Jesús M. Anzano1, Aida González-del-Rosal1, Raquel Echeverría1, Abrahan I. Velásquez2, Roberto J. Lasheras1

1Laser Laboratory, Chemistry and Environment Group, Department of Analytical Chemistry, University of Zaragoza, Faculty of Science, Zaragoza, Spain

2Faculty of Agricultural Sciences, University Laic Eloy Alfaro of Manabí, Manta, Ecuador

Correspondence to: Jesús M. Anzano, Laser Laboratory, Chemistry and Environment Group, Department of Analytical Chemistry, University of Zaragoza, Faculty of Science, Zaragoza, Spain.

| Email: |  |

Copyright © 2021 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Abstract

The present study deals with the chemical-analytical characterization of plastics, specifically analytical determination of phthalates in polyvinyl chloride (PVC) and the quantification of residual styrene (S) monomer in plastic polystyrene (PS); both polymers are commonly used in food packaging. In determining phthalates, the method’s principle used, is the precipitation of the PVC polymer followed by hydrolysis of the plasticizers and the leaching of the alcohol obtained in an organic phase. To study the efficiency of the reaction, dioctyl phthalate (DOP) has been used as a standard. In determining S, the method used, is based on the total sample-plastic dissolution followed by the precipitation of the PS leaving behind the monomer. It does not include dilution methods. In both tests, the quantitative determination is made by gas chromatography (GC).

Keywords:

Gas chromatography, Phthalates, Plastics, Polymer, Polystyrene, Polyvinyl chloride, Styrene

Cite this paper: Jesús M. Anzano, Aida González-del-Rosal, Raquel Echeverría, Abrahan I. Velásquez, Roberto J. Lasheras, Chemistry Practices for Undergraduate Students: Plastic Polymers Characterization by Gas Chromatography, Journal of Laboratory Chemical Education, Vol. 9 No. 2, 2021, pp. 21-25. doi: 10.5923/j.jlce.20210902.01.

1. Introduction

Analytical Chemistry is the science of finding, processing, and communicating information regarding the composition and structure of matter. It is the science of determining nearly all aspects of the matter that what it is and how much it exists. Analytical methodologies play an important role in industrial chemistry, as more and more the values and references that are required to control, to protect the environment and our health. Analytical Chemistry is responsible for providing the chemical information of a material system, which has posed a problem or question. In almost all industries of transformation is the necessary routine analysis of the starting products, and the product obtained, either by quality controls or as part of research and development. The production of plastics increased gradually during the depression years to 127 million pounds in 1935 that reached 600 million pounds in 1942 [1]. Polyvinyl chloride, commonly known as PVC, is a thermoplastic polymer. The related monomer, vinyl chloride, can be obtained from two natural raw materials, sodium chloride (57%) and natural gas (43%). Consequently, PVC is less dependent on nonrenewable resources in comparison to other plastics [2]. At present, PVC is one of the most versatile materials that we can find, because, with appropriate stabilizers and other additives, it can be used to produce utilitarian thermoplastics and composites [3]. At this point, various techniques for processing PVC, for instance, calendaring, extrusion molding, blow molding, compression or pressing molding, cast molding, rotational molding, and sintering are operative [4]. One of the most common additives for PVC are phthalates (plasticizers) that are used to incorporate flexibility, elongation, and elasticity to the product. Plasticizers are low volatility solvents usually esters. Though the addition of plasticizers imparts excellence to PVC, it offers resistance to recycling and results in inferior reprocessed products for which demand is less, for that reason, recycling is not advised [5]. Consequently, excessive waste is carried to landfills or incinerators. The PVC industry itself has recognized that current recycling efforts are not profitable, because the resins and recycled products are often more expensive than virgin plastic and emit toxic compounds [5]. Phthalates are substances that are physically dispersed in the polymer without changing the molecular structure and modify its properties, simply aid processing, and decrease the final cost. The most common phthalates are di-2-ethyl hexyl phthalate, di-octyl phthalate, and di-isononyl phthalate, used as general plasticizers.These additives, many of them are recognized toxins, covert PVC to a commercial product, now account for more than 60% by weight of the final product [6]. At present, the use of plasticizers has generated some controversy as phthalates cause severe damage to the environment because they are one of the most abundant and widespread synthetic pollutants. Phthalates are relatively persistent in soil and sediment [7]. They enter the body through food, air, skin contact, and blood transfusions and have an affinity for fat dissolving tissues and are bioaccumulative.Another widely used plastic is polystyrene (PS), a thermoplastic polymer, which is obtained by the polymerization of styrene (S). The first industrial production of PS glass was carried out in 1930 by the BASF Chemical Company, Germany. Since then the production process has improved substantially, which resulted in a well-established polystyrene industry. With a demand of about 13 million tons per annum, PS is now the fourth most consumed plastic, following polyethylene (PE), polypropylene (PP), and PVC [8]. However, the S may damage health (disorder nervous system and damage liver and kidneys) and may harm the environment, as indicated by the United States Environmental Protection Agency and International Agency for Research on Cancer [9]. The standard procedures for analysis of the components in plastic materials are not effective when deal with analyzing volatile compounds, due to losses and interference when using procedures such as material extraction and subsequent analysis [10]. Sometimes, the analysis of styrene cause problems, and a possible solution would be to use the head-space technique [11]. This technique is widespread because of the speed, versatility, and established automation. Despite having been annulled, we use as a reference the norm UNE 53304-7 (1976) established by the Spanish Association for Standardization and Certification used for the analysis of S. It is especially applied in packaging and plastics made from PS and copolymers that contact food.

2. Experimental

2.1. Reagents and Samples

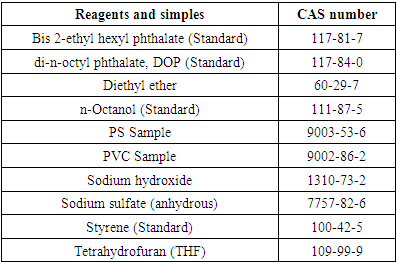

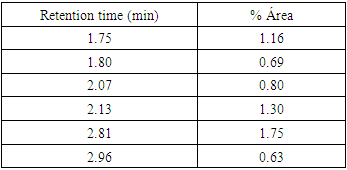

The reagents used were tetrahydrofuran (THF), di-n-octyl phthalate (DOP), NaOH (2 mol/l), diethyl ether, Na2SO4, 2-ethyl hexanol, n-octanol, and styrene (S). The PVC sample was a common cable coating, and the PS sample came from commercial polystyrene packaging. All reagents used were of analytical grade (Panreac). Detailed characteristics of samples and reagents can be reviewed using the CAS number provided in Table 1.Table 1. Detailed of reagents and samples

|

| |

|

2.2. Instrumentation

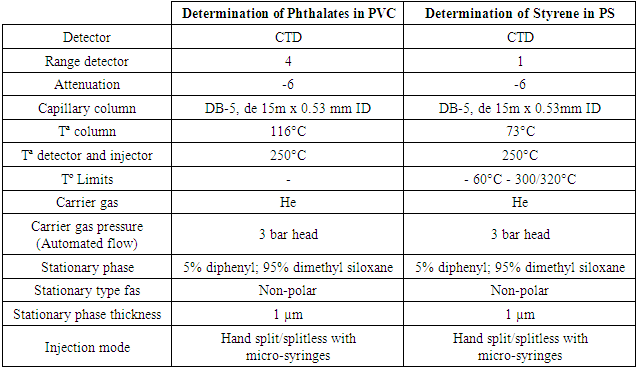

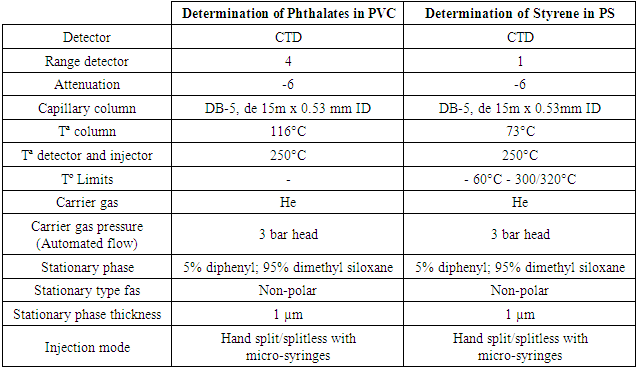

A Perkin Elmer Gas Chromatography (GC) device was used for which instrumental parameters are specified in Table 2.Table 2. Instrumental parameters of GC

