-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Journal of Laboratory Chemical Education

p-ISSN: 2331-7450 e-ISSN: 2331-7469

2021; 9(3): 37-40

doi:10.5923/j.jlce.20210903.01

Received: Sep. 13, 2021; Accepted: Sep. 30, 2021; Published: Oct. 15, 2021

A 3D-Printed Higher-Throughput NMR Tube Cleaner

Dana A. Wong , Sibo Lin

Aramco Services Company: Aramco Research Center – Boston, Advanced Materials Team, Cambridge, MA, USA

Correspondence to: Sibo Lin , Aramco Services Company: Aramco Research Center – Boston, Advanced Materials Team, Cambridge, MA, USA.

| Email: |  |

Copyright © 2021 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Nuclear magnetic resonance (NMR) tubes can be cleaned with the proposed device, which can clean five tubes at the same time. It is comprised of a 3D-printed base, polypropylene straws, and a standard vacuum filtration flask assembly. The device is durable, easy to construct and operate, and resistant to common NMR solvents. In our experience, the cleaner saves time and solvent with no drop-off in cleaning efficiency compared to other models. The materials cost of this device is tabulated to be lower than commercially available NMR tube cleaners. The stereolithography and Solidworks files for this device are shared to allow for customization, for cleaning tubes of other dimensions.

Keywords: Undergraduate Research, Graduate Research, Laboratory Instruction, NMR Spectroscopy, 3D printing

Cite this paper: Dana A. Wong , Sibo Lin , A 3D-Printed Higher-Throughput NMR Tube Cleaner, Journal of Laboratory Chemical Education, Vol. 9 No. 3, 2021, pp. 37-40. doi: 10.5923/j.jlce.20210903.01.

Article Outline

1. Introduction

- Nuclear magnetic resonance (NMR) spectrometers equipped with automated sample loaders and data acquisition allow analysis of hundreds of samples per day. Yet cleaning NMR sample tubes remains a laborious process. Custom glassware designed for cleaning NMR tubes is often expensive and fragile. Cleaning methods based on vacuum chamber degassing [1-4], while high-throughput, are operationally tedious for cleaning smaller numbers of NMR tubes, and in our experience have resulted in chipped and incompletely cleaned NMR tubes. Various methods using modified rubber stoppers on top of vacuum filtration flasks have been reported in this journal, such as those by Denton [5], Karimian [6], Landrie [7], and Butler [8], but they all only clean one tube at a time. And as a result of their subtractive manufacturing, such devices cannot easily be modified to simultaneously clean multiple NMR tubes in the same footprint. The development of 3D printers and cost-effective polymer filaments empowers STEM students and researchers to fabricate custom tools to enable or facilitate their research. Herein we report an NMR tube cleaner, easily constructed via additive manufacturing (3D printing), that is economical, durable, and capable of cleaning multiple NMR tubes simultaneously.

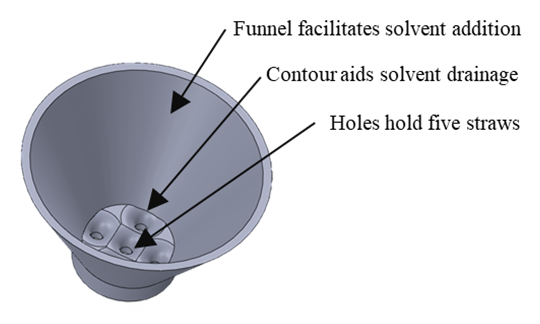

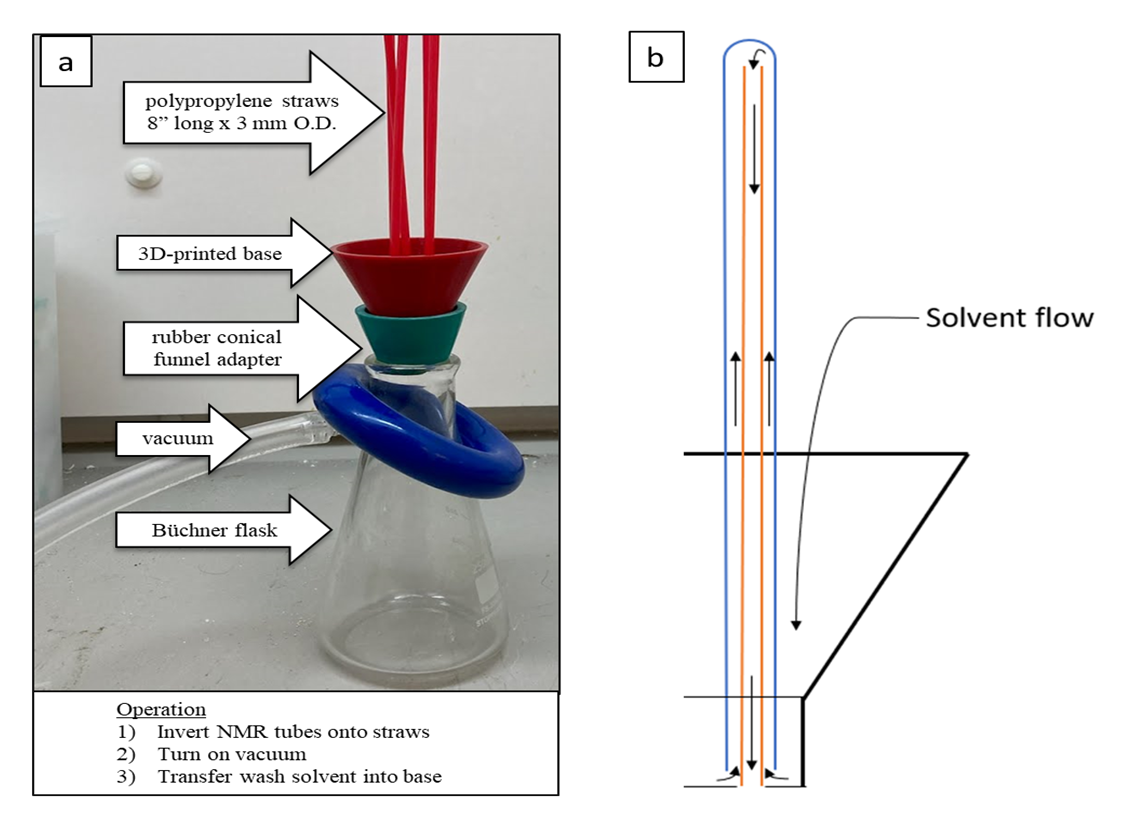

2. Construction

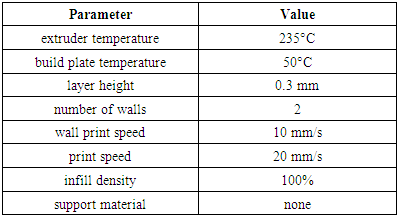

- The NMR tube cleaner consists of a 3D-printed base (Figure 1) and five straws. First, the base is constructed using a fused deposition modeling (FDM) 3D printer. The STL file [9] is downloaded, pre-processed (“sliced”) specifying no supports and 100% infill, and printed using a solvent-resistant filament. In our case, we used polypropylene (PP) filament (Amazon #B07GVV7N79) with the default print parameters from Cura version 3.6.8 with LulzBot TAZ 6 Aerostruder firmware (Table 1). Prior to printing, a layer of PP packing tape was applied to the print bed to improve adhesion between the bed and the first print layer. The printing process finished in ~3 h. Finally, five PP straws with 3 mm outer diameter and 8” length (i.e. long coffee stirrer straws, Amazon #B00ATJOMNI) are inserted into the 3D-printed base.

| Figure 1. Diagram of 3D-printed base and its design features |

|

3. Operation

- This NMR tube cleaner is operated by placing on top of a Büchner flask equipped with a rubber conical Büchner funnel adapter and attached to a vacuum source (Figure 2a). The NMR tubes are inverted, threaded onto the straws, and allowed to rest touching the 3D-printed base. If necessary, the straws should be pushed through the base so that the top of the straw does not form a seal against the closed end of the NMR tube. A wash solvent (typically acetone) is transferred into the base using a squirt bottle, where vacuum pulls the solvent up the insides of the NMR tubes, down the straws, and into the filtration flask (Figure 2b). In typical operation, a complimentary solvent (such as water) is then transferred into the base. Three or more alternating cycles of these solvents can be rapidly applied in this manner to ensure effective cleaning. If necessary, a third solvent wash (e.g. dichloromethane) can be employed to dissolve materials insoluble in the first two solvents. Excess solvent can be removed in-place by allowing vacuum to pull air through the inverted NMR tubes. The NMR tubes are then placed upside-down in a clean container overnight in a ventilated fume hood to allow residual solvent to drip out or evaporate. We have used this device to efficiently clean hundreds of NMR tubes. The working principle of this cleaner is conceptually similar to that of Butler [8] and Chemglass item #CG-1854-02, but with several nuanced advantages as discussed below.

| Figure 2. (a) Assembled NMR tube cleaner and operation instructions and (b) rinse solvent flow diagram |

4. Discussion

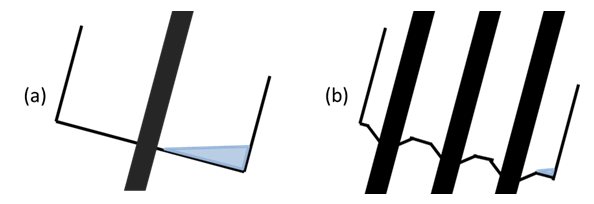

- Higher throughput. This NMR tube cleaner operates ~5x faster than single-tube models. The market presence of several commercially available 5-tube cleaners suggest that this is a conveniently sized cleaner for a typical chemistry lab. If yet higher-throughput is desired, the 3D-modelled base can be digitally modified (vide infra). While batch cleaning methods based on vacuum chamber degassing have been reported to clean hundreds of tubes per cycle, they are operationally inconvenient for cleaning fewer tubes and may not result in perfectly clean tubes. [4] We have also found that these vacuum chamber batch cleaners do not operate well with common organic rinse solvents such as acetone, dichloromethane, and hexanes. In typical operation, the chamber containing rinse solvent and inverted NMR tubes is evacuated and then refilled with atmospheric pressure. Each inverted NMR tube acts as a barometer and can only be completely filled with rinse solvent if the barometric pressure difference is sufficiently large. While this is possible with water and other solvents with low vapor pressure, volatile solvents are not able to fill the entire interior of the NMR tubes. In contrast, our device has been used with all common laboratory rinse solvents with no issue.Safe and durable. The polypropylene parts do not pose any sharps hazards and will not damage NMR tubes. Other NMR tube cleaners constructed of glass or metal parts must be handled with care to avoid personal injury or scratching of NMR tubes. Additionally, the polypropylene parts are durable and can be stored in a typical laboratory drawer without getting damaged, while devices with glass components are fragile and may need a dedicated drawer for storage. We explored using other common FDM 3D printing filaments such as polylactic acid (PLA), acrylonitrile butadiene styrene (ABS), and thermoplastic polyurethane (TPU), but found that the 3D-printed base exhibited delamination after exposure to organic solvents such as acetone and dichloromethane.Low cost. FDM 3D printers are becoming increasingly affordable and common in college campuses, research labs, online manufacturing services, and public libraries. The vacuum filtration parts are commonly available in chemistry labs. The total cost of a 500g spool of polypropylene filament and a box of 500 straws is $48 from Amazon. The prorated cost of the polypropylene filament and straws is only $1.42. This is comparable with Butler’s single-tube model ($32), and much cheaper than 5-tube models available commercially from Chemglass (#CG-1854-02: $145; or #CG-1852-02: $473) and Sigma-Aldrich (#Z513466-1EA: $562).Facilitated solvent addition. The solvent reservoir walls are flared outward to form a funnel, which facilitates pouring or squirting of rinse solvent into the device. Similar devices constructed with straight solvent reservoir walls are slower to add solvent into. Low dead solvent space. NMR tube cleaners are often assembled as needed, with imperfect levelling of the device. Cleaners that utilize a flat-bottomed solvent reservoir will then have dead solvent space, as illustrated in Figure 3a. Dead solvent space necessitates the use of excess solvent, particularly when changing between rinse solvents. The contoured bottom of our 3D-printed base minimizes dead solvent space, as shown in Figure 3b. Each straw has its own miniature funnel around it to facilitate solvent drainage. The 3D-printed contoured bottom would be tedious to implement with subtractive construction methods.

| Figure 3. Cross-sectional illustration of dead solvent space (blue) of tilted cleaners with (a) flat-bottom reservoir and (b) contoured-bottom reservoir |

5. Conclusions

- Herein we have described a higher-throughput NMR tube cleaner constructed with 3D printing. We have compared it with previously published and commercially available models, and listed numerous beneficial features of our model, many of which would have been tedious to implement without 3D printing. In addition to the practical utility of this device for cleaning NMR samples, this easy-to-construct device is intended to illustrate the accessibility and utility of 3D printing for chemical researchers.

ACKNOWLEDGEMENTS

- We wish to acknowledge Prof. Madalyn R. Radlauer and Prof. Emily Y. Tsui for testing out prototypes of this device.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML