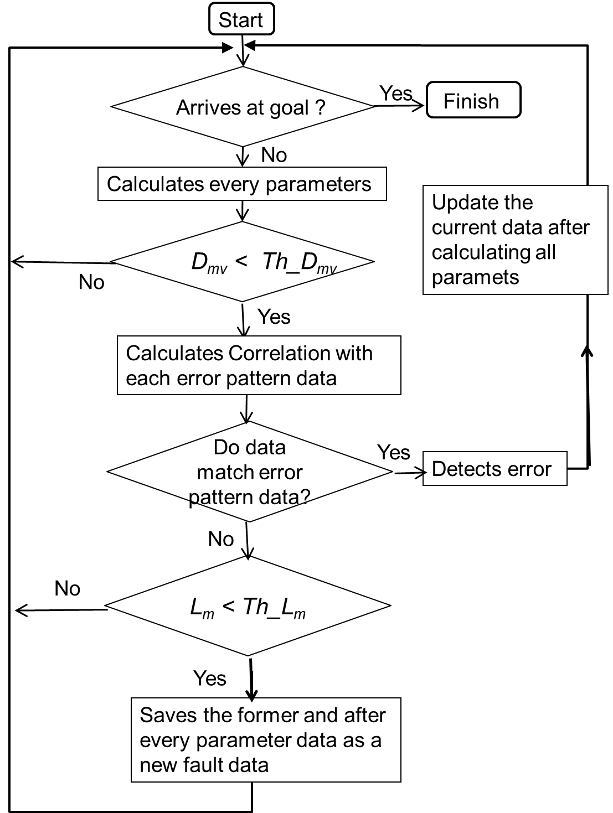

2.5. Algorithm of Classifying Faults

- In this section we first explain the algorithmfor detecting faults in velocity estimations. Figure 2 shows the flowchart of the proposed algorithm for detecting faults in velocity estimations. As described in Section 2.3, if Dmv is greater than Th_Dmv, the algorithm ascertains an unstable condition or a fault in the velocity estimation flow. Subsequently, the algorithm detects the type offaultthat occurs by comparing it with the patterns that are already stored in the algorithm. As explained in Section 2.4, the proposed algorithm uses two values that are separately calculated for detecting faults. Onevalue is obtainedusing correlation coefficient. In this algorithm, five parameters with distance-series data were used. The five values of correlation coefficient between each of the five parameterswere calculated. The expression for calculating the relative value (Cv) is given as follows:

| (5) |

| Figure 2. Flow chart of proposed algorithm for detecting faults in velocity estimation |

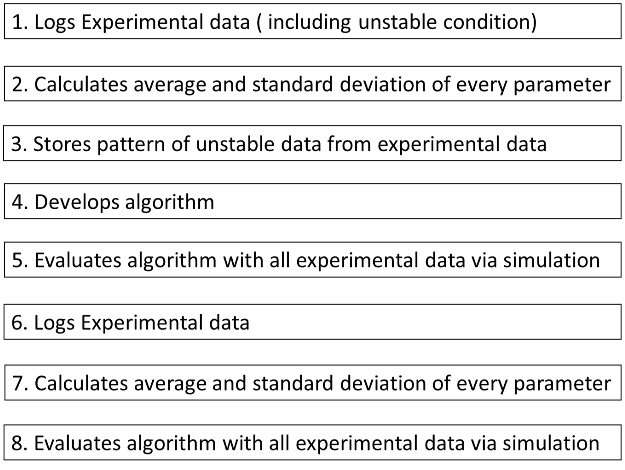

2.6. AlgorithmFlow

| Figure 3. Algorithm flow |

3.Experiments under Real-World Conditions

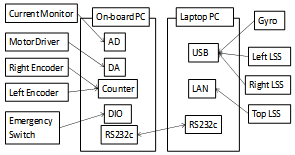

3.1.Instrumentation

- Amobile robot was usedfor the experiments. This robot was developed by modifying a wheelchair, as shown in Figure4. Figure 5 shows the system configuration of this robot. This robot can be controlled through an on-board PC using electrical signals or by a driver using a joystick. Further, it can move at a velocity of 6 [km/h]; hence, its maximum velocity was set to 4 [k/m] during the experiments, for safety reasons.

| Figure 4. Mobile robot |

| Figure 5. System configuration |

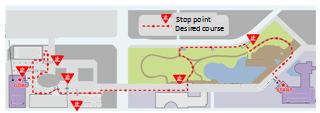

| Figure 6. Course map |

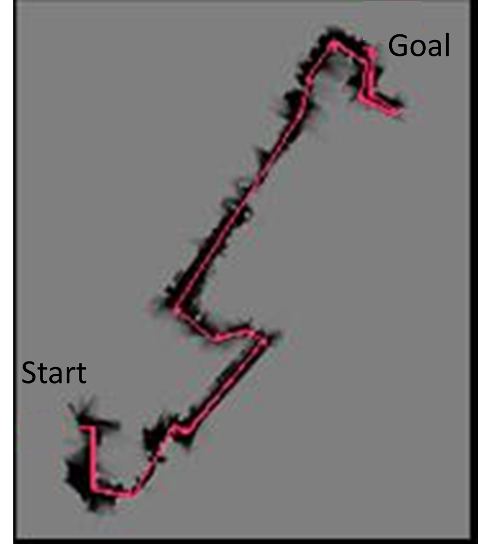

| Figure 7. Desired course and map for map-matching |

| Figure 8. Map-matching |

| Figure 9. Stop point |

| Figure 10. Experimental scene |

4. Simulation Study Using Real-World Experimental Data

4.1. Simulationsusing Real-World Experimental Data

- Simulations using real-world experimental data were performed in order to evaluate the validity of the proposed algorithm. The recognition rate of the proposed algorithm was considered to evaluate the validity of the algorithm,i.e., to obtain results indicating that the faults are detected correctly by the algorithm via simulations. Here, unknown faults are not considered because such faults were not foundwhen the algorithm was implemented.The algorithm continuously attempts to detect the type of faultthat occurs. The first detection result except for the map-matching fault is considered as the algorithm’s classifying result. The simulations wereperformed consecutively using the first to final traveling data that was obtained. The first experimental data includes three types of faults; on the other hand, the second experimental data includes only one type of fault. Nevertheless, if the proposed algorithm can detect faults using other experimental data, then the validity of the proposed algorithm can be proved.

4.2.Simulation Results and Discussion

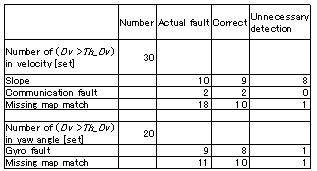

4.2.1. First experimental data

|

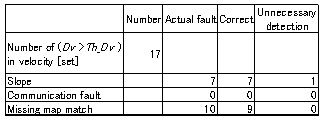

4.2.2. Second experimental data

- Table 2lists the simulation results obtained using the second experimental data. This simulation focuses on fault detection in velocity estimation, because faults #1 and #3 did not occur while performing the second set of experiments. This result shows that the proposed algorithm can detect the fault occurs when the robot climbs a slope with only one unnecessary detection. In addition, this algorithm detected communication faults correctly. This result proves the validity of the proposed algorithm for other experimental data, as well, thus validating its robustness. However, the algorithmrequires a few modifications in order to improve its reliability, which will be carried out in a future work.

|

5. Conclusions

- This paper presents a study on fault detection for improving the reliability of automated vehicles or mobile robots. Multiple experiments were performed in a public urban area (with course distance per set beingapproximately1.1[km]), where several pedestrians, bicycles, and other robots were also present. Firstly, we solved and updated a few patterns of data constellations under normal and unstable conditions for fault detection through real-world experiments. Next, on the basis of the data obtained during the unstable condition and through other experiments the methods for deciding the threshold value ofMahalanobis distance were developed. In addition, the method of constructing the patterns of fault data and detecting faults by comparing each pattern with the relative values calculated using the correlation coefficient and linear approximate equation was proposed. Simulations wereperformed in order to evaluate the validity of the proposed algorithm, and the simulation results show that the proposed algorithm detects unstable conditions and almost correctly classifies the faults. Thus, the validity of the proposed algorithmwas proved using real-world experimental data.In our future work,we intend to consider other fault patterns by collecting additional fault data sets through numerous experiments under real-world conditions using automated updating algorithm to construct the fault pattern sets for classifying faults.

NOMENCLATURES

- Ve: velocity estimated by measuring the difference between the current and the former values of the wheel encoder countVm: velocityestimated usinga map-matching algorithmDv :integral of velocity differencesmDv :Mahalanobis distance of DvTh_Dmv,: threshold ofmDvRe :yaw angle estimated by the differences between the values obtained from the right and left wheel encoderRg :yaw angle estimated bygyro sensorRm :yaw angle estimated bythe map-matching algorithmEgm:integrals of yaw angle difference(encoder)Eeg:integrals of yaw angle difference (gyro sensor)Eem :integrals of yaw angle difference (map-matching)mEgm :Mahalanobis distanceof EgmmEeg:Mahalanobis distanceof EegmEem:Mahalanobis distanceofEemTh_mE: threshold ofmEgm, mEegandmEemN :number of data setsLm:likelihood value for map-matchingTh_Lm: threshold of the likelihood value for map-matchingCl:distance value between the gradient value obtained from the linear approximate equation of the fault pattern setCc:correlationcoefficient between this equation and the current data setCv:expression forcalculating the relative valueX={Xi|i=1,2,..5}: pattern data sets stored in the algorithm (distance-series data)Y={Yi|i=1,2,..5}: current data set (distance-series data)V(X): standard deviation of XE(X): average of X

ACKNOWLEDGEMENTS

- This study was supported by the Excellent Young Researcher Overseas Visit Program of the Japan Society of the Promotion of Science (JSPS), NSF under Cyber Physical Systems (CPS) Program (ECCS-0931669), and Energy ITS Program of NEDO.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-Text HTML

Full-Text HTML