|

| |

|

2.3. Determination of Phthalates in PVC

Sample preparationWire coating was weighed precisely and was cut into small pieces. Then, it was treated with 15 ml tetrahydrofuran with stirring on magnetic core and heated at a temperature of 100°C to avoid lumps and promote dissolution. Subsequently, it was slowly dissolved in methanol. After precipitation, the solution of methanol and phthalates was filtered by gravity and decanted using a funnel and a filter paper (40 mm mesh). Next, it was heated to its total evaporation with agitation (450 rpm) at 100°C. When 90% of methanol evaporated, it was transferred back to the flask by dragging the remains with a small amount of methanol. After some time, an oily residue, phthalates, was obtained on total evaporation of the solvent.Collection of free spiritsPhthalate was dissolved with 5 ml ethanol and 5 ml NaOH (2 molar solution) was mixed. Using a micropipette, 0.1 ml DOP was added to the reaction flask. DOP, acting as an internal standard, facilitated the study of the reaction that is to what extent it completed. A mounting reflux was prepared. The reaction flask was connected to the condenser and heated on a hotplate with stirring. Refluxing was continued for 2 h at 75°C and an agitation of 300 rpm. The assembly is shown in Figure 1. | Figure 1. Reflux assembly for the reaction of hydrolysis |

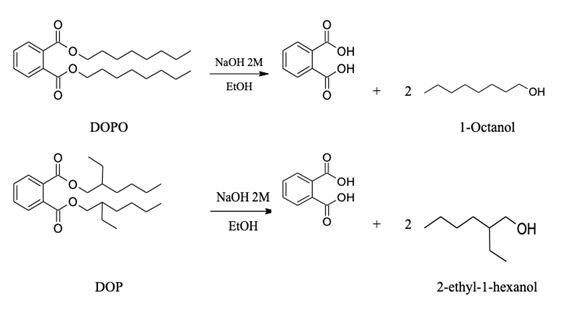

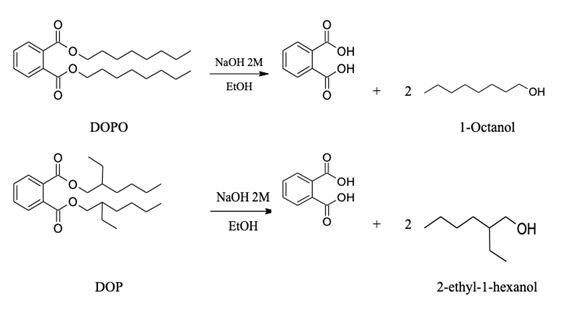

The product of the hydrolysis reaction was the corresponding alcohols of phthalates, 1-octanol and 2-ethyl-1-hexanol (Figure 2). | Figure 2. Hydrolysis reactions |

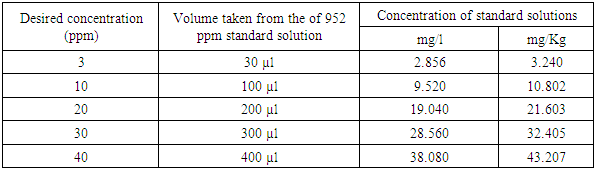

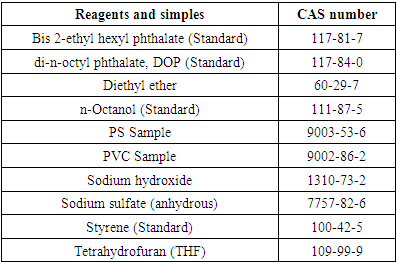

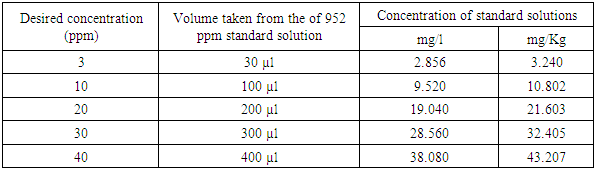

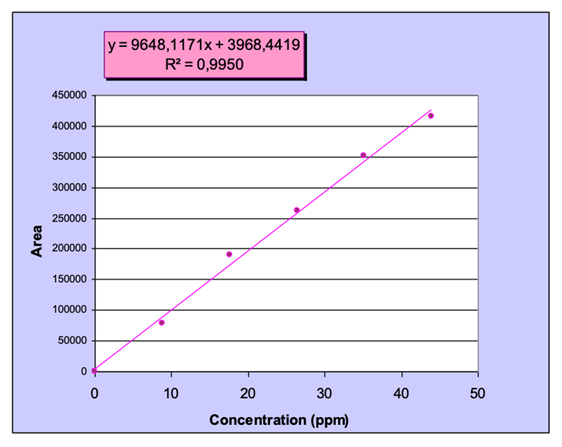

After hydrolysis, the flask is allowed to cool down to room temperature. The solution is transferred to a separating funnel and the organic phase is extracted with two fractions of 20 ml ether. Organic phase was collected that was above because of lesser density than water. The organic phase was orange and the aqueous phase was clear. The organic phase was passed over a desiccant bed Na2SO4 (anhydrous) to eliminate traces of the water present. Finally, the organic extracts were collected in a 50 ml volumetric flask and diluted to the mark with ether.Quantitative determination of phthalatesTo determine phthalates in the gas chromatograph, retention times of standard solutions (2-ethyl hexanol, n-octanol and ether) were compared with that of samples. Determination of styrene in polystyrenePreparation of standard solutions of styrene and the calibration curveAccurately weighed styrene was diluted with THF to a volume of 25 ml and was kept in the refrigerator. Then, appropriate volume of the pattern of styrene was added using micro-syringe and diluted with methanol. Concentration of styrene standard solution was 952 ppm (23.8 mg of styrene / 25 ml of solution). The solutions prepared to draw calibration curve were 3, 10, 20, 30 and 40 ppm. Values of the concentration are specified in Table 3 (mg/l and mg/kg) as obtained for these solutions with a final volume of 10 µl.Table 3. Concentrations of correction solutions for the determination of styrene in PS

|

| |

|

Sample preparationThe sample was chopped and weighed in a 400 ml beaker. Ten millilitres of THF were added and shaken to dissolve the material. On complete dissolution, 20 ml methanol was added. The precipitation of the polymer occurred, afterwards, the solution was left to rest. The supernatant was transferred quantitatively to a 25 ml volumetric flask, decanted and filtered using a glass rod, funnel and filter paper. After filtration, precipitates were washed with methanol and diluted to the volumetric mark.Quantitative determinationMeasurements were conducted in the gas chromatograph for the calibration curve and two fractions of the sample. The injection volume was one ml. If solutions were not clear at the time of injection, a fraction was filtered with Whatman syringe microfilter for 0.45 organic micrometers.

3. Results and Discussion

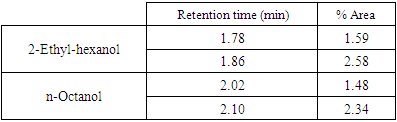

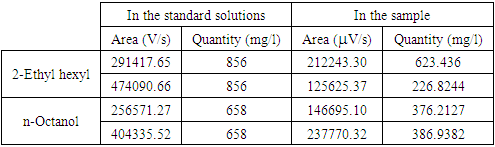

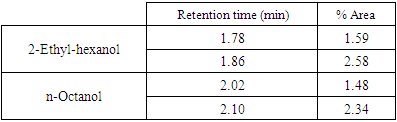

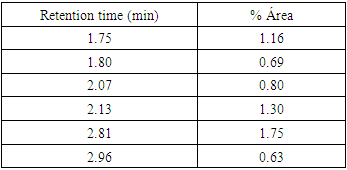

Determination of phthalates in PVC by gas chromatographyThe data obtained from the chromatograms is presented in Table 4.Table 4. Data obtained from the chromatograms in the determination of phthalates in PVC

|

| |

|

The retention time of n-octanol was higher than that of 2-ethyl hexanol, due to polar variability of both compounds. Experimental findings for the test are provided in Table 5. Table 5. Experimental results

|

| |

|

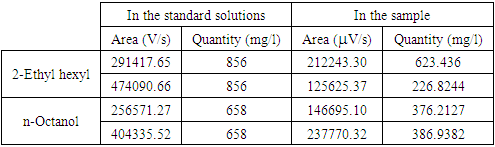

Alternatively, content of alcohol in the sample can be determined by comparing areas of standards and sample. In Table 6, the amount of alcohol (mg/l) for the standard solutions and the sample is provided, an average of 2-ethyl hexanol in the sample 425.1302 mg/l, and the average n-octanol in the sample was 381.5755 mg / L. Table 6. Quantity (mg/l) of alcohols obtained experimentally

|

| |

|

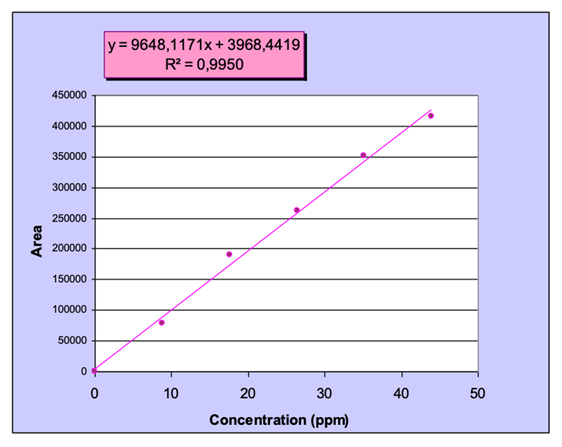

The initial amount of internal standard in sample, DOP, was 0.05 g, that may also be known as amount of n-octanol that should theoretically be obtained if performance would 100%. As the frame rate of the determination was 58%. With this performance, 2.8142 moles of 2-ethyl hexanol, and 1.4070 moles of PDO were obtained, therefore, 549.5570 mg of DOP and have 549,392.1584 mg per kg PVC.Determination of styrene in polystyrene by gas chromatographyThe calibration curve obtained by gas chromatography is shown in Figure 3.  | Figure 3. Calibration graph for styrene |

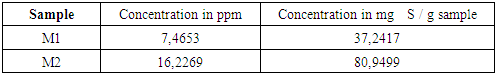

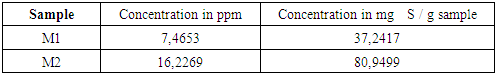

As is indicated in the data of existing legislations, the limit of quantification of styrene by GC is 3 ppm. Therefore, the detection limit as a guideline should be ten times lower, i.e. 0.3 ppm12 that were checked experimentally using MeOH as white precipitates (the column temperature was 73°C, the minimum temperature at which all compounds are volatile). Table 7 shows the concentrations obtained in mg S / g sample (ppm), the mean and standard deviation for the amount of styrene were calculated that was in the sample and the reproducibility of the method being the amount of styrene in the sample was 35.6984 mg S / g sample, 11.4806 ppm and the reproducibility of the method was 40.66%.Table 7. Concentrations obtained

|

| |

|

The standard procedures applied to the analysis of the components in plastic materials were ineffective when it comes to analyzing volatile compounds, due to losses and interference when using procedures such as removal of material and subsequent analysis. A possible solution to the problem of the analysis of styrene is the head-space technique. This technique involves establishing a balance between the gas phase and the sample (solid or liquid) of volatile components into the vial containing the sample. It is useful in the determination of volatile emissions when the sample is subjected to heating.

4. Conclusions

The use of THF, as an organic solvent, is suitable to make both the styrene standard solution and the calibration solutions, and to treat test samples. It is not a strong reagent and, therefore, it does not destroy organic matter, as H2SO4 would do. Some other similar solvents such as DMF can be used as well. The calibration is a good analytical tool because it allows to determine analyte with enough accuracy. Furthermore, in order to obtain the real mount of styrene, it is important that these errors must be small enough and have been determined as accurately as possible. The method for the phthalates determination by the addition of an internal standard, DOP, is adequate, since it has shown that the PVC sample contains diisooctil phthalate used as a plasticizer. Moreover, this seems logical because it is a cable and its use involves direct contact and continuous handling. And although phthalates are potentially toxic, bioaccumulative and probably carcinogenic compounds in humans, their concentration in everyday products does not involve a health risk. For the S determination, the amount of styrene that is in the test sample is very small and it is within the permitted limits, because the maximum stipulated by current legislation is 0.25% (g styrene per 100 g of sample).Safety and Hazards InformationSafety standards in teaching practices in laboratoriesThe working method will be adapted to the media and the facilities available in the laboratory and students will be encouraged to develop work habits that pose minimal risk and are respectable for the environment. Before using a chemical or biological products, one shall know their hazards (if any), which are usually indicated on the packaging or otherwise, appointed by the head teacher. Everyone is bound to act according to the type of substance and its hazard potential to avoid individual and collective risk. Practices will be held in the presence of a teacher, following a working protocol that specifically contemplates the risks. These protocols will be presented and discussed beforehand.Any accident of any level (even a minor issue) must be notified to the teacher, who shall act accordingly. The use of PPE (Personal Protective Equipment) is required when working in the laboratory (lab coat, gloves, goggles etc.) and necessary self-protection measures (masks, dispensers etc.) must be applied. One shall not eat, smoke or apply cosmetics products throughout the practical as well as during discussion sessions in the laboratory. Dispensers should be used always when pipetting any substance even if there is evidence of its safety (e.g. distilled water).Each instrument and apparatus shall always be accompanied by the minimum instructions for correct handling (to be discussed at the start of the internship). At the end of practical, products and materials should be arranged according to their storage and disposal protocols and the work area should be cleaned. The waste generated during the practices should be inactivated, neutralized, or deposited in special containers available in laboratories from which they can be managed as hazardous waste.

ACKNOWLEDGEMENTS

This work was supported by Spanish Government CTM2017-82929-R, the Department of Innovation, Research and University of the Aragon Regional Government and the European Social Found (group E49_20R), the University of Zaragoza and General Services Research Support -SAI of University of Zaragoza.

References

| [1] | Castka, J. F. Demonstrations on the preparation and molding of plastics. J. Chem. Educ. 1943, 20, 253. |

| [2] | Anastas, P.T.; Levy, I.J.; Parent, K.E. Green Chemistry Education: Changing the Course of Chemistry, ACS Symposium Series; American Chemical Society: Washington, DC, 2009. |

| [3] | Wilkes, C.E.; Summers, J.W.;, Daniels, C.A.; Berard, M.T. PVC Handbook; Hanser Verlag: Ohio, 2005. |

| [4] | Chanda, M.; Roy, S.K. Plastics Technology Handbook; Marcel Dekker: Newbury, Berkshire, 1998. |

| [5] | Mantia, F.P. Recycling of PVC and Mixed Plastic Waste; ChemTec Publishing: Ontario, 1996. |

| [6] | Titow, W.V. PVC Technology, 4th Ed; Elsevier Applied Science Publishers: North Ireland, 1984. |

| [7] | US-EPA, United States Environmental Protection Agency, Washington, DC, web reference: http://www.epa.gov (February, 20115). |

| [8] | BASF, The Chemical Company, Ludwigshafen, Germany, web reference: http://www.basf.com (February, 20115). |

| [9] | IARC, International Agency for Research on Cancer, Lyon, France, web reference: http://www.iarc.fr (February, 20115). |

| [10] | Amico, T.D.; Donahue, C.J.; Rais, E.A. Thermal Analysis of Plastics. .J. Chem. Educ. 2008, 85, 404-407. |

| [11] | Kolb, B.; Ettre, L.S. Static Headspace-Gas Chromatography: Theory and Practice, 2nd Ed; John Wiley and Sons: New Jersey, 2006. |

| [12] | Chan, W.H. Plasticizers in PVC: A combined IR and GC approach.. J. Chem. Educ. 1997, 64, 897. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML