-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Journal of Laboratory Chemical Education

2016; 4(2): 35-37

doi:10.5923/j.jlce.20160402.02

Fire and Explosion Hazards Expected in a Laboratory

Shireen R. Rasool1, Wedad H. Al-Dahhan2, Ali Jassim Al-Zuhairi3, Falah H. Hussein4, Kabrena E. Rodda5, Emad Yousif2

1Department of Chemistry, College of Science, Babylon University, Iraq

2Department of Chemistry, College of Science, Al-Nahrain University, Baghdad, Iraq

3College of Engineering - Al-Musayab, Babylon University, Babylon, Iraq

4College of Pharmacy, Babylon University, Iraq

5Pacific Northwest National Laboratory, Richland, Washington, USA

Correspondence to: Emad Yousif, Department of Chemistry, College of Science, Al-Nahrain University, Baghdad, Iraq.

| Email: |  |

Copyright © 2016 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Scientists at universities across Iraq are actively working to report actual incidents and accidents occurring in their laboratories, as well as structural improvements made to improve safety and security, to raise awareness and encourage openness, leading to widespread adoption of robust Chemical Safety and Security (CSS) practices. This manuscript is the fifth in a series of five case studies describing laboratory incidents, accidents, and laboratory improvements. In this study, we summarize unsafe practices involving the improper installation of a Gas Chromatograph (GC) at an Iraqi university which, if not corrected, could have resulted in a dangerous fire and explosion. We outline how the identified infractions were corrected and highlight lessons learned. By openly sharing the experiences at the university involved, we hope to minimize the possibility of another researcher being injured due to similarly unsafe practices in the future.

Keywords: Chemistry laboratory, Scientific practical skills, Fire and explosion hazards

Cite this paper: Shireen R. Rasool, Wedad H. Al-Dahhan, Ali Jassim Al-Zuhairi, Falah H. Hussein, Kabrena E. Rodda, Emad Yousif, Fire and Explosion Hazards Expected in a Laboratory, Journal of Laboratory Chemical Education, Vol. 4 No. 2, 2016, pp. 35-37. doi: 10.5923/j.jlce.20160402.02.

Article Outline

1. Introduction

- Scientists at universities across Iraq are actively working to report actual incidents and accidents occurring in their laboratories in order to encourage openness and encourage widespread adoption of robust Chemical Safety and Security (CSS) practices. In this manuscript, the fifth of a five case studies, we report safety hazards associated with the improper installation of a gas chromatograph in the postgraduate laboratory at Al-Nahrain University. After the university’s CSS committee was formed, representatives from the committee inspected the laboratory and observed a number of fire and explosion hazards. The CSS Committee’s findings and associated lessons learned are summarized in this manuscript in order to help other institutions minimize such safety hazards when installing new equipment in the future.

2. Incident Description

- Al-Nahrain University is one of the modern universities in Iraq, although the buildings used for the campus were not designed with labs and classrooms suitable for the university’s needs. As a result, renovation projects have been undertaken at the university since 2014 to meet university laboratory design specifications, including the specialized requirements associated with the department of chemistry building at the Faculty of Science. In addition to these facility renovations, the university had purchased a new Gas Chromatograph (GC) and installed it in the department’s postgraduate Laboratory without consulting the university’s CSS Committee (Figure 1). This laboratory is located within a large building containing many labs and classrooms, all of which likely would have been affected had a fire or explosion occurred.

| Figure 1. New GC with gas cylinders improperly installed, resulting in a number of safety hazards |

3. CSS Committee Findings

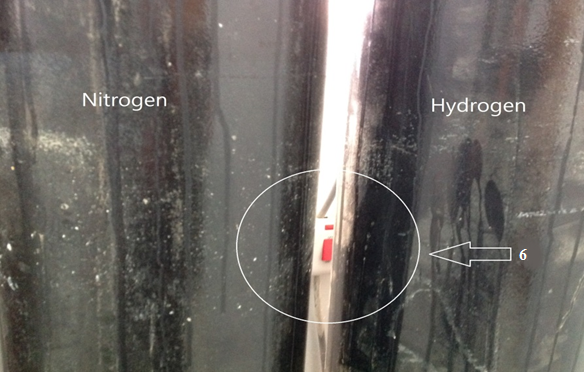

- On January 2015 the CSS Committee made a comprehensive evaluation of all laboratories of the Faculty of Science (after having a safety and security training courses set up by the CSP), including the postgraduate laboratory where the GC was installed. The inspection team discovered the following safety hazards, visible in Figures 1-4:• Cylinders are exposed to direct sunlight (Figure 1).• Cylinders are not secured in place (Figure 1).• There is insufficient space between the cylinders and they are not labelled (Figure 1).• Tubing between the gas outlet on the hydrogen gas cylinder and the GC was improperly installed, which may lead to a gas leak (Figure 2).• Fluorescent lights in the lab can spark (Figure 3). • Laboratory operating instructions were posted too high to be read. (Figure 3).• A local air conditioning (A/C) unit was present, which could spark. The main switch was between the hydrogen and nitrogen cylinders, making it hard to reach (Figure 4).

| Figure 2. Improperly installed tubing between the gas outlet and the GC, which could lead to hydrogen leaks |

| Figure 3. Fluorescent lighting installed in the laboratory and laboratory operating instructions posted too high to be able to be read |

| Figure 4. The main switch for the A/C was installed between the hydrogen and nitrogen cylinders |

4. Lessons Learned

- In addition to identifying a number of safety hazards present in this laboratory, this case study highlights concerns related to safe lab operations. While these concerns may not have ever contributed to a fire or explosion, they are nevertheless worth noting and learning from to improve lab safety at Al Nahrain universities and other institutions in the future. In particular, we note the following lessons learned from the improper GC installation described in this study: Ÿ A laboratory’s specialized needs, as well as relevant safety and security regulations must be taken into account before proceeding with a renovation or equipment installation project.Ÿ In planning the work to be done, the team performing the work must have a clear understanding of all relevant safety regulations, including fit and the function of the equipment and associated materials to be used in the laboratory, and should involve CSS committees whenever possible.Ÿ Teaching laboratories dealing with hazardous gases must be equipped in a manner that minimizes staff and students’ contact with such materials. Ÿ Gas cylinders should be affixed to the wall using a chain, clamp, or other device.Ÿ Tubing must be installed properly to minimize the possibility of leaks.Ÿ Electrical components such as lights should be rated as explosion proof.Ÿ Laboratories should be designed with central A/C instead of local units, which may spark.Ÿ Laboratories should use hydrogen gas generators instead of cylinders wherever possible.

5. Conclusions

- The safety hazards highlighted in this study could have led to severe damage to the facilities and possible loss of life. Through a systematic risk assessment and implementation of mitigation measures, properly educating staff and students about the chemical and physical hazards associated with their work, and the involvement of a knowledgeable and fully empowered CSS committee throughout a renovation or equipment installation project, such hazards can easily be minimized or avoided completely. It is our sincere hope that researchers at other universities will review the lessons summarized here and implement appropriate preventive measures in their institutions.

ACKNOWLEDGEMENTS

- The authors acknowledge the staff of the US State Department’s Chemical Security Program, Pacific Northwest National Laboratory, Al-Nahrain University and Babylon University for their encouragement.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML