-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Journal of Laboratory Chemical Education

p-ISSN: 2331-7450 e-ISSN: 2331-7469

2022; 10(3): 45-53

doi:10.5923/j.jlce.20221003.01

Received: Jul. 1, 2022; Accepted: Jul. 20, 2022; Published: Sep. 5, 2022

Laboratory Chemical Safety Assessment and Compliance in Nigeria Tertiary Institutions

Oladotun B. Isola, Mary T. Akintelu, Oseghale C. Inetianbor

Chemical Sciences Department, College of Basic and Applied Sciences, Samuel Adegboyega University, Ogwa, Edo State, Nigeria

Correspondence to: Oladotun B. Isola, Chemical Sciences Department, College of Basic and Applied Sciences, Samuel Adegboyega University, Ogwa, Edo State, Nigeria.

| Email: |  |

Copyright © 2022 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

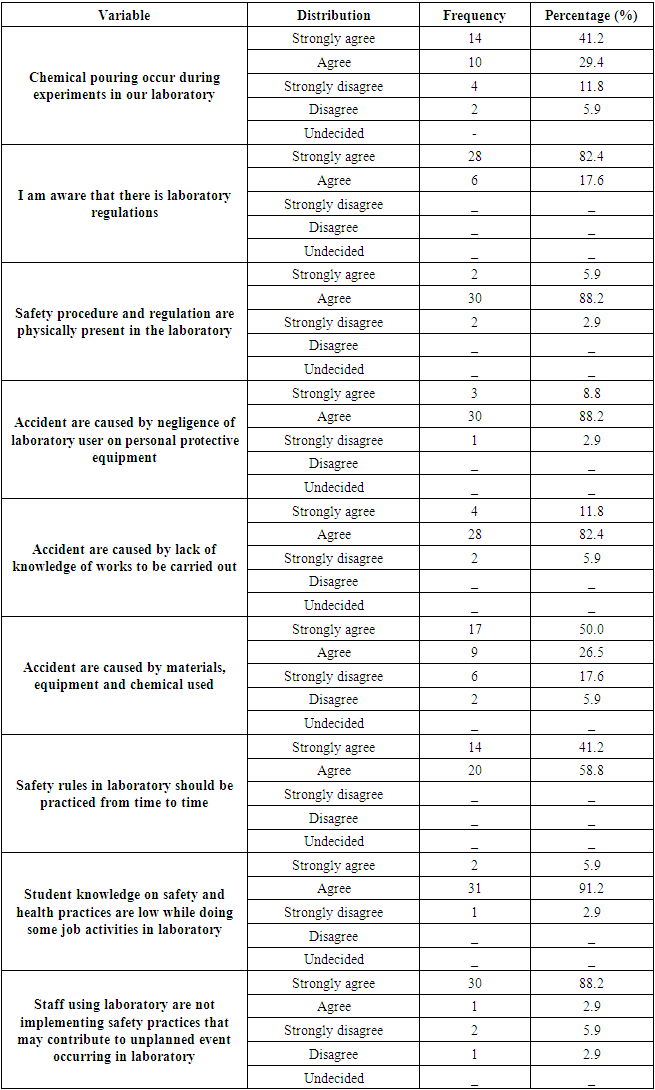

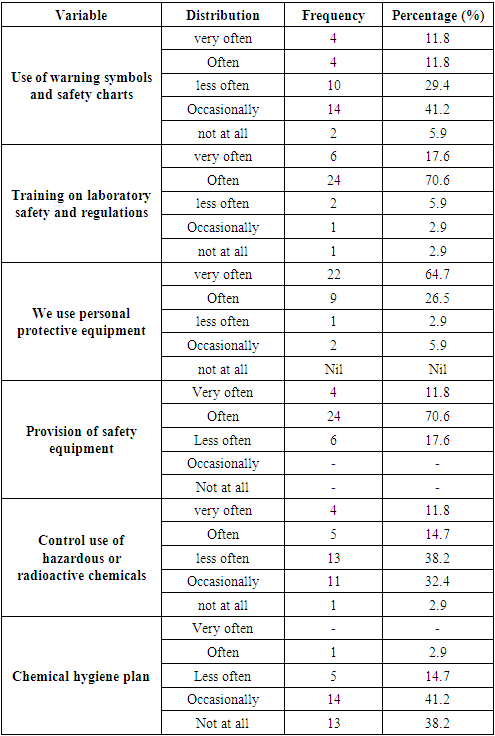

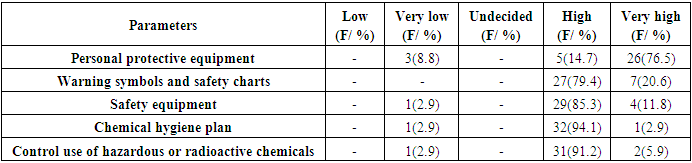

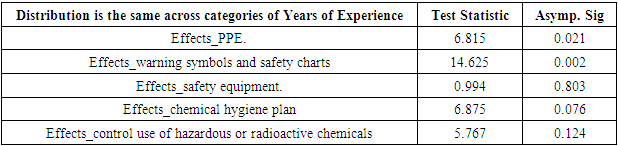

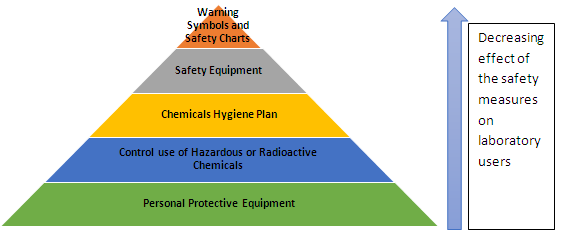

The enormous burden of work related injuries has created a global concern and major risk factors may be traced to exposure to chemical, biological, mechanical and electrical hazards among others. Laboratory chemical safety control is critical and important to the avoidance of hazards and therefore this study identify the level of awareness and compliance on chemical safety by laboratory users, the effectiveness of safety procedures and the effects it has on the laboratory users were also examined. Primary data source were employed for the study through the use of questionnaire administered to 34 laboratory technologists in four tertiary institutions in Edo state which include University of Benin, Ambrose Ali University, Samuel Adegboyega University and College Education Igueben. Data collected were analyzed using descriptive and inferential statistical techniques through special package for social sciences, SPSS (version 20). The result revealed that the use of Warning symbols and safety charts, control use of hazardous and radioactive chemicals, and chemical hygiene plans were effective in reducing the incidence of accident in the laboratory but compliance by laboratory users have been very low. Also, the result of Kruskal-Wallis test shows that the effects of PPE (F= 6.815; p<0.05) and warning symbols and safety charts (F= 14.625; p<0.05) are statistically significant and effective in reducing hazards in the laboratory. In conclusion, safety practices among laboratory users need to be improved and focus should be on establishing safety standards of operation for laboratories in educational institutions with continuous inspection to ensure compliance by relevance regulatory agencies.

Keywords: Chemical safety, Assessment, Compliance, Tertiary institutions

Cite this paper: Oladotun B. Isola, Mary T. Akintelu, Oseghale C. Inetianbor, Laboratory Chemical Safety Assessment and Compliance in Nigeria Tertiary Institutions, Journal of Laboratory Chemical Education, Vol. 10 No. 3, 2022, pp. 45-53. doi: 10.5923/j.jlce.20221003.01.

Article Outline

1. Introduction

- Laboratory chemical safeties are guidelines or procedures put in place to ensure safe handling, storage, transportation and disposal of chemicals in the laboratory. This is important in educational institutions, research institutes and industries where chemicals are in constant use because the procedures guide students and other laboratory users on safe handling of chemicals in the laboratory in order to prevent chemical hazards and accident in the laboratory. Chemicals are substances used to synthesize or manufacture chemical products in the industry and are also used for experiment by scientists in the educational sector. Current standards on hazard evaluations, risk assessments, and hazard mitigation are only applicable in the industrial settings without been replicated in the academic research laboratory environment because there is no comprehensive guidance on managing the hazards unique to laboratory chemical research in the academic environment (American Chemical Society, 2015). Safety issues should not only be peculiar to the industries but also in educational institutions such as University laboratories where chemicals and reagents are in constant use (Nurul et al, 2017). Chemical laboratories possess a greater number of unique hazards than most other general worksites and as a result present some of the greatest challenges in the prevention of injury and illness. Thus, laboratory users in educational institutions should be mandated to include hazard identification, assessment, and management in their operations, and ensure a safe working environment for themselves and other laboratory users.Hazard associated with the use of chemical can be categorized in three ways which includes hazard in chemical dispensation and use, hazard in chemical storage and transportation, hazard in disposal and environmental pollution. Chemical hazards occurs during the process of carrying out activities or scientific investigations in the laboratory, some of these activities involves chemical pouring, reagents and solution preparations, chemical labeling, chemical boiling and heating, chemical pipetting, chemical storage, transportation and disposal. The actions of preparing and pouring acids in the laboratory or other dangerous substances may result in toxic and corrosive injuries on workers from chemical spillages and spurting hazards. Hazards of mistaken identity occur when chemical bottles are not properly labeled which perhaps are often destroyed by the action of corrosive fumes and pests. The injection of chemicals through chemical pipetting could result in poisoning, irritation and in severe cases may lead to death. Boiling and heating operations is often accompanied by spilling and splashing of dangerous chemicals which has the tendency to cause hazards not only to the person carrying out the operation but also to the surroundings. Sometimes storing incompatible chemicals together has the potential of causing serious explosion due to peculiar nature of some chemicals. Exposure to sunlight, water and heat can gingered explosive reactions or create an atmosphere for chemicals to reacts. Fumes of chemicals in storage may corrode the metal parts of equipment that is kept within the vicinity of a chemical storage. The corrosive action may cause stiffness of moving parts in such equipment. This action may eventually damage the equipment and make it a hazard to a prospective user. Some of this equipment includes ovens, centrifuges, balances, homogenizers, and microscopes. Any chemical can be toxic or harmful under certain conditions (Aluko, 2007). There are generally four type of toxic entities; chemical, biological, physical and radiation: chemical toxicants include inorganic substances such as lead, mercury, hydrochloric acid, and chlorine gas, and organic compounds such as methyl alcohol, most medications, and poisons from living things (Aluko, 2007).In recent times, new educational policies in Nigeria have favoured the creation of more private and public tertiary institutions which will definitely increase demands for chemicals and reagents used in the laboratory for science and science related programs. Students, staff and all users working in chemical laboratories must be properly exposed to safety regulations associated with the use of chemicals. Therefore, to prevent and reduce the risk of accidents, awareness of the importance of safety practices need to be improved. Universities in Africa are in need of chemical safety and security facilities, professionals and resource materials as they engaged themselves in more advanced chemistry research (Temechegn Engida, 2011).The National Research Council argued that “The culture of laboratory safety depends ultimately on the working habits of individual chemists and their sense of teamwork for protection of themselves, their neighbors, the wider community and environment, and that Safety in the laboratory also depends on well-developed administrative structures and supports that extend beyond the laboratory’s walls within the institution” (National Research Council, 2005). Accidents are caused by negligence, lack of knowledge of works to be carried out as well as damage or failure either on materials, equipment and chemical used (Jamaludin, 2001). In addition, laboratory design flaws have been identified to have the potentials of increasing accidental injuries (James et al, 2014). Safety rules in laboratory should be practiced from time to time and staff should be responsible for preventing the occurrence of accidents (Sohin, 2002). Nurul et al, (2017) studied safety and health practice among laboratory staff in Malaysian education sector and their study established that, understanding of safety and health practice are low while doing some research activities in the laboratory. Their study concluded that some of the staff also did not implement safety practices that may contribute to unplanned event of accident occurring in laboratory. Students working in a chemical laboratory are more vulnerable to chemical hazards due to inexperience and negligence. Even the very experienced laboratory individuals who fail to follow safety precautions to understand potential hazard of each and every chemical may be at risk. Study on 42 construction contractors in Nigeria also found out that accident record in 2006 confirmed 5 injuries per worker and 2 accidents per 100 workers (Idoro, 2011). Although, Okolie and Okoye (2012) argued that there were no reliable accident data in Nigeria, because Occupational Safety and Health (OSH) regulatory system in the country does not report occupational accidents required as OSH regulations. This may be the reason why many universities in Nigeria are not reporting accident due to work related injuries in the laboratories. In addition, Temechegn (2011) in his research on chemical safety in laboratories of African Universities deduced from the students response on the types of laboratory hazards and how they could be controlled that: students were not using protective gloves, students were handling the occurrence of hazard with little or no professional background, and it seems that there is little or no records of accidents in the laboratory for future reference. Eguna et al., (2011) pointed out that protection management is often a belated idea in the academic laboratories of developing countries, leading to unsafe and inadequate conditions for the disposal of expired chemicals. In Ethiopia, there were 16 cases of accidents in school involving mercury spill in laboratories from 2016 to 2017 (Nurul et al, 2017). In the United States alone, Sigmann documented 164 injuries in 32 incidents (primarily in K−12 classrooms) as a result of the unsafe use of flammable liquids, inadequate safety precautions, and lack of safety training in chemical hazards among science teachers. In 1996, chemistry laboratory was engulfed in fire in the University of Texas as a result of improper disposal of sodium metal according to news report. Also, In January 2010, a chemistry graduate student at Texas Tech University was seriously injured in an explosion. The Chemical Safety Board of the University that investigated the incident while writing its report noted several factors contributed to the incident, including lack of comprehensive guidance on managing the hazards unique to laboratory chemical research in the academic environment. It revealed that current standards on hazard evaluations, risk assessments, and hazard mitigation are geared toward industrial settings and are not transferrable to the academic research laboratory environment.In 2001, there was a report of a flash fire that burned seven students of Genoa-Kingston High School in a chemistry class when an experiment went awry leaving one of the students in critical condition. Three students carrying out waste experiment in the laboratory were killed in an explosion at Beijing Jiaotong University in china as reported by the capital’s fire services (South China Morning Post, 2018). Occupational accident is an occurrence arising in the course of work, which results in fatal injury. Over 7 600 people die each day from work-related accidents resulting to over 2.78 million every year. The burden of occupational injuries is significant, both for employers and the wider economy, resulting in losses from early retirements, staff absence and rising insurance premiums (International Labour Organization ILO, 2013). According to an estimate by the ILO in 2013, 2.34 million deaths were recorded as a result of work activities. The Institute of Occupational Safety and Health, IOSH, estimated that there are 660 000 deaths a year as a result of cancers arising from work activities (Occupational Health and Safety, 2018). This study therefore examined the spate of chemical hazards among laboratory professionals and scientist. The study also identified chemical hazards occurrences among laboratory users, and the effects of safety measures put in place in the laboratory.

2. Methodology

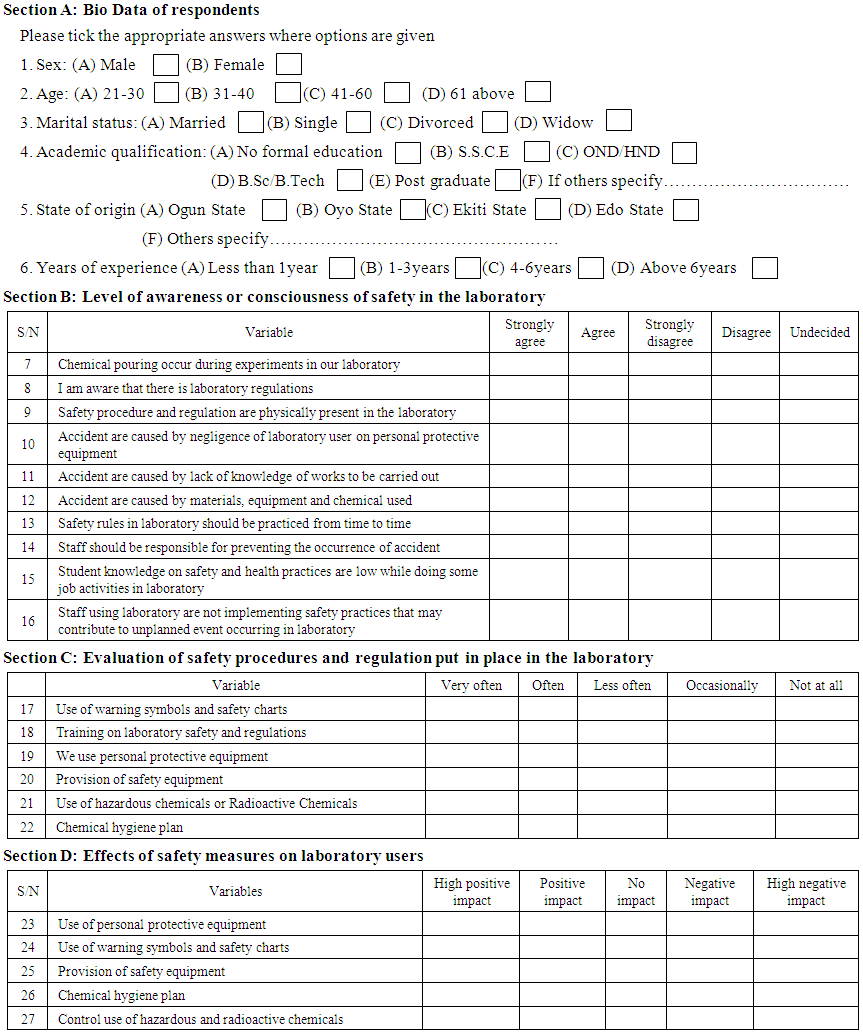

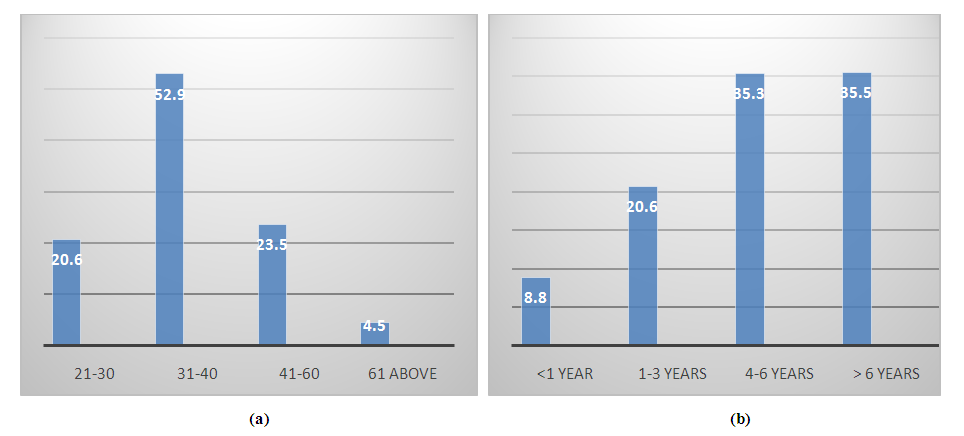

- Survey research design was used for this study. Nwodu (2006) opined that survey research is a research method that focuses on a representative sample derived from the entire population of study. The study population from which the sample was drawn for the study consists of laboratory staffs, technologist, students and lecturers in the selected tertiary institution in Edo state. This research work was carried out in four different higher institutions of learning, which includes University of Benin, Ambrose Ali University, Samuel Adegboyega University and College of Education Igueben.Data were collected through a well-structured questionnaire. Survey research method was used for the study through distribution of copies of questionnaire to collect necessary information from respondents Thirty four (34) questionnaire was developed and used as research instrument for the study, the questionnaire contained four inter- related sections, section A elicited information on the bio-data of the respondents, section B elicited information on the level of awareness on safety consciousness among laboratory technologists, section C provided information on the effectiveness of safety procedures and regulations in the laboratory, while section D elicited on the impact of safety procedure and regulations on laboratory users.The data was analyzed using descriptive statistical analysis through statistical package for social sciences (SPSS, version 20).

3. Result and Discussion

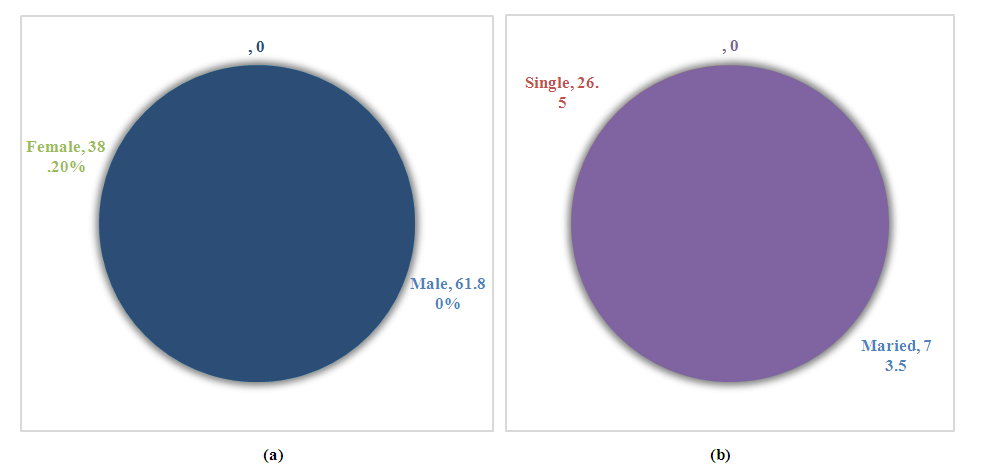

- Fig. 1 & 2 are pie and bar charts result of demographic characteristics among laboratory users in Edo State Tertiary Institutions. The result shows that majority of the laboratory users were male (61.8%) against the female (38.2%) counterparts. The result also revealed that the age of the respondents ranges from 21-30(20.6%), 31-40(52.9%), 41-60(23.5%) and 61 above (2.9%). From the result it was observed that majority of the respondent were in their middle age. The result further shows that 73.5% of the laboratory users in Edo state tertiary institution are married and 26.5% are single which means that majority of the respondents are highly responsible, dependable and this underscores the importance of having people who are emotionally stable to work in a complex science laboratory environment. Finally, the results shows that most (47.1%, 35.5%) of the laboratory users acquired post graduate degree and have the minimum of 6 years work experience respectively.

| Figure 1. (a) Percentage of respondent gender (b) Percentage of respondent marital status |

| Figure 2. (a) Percentage of the respondent age (b) Percentage of respondent work experience |

|

|

|

| Figure 3. Showing hierarchy of effects of safety measures on laboratory users |

|

4. Conclusions

- This study examined the effectiveness of safety procedures and its effects on laboratory users. Results shows that safety practices among laboratory users need to be improved and focus should be on establishing safety standards of operation for laboratories in educational institutions with continuous inspection to ensure compliance by relevant regulatory agencies.

5. Recommendations

- Based on the findings and conclusion, the following recommendations are put forward for consideration by technologists and all laboratory users.1. Technologists in collaboration with the environment health and safety officers should always train all laboratory users on causes and effects of chemical laboratory hazards and how it can be controlled.2. Laboratory staff should ensure the compliance to laboratory rules and regulations. 3. There should be safety regulations and standards for operating a science laboratory in academic institutions.4. Regular safety inspections and control should be put in place in every institution or by relevant regulatory agencies.5. Every laboratory should have a chemical hygiene plan.6. Updated records of experience on laboratory accidents should be kept by laboratory staff.7. Students taking science practical should be given safety test as part of their laboratory course requirement to reinforce knowledge of safety on semester basis.8. Use of personal protective equipment (PPE) should be enforced from time to time on all laboratory users by laboratory managements.9. Technologists, scientist and other institutions concerned like the Nigeria Institute of Science Laboratory Technologists should create awareness and assess the level of compliance to safety procedure and regulation by laboratory users.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML