-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Journal of Civil Engineering Research

p-ISSN: 2163-2316 e-ISSN: 2163-2340

2021; 11(1): 19-28

doi:10.5923/j.jce.20211101.03

Received: Mar. 16, 2021; Accepted: Apr. 23, 2021; Published: May 15, 2021

Effectiveness of the Modern Methods of Construction in Terms of Cost and Time: A Case Study of the United Kingdom

Abdussalam Shibani, Araz Agha, Dyaa Hassan, Yaseen Al-Hadeethi, Mou Choudhury

School of Energy, Construction and Environment, Coventry University, Coventry, CV1 5FB, United Kingdom

Correspondence to: Araz Agha, School of Energy, Construction and Environment, Coventry University, Coventry, CV1 5FB, United Kingdom.

| Email: |  |

Copyright © 2021 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

In the past few years, the housing sector has witnessed an increase in the application of modern methods of construction (MMC) in the construction processes to address the existing housing shortage and improve the quality of buildings. However, despite the widely reported benefits of such methods, their uptake within the industry has been limited. This paper reports the findings made from a research that sought to investigate the effectiveness of MMC in terms of cost and time. A questionnaire survey was applied whereby five of the top construction companies in the country and 30 academicians it the field of construction were interviewed. The results obtained indicate that the current utilisation of MMC in the large and medium-sized housing companies is insufficient, but the level is expected to increase due to the growing pressure to improve on cost, time, quality, productivity, wastages, and health and safety of the workers. However, the perceived higher capital cost compared to the traditional method has been a major hindrance to the adoption of MMC. Despite this, as for a revolution in the construction industry of using modern construction methods, off-site MMC is not every company choice of construction form due to its higher capital and initial costs. This paper recommends a set of strategies that can be used to address the uncertainties surrounding the effectiveness of MMC and improve its usage among the construction companies.

Keywords: Modern Methods of Construction (MMC), Construction, House builders, Offsite manufacturing, UK

Cite this paper: Abdussalam Shibani, Araz Agha, Dyaa Hassan, Yaseen Al-Hadeethi, Mou Choudhury, Effectiveness of the Modern Methods of Construction in Terms of Cost and Time: A Case Study of the United Kingdom, Journal of Civil Engineering Research, Vol. 11 No. 1, 2021, pp. 19-28. doi: 10.5923/j.jce.20211101.03.

Article Outline

1. Introduction

- The use of MMC has consistently gained popularity since the end of the World War I and II. Alternative forms of construction are said to have been introduced after the world wars, with a variety of innovative house building systems popping up and continuing to grow up to date. For instance, prefabrication, which is one of the classifications of MMC, has been in use in the UK for many years, particularly after the demand for housing surged after the two wars [1]. Although about a million homes were prefabricated in the 20th century, the quality of materials and artistry used raised controversy, which resulted in a negative perception currently associated with MMC [2].In recent years, the use of MMC for housing has increased considerably, though not at a desirable rate. Although the majority of contractors in the construction industry are still applying the traditional methods, the need for sustainability, quicker processes, and the existing skill shortages have increased the need for modern methods, which are anticipated to sustainable and cost-effective [3]. MMC is often associated with an enhanced speed of construction, minimal defects in structures, and reduced wastes and energy consumption due to their application of off-site manufacturing [4]. Although the construction sector is yet to come up with a universal definition of MMC, there seems to be a general agreement among the researchers in describing the term as a composition of all construction approaches that seek to promote sustainability, construction efficiency, and quality of structures. The approaches that are presently being used in the UK and other parts of the globe differ significantly from the conventional methods used in the building sector. Many of them (referred to as MMC) incorporate off-site manufacturing and prefabrication of materials [4]. Current debates, however, revolve around the classification of modern methods of constructions. Nonetheless, MMC can be classi-fied into five categories, that is, panelised frames, volumetric system, hybrid system, sub-assemblies and components, and modular system [5] [6]. Kamar et al., (2011) [3] define panels as two-dimensional structures whose infill elements are assembled on site. They include pre-assembled floor, roof panels, and walls. Frames, on the other hand, refer to the factory-assembled structures that provide the necessary structural support during the construction processes. Kamar and his colleagues observed that these structures are supplied promptly to the site, which increases the speed of construction and reduces the inaccuracies associated with on-site cutting. Steel frame modules are the most commonly used frames, with the UK being one of the leading countries in steel usage. The feature of steel as an element that can be mould into any shape or form is said to be one of the main reasons to why it is widely used in off-site manufacturing [7]. Volumetric systems refer to the materials assembled in a factory and then mounted onto or within a structure [8]. For instance, the internal structures of items such as washroom pods and plant rooms are completed off-site and then brought to the site for installation. In this case, the materials used are often timber, steel and concrete [9]. Modular systems and volumetric systems are similar in their functionalities, but the former is much bigger than the latter. Moreover, both the internal and external parts of a modular system are manufactured offsite. One of the main strengths of modular systems is the fact that they are said to be easily customisable using the modern techniques to suit the needs of the clients [8]. Moreover they noted plant rooms are labour intensive and therefore their off-site production may provide significant economic benefits in terms of cheap labour. Off-site production of plant rooms is also associated with reduced completion time for projects and improved efficiency. The sub-assemblies, on the other hand, are mainly used to cater for the methods that do not fit the description of off-site manufacturing (OSM) systems [10]. Therefore, the term refers to basic components that are produced in factories such as the doors, block floors foundation systems, windows, concrete beams, and stairs. He defines the term as building components that are built off-site but are not critical to the main structure of a building. He, therefore, considered sub-assemblies as the most conventional and commonly used system in OSM [10].

1.1. The Development of MMC

- The prefabrication of building components is believed to have begun in the early 20th century. However, there have also been examples of previous use, such as the construction of the first iron bridge in the United Kingdom in 1779. The most significant push for OSM in the housing sector is said to have started after the First and Second World Wars, with the need for new buildings and reconstructions of those that were destroyed during the wars being the primary reasons [2]. Since then, other factors that have contributed to the push include skills shortage, quality enhancement, development in building regulations, sustainability, and environmental performance, and accuracy in buildings. The construction industry has always been associated with the shortage of skills, which in turn has had an adverse impact on quality and pace of projects [11]. For this reason, there has been an increased need for modern methods of construction, where much of the construction process is carried out in a factory-controlled environment, thus reducing the requirement for skills on-site. According to Kamar et al., (2011) [3] the off-site production of building components enhances quality and helps in reducing the risks attributed to on-site quality management. Kamar and his colleagues observed that, though quality management is still critical on the construction site, it could be improved by having some of the site-based work performed off-site. Although the situation regarding the reduction of quality is difficult to measure, the construction sector has on various occasions suffered from quality assurance challenges. However, as Rahman (2013) [12] pointed out, the current problem relating to quality is centred on improvement rather than assurance. The sector has always sought to enhance the quality of structure through modern technologies and approaches, while at the same time ensuring that productivity and sustainability are improved. In addition, the changes in customer expectations, especially in the housing industry, have heightened the need for continuous enhancement of quality [13]. For this reason, MMC has been viewed as an efficient solution to the quality problems associated with the traditional methods of construction. For many years, the building regulations and related frameworks have been evolving at an alarming rate not only in the UK but also in other parts of the word [13]. As a result, there has been a growing need for increased adoption of MMC in the construction industry. For instance, the need for a threshold performance concerning thermal and sound insulation and energy consumption requires a construction method that is measurable and predictable. Furthermore, the possibility of performance evaluation after the completion of a building places a much more significant need for a reliable and verifiable method than it was previously required [4]. Therefore, the use of off-site manufacturing methods is seen as a better way of achieving reliability and compliance with the regulations than the conventional site-based techniques. The increased attention to the environmental impact of construction processes has also enhanced the need for sustainability of structures and construction methods (Lehmann, 2013). In this case, the application of MMC using off-site production, efficient components, and supply chain management is seen as one of the best approaches that can be used to reduce wastage and the associated environmental impact. As Nadim and Goulding, (2010) [13] argue, the quality control mechanisms employed in MMC can enhance airtightness, thus improving the thermal performance of the structure. The study observed that off-site manufacturing plays a critical role in reducing the environmental disturbances around the construction sites [13].

1.2. Advantages and Disadvantages of MMC

- The use of MMC such as prefabrication is associated with numerous advantages, for instance, noted that MMC could provide an opportunity through which the benefits offered by off-site manufacturing can be capitalised on. One of these benefits is the increased pace of construction process, with the eight days' completion of the 32 self-contained flats in London by the modular building contractors being a perfect example [13]. The Peabody Trust's Murray Grove scheme is also said to have saved close to five months in comparison to the traditional methods [14]. As previously indicated, quality of the product is enhanced when building components are produced at the factory conditions. On-site production is said to have an adverse impact on the quality of construction materials such as the concrete, especially when weather conditions are not favourable. For instance, at sweltering conditions, too much water is usually wasted through evaporation when concrete is curing. On the other hand, when the temperature is below the required level, there are slow chemical reactions during the curing process. Therefore, both extremes have adverse impacts on the compressive strength of the concrete [13]. The use of MMC such as the prefabrication is also associated with improved health and safety of the personnel around the site. For example, Nadim and Goulding (2010) [13] noted that, the prefabrication eliminates the congestion within the site area and the amount of work required there since much of the work is done under factory conditions. In support of this, a report presented by the Health and Safety Executive indicated that deadly accidents are more than five times likely to occur in the construction sites than in the factory settings [15]. Off-site manufacturing also ensures that standardised materials can be applied in a controlled environment, where minimum tolerance can be achieved through proper supervision. Another benefit associated with MMC is its ability to reduce the amount of waste during the construction process. For instance, Boyd et al, (2012) [16] term the lean processes employed in off-site manufacturing as critical to efficient utilisation of resources. He noted that the prefabrication of building components provide an opportunity through which materials can be re-used and recycled, thus reducing wastage. Moreover, the modern OSM systems are said to have been built using a lightweight steel frame, which consumes less energy than other components such as the concrete [16]. Despite the numerous benefits associated with MMC or offsite manufacturing, several barriers such as the issue of cost limit its adoption in the sector. Some scholars claim that the prefabrication process is more expensive than the traditional method. For instance, a study conducted by Davis Langdon revealed that off-site manufacturing has a cost premium of 12 between 10 and 25 percent [15], other scholars argue that, though there is a premium in cost, the enhanced speed of construction and increased quality compensate for the loss of money (Pan and Sidwell, 2011) [17]. They also observe that most prefabricated components are designed in a manner that they can quickly be repaired and maintained, thus offering long-term benefits in terms of maintenance cost. Nonetheless, there has not been a universally accepted method for quantifying the amount regained through such benefits. Other challenges associated with MMC include the high set up cost with which they are associated. According to Rahman (2013) [12], much of the construction work in the UK is carried out using the conventional methods, which has aggravated the shortage of a competent skill base that can be used to perform off-site manufacturing. Similarly, Nadim (2012) [13] observed that the cost of starting prefabrication plants is considerably high, which may be the primary reason to why the technique is not widely applied. Moreover, some of the past systems are negatively perceived due to the designs and aesthetics, thus implying that they are not suitable to everyone's taste and preference. The introduction should provide a clear statement of the problem, the relevant literature on the subject, and the proposed approach or solution. It should be understandable to the colleagues from a broad range of scientific disciplines.According to MTech Consult Limited (2009) [29], MMC require developers to purchase all relevant materials before kick starting a project, which necessitates high initialization costs. In particular, increments in cost of employing MMC have been associated with increase in execution time, which are the two most cited challenges of OSM systems. Apparently, MMCs have been marred with inconsistencies concerning the experiences held by different households. In particular, while some individuals find the methods challenging to adapt because of factors such as implementation feed, others consider them as high quality and cost-efficient. In other words, although some OSM components from different suppliers might be benefits to some users, other components could be adversely affecting users. This necessitates an empirical research for investigating the effectiveness of MMC in terms of cost, time, and quality. Unfortunately, there is little literature explicating the degree of effectiveness of MMCs in the construction of house, particularly in terms of time and cost. Literature inadequacy in this field occurs at a time when housing has become a challenge not only in the UK but also in other places of the world, which can be better solved with functionally and cost-efficient construction methods. Frankly, tradition methods of construction are yet to prove reliable with regard to solving the housing inadequacies despite having been applied for more than centuries. As such, although modern methods of construction are negatively perceived, they could be the solution to the housing problem, which forms the background for measuring their effectiveness. In particular, a study of this nature might be crucial in determining whether MMCs are worthwhile or whether onsite methods are the future of construction in the UK. In light of the literature gap and research problem elucidated above, this project seeks to assess the effectiveness in terms of cost and time of the adoption of MMC in the UK’s construction industry. the following is research objectives: • Investigating the utilisation of MMC in positively impacting the housing segment in the United Kingdom; • To analyse costs efficiency in the utilisation of MMC in the UK building industry in comparison to traditional methods of construction; and • Evaluate the efficiency in time for the utilisation of MMC in the UK building sector, as compared to conventional methods of building.

2. Methods

- The term research design refers to a framework or a detailed plan used when conducting research. It is also referred to as a strategy employed by researchers when searching for solutions to an established research problem [18]. It, therefore, involves a comprehensive and logical integration of elements such as data collection methods, research approach, and data analysis and presentation. The research design employed is said to be a critical factor in the determination of authority, trustworthiness, and authenticity of the data obtained and the research findings [19]. According to Lewis (2015) [19], the choice of a research design to be used in a study is heavily dependent on several factors. First, the choice depends on the context of the research problem, paradigms, perspectives, and the assumptions made during the research. Secondly, the choice on the feasibility of the available options as well as on the nature of the research aims and objectives. Lastly, the choice depends on the nature of information that the research seeks to establish. Similarly, Fellows and Liu (2015) [18] observed that the choice of research design is significantly influenced by the phenomenon being explored and the proficiency of the research.

2.1. Data Collection

- The study used both primary and secondary methods of data gathering, which allowed the data obtained to complement each other. The primary methods of data collection took the form of survey whereby the questionnaires were sent out to the academicians and the practitioners in the construction industry. The selected sample included 5 construction firms in the UK and 30 academicians in the field of construction, based in the same country. Convenience sampling was applied because the sample had to be in the building industry and aware of the application of MMC. The questionnaires used incorporated both open-ended and close-ended questions. Secondary sources, on the other hand, took the form of literature from various sources discussing MMC. They included books, journals, and online articles. Besides, the study used a mixed research approaches where both qualitative and quantitative techniques were applied. The use of a mixed research design ensured that the shortcomings of one technique were overcome by the other [20]. Quantitative methods adopt approaches that are scientific, and in which the study of theories and that of the existing literature, leads to precise aims and objectives. Additionally, quantitative methods result in a hypothesis that can be tested and explained [18]. On the other hand, qualitative research entails the exploration of the topic being investigated and, in some instances takes place without prior formulations. This is typically done with the aim of collecting and understanding data collected. Qualitative research thus tends to be exploratory [21], [22].

2.2. Interview

- A semi-structured interview offers structure, while also being flexible to allow for unanticipated ideas to emerge [23]. Likewise, another advantage is that data can be recorded and reviewed several times by the researcher to help produce an accurate interview [24]. Therefore, semi structured interview is a more balanced form of qualitative data compared to using unstructured interviews, where there are no set questions prior to attending the interview. In contrary, Rubin & Rubin 2005 [23] criticised interviews as being ‘time consuming for data collection and analysis’ which is a disadvantage for this method as [24] also agrees as well. Nonetheless, interviews enable a greater level of detailed response because it facilities interviewees to ‘speak in their own voice and express their own thoughts and feelings’ [24]. Observational and experimental will not be used in this research due to this paper being a mostly researched based study.

2.3. Data Analysis

- Since the research sought to establish the time- and cost-effectiveness of MMC in the UK housing sector, questionnaires and review of literature were used as the primary data collection methods. The literature review ensured that the results obtained were of high quality and could be generalised. In this case, due to the incorporation of both qualitative and quantitative approaches, the data was analysed by first being converted into textual and statistical forms, which allowed the researcher to understand the information and make inferences. Some of the data obtained were presented mathematically to allow statistical conversions to be carried out [25-26].

2.4. Ethical Considerations

- It is generally agreed that there are five broad ethical considerations that a researcher is supposed to make in the course of his/her study [27]. They include voluntary participation, anonymity, and confidentiality, informed consent, the potential for harm, and communication of the results. In order to address all these ethical issues, the respondents were introduced to the subject matter to ensure that they understood the aims and objectives that the research sought to achieve. In addition, the respondents were given a form that asked them to give their consent for participation in the research. The content matter of the questionnaires was formulated in line with the aims, as well as the objectives of the study.

3. Results and Discussion

3.1. Questionnaire

- Evidence from the literature indicates that a significant number of houses in the UK are still being built using the conventional methods of construction [29]. However, the utilisation of MMC for housing has increased in the past few years due to several factors including the growing demand for faster construction and scarcity of skills. Nonetheless, there are still uncertainties about the extent of MMC application in the housing sector [11]. A few large private organisations are said to have lately invested a significant number of resources in MMC plants and therefore the production is expected to increase. For instance, it is estimated that at least 25,000 homes per year will constructed using MMC [13].

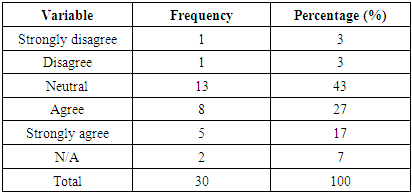

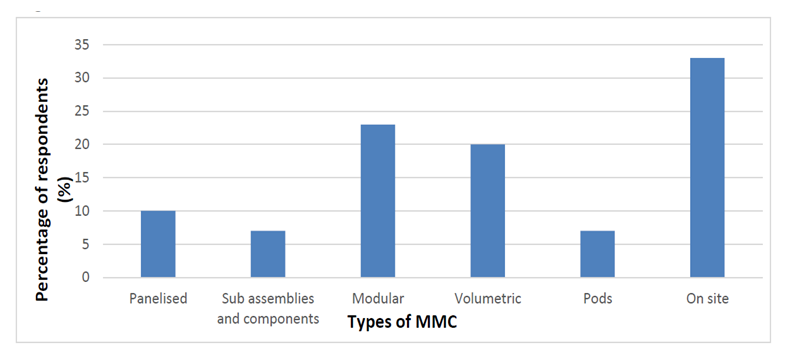

| Figure 1. Types of MMC is used in the company/project |

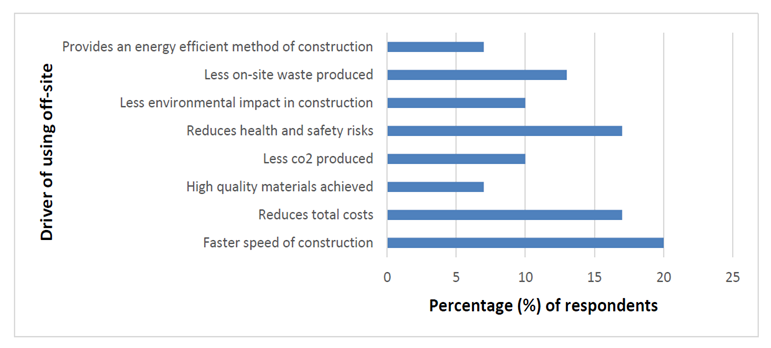

| Figure 2. Portrays the response of the house builders aimed at finding out the benefits of using MMC in the housing industry |

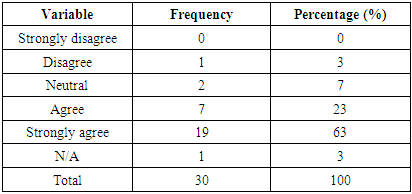

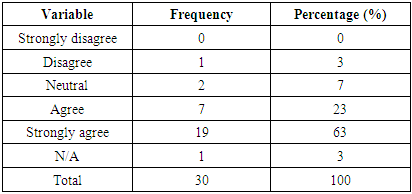

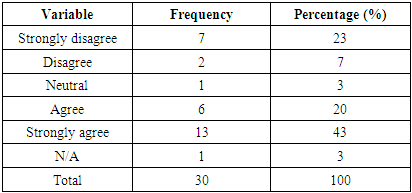

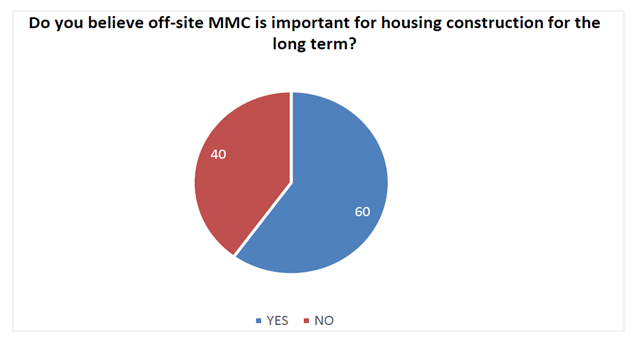

| Figure 3. The respondents agreeing to MMC construction |

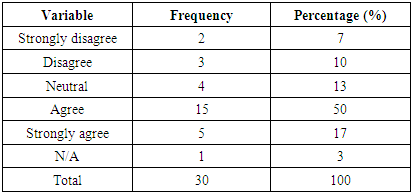

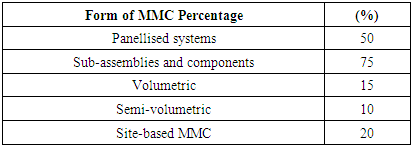

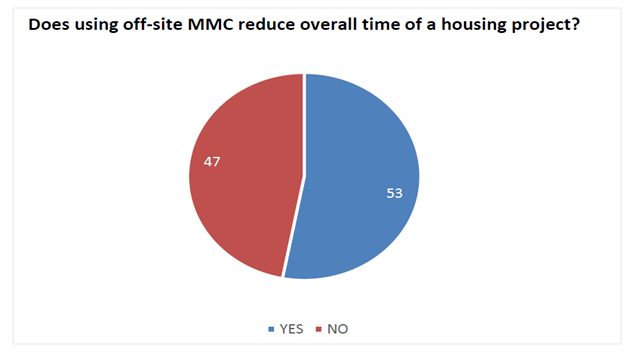

| Figure 4. Off-site MMC reducing the overall time of a housing project |

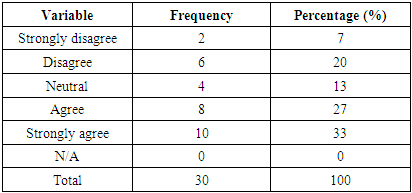

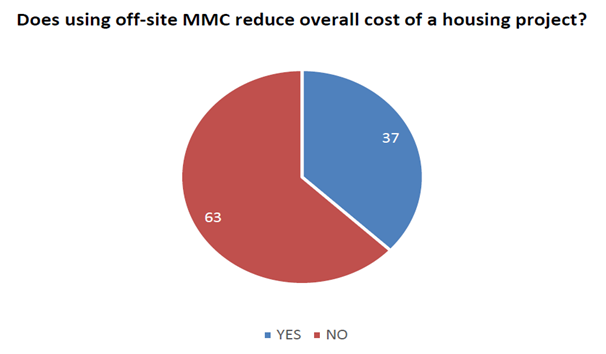

| Figure 5. The MMC can reduce the overall cost of a housing project |

|

|

|

|

|

|

3.2. Interview

3.2.1. Utilisation of MMC in the UK

- The interviews conducted regarding this objective indicated that a substantial number of house constructors and housing organisations are utilising, or have considered, at least one modern method of construction in their building plans. Of all the interviewees from large and medium-sized housing companies, only three claimed to have not applied or considered at least one form of MMC in the past 5 years. According to most participants, the most com-monly used form of MMC includes sub-assemblies and components, panellised systems, semi-volumetric and vol-umetric constructions respectively. Almost three quarters of the house builders and half of the housing companies inter-viewed in this study claimed to have used sub-assemblies and components. However, opinions remain divided with more than half of the participants in each case indicating to have rejected or not likely to consider using them at all.

|

3.2.2. Positive Impact of MMC in the Housing Segment in the UK

- Finding out the positive impact that MMC may have had on the UK's housing industry was another core objective of this study. A review of the available literature regarding this issue indicated that the evidence of MMC benefits is still inconclusive, considering that only few studies have investigated the matter. However, the participants interviewed in the present study associated MMC to several benefits including, energy saving, addressing the existing skills shortage, reduction in wastes, fewer trips to and from the sites, improved quality of buildings and health and safety of workers. The majority of the participants (construction firms and academicians) indicated that homes constructed using MMC require lesser heating energy than those built using the traditional methods of construction. For instance, one of the respondents argued, "MMC homes have more insulation components on the walls and roofs than the conventional houses, thus reducing the amount of energy required for heating. Moreover, there are fewer air leakages from the houses." It also emerged the increased interest in MMC among the construction companies is because of the anticipation that the energy requirement regulations will soon become stricter. Another positive impact of using MMC in house construction is the reduction of wastes resulting from on-site processes. A review of the literature indicates that waste from the construction and demolition processes accounts for 25% of UK waste [28]. As such, over three-quarters of the participants expressed their confidence that the use MMC is going to reduce the amount of waste being produced around the building sites. One particular respondent observed, "The use of modern methods of construction allows factory components to be ordered to the correct specifications, thus limiting the risk of on-site spillage, especially during wet weather." The use of MMC was also found to have a positive impact on the transport cost because fewer trips to and from the construction sites are required. According to one of the participants, "the development of a significant portion of a house in factories reduces the overall number of trips to a construction site." The participant further observed that most of the construction works are often carried out on ‘brownfield' sites in the cities, and therefore the use of MMC or off-site manufacturing is crucial in that respect. More than two-thirds of the participants cited health and safety of workers as one of the most significant benefits of using MMC. Statistics indicate that the construction sector is one of the most dangerous with regards to the safety of workers, with close to 100 fatalities per year in the United Kingdom being associated with the industry [13]. For this reason, most participants claimed that MMC is safer than the traditional methods since the risk of accidents in a controlled factory setting is significantly reduced, with workers also spending less time on the building site.

3.2.3. Cost-effectiveness of Using MMC Compared to Traditional Methods

- There were mixed opinions among the participants concerning the cost-effectiveness of modern methods of construction in comparison to the traditional ones. A significant number of house builders argued that MMC are cheaper than the conventional methods while others indicated that MMC leads to an increased cost of construction by around 8-10%. The majority of the respondents were unable to differentiate the cost-effectiveness of the two methods. They claimed that the confidentiality of project financial information and variations in the building costs of the traditional methods make is it difficult to make comparisons. In addition, though MMC is said to have a significant potential to lead to reduced initial costs, increased cash flow, and faster sales returns [17], only 45% of the participants indicated to have experienced cost reduction and enhanced profitability. The majority seemed undecided on the cost-effectiveness of MMC in comparison to the conventional methods. Furthermore, the use of MMC was not considered to have reduced the dependence on specific construction materials such as bricks, which are critical regardless of the construction method used. For this reason, 80% of the respondents disagreed with the notion that the use of MMC minimises the cost of materials. However, 60% of the house builders interviewed in this study agreed with the statements that: (1) MMC minimises service utilities cost; (2) MMC minimises labour cost; and (3) MMC minimises maintenance cost.

3.2.4. Discussion

- The survey results and a review of the literature indicate that the utilisation of MMC in the UK's housing sector is still not up to the required levels. A significant number of the house builders are still satisfied with the conventional methods and are not ready to embrace MMC. This scenario, however, does not necessarily imply that house builders are not aware of the potential of MMC to revolutionise the construction industry. Instead, the low level of contentment with the use of MMC may be due to the existing apathy in the utilisation of such methods [13], with the majority of builders, unsurprisingly, indicating that they have considered applying at least one form of MMC. Moreover, because most of the participants had little experience with the technologies, their opinions may have been influenced by the existing perceptions about MMC. Regarding the positive impact of MMC on the UK housing sector, this study has shown that the benefits of the methods are yet to be clearly understood. However, those who have used the methods associate them with several benefits, with key among them being cost and energy savings and an improvement in the health and safety workers. Although there is still no sufficient evidence concerning these particular benefits, it is clear from this study that the use of MMC has a significant potential to contribute to the government agenda of reducing the amount of energy consumed, mainly on heating and other housing-related activities. Moreover, the use of MMC is likely to reduce the transport and labour costs, with fewer trips and labourers being required on-site. This observation is consistent with the findings made by Taylor, (2010) [7], who indicated that MMC often apply off-site manufacturing of components, which reduces the number of workers required on the construction site and the number trips in and out of the sites. The cost-effectiveness of MMC in comparison with the traditional methods appears to be unclear because the cost has been cited as both a barrier and a benefit. According to Pan and Sidwell (2011) [17], one of the main reasons as to why some people view the cost of using MMC as high than the traditional methods is because some benefits such as improved quality of buildings and fewer mistakes are not reflected in the project accounts. The time-effectiveness of MMC also seemed to divide the opinions of the participants, with half of the construction companies being uncertain about the benefit. However, there seemed to be a consensus among the house builders that MMC is faster than the traditional methods, with all those who have used the methods citing speed as the main reason as to why they choose to apply them. Pan and Sidwell (2011) [17] noted that the housing companies might not be convinced of this benefit because some them do not have direct control over the planning because of their dependence on the contractors [29-31].

4. Conclusions

- This study sought to establish the cost and time-effectiveness of utilising MMC in the in the UK's housing sector. Inclusively, it has been established that MMC has a significant potential to play a leading role in addressing the current housing shortage and improving the efficiency of the construction processes precisely in the UK. Against the backdrop of insufficient adoption of MMC, this paper investigated the perspectives of the construction companies and house builders regarding the effectiveness of MMC using a survey sample of 5 top construction firms and 30 academicians in the field. The study has established that, though there are still uncertainties about some of the benefits of MMC, the conventional drivers such as speed, quality, performance, and cost remain critical factors in the adoption of MMC. The study also suggests that modern methods of construction are efficient in terms of time compared to the traditional methods. However, more analysis and empirical research need to be conducted to establish their cost-effectiveness because the stakeholders in the industry seem uncertain about the benefit. Factors such as energy saving, reduction in wastes, reduction in transport cost, improved quality of buildings, and health and safety of works appear to be the most significant impacts that MMC have had in the housing sector in the UK. Nonetheless, it has been established that the perceived higher capital cost has been one of the major obstacles to the utilisation of MMC and therefore the strategies revolve around changing the public perceptions and provision of guidance in the decision-making processes.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML